TRISKEL MARINE integrel User manual

TRAINING AND

INSTALLATION GUIDE

ADVANCED GENERATOR REPLACEMENT TECHNOLOGY

Please Note

Integrel is classified as an “extra low voltage DC system” and falls

within the scope of the international standard ISO 10133:2017

and ABYC E11. It is strongly recommended that a copy of these

standards is studied before proceeding with the installation of

the Integrel system. Nothing in this guide supersedes these two

standards and if conflicting information is found, the standards

will always prevail.

Target Audience Assumptions

It is assumed that the reader of this installation guide is a trained

electrical installer with an adequate knowledge of marine electrical

engineering terms, concepts, language and abbreviations.

ADVANCED GENERATOR REPLACEMENT TECHNOLOGY

IMPORTANT SAFETY INSTRUCTIONS. Electromechanical

equipment, including generator sets, transfer switches,

switchgear, and accessories, can cause bodily harm and pose

life-threatening danger when improperly installed, operated, or

maintained. To prevent accidents be aware of potential dangers

and act safely. Read and follow all safety precautions and

instructions. SAVE THESE INSTRUCTIONS.

This manual has several types of safety precautions and

instructions: Danger, Warning, Caution, and Notice.

DANGER

Danger indicates the presence of a hazard that will cause severe

personal injury, death, or substantial property damage.

WARNING

Warning indicates the presence of a hazard that can cause

severe personal injury, death, or substantial property damage.

CAUTION

Caution indicates the presence of a hazard that will or can

cause minor personal injury or property damage.

NOTICE

Notice communicates installation, operation, or maintenance

information that is safety related but not hazard related.

Safety decals affixed to the equipment in prominent places

alert the operator or service technician to potential hazards and

explain how to act safely. The decals are shown throughout this

publication to improve operator recognition. Replace missing or

damaged decals.

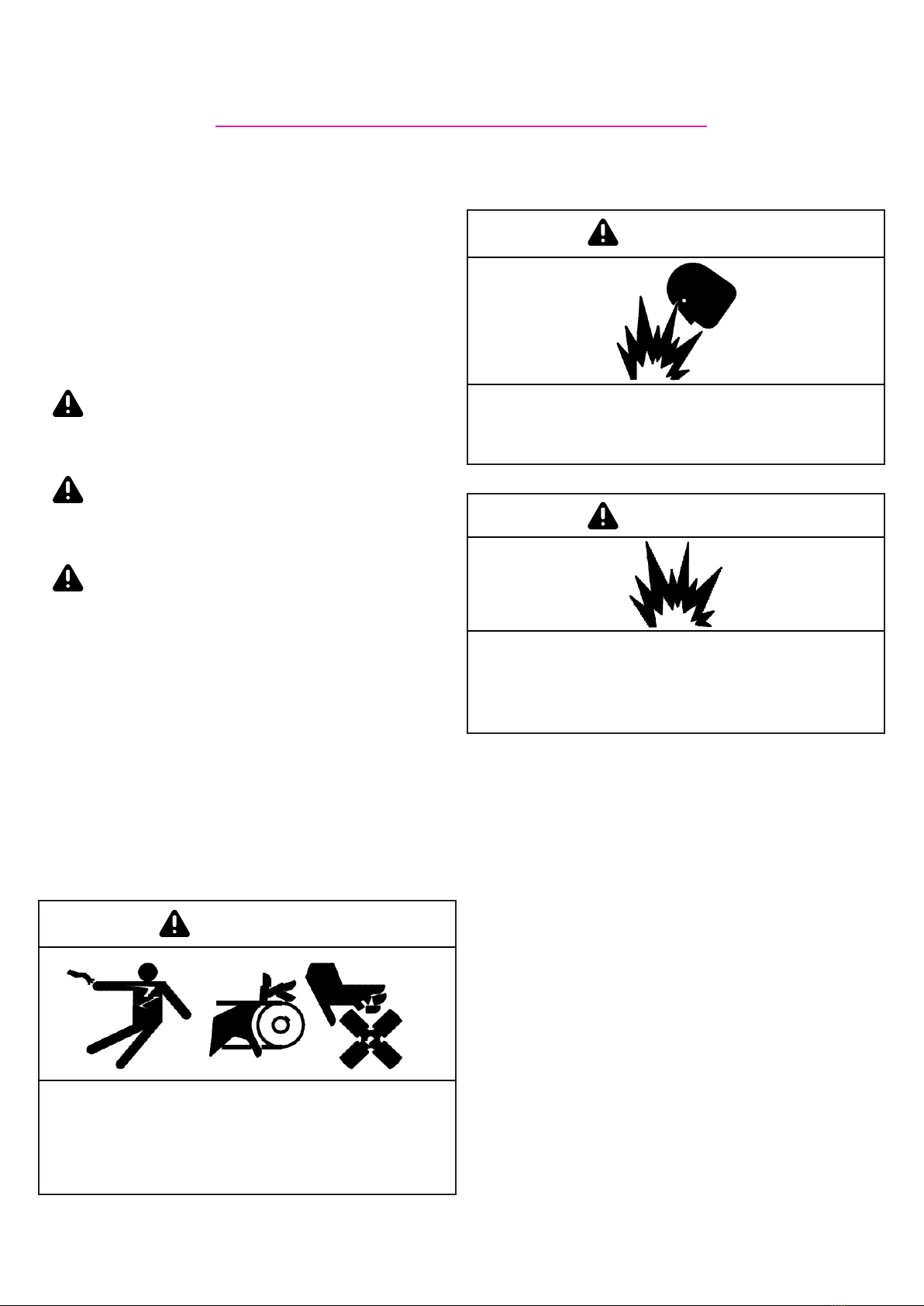

Accidental Starting

WARNING

Accidental starting. Can cause severe injury or death.

Disconnect the battery cables before working on the generator

set. Remove the negative (-) lead first when disconnecting the

battery. Reconnect the negative (-) lead last when reconnecting

the battery.

Battery Safety

WARNING

Sulfuric acid in batteries. Can cause severe injury or death.

Wear protective goggles and clothing. Battery acid may cause

blindness and burn skin.

WARNING

Explosion. Can cause severe injury or death. Relays in the

battery charger cause arcs or sparks.

Locate the battery in a well-ventilated area. Isolate the battery

charger from explosive fumes.

Battery gases. Explosion can cause severe injury or death.

Battery gases can cause an explosion. Do not smoke or permit

flames or sparks to occur near a battery at any time, particularly

when it is charging. Do not dispose of a battery in a fire. To

prevent burns and sparks that could cause an explosion, avoid

touching the battery terminals with tools or other metal objects.

Remove all jewellery before servicing the equipment. Discharge

static electricity from your body before touching batteries by

first touching a grounded metal surface away from the battery.

To avoid sparks, do not disturb the battery charger connections

while the battery is charging. Always turn the battery charger

off before disconnecting the battery connections. Ventilate the

compartments containing batteries to prevent accumulation of

explosive gases.

Battery short circuits. Explosion can cause severe injury

or death. Short circuits can cause bodily injury and/or

equipment damage. Disconnect the battery before generator

set installation or maintenance. Remove all jewellery before

servicing the equipment. Use tools with insulated handles.

Remove the negative (-) lead first when disconnecting the

battery. Reconnect the negative (-) lead last when reconnecting

the battery. Never connect the negative (-) battery cable to the

positive (+) connection terminal of the starter solenoid. Do not

test the battery condition by shorting the terminals together.

SAFETY PRECAUTIONS & INSTRUCTIONS

3

Explosive fuel vapors can cause severe injury or death. Take

additional precautions when using the following fuels:

Natural Gas—Adequate ventilation is mandatory. Because

natural gas rises, install natural gas detectors high in a room.

Inspect the detectors per the manufacturer’s instructions.

Hazardous Noise

CAUTION

Hazardous noise. Can cause hearing loss.

Always wear ear production when engine room sound proofing

is incomplete

Engine noise. Hazardous noise can cause hearing loss.

Generator sets not equipped with sound enclosures can produce

noise levels greater than 105 dBA. Prolonged exposure to noise

levels greater than 85 dBA can cause permanent hearing loss.

Wear hearing protection when near an operating generator set.

