3

Contents

1 Introduction/Usage conformant with intended purpose.3

2 Safety instructions.............................................................3

2.1 General safety instructions......................................3

2.2 General safety instructions......................................4

2.3 Symbols in the operating manual……………………….5

2.4 Protective devices........................................................5

3 Environmental protection....................................................5

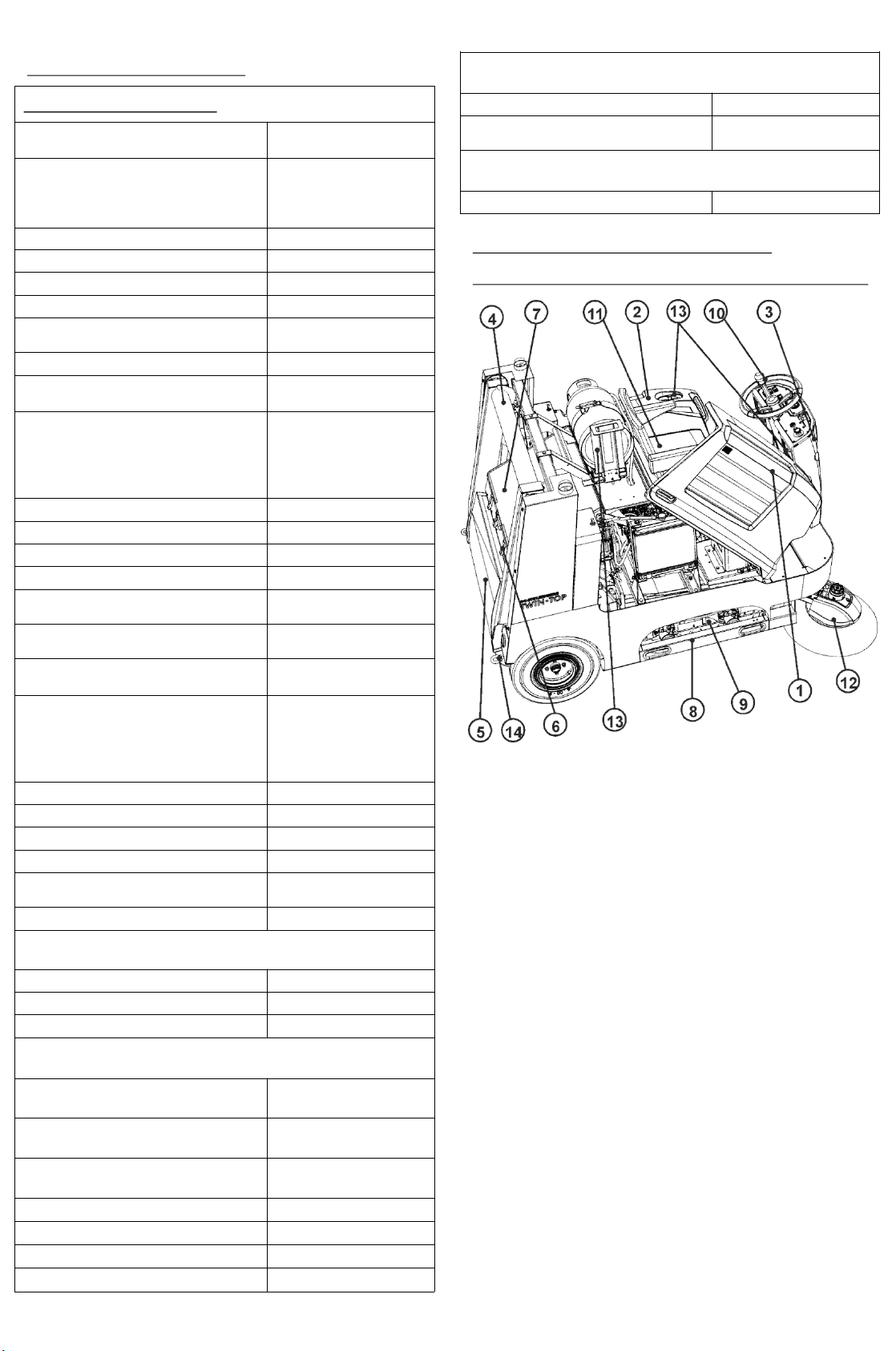

4Device description…………………………….................................5

4.1 Function...............................................................................5

