54

Special safety instruction

This sign means that you must caution for the danger occurred in the special condition.

Warning

■Do not supply water during use.

When water gets into a motor, you can be killed by an electric shock.

■Do not use the wet tools or in the rain.

You can be killed by an electric shock or injured seriously.

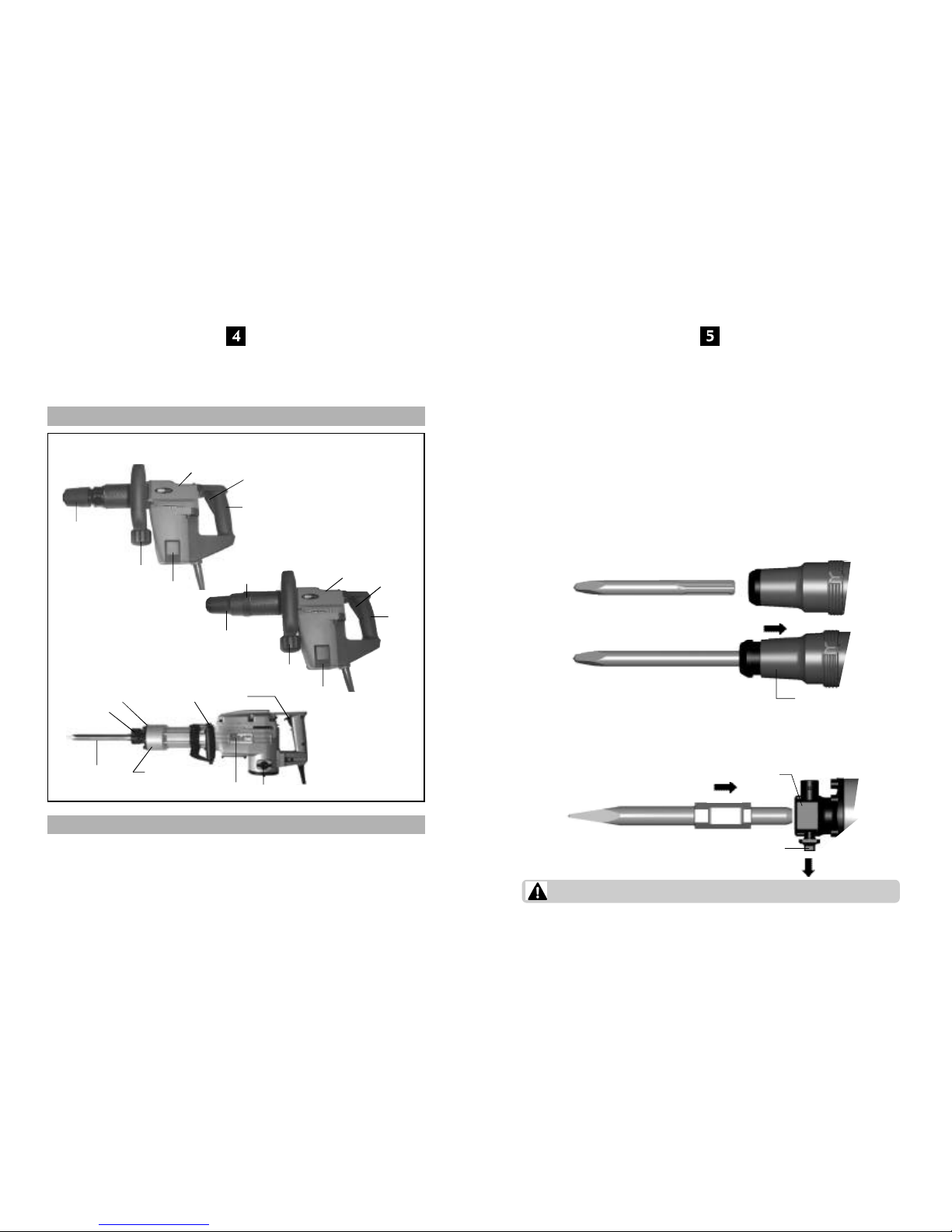

■Do not make your fingers and hands touch with the bull point during

operation.

When your fingers and hands are touched with the bull point or caught in it, you

may be injured seriously.

■Set the bull point not to be come out.

When the bull point is come out suddenly during the operation, other people near

the working place can be injured.

■Make sure the tool is earthed before use.

When the tool is not earthed, you may be injured by an electric shock.

■Make sure the switch is off before you plug in the electric cord.

When you plug in the power source with the tool switched on, you may be injured

seriously by sudden rotation of bull point.

■Always wear the safety goggle during operation.

Your eyes may be hurt seriously by crushing power.

■You must wear the dust mask.

Dust occurred during the operation can injure your health.

The instructions in this user’s guide include critical information for safe

use. When you do not keep the instructions, you may cause death, serious

injury and property damage.

For safe use,‘warning’and‘caution’are represented in the instructions

under the degree of danger as follows.

Caution is represented to prevent the accident might be occurred during use and handling of the

power tool. As warning and caution cannot cover all possible situations, you must be careful

while using or keeping of the tool. Please read through the instructions to prevent any accident.

Warning

In case where is high possibility of

occurrence of serious injury or death

accident if directed matter is violated.

Caution

In case where is possibility of

occurrence of serious injury or death

accident if directed matter is violated.

Caution

In case where is possibility of occurrence of

either trouble failure not to be able to use

product or performance deterioration if

directed matter is violated.

12. Do not overreach.

Keep proper footing and balance at all times.

13. Maintain your tools with care.

Keep your tools clean and sharp so that you will be able to work with them efficiently

and safely.

Follow maintenance rules and replacement instructions.

Periodically examine your tool’s plugs and cords. They must be serviced only by

qualified repair personnel.

Periodically examine extension cords, and replace damaged ones promptly.

Keep the handles of your power tools dry and free from oil or grease.

14. Keep electric plug pulled off.

Always pull off your tools’ electric plugs from their power supply before making any

adjustments on them, before changing their accessories, (such as drills, blades, bits,

and cutters), or before storing them.

15. Remove adjusting keys.

Check to see that keys and adjusting wrenches have been removed from your tools

before you switch them“ON”.

16. Avoid accidental starting.

Carrying tools with your finger on the switch or plugging in tools with their switches

“ON”may cause them to accidentsally start.

Before plugging in a tool, make sure the switch is“OFF”.

17. Use an outdoor extension cord when operating tools outdoors.

When operating a power tool outdoors, use an outdoor extension cord rated for outdoor

use.

18. Stay alert.

Watch what you are doing and use common sense when operating a power tool.

Do not use a power tool when you are having difficulty in concentrating on your work.

19. Check your tools before using them.

Make sure your tools’ safety devices and running parts are functioning well and that

the latter are not caught in anything before you use them. Correct assembly is

necessary for perfect operation. If a safety device or part is damaged, have it serviced

at a Keyang Service Center. Do not use a tool when its switch is not functioning.

20. Exercise caution!.

Use only parts and accessories that are recommended by your tools’ manufacturers or

that are specified in your tools’ manuals. Using parts and accessories that are not

specified in your manuals or catalogues may cause injuries.

21. Have your tools serviced only by qualified repair personnel.

Follow safety rules when operating power tools. Only qualified electrical repair

personnel must service tools. Service or maintenance performed by unqualified

personnel may cause accidents.