Hazardous Voltage/Moving Parts

DANGER

Hazardous voltage. Moving parts. Will cause severe injury or

death.

Operate the generator set only when all guards and electrical

enclosures are in place.

WARNING

Hazardous voltage. Backfeed to the utility system can cause

property damage, severe injury, or death.

If the generator set is used for standby power, install

an automatic transfer switch to prevent inadvertent

interconnection of standby and normal sources of supply.

CAUTION

Welding the generator set. Can cause severe electrical

equipment damage.

Never weld components of the generator set without first

disconnecting the battery, controller wiring harness, and

engine electronic control module (ECM).

WARNING

Short circuits. Hazardous voltage/current will cause severe

injury or death.

Short circuits can cause bodily injury and/or equipment

damage. Do not contact electrical connections with tools or

jewellery while making adjustments or repairs. Remove all

jewellery before servicing the equipment.

Grounding electrical equipment. Hazardous voltage will cause

severe injury or death. Electrocution is possible whenever

electricity is present. Ensure you comply with all applicable

codes and standards. Electrically ground the equipment,

transfer switch, and related equipment and electrical circuits.

Turn off the main circuit breakers of all power sources before

servicing the equipment. Never contact electrical leads or

appliances when standing in water or on wet ground because

these conditions increase the risk of electrocution.

Connecting the battery and the battery charger. Hazardous

voltage will cause severe injury or death. Reconnect the

battery correctly, positive to positive and negative to negative,

to avoid electrical shock and damage to the battery charger and

battery(ies). Have a qualified electrician install the battery(ies).

Servicing the generator set when it is operating. Exposed

moving parts will cause severe injury or death. Keep hands,

feet, hair, clothing, and test leads away from the belts and

pulleys when the generator set is running. Replace guards,

screens, and covers before operating the generator set.

4

Heavy Equipment

WARNING

Unbalanced weight. Improper lifting can cause severe injury

or death and equipment damage.

WARNING

Hot engine and exhaust system. Can cause severe injury or

death.

Do not work on the engine set until it cools.

Servicing the alternator. Hot parts can cause severe injury or

death. Avoid touching the alternator field or exciter armature.

When shorted, the alternator field and exciter armature become

hot enough to cause severe burns.

Hot parts can cause severe injury or death. Do not touch hot

engine parts. The engine and exhaust system components

become extremely hot during operation.

Refer to the Health and Safety Executive’s publications found at

http://www.hse.gov.uk/pubns/indg139.pdf

Fire and Ignition Protection

Where applicable, always follow the appropriate installation

standards regarding ignition protection. Electrocution is

possible whenever electricity is present. Ensure you comply

with all applicable codes and standards.

**Please locate any fire suppression sensors away from any

high power alternators and generators. These devices can

generate sufficient heat to trigger the suppression systems if in

close proximity**

5

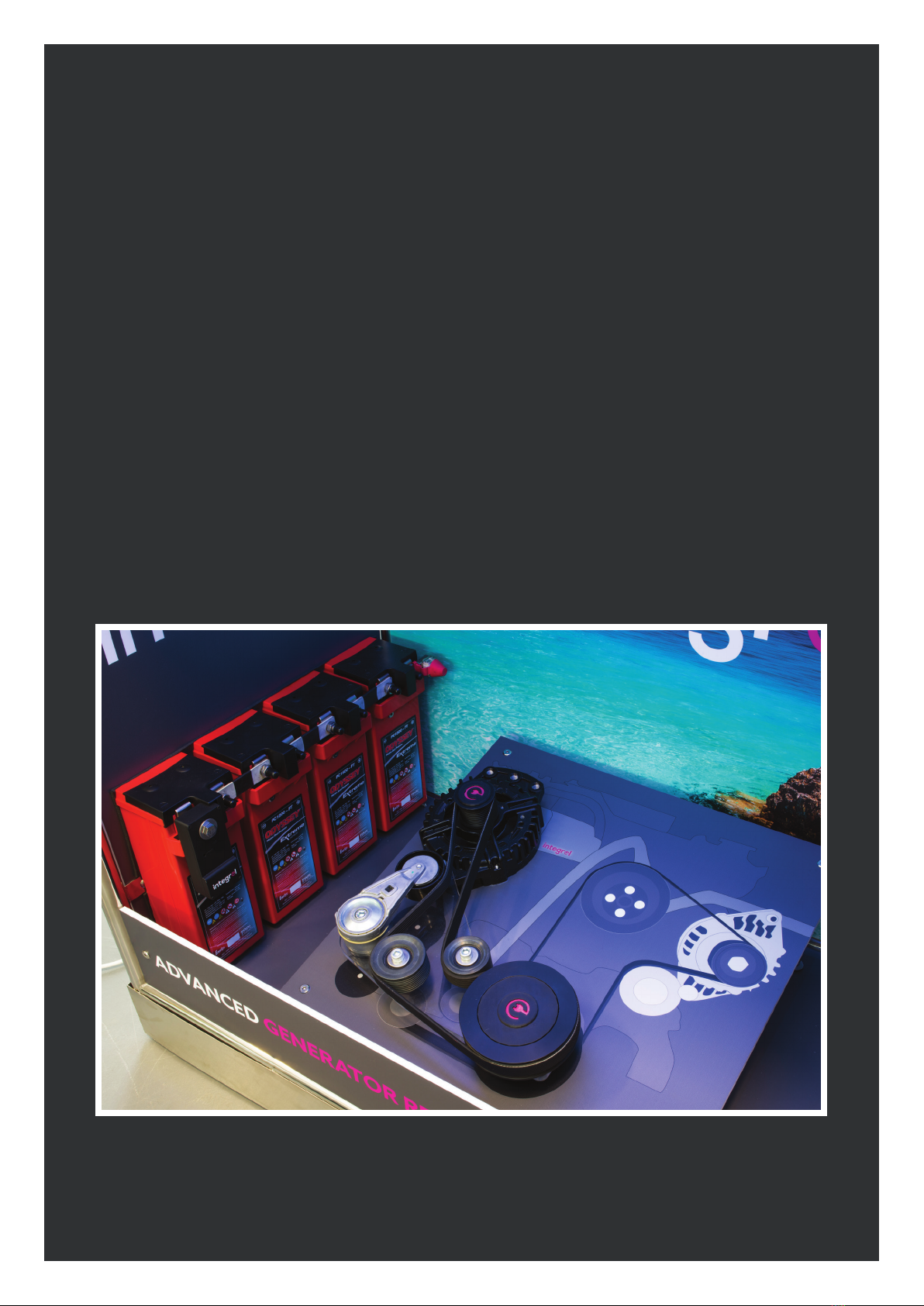

Introduction

Integrel is a modern, intelligent way of generating, storing and distributing electrical energy

in off-grid applications, such as recreational marine craft, without fitting a standalone

generator with a second engine. It is completely automatic, delivering significant amounts

of energy seamlessly throughout the vessel without user input. It is fuel-efficient, reducing

overall fuel consumption for propulsion and generation, and very cost-effective with virtually

no maintenance costs. Integrel completely replaces a conventional generator and delivers

all of the power that you need to make living on board as comfortable as living at home.

For the boat builder, the Integrel system simplifies the electrical energy system substantially.

It is a complete power generation, storage, conversion and distribution system, providing

all of the vessel’s energy needs in one consolidated package. The Integrel system also

provides additional safety, engine and battery management tools for the end user for

handling today’s modern lithium-ion battery banks. The system will automatically alert the

user when the batteries need to be re-charged.

Simple busbar connections are provided for all AC and DC voltages and no changes are

required to the vessel’s downstream electrical systems.

Contents

1. Overall System Configuration and Components 8

2. Tools Required 10

3. Pre-fit Boat Survey 10

4. System Schematic 11

5. Installing and Connecting the Batteries 12

a. Lithium-ion 12

b. Lead-acid 12

6. Battery Bank Sensors 13

7. 48V DC System 13

8. Controller 14

9. Inverter 16

10. DC-DC Converter 16

11. Screen Interface 16

12. Comms, Cabling and Junction Box 17

13. Final Connections and Commissioning 18

14. Appendices 20

• 9kW engine mounted generator - the source of

Integrel’s electrical power.

