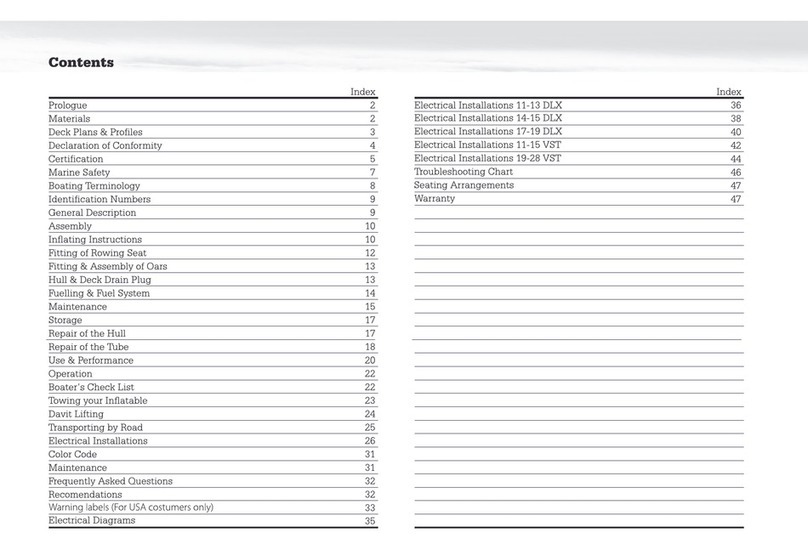

5

1 Nautilus 11 DLX HPI-088-001 C 3 VII

2 Nautilus 12 DLX HPI-088-002 C 3 VII

3 Nautilus 13 DLX HPI-088-003 C 3 VII

4 Nautilus 14 DLX HPI-088-004 C 3 VII

5 Nautilus 15 DLX HPI-088-005 C 3 VII

6 Nautilus 17 DLX HPI-088-006 C 3 VII

7 Nautilus 19 DLX HPI-088-007 C 3 VIII

8 Nautilus 19 DLX-I/O HPI-088-008 C 3 VIII

9 Oceanus 11 VST HPI-088-009 C 3 VII

10 Oceanus 12 VST HPI-088-010 C 3 VII

11 Oceanus 13 VST HPI-088-011 C 3 VII

12 Oceanus 14 VST HPI-088-012 C 3 VII

13 Oceanus 15 VST HPI-088-013 C 3 VII

14 Oceanus 19 VST HPI-088-014 C 3 VIII

15 Oceanus 24 VST HPI-088-015 B 3 VIII

16 Oceanus 28 VST HPI-088-016 B 4 X

17 19 MACC HPI-088-021 C 3 VIII

18 19 OPEN HPI-088-022 C 3 VIII

19 Navigo 8 VS HPI-088-023 C 2 V

20 Navigo 9 VS HPI-088-024 C 2 V

21 Navigo 10 VS HPI-088-025 C 3 VII

22 Navigo 12 VS HPI-088-026 C 3 VII

23 Navigo 13 VS HPI-088-027 C 3 VII

24 Navigo 14 VS HPI-088-028 C 3 VII

25 Ventus 8 VL HPI-088-029 C 2 V

26 Ventus 9 VL HPI-088-030 C 2 V

27 Ventus 10 VL HPI-088-031 C 3 VII

28 Ventus 12 VL HPI-088-032 C 3 VII

CERTIFICATION

MODELS HPI 2011

Certication CE CAT. ISO

6185 Type MODELS HPI 2011

Certication CE CAT. ISO

6185 Type

29 Lammina 8 AL HPI-088-033 C 1 II

30 Lammina 9 AL HPI-088-034 C 2 V

31 Lammina 9,5 AL HPI-088-035 C 2 V

32 Lammina 10 AL HPI-088-036 C 2 V

33 Lammina 11 AL HPI-088-037 C 2 V

34 Lammina 12 AL HPI-088-038 C 3 VII

35 Lammina 13 AL HPI-088-039 C 3 VII

36 Lammina 14 AL HPI-088-040 C 3 VII