Sourcetronic ST600 Series User manual

SOURCETRONIC – Quality electronics for service, lab and production

Frequency Inverter ST600 and ST600SP

Quick Start Guide

Quick Start Guide for ST600 Series Frequency Inverters Introduction

1

Introduction

This abridged manual briefly describes the external wiring, the terminals, the keypad, the quick start steps, as well

as the most common function parameter settings, errors and solutions and the most commonly used communica-

tion and PG cards for Sourcetronic ST600 and ST600SP series frequency inverters.

Visit www.sourcetronic.com for more information or refer to the detailed full version of the manual.

Warning!

This guide only contains the most basic information on installation and commissioning. Failure

to observe the safety instructions and the installation and commissioning instructions in the

corresponding documentation can lead to accidents, including damage to the appliance, inju-

ries or even death.

Only trained and qualified specialists may carry out the relevant work!

Danger!

Never carry out work such as wiring, inspection or replacement of components while the power

supply is switched on. Before carrying out this work, ensure that all input power supplies have

been disconnected and wait at least the time specified on the VFD (see below) or until the DC

bus voltage is less than 36 V.

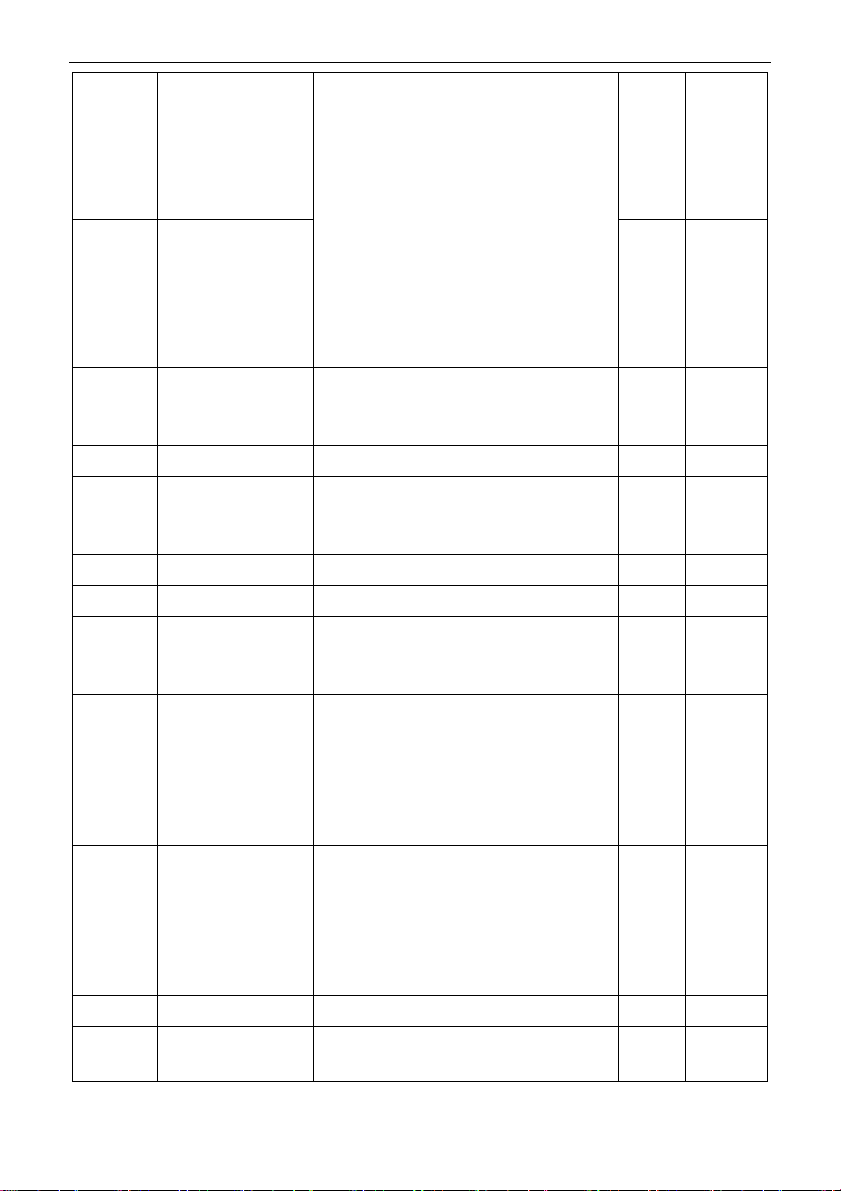

VFD Model

Minimum Waiting Time

1R5G3–110G3

5 min

132G3-315G3

15 min

355G3 and above

25 min

Quick Start Guide for ST600 Series Frequency Inverters External Wiring

2

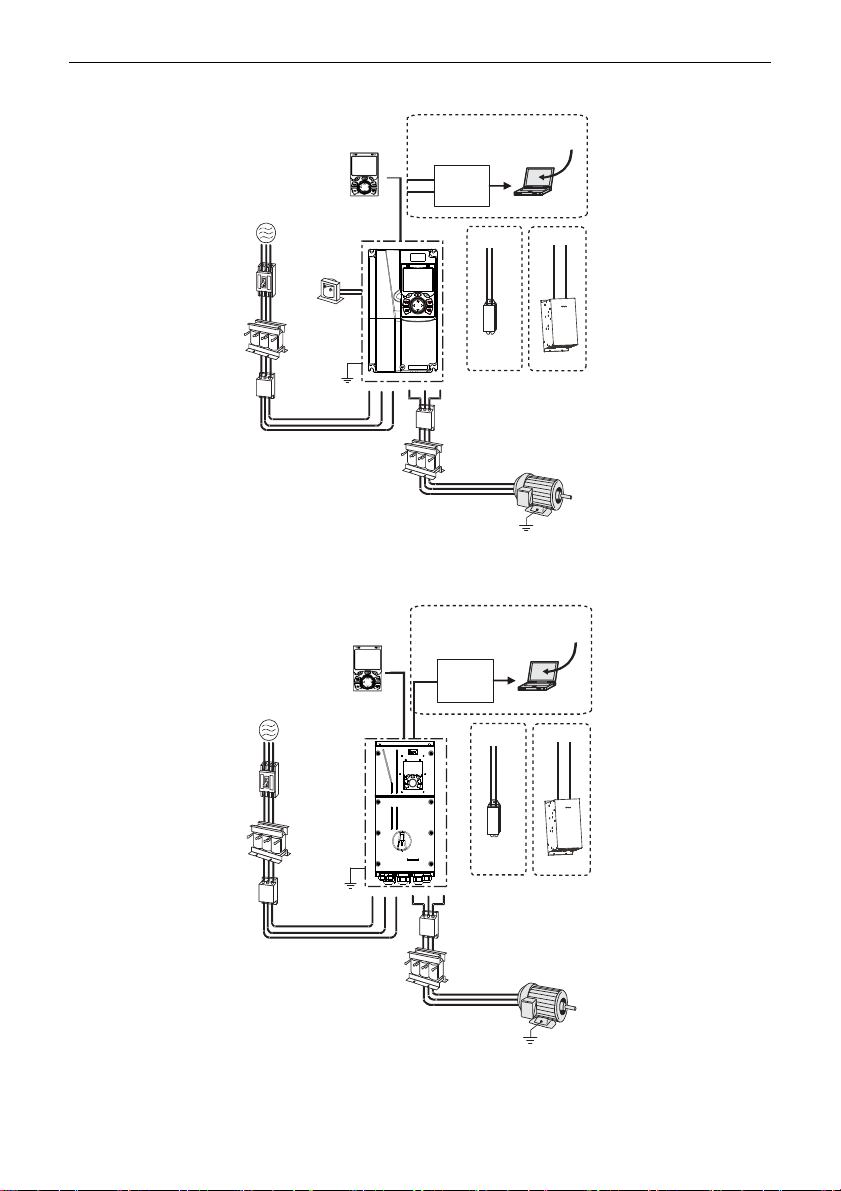

1External Wiring

Power supply

Breaker

Input filter

Input reactor

Earth

DC reactor

LCD keypad

P1

+

+-

PB

Brake

resistor Brake unit

PC

RS485–

RS232

converter

Output filter

Output reactor

Motor

Earth

+

Upper PC

software

485+

485-

Standard

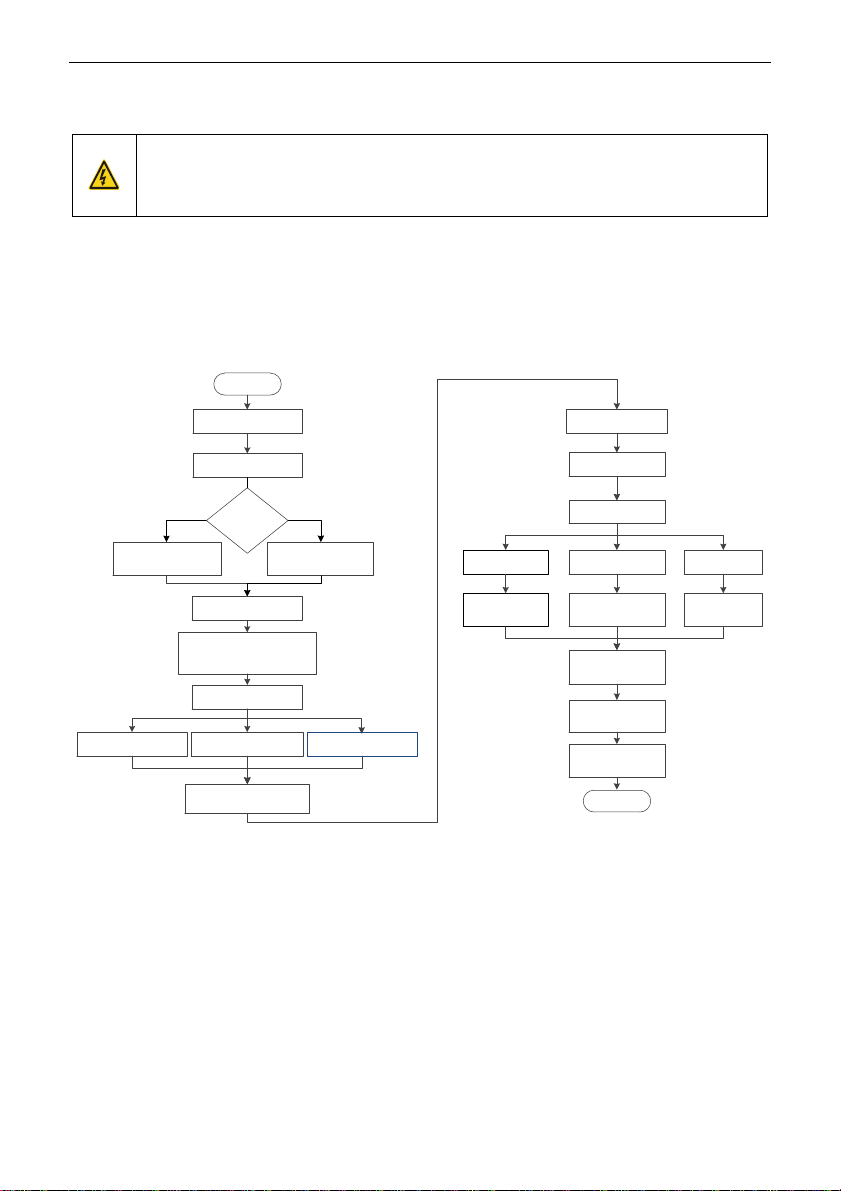

Figure 1-1 ST600 System Configuration

Figure 1-2 ST600SP System Configuration

Power supply

Breaker

Input filter

Input reactor

Earth

LCD keypad

+-

PB

Brake

resistor Brake unit

PC

Adapter

(cable)