• Engine mounting kit - specifically designed for the

vessel’s propulsion engine.

• System controller - the black box which monitors and

controls all of the system components.

• Battery sensor(s) (lead-acid or lithium-ion) - to

monitor the vessel’s battery systems, track state of

charge and set desired charging voltage.

Integrel controller

Integrel generator

AC distribution panel

48v negative busbar

Screen

48v battery data

Shore supply

48v positive busbar

Input from renewables

10mm

4 mm

4mm

70mm

70 mm

70mm

Gear detect

12v negative busbar

xxA

30A

Integrel system boundary

48

12

5A breaker

4mm

20A breaker

400A

MRBF

midi

30A

midi

30A

midi

ANL/class T

20A o/p

positive busbar

To existing 12/24v

Engine start battery

Permanently live 12v busbar

4mm

48

12

5A breaker

30A

midi

20A o/p

Data cable to sensors on:

House bank

200Ah200Ah

48v storage bank

200Ah200Ah

48v storage bank

Victron 24v200Ah Li ion batteries

400A

ANL/class T

B A

Li ion safety switch

200A breaker

Power conversion

Energy storage

3/5/8kVA 110/220v

Inverter/charger

Generation and control

J1939

400A

ANL/class T

200Ah200Ah

48v storage bank

Major 48v loads

winches/windlasses/thrusters

xxA

midi

70 mm

8

1. OVERALL SYSTEM CONFIGURATION AND COMPONENTS

The core components of the Integrel system and their functions are as follows:

• Integrel battery safety switch - a smart switch that

will disconnect automatically in any safety critical

event.

• 48v to 12/24v DC-DC converter - various options

available.

• 5” touch screen user interface - displays live

information of the Integrel system.

• Screen interface box - converts our own CAN data

into a format compatible with the screen.

• Communications junction box - the point where all

of our network cables can meet.

• Switch panel - Also included is a switched breaker

panel for the Integrel controller and DC-DC converter

Additional third party components which complete

the Integrel system are:

• Batteries for energy storage, either lead-acid or

lithium-ion, configured for 48V DC.

• Inverter/charger to convert electrical energy stored

at 48V DC to 110/240V AC. It also allows you to charge

your batteries from shore power.

9

Skills Required

Installing an Integrel system is less complex and time consuming than installing a traditional generator, but still

requires experience and guidance from Triskel Marine. It is intended to be installed by a qualified installer, with

online access to Integrel’s system setup software and other Integrel resources.

As far as possible, everything is preconfigured, including wiring harnesses. Detailed videos are available on the

Integrel Marine YouTube page to illustrate the various stages.

(https://www.youtube.com/channel/UCyxkU5XIGfVQW4MSbnQ7WVw)

The Integrel system can mostly be installed with

commonelectricalhandtools. Mostmarineelectricians

will have:

• Insulated screwdrivers

• Insulated spanners

• Standard spanners (metric and imperial)

• Allen keys

• Socket set

• Ratcheting insulated terminal crimp tool

• Non insulated terminal crimp tool 10mm2-120mm2

(8AWG - 4/0AWG)

• Hot air gun

• Cordless drills for mounting parts

• Thermal imaging camera

• Independent 12V power source/battery

• Insulation strippers

You may not have a thermal imaging camera, however

we feel this is a crucial piece of equipment for checking

your work and ensuring there are no bad connections.

2. TOOLS REQUIRED

Prior to starting the installation, it is essential to carry

out a physical survey of the boat to identify where the

individual components will be fitted. This is particularly

important for the batteries which are likely to be the

largest and heaviest items. For specific sizes and weights,

please refer to our website. Batteries must be installed in

a dry space and well clear of any area where there might

be water ingress (see ISO 10133 for details). Ensure all

restraints and mounts are to a suitable standard.

Batteries

All batteries, but particularly lithium-ion, are sensitive

to temperature. It is essential that the batteries are

positioned in the coolest possible location in the boat

and there is plenty of air circulation around them.

lithium-ion batteries will automatically disconnect if their

internal temperature exceeds a given limit, which may be

as low as 45°c. If prolonged operation in high ambient

conditions is required, careful attention must be paid to

the manufacturers’ operating limits and battery choices

should be made accordingly. There may also be low

tempertature usage limits with some batteries.

Lead-acid battery spaces must be vented to the exterior.

If in doubt about the effect of the battery weight on boat

trim, consult a naval architect.

Cable Routes

Routes for cabling need to be identified as part of the

survey, bearing in mind that cable lengths should be

kept to a minimum to reduce cable losses. Details of

recommended cable sizes are given in Annex B. Most

vessels have conduits for major cable runs and these

should be used where possible.

Please note: the positive and negative power cables

should be run together to reduce stray magnetic fields.

These should always be kept clear of bilge areas. Data

cables, AC power cables and DC cables should be run

separately if possible.

Generator

The generator is mounted on the front end of the engine

and is normally driven from an additional pulley bolted

to the existing crank pulley. Depending on the make of

engine, the Integrel generator may extend outside the

normal envelope of the engine. Be sure to check that

there is sufficient room to accommodate any overhang.

Installation instructions are included with each specific

engine fitting kit.

Screen

The screen can be mounted remotely from the other

system components and should be positioned where

it is easy to see from the main saloon. The display has

been designed to show the battery state of charge and

voltage at a glance and it is useful to be able to see it

easily from all of the common spaces. The screen also

displays various alarms and alerts and must be accessible

in order to acknowledge and clear alerts. A template for

the screen cut-out is given in Annex C, or you can use the

supplied screen mounting panel.

Battery Switches

The main battery switches are solenoid operated and

are normally actuated automatically by the system itself.

They are also fitted with a mechanical actuator and need

to be accessible in case of an electrical failure. Ensure

you have a suitable location available for the switches.

Busbars

These are used as a primary means of connecting

common DC power cables. Ensure all connections are

booted and protected from short circuit.

Battery sensor

The battery sensor measures battery parameters such

as individual battery voltage and bank temperature. The

sensor then communicates with the controller, which

delivers the right amount of power to correctly charge

your battery banks as quickly and efficiently as possible.

3. PRE-FIT BOAT SURVEY

11

Loom

The main loom is supplied in two parts, the three main

phase cables are together in one part, and the second

part has smaller wires. These two looms connect the

controller to the generator, which allow the controller

to accurately control the generator output. The

loom with the three phase cables transports the AC

power from the generator to the controller where it is

rectified to 48V DC. The loom with the smaller cables

brings temperature inputs from the engine, generator

and ambient to further optimise generation. We also

use this loom to detect when gear is selected, which

allows propulsion to always be prioritised.

Inverter/Charger

We recommend fitting an inverter/charger suitable for

giving you all the AC power you need, which is how the

48V DC is converted into either 110V or 230V AC. The

charger element of the inverter is used to maintain

the 48V batteries when shore power is available. It

is advised that the inverter be placed as close as

practicable to the batteries, and that the cable be

upsized to prevent potential ripple under load.

DC-DC Converter

The DC-DC converter, gives a trickle charge from the

48V battery storage bank to the 12V/24V house banks.

This is often a setting that must be set to the house

bank float voltage, and is normally left on at all times.

This should be set to ‘float voltage’ for the house bank.

On/Off Switch

The Integrel switch should be left on at all times,

therefore it should be located in a position where it

cannot be knocked. The Integrel system uses a very

small amount of power in sleep mode but can draw up

to 15A whilst generating. The supplied switch panel

also has a switch for the DC-DC converters to allow

the owner to turn these off should the boat be left

without shore power.

Controller

The main controller should be sited in a dry location

within a 3m cable run of the generator. The system

needs reasonable airflow and under heavy load can

become hot, so please consider the location carefully.

