Owner’s Manual

Aircon / Heating - 72 Viking Sport Cruiser 61FY

v1.0

••••••••••••••••••••••••••••••••••••••••••••••••••••••

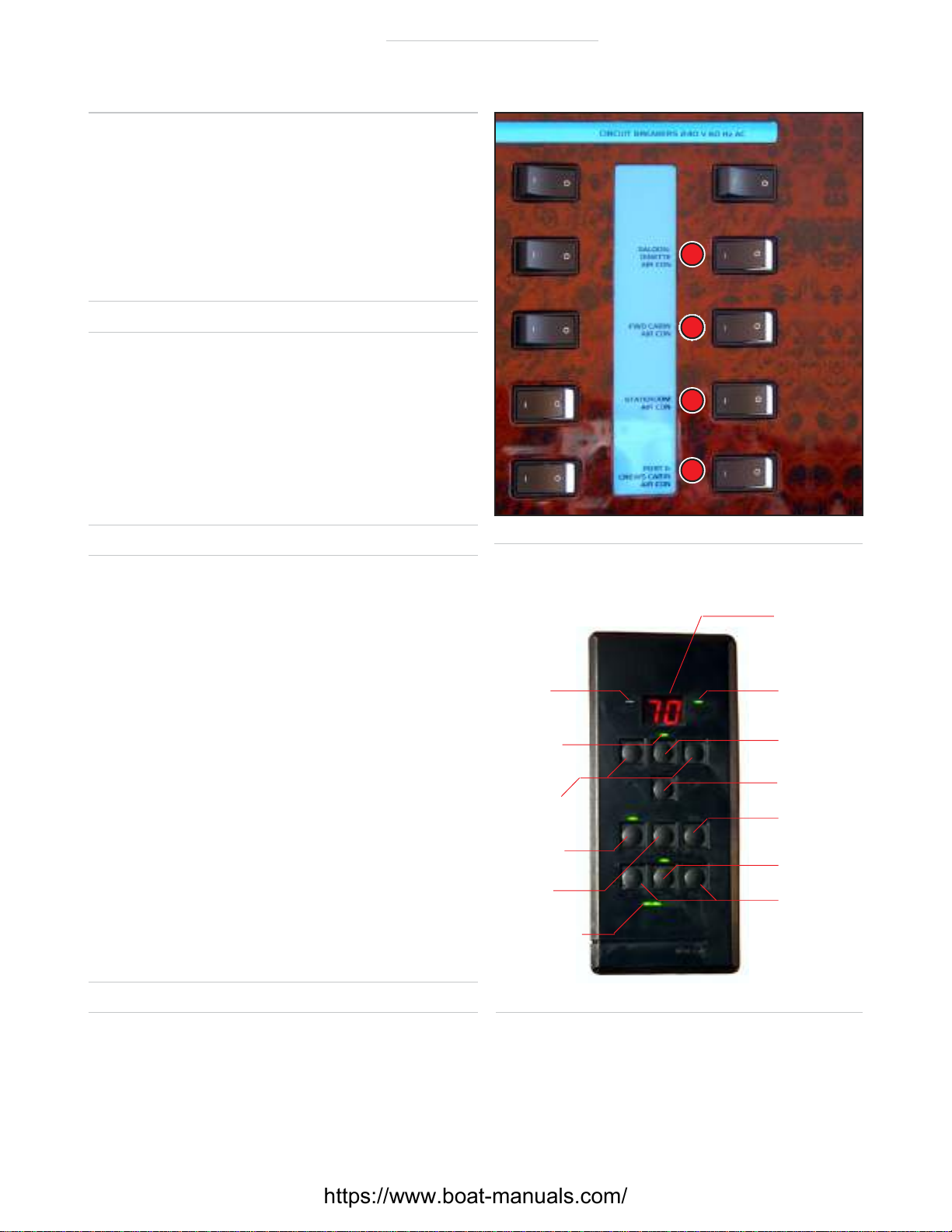

Check voltage and

load – 240 volts

Reduce load if a A/C

breaker. With an Iso-Boost

transformer and 100 amp

service, low voltage should not be a problem, but you

may be unable to switch on all units. Remember as

voltage decreases amperage increases.

The SMX units also display error codes (see SMX

manual for details). System fault codes are displayed

if, for example, compressors are overheating because

the seawater strainer is partially blocked with weeds.