Output filter

Output reactor

Motor

Earth

+

Upper PC

software

485+

485-

Optional

Quick Start Guide for ST600 Series Frequency Inverters Terminals

3

2Terminals

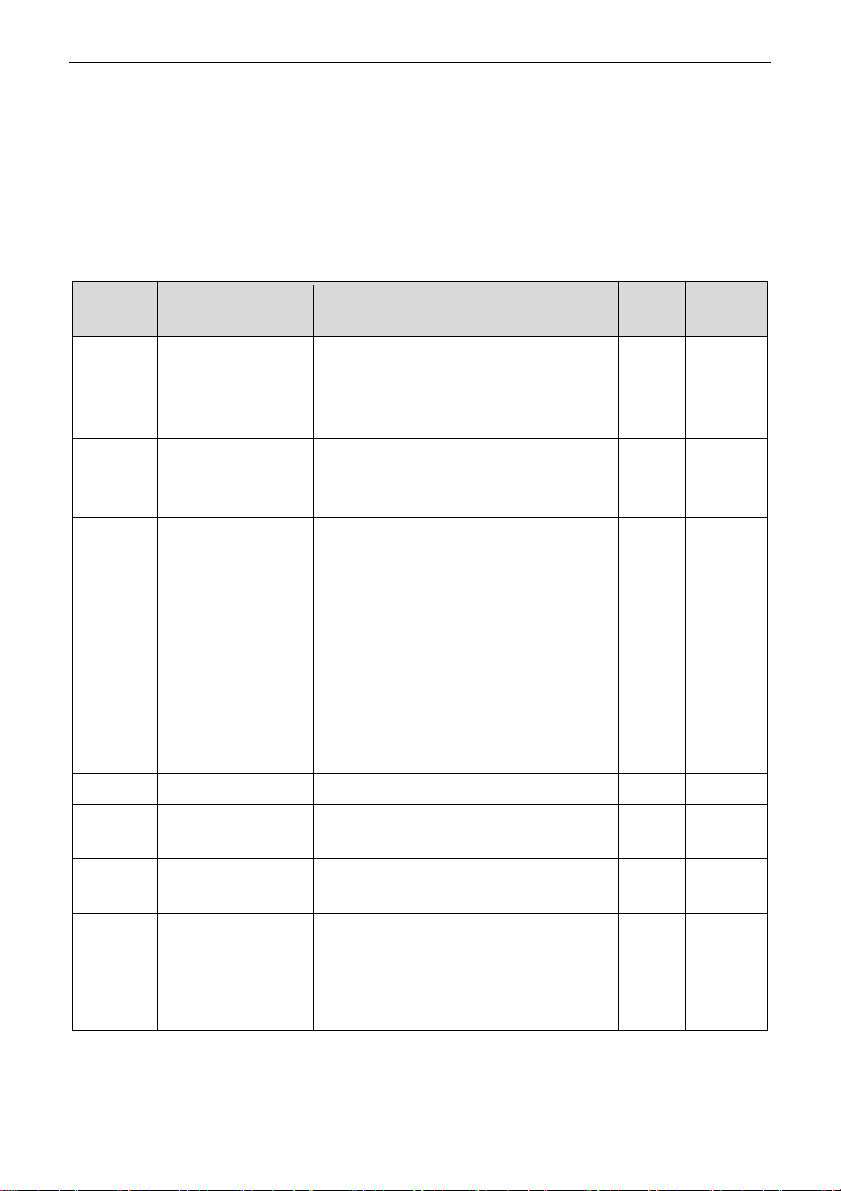

Figure 2-1 Main Circuit Wiring for Standard Models

Figure 2-2 Main Circuit Wiring for SP Models

037G3 and lower

models

045G3 - 110G3

models

132G3 and higher

models

Braking resistor

Braking unit

Braking resistor

Braking resistor

Braking unit

Input

reactor

Input

filter

Fuse

Input

reactor

Input

filter

3PH power

380V(-15%)-440V(+10%)

50/60Hz

R

S

T

R

S

T

U

V

W

PE

U

V

W

PE

Output

reactor

Output

filter

M

(+) (-)

P1

(+) (-)

PB

Fuse

Fuse

Input

reactor

Input

filter

R

S

T

U

V

W

PE

Output

reactor

Output

filter

Output

reactor

Output

filter

M

M

(+) (-)

DC+

DC-

DC+

DC-

DC reactor

3PH power

380V(-15%)-440V(+10%)

50/60Hz

3PH power

380V(-15%)-440V(+10%)

50/60Hz

All models

Braking resistor

Input

reactor

Input

filter

Fuse

3PH power

380V(-15%)-440V(+10%)

50/60Hz

R

S

T

U

V

W

PE

Output

reactor

Output

filter

M

(+) (-)

PB

Quick Start Guide for ST600 Series Frequency Inverters Terminals

4

+24V

PE

COM

S4

S3

S2

S1

HDIB

PW

HDIA

Forward running

Forward jogging

Fault reset

+10V

AI1

AI2

GND

PE

-10V

(external)