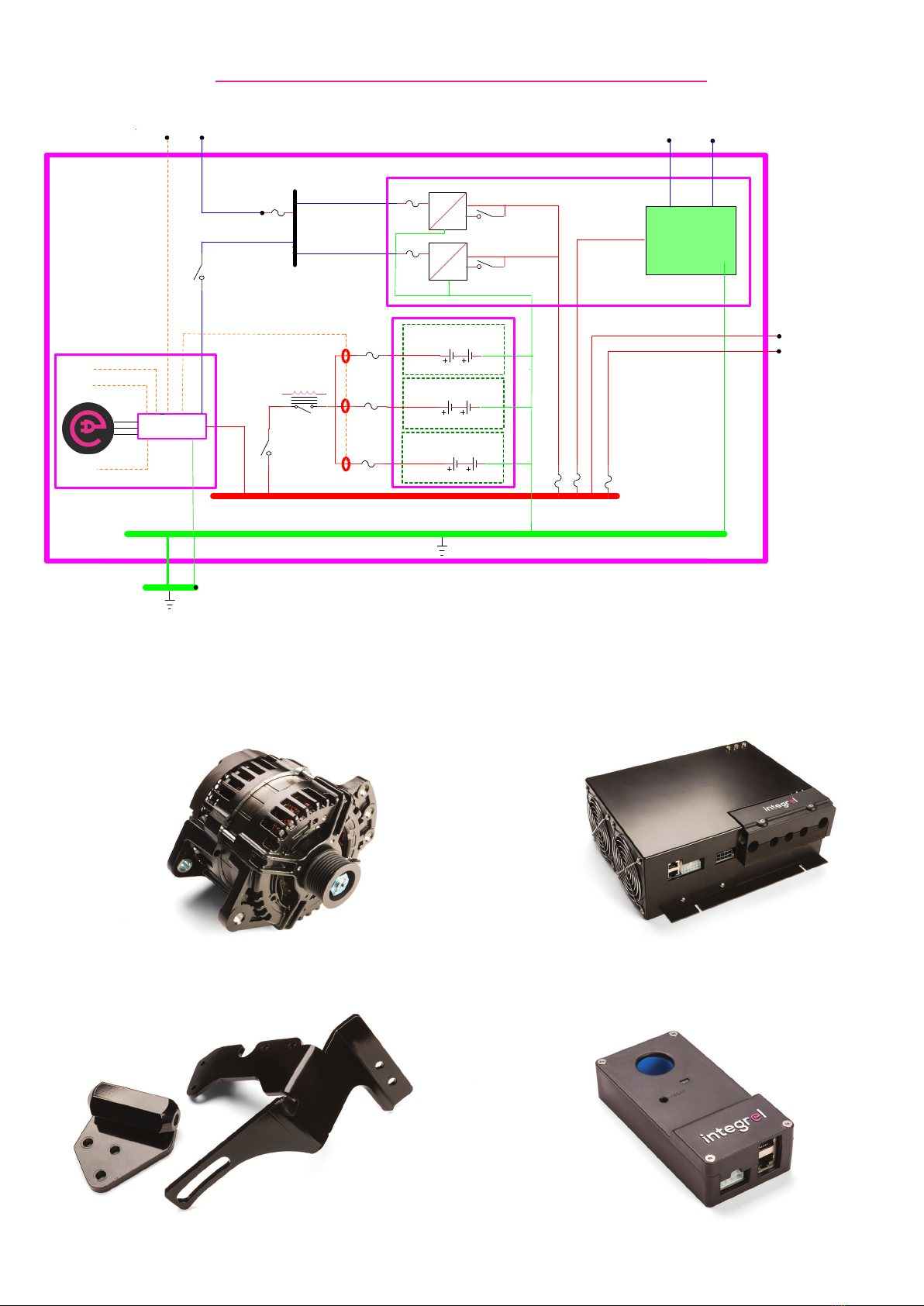

4. SYSTEM SCHEMATICS

A detailed schematic is provided for each particular

installation and should be followed closely. Each circuit

within the schematic has been designed in the light of

many years of experience and no changes should be

made without referring back to Triskel Marine.

A few basic principles are illustrated in the attached

schematics:

• Each battery bank is individually connected to the

48V power busbars (positive and negative) and must

not be paralleled together in any other way. Each of the

banks is fitted with a battery sensor which monitors

battery state of charge and determines the charging

voltage. If the batteries are not individually connected

to the busbar, the state of charge calculation will be

wrong.

• We normally fit a permanently live 12V busbar

supported by a DC-DC converter from the main energy

storage batteries and by the 12V house battery bank.

This allows the Integrel controller to be left energised

when the rest of the boat is powered down, in order to

keep track of the battery state of charge. If the system

is fully powered down, state of charge will be reset on

the next occasion that the batteries are charged to

100%.

• Cable and fuse sizing in the schematics is based on

ISO 10133 and ABYC E-11. Guidance is provided in

annex B.

• Overall management of the system is provided by

the controller which receives information from all of

the system components via a closed data network.

Data cables are fitted to each device and may be daisy-

chained together, connected in a star configuration or

a combination of the two.

• You may require multiple battery sensors, please

ensure you have the required number of sensors and

cables.

12

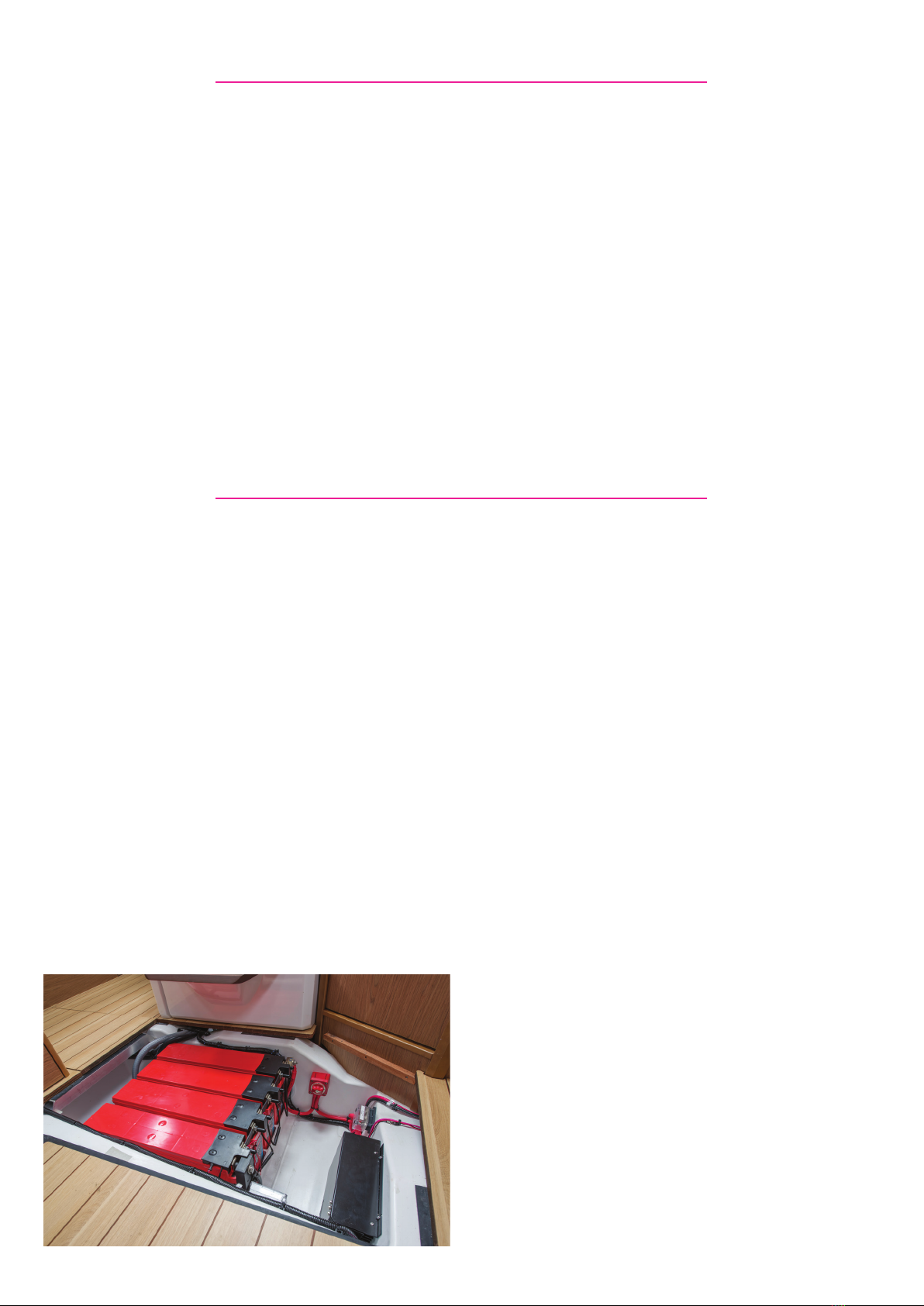

5. INSTALLING AND CONNECTING THE BATTERIES

The Integrel system works equally well with both lead-

acid and lithium-ion batteries. The type and number of

batteries will have been determined during the system

design phase and the choice is influenced by a number

of factors:

• Typical 24 hour AC and DC power consumption

• Maximum loads seen on all circuit types

• Desired period of autonomy (“silent operation”)

• Typical 24 hour operational profile

Battery Choice and Installation

5.1 We currently support the following battery

manufacturers: Torqeedo, Victron, Relion and

Mastervolt. These weigh in excess of 25kg each, so

consideration must be taken as to where they are

sited, supported and secured.

