Abacus Lighting, Sutton-in-Ashfield, Nottinghamshire, NG17 5FT, England. Tel: (+44) 01623 511111, www.abacuslighting.com

1

Product Manual

November 2022

1. Safety ........................................................................................................................ 2

2. Installation................................................................................................................ 3

2.1. General ....................................................................................................................................... 3

2.2. Mast Positioning ........................................................................................................................ 3

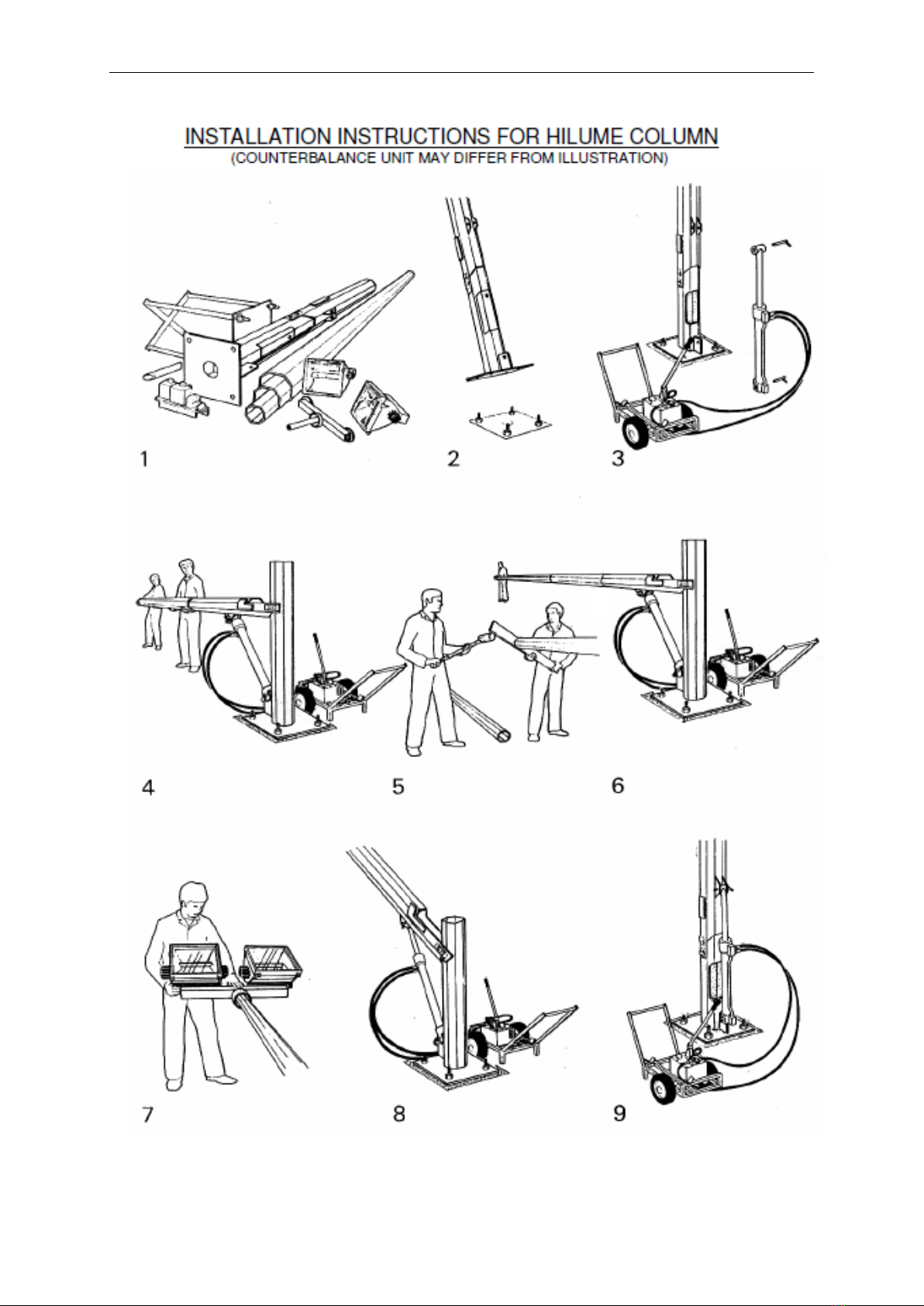

2.3. Mast Assembly ........................................................................................................................... 4

3. Operation .................................................................................................................. 7

3.1. General ........................................................................................................................................7

3.2. Moving the Counterbalance (RLH5 only) ................................................................................ 8

3.3. Checks Before Use ..................................................................................................................... 8