AO1

V I

SW2

GND

Analog output

0-10V/0-20mA

Y1

CME

COM

HDO

Optional between high-

speed pulse output and

open collector output

485+

485-

PE

RS485

communication

RO2C

RO2B

RO2A

RO1C

RO1B

RO1A

Relay 1

output

Relay 2

output

ON OFF

SW3

multi-function

analog input

H1

H2

+24V

S2

S1

Safety

controller

Open circuit

Safety

input

Safety

switch

Y1

output

Safety state

feedback

Power used for

frequency setting

VFD

Figure 2-3 Control Circuit Wiring

Quick Start Guide for ST600 Series Frequency Inverters Terminals

5

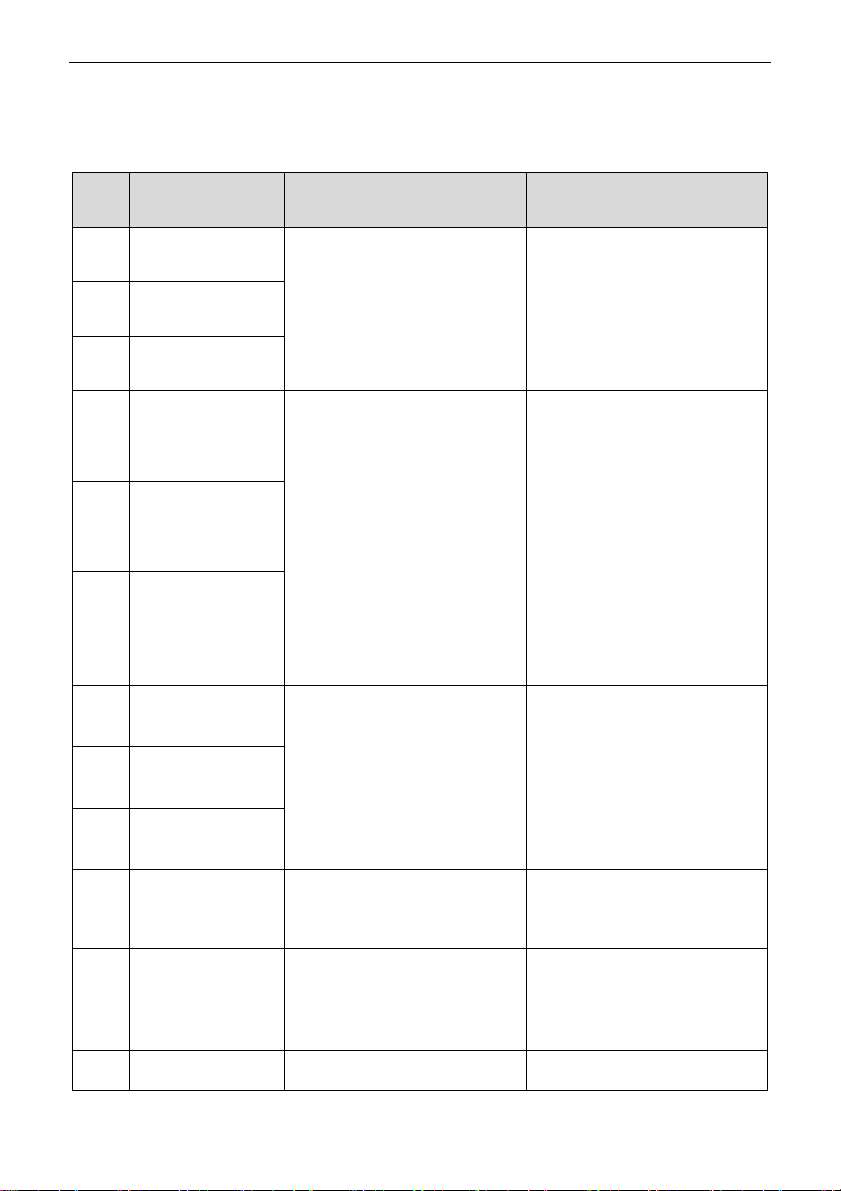

Table 2-1 VFD Terminal Description

Terminal

Description

Main Circuit Terminals

R, S, T

3PH AC input terminals, connected to the grid

U, V, W

3PH AC output terminals, usually connected to the motor

P1

P1 and (+) connect to external DC reactor terminals.

(+) and (-) connect to external braking unit terminals or shared DC bus terminals.

PB and (+) connect to external braking resistor terminals.

(+)

(-)

PB

PE terminal. The PE terminals of each machine must be grounded reliably.

Control Circuit Terminals

+10V

Locally provided +10.5V power supply

AI1

Analog input. Range: 0–10V/0–20mA. Function code P05.50 specifies whether to use voltage or

current input.

AI2

Analog input. Range: -10V – +10V

GND

Reference ground of +10.5V

AO1

Analog output. Range: 0–10V/0–20mA. SW2 is used to select voltage or current output.

RO1A

Relay output. RO1A: NO; RO1B: NC; RO1C: common

Contact capacity: 3A/AC 250V, 1A/DC 30V

RO1B

RO1C

RO2A

Relay output. RO2A: NO; RO2B: NC; RO2C: common

Contact capacity: 3A/AC 250V, 1A/DC 30V

RO2B

RO2C

HDO

Switch capacity: 50mA/30V. Output frequency range: 0–50kHz. Duty ratio: 50%

COM

Reference ground of +24V

CME

Common terminal of open collector output; short connected to COM by default

Y1

Switch capacity: 50mA/30V; Output frequency range: 0–1kHz

485+

RS485 differential signal communication port. The standard communication interface should use a

shielded twisted pair cable. Specify whether the 120 Ω matching resistor of the RS485 communi-

cation should be connected via the DIP switch or the jumper.

485-

PE

Grounding terminal

PW

External power input terminal for digital input circuits. In NPN mode, short-circuit PW and +24V. In

PNP mode, short-circuit PW and COM.

+24V

User the power supply provided by the VFD. Max. output current: 200mA

Quick Start Guide for ST600 Series Frequency Inverters Terminals

6

S1–S4

Digital Input:

Internal impedance: 3.3kΩ

12–30V voltage input is acceptable

Bidirectional input terminals, supporting both NPN and PNP connection methods

Max. input frequency: 1kHz

Programmable digital input terminals, the exact functions of which can be set via related

parameters

HDIA

Channels for Both High Frequency Pulse Input and Digital Input:

Max. input frequency: 50kHz

Duty ratio: 30%–70%

Supports quadrature encoder input when both HDIA and HDIB are available, with the speed

measurement function

HDIB

+24V–H1

Safe Torque Off (STO) Inputs:

Redundant STO input, connected to the external NC contact. When the contact opens, STO

is activated and the VFD stops the output.

Shielded cables with a maximum length of 25m are used for the safety input signal cables.

Terminals H1 and H2 are short-circuited to +24 V by default. Remove the jumper from the

terminals before using the STO function.

+24V–H2

Quick Start Guide for ST600 Series Frequency Inverters Keypad

7

3Keypad

The specifics of the keypad may vary between product models.

12

7

456

11

8

910

12

3

13

14

15

Figure 3-1 Standard Model Keypad

Figure 3-2 SP Model Keypad

Quick Start Guide for ST600 Series Frequency Inverters Keypad

8

No.

Name

Description

1

State

Indicators

Operation Indicator:

LED off – the VFD is stopped;

LED on – the VFD is running

LED blinking – the VFD is in parameter autotuning

2

Error Indicator:

LED on – the VFD is in error state

LED off – the VFD is in normal state

LED blinking – the VFD is in pre-alarm state

3

Short-cut key indicator, which displays different state under different functions,

see definition of QUICK/JOG key for details

4

Function Keys

The function of the function key depends on the respective menu.

The function of the function key is displayed in the footer.

5

6

7

Shortcut Key

Custom. By default, the button is defined as the JOG function. The function of

the shortcut button can be set via P07.02, as shown below.

0: No function;

1: Jogging (linkage indicator (3); logic: NO);

2: Reserved;

3: Switch between FWD and REV (linkage indicator (3); logic: NC);

4: Clear UP/DOWN settings (linkage indicator (3) logic: NC);

5: Coast to stop (linkage indicator (3); logic: NC);

6: Switch the operating command reference value mode in sequence (linkage

indicator (3); logic: NC);

7: Reserved;

Note: If default values are restored, the set function of the shortcut key returns

to 1 (jogging).

8

Confirmation Key

The function of the confirmation button varies depending on the menu, e.g. con-

firmation of parameter setting, confirmation of parameter selection, calling up the

next menu, etc.