5.1.1 It is important to note that battery

age, chemistry, brand and capacity must

not be mixed. This applies not only to the

batteries within each bank but also across

all banks. If you chose to add another

bank of batteries at a later stage, these should

be monitored for a full charge and discharge

cycle. If any discrepancy is seen between new

and old banks, all old banks must be replaced.

5.2 When unpacking lead-acid batteries, be sure to

check the voltages. They should all be above 12.8V

and should have a difference of no more than 0.2V

between batteries.

5.3 With lithium-ion batteries, it is common practice

to ship these at or below 50% state of charge (SOC).

In contrast to lead-acid batteries, lithium-ion batteries

do not like being left at 100% SOC. These batteries will

not balance individual battery voltage if they are not

properly synchronized before linking together in series.

For this reason, it is common practice to charge each

battery to a certain voltage stipulated by the battery

manufacturer before connecting batteries together

in series. Please refer to the battery manufacturer’s

installation instructions for details on this procedure.

**This procedure is vital for a system to work

effectively and for the useable capacity to be

maximised. Please refer to the battery manufacturer

documentation for more information**

5.4 Once you have confirmed the batteries are in good

condition and correctly charged, a suitable location

should be found where the batteries can be mounted

and secured properly. The best solution is to mount

the batteries close to each other with a suitable air

gap between blocks. Batteries should be packed

and secured so they will not move should the boat

encounter rough seas. If it is not possible to mount

batteries in one area, cable lengths between batteries

should be kept as short as possible and all link cables

should be made of at least 70mm2 tinned marine

cable. It is important to try and keep all batteries

in the system at a similar ambient temperature, as

differences between batteries or battery banks can

cause imbalances between them.

5.5 Link bars or cables should be fitted and torqued to

the battery manufacturer’s specifications.

5.6 A high interrupt current fuse (such as a Class T

or ANL fuse) should be fitted as close as practically

possible to the positive battery terminal, this will

protect the battery from a short circuit and should be

rated at well above the maximum expected load. A

breaker should also be fitted to protect the cable from

overcurrent. This should be fitted as stipulated in the

schematic for the individual installation.

5.7 In some cases, a battery terminal stud may be

supplied, which allows the battery bank sensor to

be fitted right next to the battery bank. If a terminal

stud is not supplied, or will not fit for the particular

installation, it is recommended that the battery sensor

is fitted over one of the battery cables (it may be

necessary to fit the sensor before crimping the final

terminal on to allow the sensor to pass over the cable

end). The chosen cable must take the entire bank

current - this could be a positive or a negative cable,

but not an intermediate link cable.

***Do not connect any battery bank until ALL other

48V wiring is complete***

**Always follow battery manufacturers installation

and application instructions**

5.8 The Integrel safety switch should be fitted as

close to the battery bank as possible, with no other

connections between it and the battery other than

the primary fuse (all load and charge sources need to

be on the switched side of the safety switch, not the

battery side). When a battery bank reaches a critical

low voltage or high temperature it will automatically

disconnect the bank to prevent damage to the battery.

The positive cable connects to the 48V positive

battery terminal, and the negative cable connects to

the negative terminal. If connected to the Integrel

data bus, it can also monitor and report other fault

conditions on the bus. Some battery types require

specific interfacing between the battery BMS and the

safety switch to allow disconnect and control directly

from the battery. This may require an optional wiring

loom as it is battery and model specific. Please contact

Integrel for more information as required, this should

be considered as part of the initial specification and

schematic process.

The main battery cables connect directly to the main

terminals. This should be done with the switch in the

off position, by pulling up on the knob. This knob

allows manual activation of the switch should it be

required.

13

6. BATTERY BANK SENSORS

7. 48V DC SYSTEM

7.1 Find a suitable place for the battery solenoid switch,

this should be on the positive battery cable as close to

the battery bank as is practical. Fix the battery switch

in place with appropriate fastenings. Further details

will be provided with the switch.

***Ensure that battery switch is in the off position***

***Do not connect at this time***

7.2 Find a suitable place for the positive and negative

busbars. Use different locations for each busbar. It

should not be possible to short with a spanner between

the two busbars whilst working on them.

7.3 Select the appropriate size cables for connecting

the battery bank with the busbar for the maximum

possible load. These will be detailed in the system

schematic. As mentioned previously, a high interrupt

capacity fuse AND an appropriately sized circuit

breaker should be fitted before the battery switch.

The fuse will protect the battery and the breaker will

protect the cabling.

***Always size cable appropriately***

7.4 Connect the 48V negative busbar to the boat’s

common grounding point with a suitably sized cable

(no less than 35mm2). If not already linked, also fit a

negative link between any 12V and 24V battery banks.

7.5 Run cables between the busbar and the battery

bank(s), but do not connect.

Important:

• Always ensure the 48V system is isolated before working on it.

• Ensure a fuse/breaker is appropriately sized and sited (on the positive side) for every

reduction in cable cross-sectional area where the cable is in use.

• Label all cables at both ends.

6.1 Place the battery bank sensor over the sensor post

or battery bank cable.

6.2 The bank sensor loom will have between 3 and 6

cable ends depending on your chosen batteries and

the voltage of the bank. please refer to Annex D. The

twin core black cable with the non insulated terminal

on the end is the temperature tap. The black wire is 0V.

The remaining four red cables are voltage tap 1, 2, 3

and 4. If using a loom for the PC1800 batteries with the

copper busbars, tap 1 is the shortest and tap 4 the

longest. If using the non-specific battery loom, the

terminals will be labelled.

6.3 If using 4 x 12V batteries, use tap 1 for 12V

(from 0V tap), tap 2 for 24V, tap 3 for 36V and

tap 4 for 48V.

If using 24V batteries use tap 1 for 24V and tap

2 for 48V. If using a single 48V battery use tap 1 for

48V.

6.4 Fit the 0V tap at the point where the negative cable

leaves the battery bank.

6.5 Fit the positive voltage taps as shown in Annex D.

6.6 Re-fit and tighten all terminal fastenings and

torque to manufacturer’s specification.