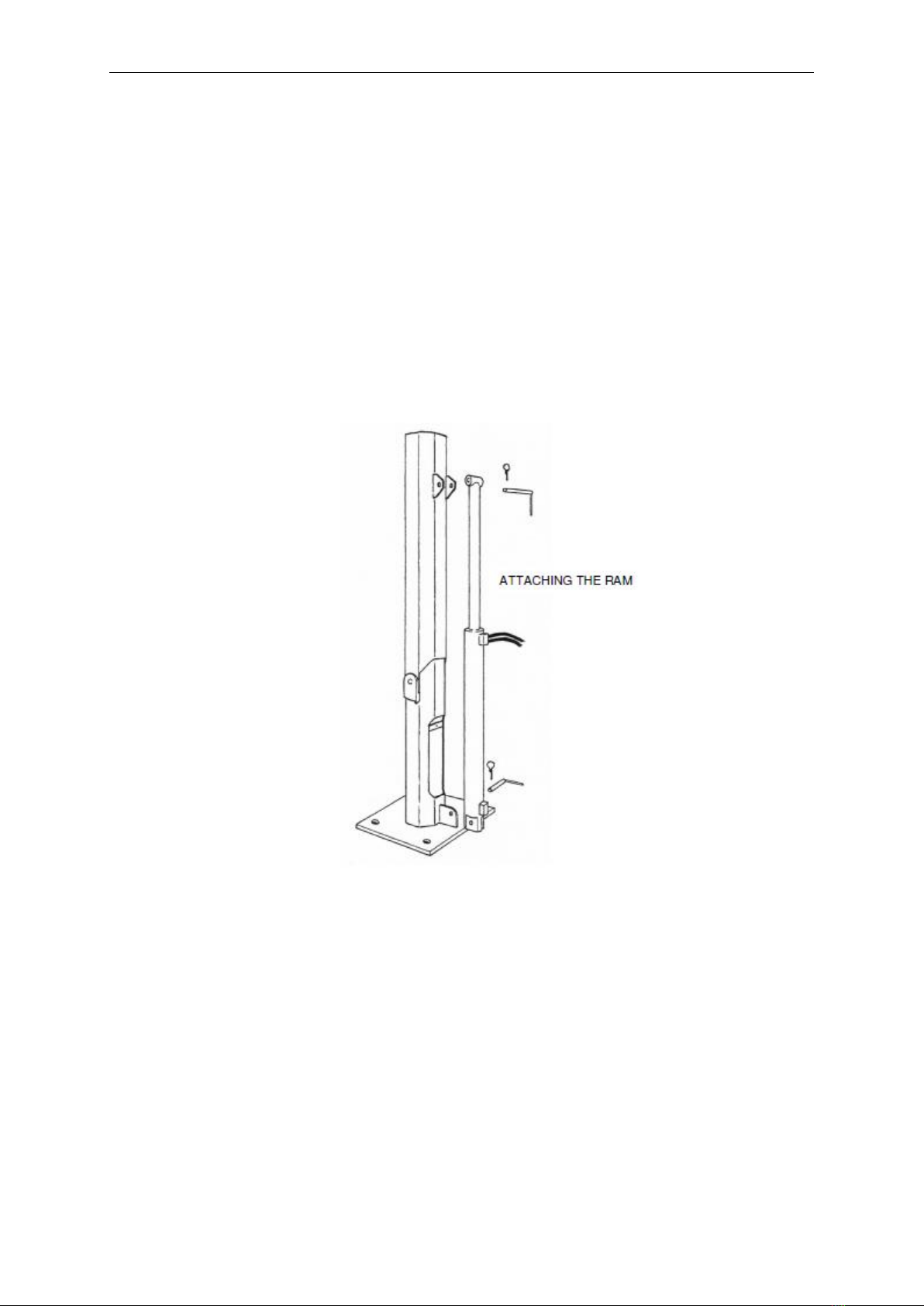

3.4. Fitting the Ram to the Mast ...................................................................................................... 9

3.4.1. HL250 Mast (RLH5 only) ..................................................................................................... 9

3.4.2. HL250 Mast (RLH7 only)...................................................................................................... 9

3.4.3. HL330 Mast ........................................................................................................................... 9

3.5. Lowering the Mast ....................................................................................................................10

3.6. Raising the Mast ....................................................................................................................... 11

3.7. Removing the Ram ...................................................................................................................12

3.7.1. HL250 Mast ..........................................................................................................................12

3.7.2. HL330 Mast ..........................................................................................................................12

3.7.3. Depressurising Procedure ....................................................................................................12

4. Maintenance ........................................................................................................... 14