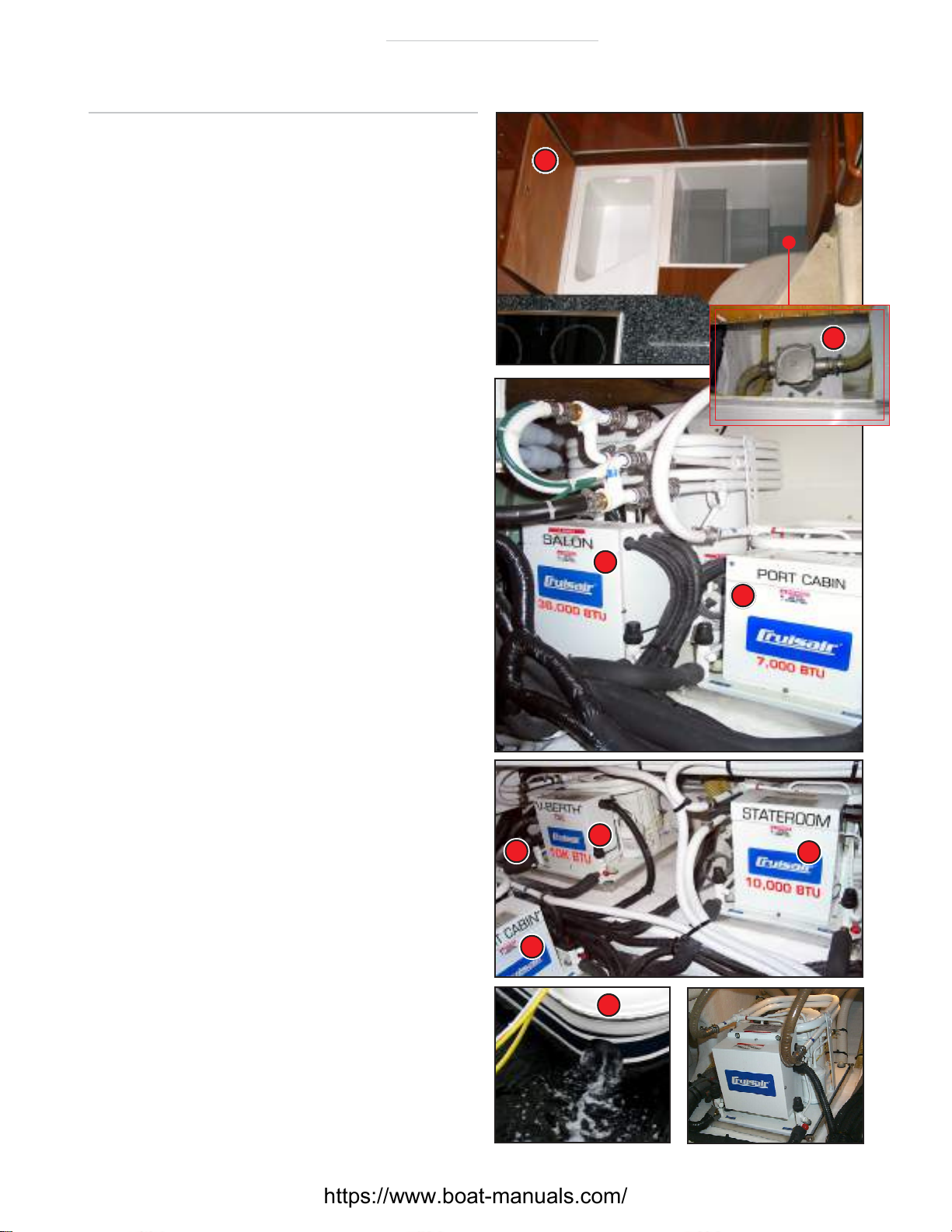

To clean the seawater strainer. . .

•Switch off ALL breakers for the A/C system.

•Close seacock S. Have a dish handy to dump sea-

water and debris from the strainer into it.

•Loosen the four bolts holding the cap B.Seawater

will come out. Avoid getting seawater into the com-

partment by having an absorbent cloth around the

cap. Ease up and remove bolts and cap.

•Remove the internal screen. Clean out all weeds

and other debris.

•Replace the screen and cap, tighten down the nuts.

•Open the seacock S; the strainer should quickly fill

with seawater. Check the cap for leaks. If OK, switch

the system on.

•Check again to ensure there are no leaks.

•Check that discharge

flow is normal.

Regularly check the A/C strainer

for weeds and other debris.

Remember – this is below the

waterline! So shut the seacock.

Troubleshooting the System

One of the advantages of a direct expansion system is its

simplicity. It depends simply on:

•an unobstructed supply of seawater,

•correct voltage,

•free flowing air supply to the return air grilles, and

•unobstructed air discharge ducts.

Any one of these items that is not up to par will give you

a problem.

If the air conditioner is running in weedy water, the strainer

can quickly fill with weeds. Don’t neglect to regularly check

the A/C strainer for weeds, sea urchins and other debris. If

anything gets through the strainer it can slow down the

magnetic drive to the pump. However, the strainer will not

stop sand, and that may damage the seawater pump. Over

time, sand in the water can erode the double wall pipe

above the compressor.

Also be aware that suction at the thru-hull may attract

plastic junk in the water, preventing seawater getting to

the pump. Get to know the normal appearance of dis-

charge from the compressors through the engine exhaust

so you can tell if flow is reduced.

Do NOT obstruct the return air grilles with furniture, cush-

ions or newspapers. If air cannot get through obviously

the air in the cabin cannot be cooled or heated.

The same thing happens if the air filter screen behind the

return air grille is not cleaned – very quickly dust builds

up, starving the system of free flowing air. You should

check screens every two weeks if the vessel is in con-

stant use, monthly if not.

Check the dock voltage, if it is low, below 205 volts, you

should be selective in how many units you run or, if cool-

ing, set them at a higher temperature.

If you leave the system on when you are away for a few

days, arrange for someone to check that it is operating

properly (and leave the SHOWER DISCHARGE PUMP on).

These are very simple checks – if they are done the sys-

tem will perform as designed, and maintain a constant

pleasant temperature throughout the vessel.

S

B

S

https://www.boat-manuals.com/