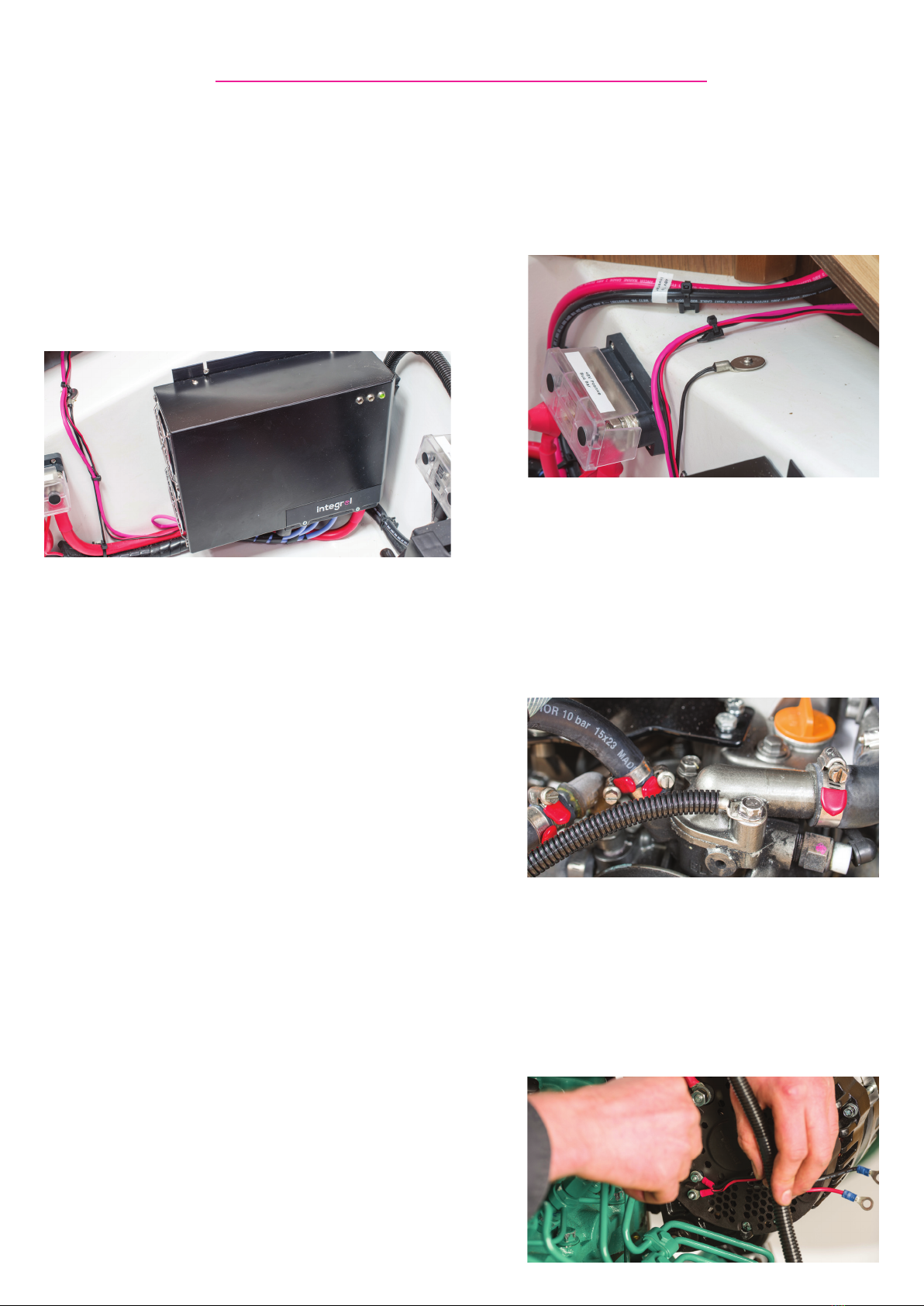

8. CONTROLLER

8.1 The positioning of the controller is important.

It should be within a 3m cable run of the Integrel

Generator (cable loom is supplied at 2.9m), and should

also be located in a clean and dry environment. The

controller is designed to be bulkhead mounted with

the fans on the left, however it may be mounted in

either orientation. If bulkhead mounting in the portrait

orientation the fans must be at the bottom. The

controller can also be mounted on a horizontal surface

providing it is properly secured.

8.2 Once the correct location has been determined, the

controller should be mounted with four appropriate

screws, once the holes are marked. It is best to screw

the lower two screws in most of the way and slide

the controller onto these, before adding the last two

screws and tightening all four.

8.3 Connect the Integrel generator to the controller

with the two pre-made looms supplied. The first loom

has two Molex plugs (one black, one white) and is for

the data input, power to the controller and power

to the generator. The plugs should be fitted to their

appropriate holes on the controller.

8.3.1 You will notice there are a pair of cables

attached to the black plug that are separate to

the rest of the loom. These are the main 12V

power cables to power the system and

should see no more than 20A. The positive

should be attached to a breaker for the system

and the negative to the boat’s negative.

8.3.2 Working your way away from the

controller, the first connection you will see is

the two-way Molex plug for the gear detect

switch. This plug should remain connected if

you plan on using a neutral switch from the

gearbox, or if you plan on extending these

cables from the engine side of the loom to

the throttle control neutral switch. If you plan

on using a neutral switch nearer the Integrel

controller, you should separate this plug and

use the adaptor loom provided. It may be

necessary to extend this to reach the throttle

control. See Annex E.

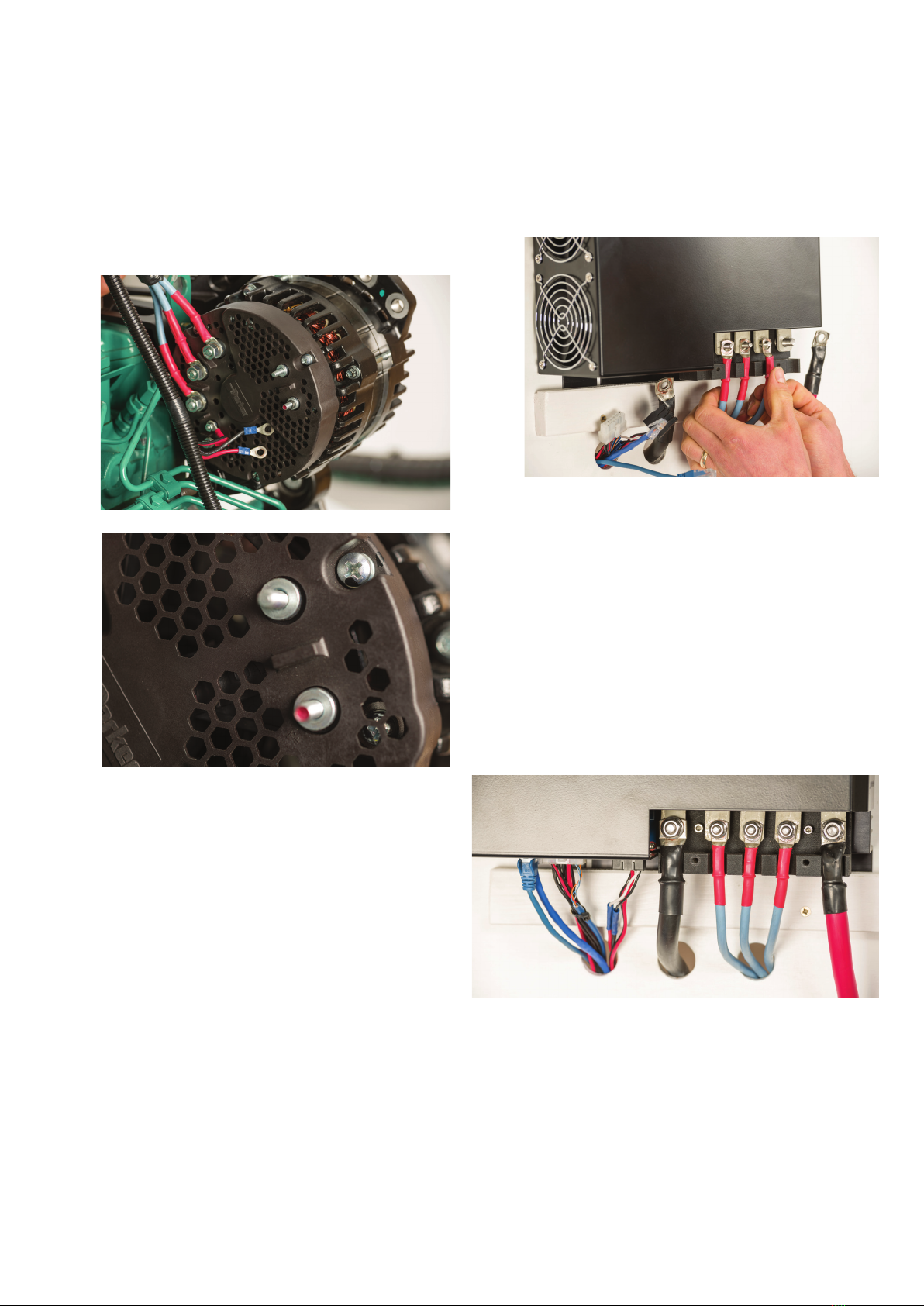

8.3.3 Continue working away from the

controller, the next terminal you will find is

the ambient temperature tap. This will be

around 0.5m from the controller. It is a 10mm

ring terminal connected with a twin core

cable. Secure this to a bulkhead in the same

space as the controller.