9

Running Key

In keypad operation mode, this button is used to start VFD operation or to initiate

autotuning.

10

Stop/Reset Key

During operation, you can stop the VFD or stop the autotuning by pressing the

Stop/Reset button; this button is limited by the setting of P07.04. While in error

state, all control modes can be reset with this button.

Quick Start Guide for ST600 Series Frequency Inverters Keypad

9

11

Direction Keys

UP: The function of the UP key varies depending on the interface, e.g. moving

the displayed element upwards, moving the selected element upwards, changing

digits, etc;

DOWN: The function of the DOWN key varies depending on the interface, e.g.

moving the displayed element downwards, moving the selected element down-

wards, changing digits, etc;

LEFT: The function of the LEFT key varies depending on the interface, e.g.

switching the monitoring interface, e.g. moving the cursor to the left, exiting the

current menu and returning to the previous menu, etc;

RIGHT: The function of the RIGHT key varies depending on the interface, e.g.

switching the monitoring interface, moving the cursor to the right, calling up the

next menu, etc.

12

Screen Display

240×160 dot-matrix LCD; able to display three monitoring parameters or six sub-

menu items simultaneously

13

RJ45 Interface

You can use the RJ45 interface to connect to the VFD.

14

Clock Battery Holder

You can use the battery holder for replacing or installing a battery for the clock.

15

USB Terminal

Mini USB terminal

Quick Start Guide for ST600 Series Frequency Inverters Quick Start

10

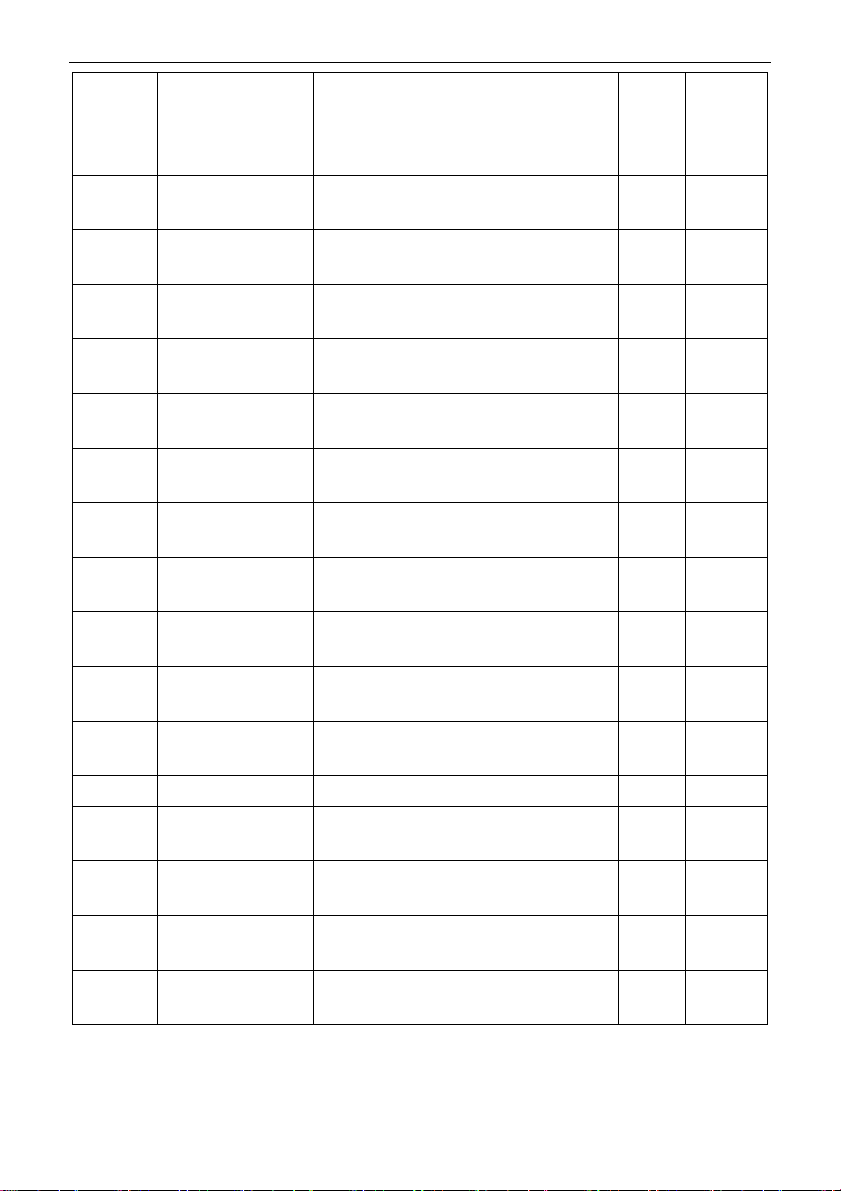

4Quick Start

4.1 Check Before Power-On

Ensure that all terminals have been securely connected.

Ensure that the motor power matches the VFD power.

4.2 First Operation

Make sure the wiring and power supply are correct and close the AC power supply air switch on the VFD input

side to turn on the device. The LCD user interface will launch the setup wizard to guide you through the setup.

The quick start flowchart is as follows:

Start

Power on after the wiring

is connect ed properly

Restore to default values

Set the motor param et ers

(P02.01–P02.05) as per

the mot or nam eplate

Set the motor param et ers

(P02.15–P02.19) as per

the mot or nam eplate

Press QUICK/ JOG to start

pilot run

If the mot or rotates in an

incorrect direction, power off and

exchange the motor wires of any

two phases, and power on again

Set autotuning mode

(P00.15)

Press RUN to start

autotuning (Aut omatical ly

stop once finished)

Asynchronous

mot or (AM)

Synchronous

mot or (SM)

Mot or

select ion

P02.00 or

P12.00

…

Set running frequency

(P00.06)

Set speed running

control mode (P00.00)

SVC 0 (P00.00=0) SVC 1 (P00.00=1) SVPWM (P00.00=2)

Set vector cont rol

param et ers in P03

group

Set vector cont rol

param et ers in P03

group

Set V/ F param et ers

in P04 group

Set start/stop control

param et ers in P01

group

Give the running

comm and to run

Give the stop

comm and to stop

Set running command

channel (P00.01, P00.02)

Set P00.15=2 to perform

static aut otuning 1

Set P00.15=3 to perform

static aut otuning 2

Set P00.15=1 to perform

rotary autotuning

End

Quick Start Guide for ST600 Series Frequency Inverters Important Function Parameter Settings

11

5Important Function Parameter Settings

Only a few common function parameters and typical values are briefly described below.

