Installer Instructions

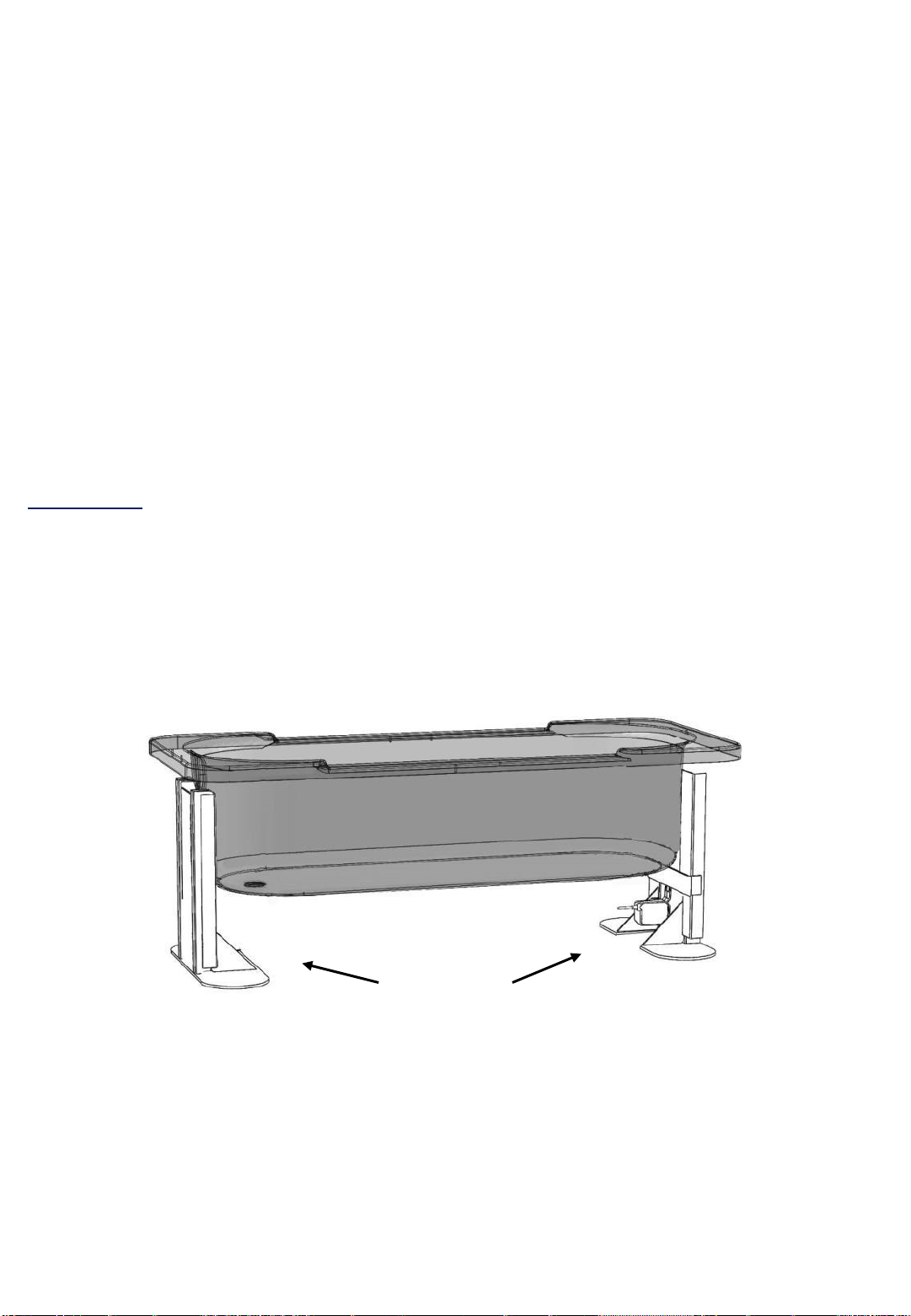

This product is heavy. Two persons minimum to move the unit.

The bath is a two person install. Attempting a one person install is not recommended, and

may result in damage to the bath.

Always check around the bath for any obstructions before raising or lowering the bath.

Never drop or insert any objects into any openings.

WARNING! The bath is only to be installed on concrete ground level flooring. If

upper level installation is required it must not be without reference technical support.

WARNING! Check floor loading capacity against bath weight. Total weight

(maximum) is 800kg (including water and maximum user weight).

If the flooring is not capable of withstanding the 800kg load the bath must not be

installed!

WARNING! Risk of electric shock; connect only to a separate circuit protected by an RCD.

Risk of electric shock; do not permit electric appliances (such as a hair dryer, lamp,

telephone, radio or television) within 2 metres of this bath.

The unit must be connected to an RCD. Such a circuit is to be provided by a qualified

electrician and should be tested on a routine basis.

To test the RCD push the test button; the RCD should interrupt power. Push the RESET

button; power should be restored. If the RCD fails to operate in this manner there is the

possibility of an electrical shock. Do not use this unit. Isolate the unit and have the

problem corrected by a qualified service representative before any further use.

Whirlpool and spa motors where fitted must be connected to an RCD protected outlet as

must any electrical accessories.

Although compliant with IEC/EN60601-1-2 for EMC, the bath may still cause interference

with sensitive medical equipment. Should any electro-magnetic interference be

experienced whilst using this product, remove the user immediately and seek medical

advice.

Where a safety lap belt is supplied this must be used for the safety of the bather.

WARNING! If this unit is to be utilised by many different bathers, we would strongly

recommend that it is cleaned regularly with a medical disinfectant as well as following a

strict cleaning routine.

WARNING! This Bath moves. Ensure there are no objects or persons that can become

trapped or injured while the bath raises or lowers.

Gemini 2000 Installation Manual v1.3 3