8.3.4 The next twin core cable with a single

ring terminal at the end is the engine

temperature tap. This will be located at the

engine end of the loom and should be

positioned at the hottest point of the engine’s

fresh water cooling circuit, ideally the

thermostat housing. Ensure this cabling is

properly protected and secured to avoid any

damage from engine vibrations.

8.3.5 At this point you will be left with four

ring terminals, a pair of bare ends, and a 4-pin

plug on this loom. You will notice that there

will be two pairs of ring terminals, a pair of

4mm and a pair of 5mm ring terminals. The

4mm terminals are the thermistor

connections. These are to be fitted to the two

4mm studs on the back of the generator.

15

8.3.6 The larger pair of ring terminals are the

field connections. Careful attention should be

paid to the polarity of these terminals. The

red cable should go on the F+ terminal. The

black cable should go on the F- terminal. (If

these are fitted incorrectly, the max output

will not exceed 1.5kW, but no damage will be

done).

8.3.7 The remaining 4-pin plug is an optional

plug to be used if the engine has an ECU. An

adapter cable will be supplied if the engine is

capable of this function.

8.3.8 Remaining bare-ended cables are for

the neutral detect switch, as mentioned

previously (see Annex E). You may have a

neutral detect switch available on the gearbox.

If you plan on using this, then you should

ensure the in-line plug is connected at the

controller end. If you have disconnected the

plug at the controller end, this cable is

redundant. If the throttle control is already

connected to the engine loom, it may be

possible to pick up the gear detect via

the engine CAN BUS network, in this case the

engine ECU adapter must be used. These

ECU cables are engine specific and

various options are available. Please contact

Integrel for advice, and this should be

considered during the specification process.

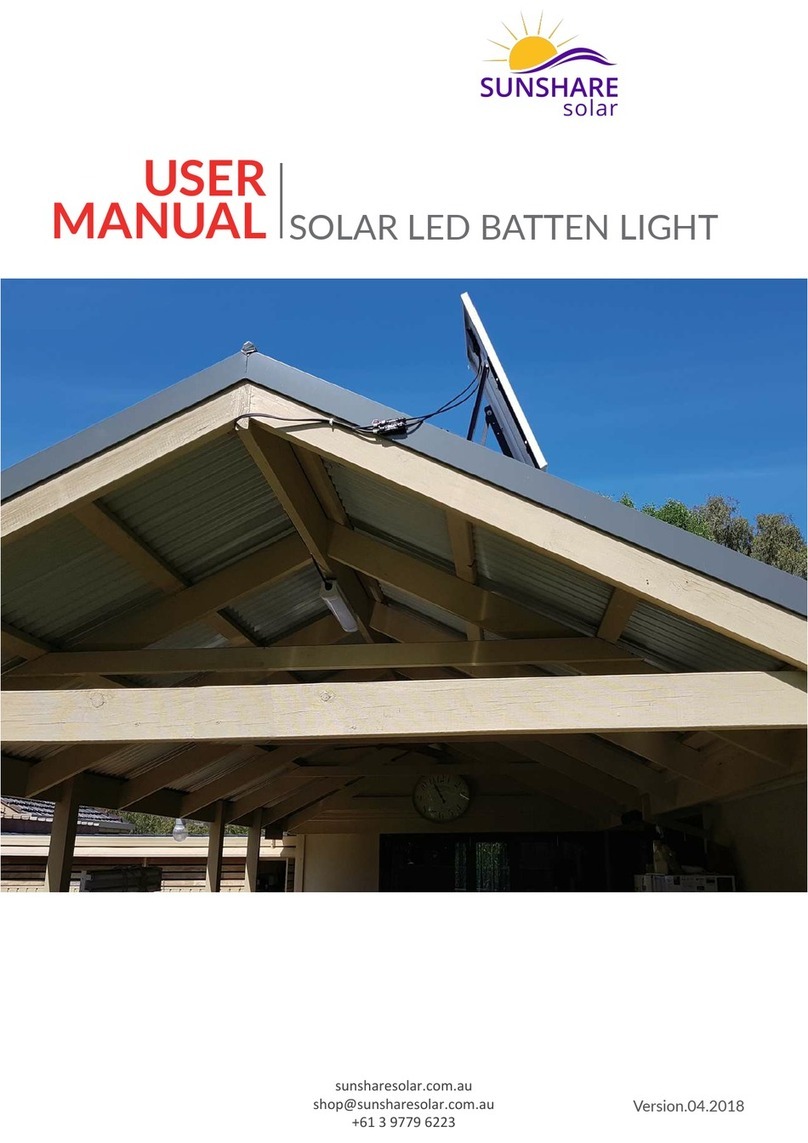

8.4 The second loom houses the three phase

cables. These transport the unrectified power from

the generator to the controller where the power is

rectified. It is not important which phase cable goes

to which stud on the generator or the controller.

8.4.1 At the controller end, first remove the

plastic terminal cover, then connect the three

phase cables to the three M6 studs on the

controller.

8.4.2 Then connect the other with the 8mm

studs to three phase studs on the generator.

8.5 Run in and connect the positive and negative

cables between the respective busbars and the

positive and negative studs on the controller. Ensure

correct connection!

16

9. INVERTER

9.1 Find a clean, dry place away from sensitive electronics

and securely mount the inverter in accordance with the

manufacturer’s specifications.

*** Inverters have large capacitors. Once connected

to 48V, they will be charged - bear this in mind when

working on the 48V system. There may be significant

residual energy stored in the inverter even after it has

been turned off**

9.2 Run in and connect the positive and negative cables

to their respective busbars. These should be fused

according to cable sizing all noted on the installation

schematic. Always keep the inverter location as close as

possible to the batteries.

*** Ensure all 240V/110V power is disconnected from the

boat, including other inverters***

9.3 Connect the AC power as described in the inverters

manual.

9.3.1 Depending on the boat setup, it may

be necessary to use different feeds to that of

a standard inverter. Some boats have two AC

circuits, one powered only by shore power

and one that can be powered by an inverter.

If you have sized the inverter appropriately,

you can connect into the shore power circuit.

This means you will be able to supply all

appliances on your boat, including the high

power consumers such as water heaters,

microwaves and cookers.

9.4 Switch the inverter on and configure the charging

profiles correctly for the battery make and model you

have. This is essential for lithium-ion batteries.

10. DC-DC CONVERTER

10.1 Find a suitable location that is clean and dry.

Mount the DC-DC converter with suitable fastenings.

10.2 Run in and connect a suitably sized positive cable

from the 48V busbar through a suitably sized circuit

breaker or fuse to the 48V positive terminal on the DC-

DC converter via the supplied switch.

10.3 Run in and connect the same sized negative cable

directly from the 48V negative busbar to the DC-DC

converter.

10.4 Run in and connect the positive and negative

cables directly to the 12/24V house ban. These cables

should be suitably sized and fused. Note that there

will be more current flowing on the 12V/24V side.

10.5 Refer to DC-DC converter installation instructions

for remote switching. With some models it may be

possible to switch the DC-DC converter without

passing all input current through a switch.

***Ensure negative cables are both connected and

commoned. A smaller busbar is useful for this***

11. SCREEN INTERFACE

11.1 Find a suitable place to mount the display screen

where it is possible to flush mount and have access to

run the cabling. It should be easy to read and reach,

and secured with appropriate fixings.

11.2 Fit the screen interface box within 200mm of the

screen, this should be semi accessible as this is the

point at which the system software can be updated via

the USB port.

11.3 Connect the screen loom between the screen

interface box white 12-way Molex plug and the two

deutsch plugs on the back of the screen. Though

the plugs have the same number of pins, they have a

different register and will only fit in the correct socket.

11.4 The supplied alarm buzzer should be connected

to the four-pin connector and mounted appropriately.

11.5 Given the screen is a relatively high

user of power, it is important that the Screen

interface box is plugged directly into one of

the ports on the controller as this is the only

power source on the Integrel CAN bus system.

