3 AD-4411

Contents

1. Introduction ....................................................................................................................5

1.1. Safety precautions.....................................................................................................5

2. Part names.....................................................................................................................6

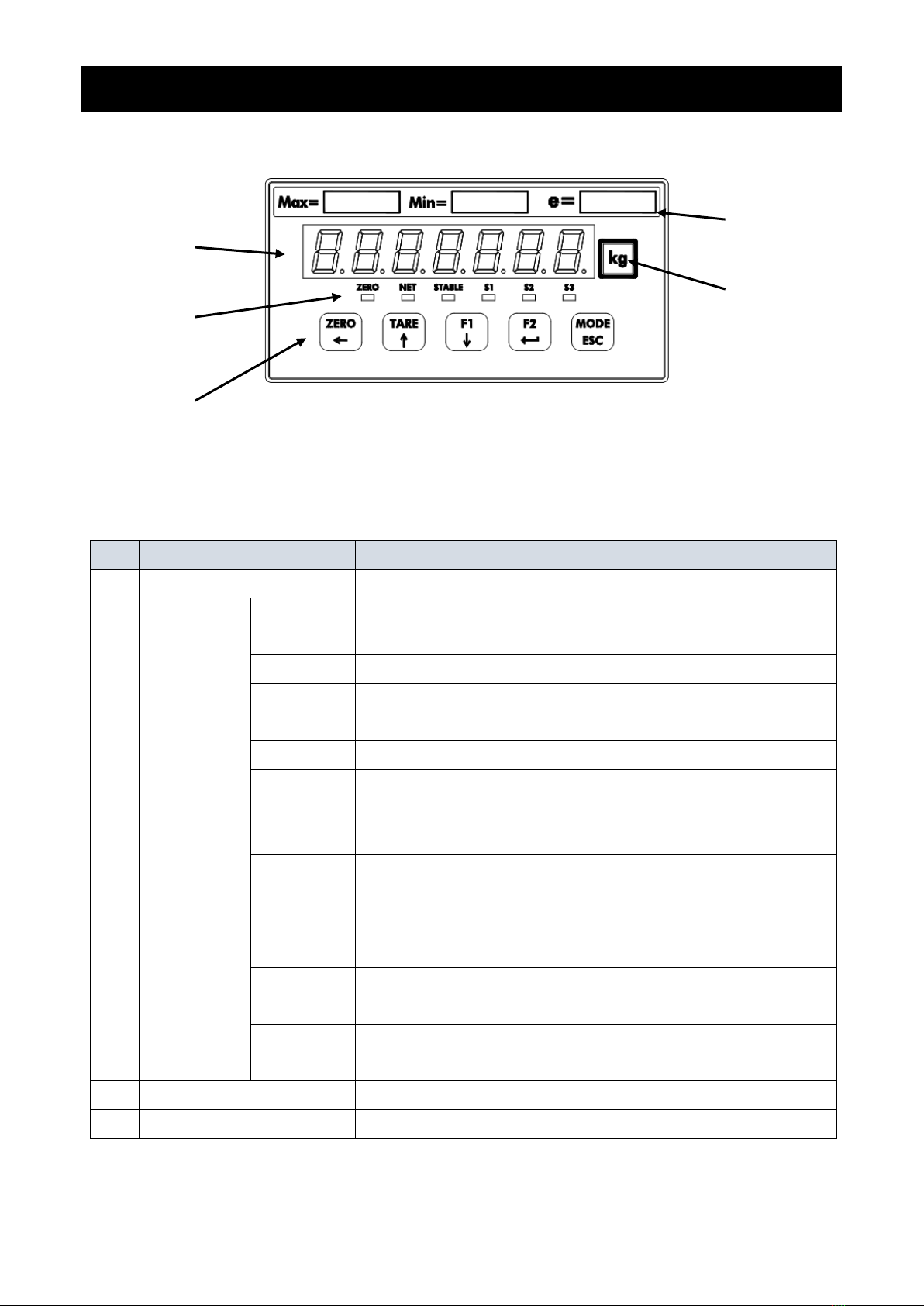

2.1. Front panel.................................................................................................................6

2.2. Rear panel .................................................................................................................7

2.3. Accessories ...............................................................................................................7