"○" indicates that the value of the parameter can be changed when the VFD is in stop or operating mode.

"◎" indicates that the value of the parameter cannot be changed while the VFD is in operation.

"●" indicates that the value of the parameter is recognized and saved, but cannot be changed.

(The VFD automatically checks parameter changes and restricts them to prevent invalid settings.)

Function

Code

Name

Description

Default

Modifiable?

P00.00

Speed Control Mode

0: Sensorless vector control (SVC) mode 0

1: Sensorless vector control (SVC) mode 1

2: Space voltage vector control mode

3: Closed-loop vector control mode

2

◎

P00.01

Channel Of Running

Commands

0: Keypad

1: Terminal

2: Communication

0

○

P00.02

Communication Mode Of

Running Commands

0: Modbus/Modbus TCP

1: PROFIBUS/CANopen/DeviceNet

2: Ethernet

3: EtherCAT/PROFINET/ Ethernet IP

4: Programmable expansion card

5: Wireless communication card

6: Reserved

Note: The options 0 (for Modbus TCP), 1, 2, 3, 4

and 5 are add-on functions, valid only when config-

ured with related expansion cards.

0

○

P00.03

Max. Output Frequency

Max (P00.04; 10)–630.00Hz

50.00Hz

◎

P00.04

Upper Limit Of Running

Frequency

P00.05–P00.03 (Max. output frequency)

50.00Hz

◎

P00.05

Lower Limit Of Running

Frequency

0.00Hz–P00.04 (Upper limit of running frequency)

0.00Hz

◎

P00.06

Channel to Set

Frequency Reference

Value A

0: Keypad

1: AI1

2: AI2

3: AI3

0

○

Quick Start Guide for ST600 Series Frequency Inverters Important Function Parameter Settings

12

P00.07

Channel to Set

Frequency Reference

Value B

4: High-speed pulse HDIA

5: Simple PLC program

6: Multi-step speed running

7: PID control

8: Modbus/Modbus TCP communication

15

○

P00.10

Frequency Set

Through Keypad

0.00 Hz–P00.03 (Max. output frequency)

50.00Hz

○

P00.11

ACC Time 1

0.0–3600.0s

Model-

dependent

○

P00.12

DEC Time 1

Model-

dependent

○

P00.13

Running Direction

0: Run forward

1: Run backward (reverse)

2: Disable reverse running mode

0

○

P00.14

Carrier Frequency

Carrier

frequency

Electromagnet ic

noise

Noise and

leakage current

Heat

dissipation

1kHz

10kHz

15kHz

High

Low

Low

High

Low

High

Model-

dependent

○

P00.15

Motor Parameter

Autotuning

0: Disable

1: Rotary autotuning 1

2: Static autotuning 1 (full)

3: Static autotuning 2 (partial)

0

◎

P00.18

Restore Function

Parameters

0: Disable

1: Restore defaults (excluding motor parameters)

2: Clear error records

5: Restore defaults (factory test mode)

6: Restore defaults (including motor parameters)

0

◎

P01.00

Start Mode

0: Direct start

1: Start after DC braking

2: Start after speed tracking

0

◎

P01.08

Stop Mode

0: Decelerate to stop

1: Coast to stop

0

○

P01.09

Starting Frequency Of

DC Braking For Stop

0.00Hz–P00.03 (Max. output frequency)

0.00Hz

○

P01.11

DC Braking Current

0.0–100.0%

0.0%

○

P01.12

DC Braking Time

Until Standstill

0.00–50.00s

0.00s

○

Quick Start Guide for ST600 Series Frequency Inverters Important Function Parameter Settings

13

P01.18

Terminal-Based

Operating Command

Protection At Power-On

0: Terminal-based operating commands are in-

active at power-on

1: Terminal-based operating commands are active

at power-on

0

◎

P02.00

Type Of Motor 1

0: Asynchronous motor (AM)

1: Synchronous motor (SM)

0

◎

P02.01

Rated Power Of AM 1

0.1–3000.0kW

Model-

dependent

◎

P02.02

Rated Frequency Of

AM 1

0.01Hz–P00.03 (Max. output frequency)

50.00Hz

◎

P02.03

Rated Speed Of AM 1

1–60000rpm

Model-

dependent

◎

P02.04

Rated Voltage Of AM 1

0–1200V

Model-

dependent

◎

P02.05

Rated Current Of AM 1

0.8–6000.0A

Model-

dependent

◎

P02.15

Rated Power Of SM 1

0.1–3000.0kW

Model-

dependent

◎

P02.16

Rated Frequency Of

SM 1

0.01Hz–P00.03 (Max. output frequency)

50.00Hz

◎

P02.17

Number Of Pole Pairs

Of SM 1

1–128

2

◎

P02.18

Rated Voltage Of SM 1

0–1200V

Model-

dependent

◎

P02.19

Rated Current Of SM 1

0.8–6000.0A

Model-

dependent

◎

P02.23

Counter-Emf Of SM 1

0–10000

300

○

P03.00

Speed-Loop

Proportional Gain 1

0.0–200.0

20.0

○

P03.01

Speed-Loop Integral

Time 1

0.000–10.000s

0.200s

○

P03.03

Speed-Loop

Proportional Gain 2

0.0–200.0

20.0

○

P03.04

Speed-Loop Integral

Time 2

0.000–10.000s

0.200s

○

Quick Start Guide for ST600 Series Frequency Inverters Important Function Parameter Settings

14

P03.09

Current-Loop

Proportional

Coefficient P

0–65535

1000

○

P03.11

Torque Setting Method

0–1: Keypad (P03.12)

2: AI1

3: AI2

4: AI3

5: Pulse frequency HDI

6: Multi-step torque

7: Modbus communication

0

○

P04.01

Torque Boost Of Motor 1

0.0%: (Automatic torque boost), 0.1%–10.0%

0

○

P04.09

V/F Slip Compensation

Gain Of Motor 1

0.0–200.0%

100.0%

○

P04.10

Low-Frequency

Oscillation Control

Factor Of Motor 1

0–100

10

○

P04.11

High-Frequency

Oscillation Control

Factor Of Motor 1

0–100

10

○

P05.01

Function Of S1

0: No function

1: Run forward

2: Run backward

3: Three-wire operating control (SIN)

