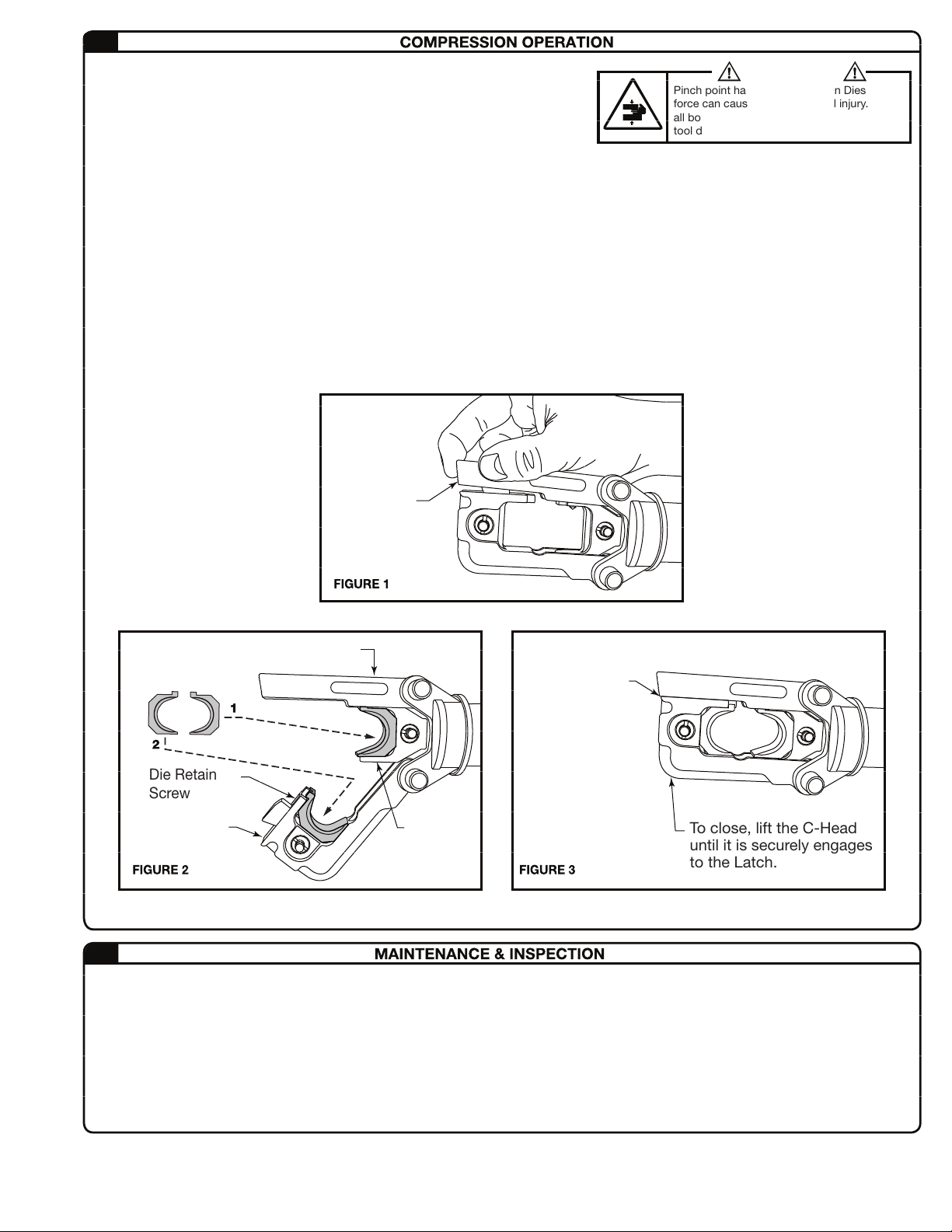

4.0 IMPORTANT OPERATING PRECAUTIONS

TROUBLESHOOTING

3.6

Problem Cause Solution

The motor does not operate at all.

The battery is not charged or defective. Charge or replace the battery.

There is dust or foreign objects lodged at

the battery contacts. Remove foreign objects.

The switch is misaligned. Check to see if switch is aligned with trigger,

consult tool service.

The motor runs but ram will not advance, or ram

advances but will not build pressure.

Consult tool service.

Air in hydraulic system.

Insufcient hydraulic oil.

Hold the tool with head towards the oor to

allow air to rise towards top of oil bladder.

Defective hydraulic circuit. Consult tool service.

The ram will not retract

Tool did not complete a full cycle and

bypass.

Depress trigger and allow tool to reach full

pressure and bypass, then depress release

button to retract the ram.

The connector is jammed in compression

dies.

Depress and hold release button while prying

compression dies apart.

The release button is bent or misaligned. Consult tool service.

4.1 PRECAUTIONS FOR COMPRESSION TOOL

1. Select the appropriate dies for the connector and

conductor to be compressed. Incorrect combinations

result in inferior connections between the connector and

conductor and are an electrical hazard.

2. Never operate the tool without dies installed.

3. Always point the tool away from other people.

4. If the tool is stored for an extended period at a

temperature of less than 25º F (-5º C), the tool should be

allowed to return to room temperature to ensure smooth

operation. Use the tool only after it has been at room

temperature for 1 hour.

5. Do not drop the tool. Dropping the tool may damage the

hydraulic circuit and cause malfunctions.

6.

Keep the head and ram clean and free of debris. Solvents

can be used to clean the head but should not be used on

the plastic body. Use soap & water to clean the body.

PRECAUTIONS FOR THE BATTERY PACK

4.2

1. Do not short circuit the contacts or expose the

battery to water, oil or solvents.

2. Do not disassemble or attempt to repair the

battery.

3. Do not dispose of the battery by burning or as residual waste.

4. Do not drop or otherwise abuse the battery.

5. Do not leave the battery in locations where it will be

exposed to a temperature greater than 104 degrees F (40

degrees C) for an extended period.

6. The battery has a limited life. When the charge holding

capacity becomes about 1/2 that of the original capacity,

the battery should be replaced.

7. If the battery is stored without being charged, natural

drainage will cause the power to be reduced. The battery

should be charged every 3 months if not in use regularly.

PRECAUTIONS FOR THE CHARGER

4.3

1. The Right LED lamp illuminates green and remains on when the unit begins charging a battery. The indicator Blinks Green

when charging is completed.

2. This unit is for charging battery BAT-LI 34 only. Do not use the charger for any other devices.

3. The Charger automatically calibrates the battery as needed for optimized charging. The Right LED lamp will Illuminate Green

then Blink Red 4 times to indicate calibration. Charging will begin after calibration completes.

4. Charge batteries at an ambient temperature of 50-95 degrees F (10-35 degrees C). Charging time is approximately 60

minutes for 100% capacity. If the Right LED Blinks RED, the battery is too HOT/COLD. Leave the battery in the charging slot

and charging will begin once the proper temperature is reached.

5. Never short circuit the output contacts.

6. Do not expose the charger to water, oil or solvents.

7. Do not disassemble, modify, drop or otherwise abuse the charger.

TA04902 C Page 6 of 8