4.1. Mast Type Identification ..........................................................................................................14

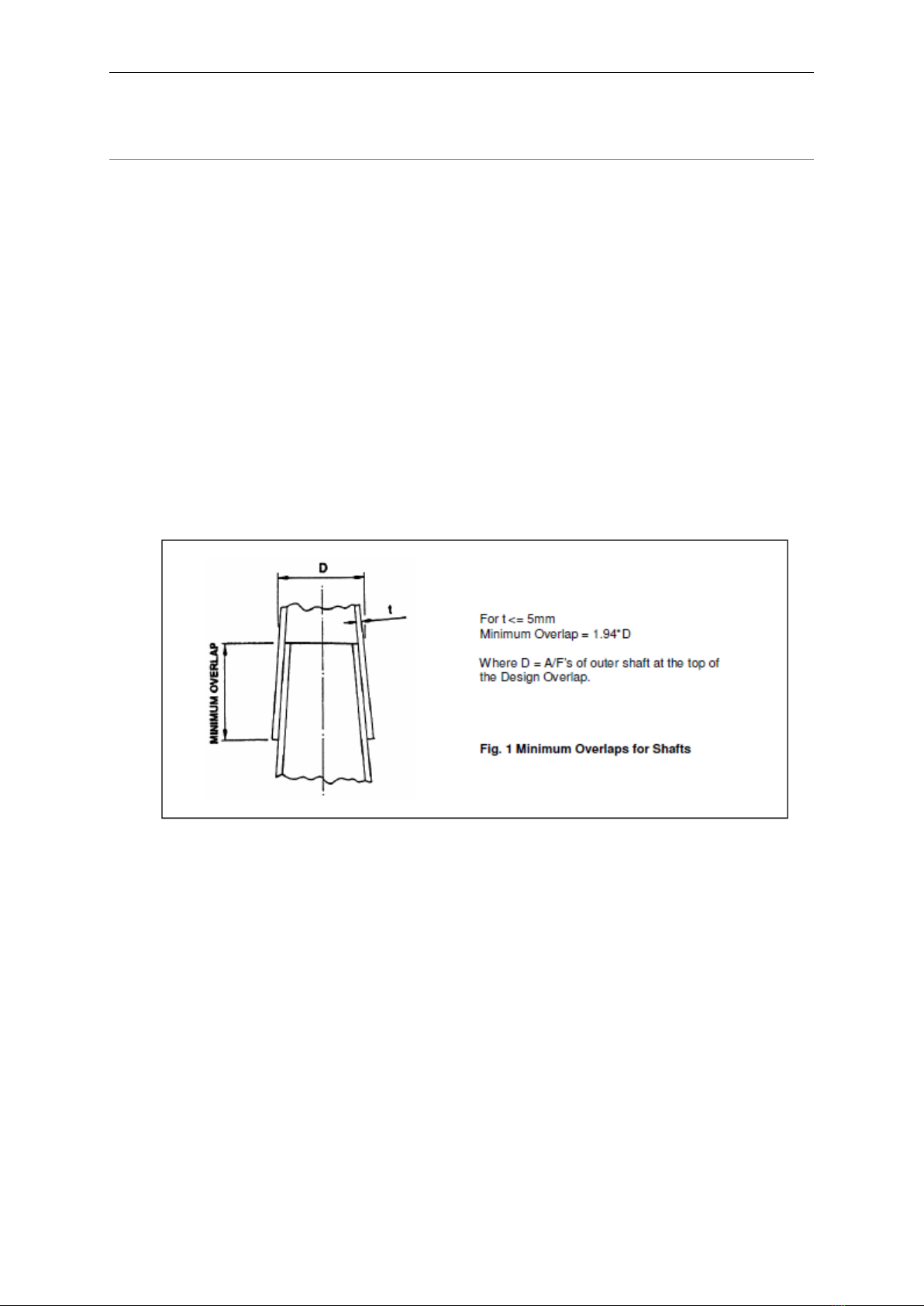

4.2. Masts ......................................................................................................................................... 15

4.2.1. Every Time the Mast is Lowered.......................................................................................... 15

4.2.2. Every 12 Months ................................................................................................................... 15

4.2.3. As Required ...........................................................................................................................15

4.3. Counterbalances .......................................................................................................................16

4.4. Hydraulic Hoses .......................................................................................................................19

5. EN 1090 Certificate of Conformity ..........................................................................20

6. CE Marking ............................................................................................................. 21

7. Environmental Advice............................................................................................. 22

7.1. General ..................................................................................................................................... 22

7.2. Information.............................................................................................................................. 22

8. Equipment Classification ........................................................................................ 23