4: Jog forward

5: Jog backward

6: Coast to stop

7: Reset errors

9: External error input

10: Increase frequency setting (UP)

11: Decrease frequency setting (DOWN)

1

◎

P05.02

Function Of S2

4

◎

P05.03

Function Of S3

7

◎

P05.04

Function Of S4

0

◎

P05.29

AI2 Lower Limit

-10.00V–P05.31

-10.00V

○

P05.35

AI2 Upper Limit

P05.33–10.00V

10.00V

○

P06.01

Y1 Output

0: Inactive

1: Running

2: Running forward

3: Running backward

4: Jogging

5: VFD in error

6: Frequency level detection FDT1

8: Frequency reached

0

○

P06.03

RO1 Output

1

○

P06.04

RO2 Output

5

○

Quick Start Guide for ST600 Series Frequency Inverters Important Function Parameter Settings

15

P06.14

AO1 Output

0: Operating frequency

1: Set frequency

3: Rotation speed (Relative to the speed corre-

sponding to max. output frequency )

4: Output current (Relative to twice the VFD rated

current)

5: Output current (Relative to twice the motor rated

current)

6: Output voltage (Relative to 1.5 times the VFD

rated voltage)

7: Output power (Relative to twice the motor rated

power)

0

○

P06.16

HDO High-Speed Pulse

Output

0

○

P06.17–

P06.21

AO1 Output

Upper/Lower Limit

Settings

For details, see the full version of the e-manual.

○

P07.00

User Password

0–65535

0

○

P07.27–

P07.32

Present Error Type –

5th-Last Error Type

0–76

(0: No error)

For details, see the full version of the e-manual.

0

○

P08.28

Auto Error Reset Count

0–10

0

○

P08.29

Auto Error Reset Interval

0.1–3600.0s

1.0s

○

P14.00

Local Communication

Address

1–247

Note: The communication address of a slave can-

not be set to 0.

1

○

P14.01

Communication Baud

Rate

0: 1200BPS

1: 2400BPS

2: 4800BPS

3: 9600BPS

4: 19200BPS

5: 38400BPS

4

○

P14.02

Data Bit Check

0: No check (N, 8, 1) for RTU

1: Even check (E, 8, 1) for RTU

2: Odd check (O, 8, 1) for RTU

3: No check (N, 8, 2) for RTU

4: Even check (E, 8, 2) for RTU

5: Odd check (O, 8, 2) for RTU

1

○

P15.01

Module Address

0–127

2

○

P15.02–

P15.12

Received Pzd2–

Received Pzd12

0–31

1: Set frequency (0–Fmax, unit: 0.01Hz)

0

○

Quick Start Guide for ST600 Series Frequency Inverters Important Function Parameter Settings

16

and

P16.32–

P16.42

2: PID reference (-1000–1000, in which 1000 corre-

sponds to 100.0%)

3: PID feedback (-1000–1000, in which 1000 corre-

sponds to 100.0%)

4: Torque setting (-3000–+3000, in which 1000 cor-

responds to 100.0% of the motor rated current)

5: Upper limit of the FWD operating frequency (0–

Fmax, unit: 0.01 Hz)

6: Upper limit of the REV operating frequency (0–

Fmax, unit: 0.01 Hz)

7: Upper limit of the electromotive torque (0–3000,

in which 1000 corresponds to 100.0% of the motor

rated current)

8: Upper limit of the braking torque (0–3000, in

which 1000 corresponds to 100% of the motor rated

current)

P15.13–

P15.23

and

P16.43–

P16.53

Sent Pzd2–Sent Pzd12

0–31

1: Operating frequency (x100, Hz)

4: Output voltage (x1, V)

5: Output current (x10, A)

6: Actual output torque (x10, %)

7: Actual output power (x10, %)

8: Rotation speed (x1, RPM)

0

○

P20.00

Encoder Type Display

0: Incremental encoder

1: Resolver-type encoder

2: Sin/Cos encoder

3: Endat absolute encoder

0

●

P20.01

Encoder Pulse Number

0–16000

1024

◎

P20.02

Encoder Direction

0x000–0x111

Ones digit: AB direction

0: Forward

1: Reverse

Tens digit: Z pulse direction (reserved)

0: Forward

1: Reverse

Hundreds digit: CD/UVW pole signal direction

0: Forward

1: Reverse

0x000

◎

P20.03

Detection Time Of

Encoder Offline Error

0.0–10.0s

2.0s

○

Quick Start Guide for ST600 Series Frequency Inverters Possible Errors and Solutions

17

6Possible Errors and Solutions

Note: Our error code scheme is being upgraded. Some products use the old scheme and the others use the new

one, which are listed in "Error code display".