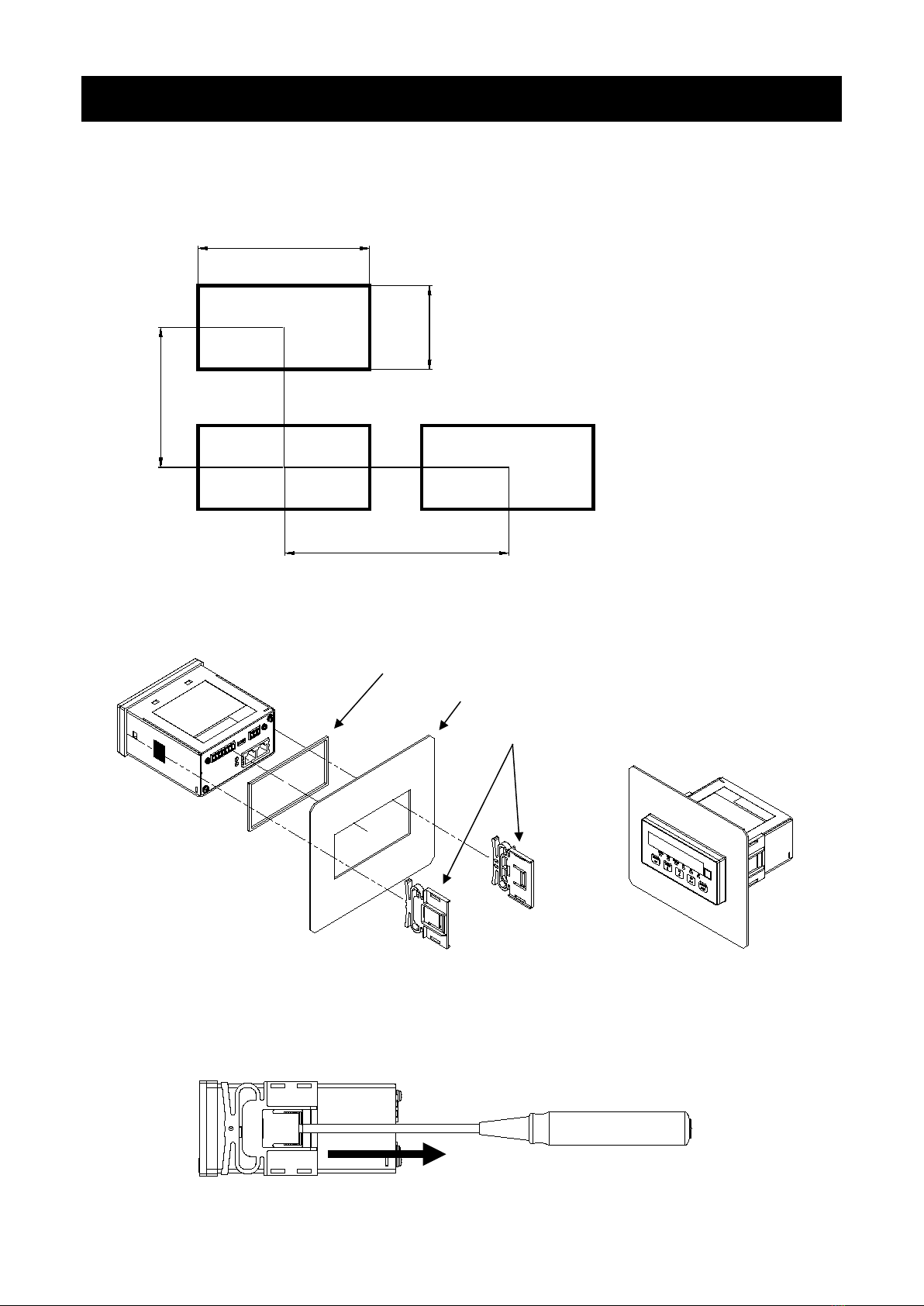

3. Installing to the control panel..........................................................................................8

3.1. Installing the indicator to the control panel.................................................................8

3.2. Removing the indicator from the control panel ..........................................................8

4. Connection to power supply ...........................................................................................9

4.1. DC power supply assignment ....................................................................................9

4.2. Connection diagram...................................................................................................9

5. Connection to load cell .................................................................................................10

5.1. Load cell input terminal assignment.........................................................................10

5.2. Connection diagram.................................................................................................10

6. Operation mode............................................................................................................12

7. Calibration ....................................................................................................................13

7.1. Settings required before calibration .........................................................................13

7.2. Digital calibration .....................................................................................................13

7.3. Actual load calibration..............................................................................................14

8. Basic functions .............................................................................................................17

8.1. Main display.............................................................................................................17

8.2. Power-on zero .........................................................................................................17

8.3. Zero-setting..............................................................................................................18

8.4. Zero tracking............................................................................................................18

8.5. Tare .........................................................................................................................18

8.6. Gross / Net display selection ...................................................................................18

8.7. Center-zero detection ..............................................................................................19

8.8. Stability detection.....................................................................................................19

8.9. High resolution display selection..............................................................................19

8.10. Comparator............................................................................................................19

9. Industrial Ethernet ........................................................................................................20

9.1. EtherNet/IP (AD-4411-EIP)......................................................................................20

9.2. PROFINET (AD-4411-PRT).....................................................................................22

9.3. EtherCAT (AD-4411-ECT) .......................................................................................23

9.4. Cyclic data layout.....................................................................................................24

10. USB............................................................................................................................28

10.1. Communication specification .................................................................................28

10.2. Coil data address...................................................................................................29

10.3. Holding register data address................................................................................30

11. Checking software version / hardware .......................................................................34

11.1. Checking software version.....................................................................................35

11.2. Checking display....................................................................................................35

11.3. Checking key switches ..........................................................................................35

11.4. Checking load cell input.........................................................................................35

12. Troubleshooting..........................................................................................................36

12.1. Hardware error.......................................................................................................36

12.2. Checking the connection to load cell with using a multimeter................................37

12.3. Check list ...............................................................................................................38

13. Initialization.................................................................................................................39

14. Setting functions.........................................................................................................40