17

12. COMMS CABLING AND JUNCTION BOX

12.1 Find a clean dry place for the junction box as close

to the centre of the kit as possible and secure with

appropriate fastenings.

12.2 Run cables from the junction box to:

12.2.1 Battery safety switch

12.2.2 Battery sensor(s)

12.2.3 Controller

12.3 Many of the components have the facility to

“daisy chain” the data cables. This is possible if

components are close by, but depending on the

system layout it may be better to bring all cables to

the junction box where possible.

12.4 We operate a CAN bus system. For this to work

properly, we need two terminating resistors connected

to the data bus. The junction box and the screen

interface box both have resistors built into the circuit

board.

12.5 If a second junction box or second screen

interface box is to be used, you will need to make sure

you don’t have more than two terminating resistors in

the system. This can be done by removing the correct

number of “jumpers”. To do this, first remove the lid

and, with tweezers or long nosed pliers, remove the

“jumper” from the position marked R120, as shown in

the images below.

18

13. FINAL CONNECTIONS AND COMMISSIONING

13.1 Check all 48V connections for correct connection

and tightness.

13.2 With the battery switches locked off (turn the knob

90 degrees to the ‘off’ position – this feature is only

intended for use during installation), connect all 48V

battery banks. Be sure to include the tap cables for the

bank sensor and battery safety switch at this time.

13.3 Turn the Integrel system on at the Integrel switch

panel.

13.4 IMPORTANT! At this point the system will require

configuration using the Integrel setup application. Please

see annex F for details on this.

13.5 If there are any issues with the installation, there will

be a beep from the display screen and an error displayed.

Common installation errors are incorrect or missing

voltage or temperature sensors, or other cabling issues.

The screen errors will pinpoint as closely as possible the

source of the fault, which should be rectified in order.

A ‘Low system voltage’ is an acceptable error, as this

message means that all sensors are functioning correctly,

but the main battery switches are open. This message

should clear when you reach stage 13.7.

13.6 It is important to set the zero reference of the

sensors. Plug in the configuration loom (supplied to

installers on request, not a standard item), and connect

to an independent 12V power source that is not being

monitored by the sensors.

**It is possible to set the zero point and current polarity

through the setup app, please see Annex F. The

following instructions are to set up sensors directly

during installation. Either method is acceptable**

13.6.1 With all battery switches off (including

any form of charging) and the DC-DC

converter(s) off, go to each battery sensor

and insert an object such as a 3mm allen key

into the “reset” hole. Press and hold the zero

button until the blue light comes on. It is

important to release as soon as the light

changes to blue.

13.7 One at a time, switch the battery banks on. If you

locked the safety switch out (see point 13.2) during

installation, return the knob to the correct position before

you do this.

13.8 Look at each battery bank current readings on

the display screen. For each bank in turn, apply a load

or charge to ensure the polarity is correct. If you are

discharging, the power figure should read negative kW.

If you are charging, power displayed should be a positive

figure.

13.8.1 If the current flow on the sensors is

incorrect, press the “reset” button again. This

time, hold the button past the point at which

the blue light comes on and release when the

blue light goes off again. This will change the

polarity. Now repeat step 13.6.1 to properly

set the zero on that bank.

13.9 Remove the configuration loom and separate the

12V source and return to the boat’s power for the system.

13.9.1 Switch the DC-DC converters on at the

Integrel panel.

13.10 Start the engine. If a connection to the engine ECU

had been made, the generator will not begin generating

until the engine coolant reaches 30oC. After this point,

the generator will begin to work. The generator page will

show an output in kW.

13.11 Charge the 48V batteries on shore power for 24

hours. This will ensure the state of charge figures are

correctly setup.

13.12 Unplug the boat from shore power.

13.12.1 With the electrical system under load,

(use electrical appliances to draw lots of

power off the batteries), allow the battery

state of charge to drop to around 80%.

13.12.2 With the electrical loads still on, start

the engine and run at 1/3 to 1/2 throttle. The

output should peak between 8kW and 9kW.

This will then drop to between 6kW and 8kW

as the generator will be limited on

temperature.

13.12.3 Check all 48V connections with a

thermal imaging camera. Ensure the system

has been running for several minutes under load

before concluding this check. Any connections

with high temperatures should be

disassembled and checked once the system

has been turned off, all batteries isolated and

the connection has been allowed to cool.

19

***Do not check terminal connection by

touch, they may cause burns.***

13.12.4 Once you have checked all terminals,

turn off all non-essential appliances and allow

the system to complete a charge cycle. This

may take an hour or more if you are using a

large battery bank. It is important that you

observe the system tripping to the float

voltage stated on the battery page.

Post-Installation Checklist

Engine

• All nuts and bolts are correctly fitted and torqued to

specification.

• The belt is fitted correctly.

• Engine test run and belt alignment checked.

Electrical System

Here are a few points to check through once the

installation has been completed:

• Batteries correctly installed, supported and secured.

• Battery connections torqued to specification.

• All electrical connections checked with a thermal

imaging camera whilst under load.

• All battery sensors read correct direction of current

flow.

• With batteries discharged and engine running at 2/3

throttle, maximum output was ______kW.

• With the system charging hard, the generator

temperature stabilised and engine running at 1/3

throttle in neutral, the sustained output was _____kW.

• With the system charging at idle in neutral, selecting

gear brings the generator output to zero.

When charging hard, individual battery voltages were:

• All 48V battery banks have been on shore-power

charge for at least 24 hours.

• Owner has been briefed about the workings of the

system, what to expect in terms of output with their

particular type of batteries and the limitations of the

system.

Firmware and Software Updates

It is possible to simply update the entire system should

any future development or improvements need to be

made.

The update file can emailed or downloaded from the

Integrel system website. This file should be copied to

a USB memory stick without changing the filename.

With the Integrel system powered up, insert the

memory stick into the USB connector located between

the data cables on the screen interface box. After a few

seconds, the display will change to ‘installing update’.

**Do not power down the system at this point**

Once the update has loaded, the display screen will

reboot. Any devices or sensors on the system that

also need an update will be detected, and the screen

will ask for confirmation before updating each in turn.

Once the updates are complete, the screen will revert

to the standard display, and the system is ready to use.

At this point, it is safe to remove the USB drive from

the system.

Bank 1 – Block 1_____V Block 2_____V Block 3_____V Block 4_____V

Bank 2 – Block 1_____V Block 2_____V Block 3_____V Block 4_____V

Bank 3 – Block 1_____V Block 2_____V Block 3_____V Block 4_____V

Bank 4 – Block 1_____V Block 2_____V Block 3_____V Block 4_____V

20

APPENDICES

Annex A

Integrel controller

Integrel generator

AC distribution panel

48v negative busbar

Screen

48v battery data

Shore supply

48v positive busbar

Input from renewables

10mm

4 mm

4mm

70mm

70 mm

70mm

Gear detect

12v negative busbar

xxA

30A

Integrel system boundary

48

12

5A breaker

4mm

20A breaker

400A

MRBF

midi

30A

midi

30A

midi

ANL/class T

20A o/p

positive busbar

To existing 12/24v

Engine start battery

Permanently live 12v busbar

4mm

48

12

5A breaker

30A

midi

20A o/p

Data cable to sensors on:

House bank

200Ah200Ah

48v storage bank

200Ah200Ah

48v storage bank

Victron 24v200Ah Li ion batteries

400A

ANL/class T

B A

Li ion safety switch

200A breaker

Power conversion

Energy storage

3/5/8kVA 110/220v

Inverter/charger

Generation and control

J1939

400A

ANL/class T

200Ah200Ah

48v storage bank

Major 48v loads

winches/windlasses/thrusters

xxA

midi

70 mm

Table of contents

Popular Inverter manuals by other brands

Sunshare Solar

Sunshare Solar Solar LED Batten Light user manual

Bolanmu Energy

Bolanmu Energy xth 3000-12 ASSEMBLY QUICK GUIDE

Sungrow

Sungrow SC50HV user manual

RBI

RBI UL 2703 installation guide

Siemens

Siemens SINAMICS V20 Inverter operating instructions

Xantrex

Xantrex Trace Series installation instructions