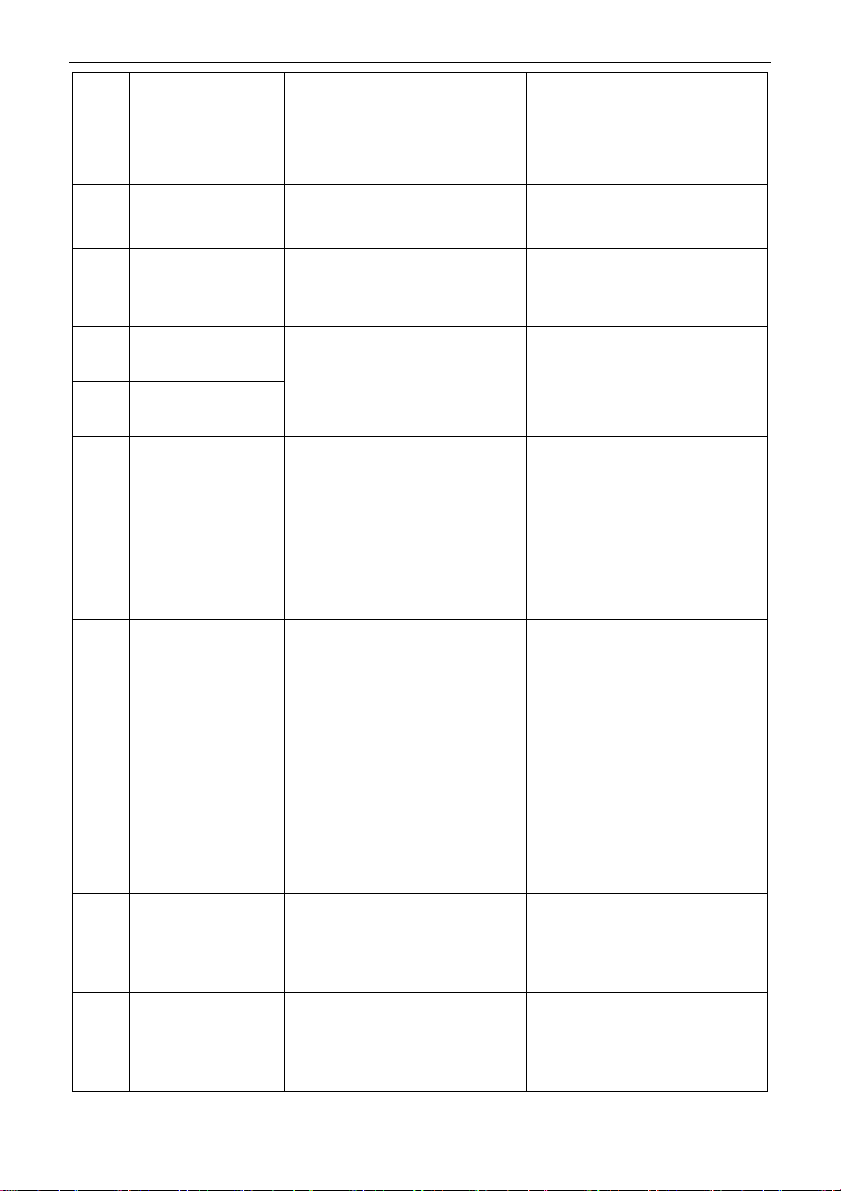

Error

Code

Error Type

Possible Cause

Corrective Measures

OUt1

[1] Inverter Unit U Phase

Protection

Acceleration is too fast;

IGBT module is damaged;

Malfunction due to interference; wires

are poorly connected;

To-ground short-circuit occurred

Increase acceleration time;

Replace the power unit;

Check the wires;

Check for sources of strong interfer-

ence in the vicinity of the peripheral

device

OUt2

[2] Inverter Unit V Phase

Protection

OUt3

[3] Inverter Unit W

Phase Protection

OC1

[4] Overcurrent During

Acceleration

Acceleration is too fast;

Grid voltage is too low;

VFD power is too small;

Load transient or exception occurred;

To-ground short-circuit or output

phase loss occured;

Strong external interference;

Overvoltage stalling protection is not

enabled

Increase the ACC/DEC time;

Check the input power;

Select a VFD with larger power;

Check if the load is short-circuited (to-

ground short-circuit or line-to-line

short-circuit) or the rotation is not

smooth;

Check the output wiring;

Check for sources of strong interfer-

ence;

Check the setup of related function

codes.

OC2

[5] Overcurrent During

Deceleration

OC3

[6] Overcurrent During

Constant Speed

Running

OV1

[7] Overvoltage During

Acceleration

Deceleration is too short;

Exception occurred at the input volt-

age;

Large energy feedback;

Lack of braking units;

Dynamic braking is not enabled, and

the deceleration time is too short.

Check the input power;

Check if the load deceleration time is

too short; or if the motor starts up dur-

ing rotation;

Install dynamic braking units;

Check the settings of related function

codes

OV2

[8] Overvoltage During

Deceleration

OV3

[9] Overvoltage During

Constant Speed

UV

[10] Bus Undervoltage

Error

Grid voltage is too low;

Overvoltage stalling protection is not

enabled

Check the grid input power;

Check the setup of related function

codes

OL1

[11] Motor Overload

Grid voltage is too low;

Rated motor current is set incorrectly;

The motor stalls, or the load jumps vi-

olently

Check the grid voltage;

Reset the rated motor current;

Check the load and adjust the torque

boost

OL2

[12] VFD Overload

Acceleration is too fast;

Increase acceleration time;

Quick Start Guide for ST600 Series Frequency Inverters Possible Errors and Solutions

18

The motor restarts during rotation;

Grid voltage is too low;

Load is too large;

Power is too low;

Avoid restart after stop;

Check the grid voltage;

Select a VFD with larger power;

Select a suitable motor

SPI

[13] Phase Loss On

Input Side

Phase loss or intense fluctuation oc-

curred to R, S and T input

Check the input power;

Check installation wiring

SPO

[14] Phase Loss On

Output Side

Phase loss occurred to U, V, W output

(or the three phases of the motor are

asymmetrical)

Check the output wiring;

Check the motor and cable

OH1

[15] Rectifier Module

Overheating

Air duct is blocked or fan is damaged;

Ambient temperature is too high;

Long-term overload

Ventilate the air duct or replace the

fan;

Lower the ambient temperature

OH2

[16] Inverter Module

Overheating

CE

[18] Modbus/Modbus

TCP Communication

Error

Baud rate is set incorrectly;

Communication line error;

Communication address error;

Communication suffers from strong in-

terference

Set a suitable baud rate;

Check the wiring of communication

interfaces;

Set a suitable communication ad-

dress;

Replace or change the wiring to im-

prove anti-interference capacity

tE

[20] Motor Autotuning

Error

Motor capacity does not match with

the VFD capacity, this error may occur

easily if the difference between them

is exceeds five power classes;

Motor parameters are set incorrectly;

The parameter settings obtained via

autotuning deviate sharply from the

standard standards;

Autotuning timeout

Select a different VFD model, or ena-

ble V/F control mode;

Set the correct motor type and name-

plate parameters;

Empty the motor load and restart au-

totuning;

Check the motor wiring and parame-

ter setup;

Check whether the frequency upper

limit is larger than 2/3 of the rated fre-

quency

dEu

[34] Speed Deviation

Error

Load is too heavy, or stalling occurred

Check the load to ensure it is suitable,

increase the detection time;

Ensure that the control parameters

are set correctly

STo

[35] Maladjustment Error

Control parameters of synchronous

motor is set improperly;

The parameter settings obtained via

autotuning are inaccurate;

Check the load to ensure it is suitable,

Ensure that the control parameters

are set correctly;

Quick Start Guide for ST600 Series Frequency Inverters Possible Errors and Solutions

19

The VFD is not connected to the motor

Increase the maladjustment detection

time

Other manuals for ST600 Series

1

This manual suits for next models

46

Table of contents

Other Sourcetronic Inverter manuals