4.2 Technical specifications................................................6

4.3 Control and functional elements................................6

4.3.1 Overview of control and functional elements……6

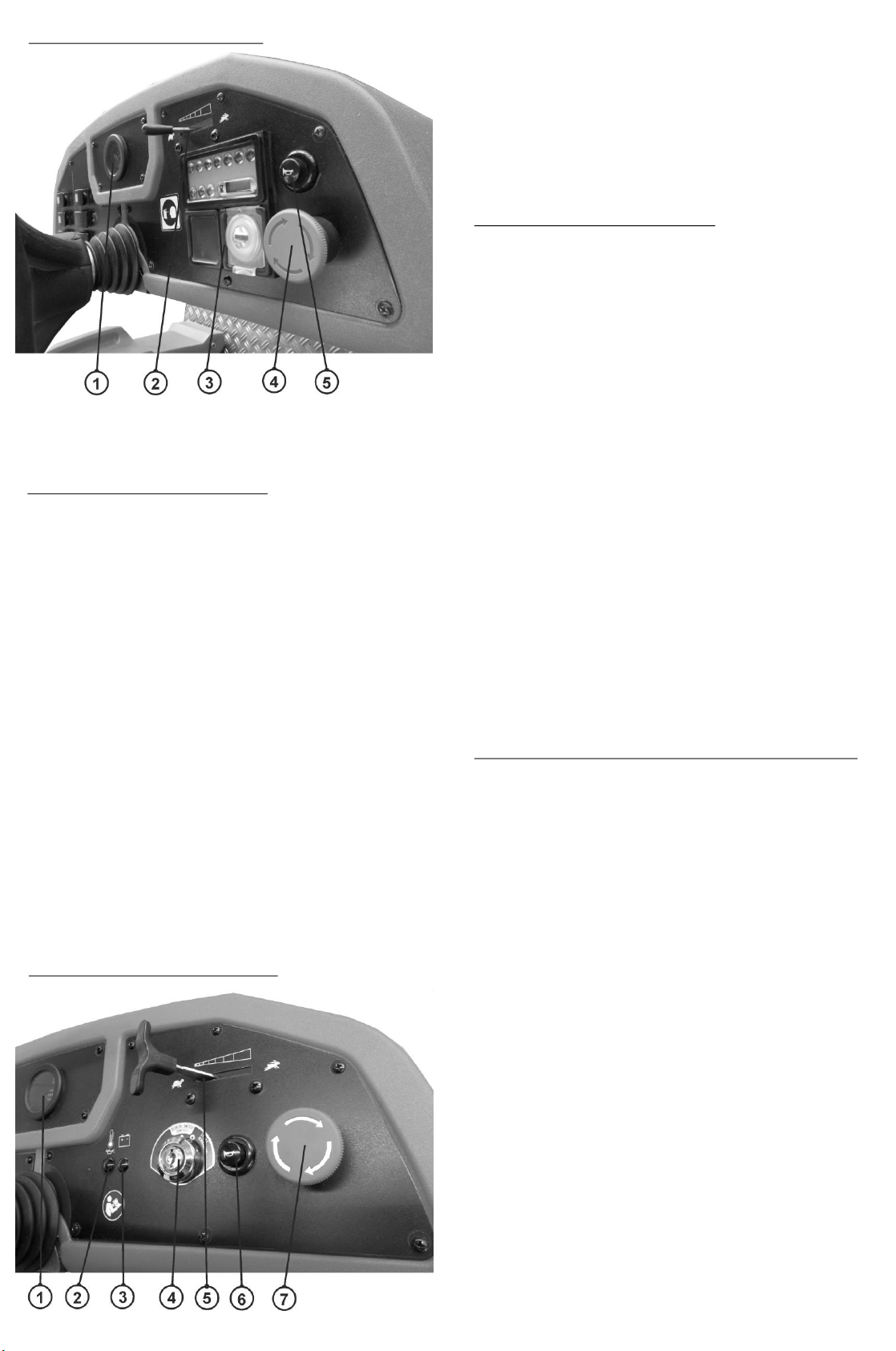

4.3.2 control panel diesel…………..………..……………………7

4.3.3 control panel unit diesel…...….…..……………………7

4.3.4 control panel LPG…………..….………….………………….…7

4.3.5 control panel petrol……….…………….………………………7

4.3.6 control panel left hand…....…………..………………………7

4.4 Unloading the machine..................................................9

4.5 Initial operation..........................................................9

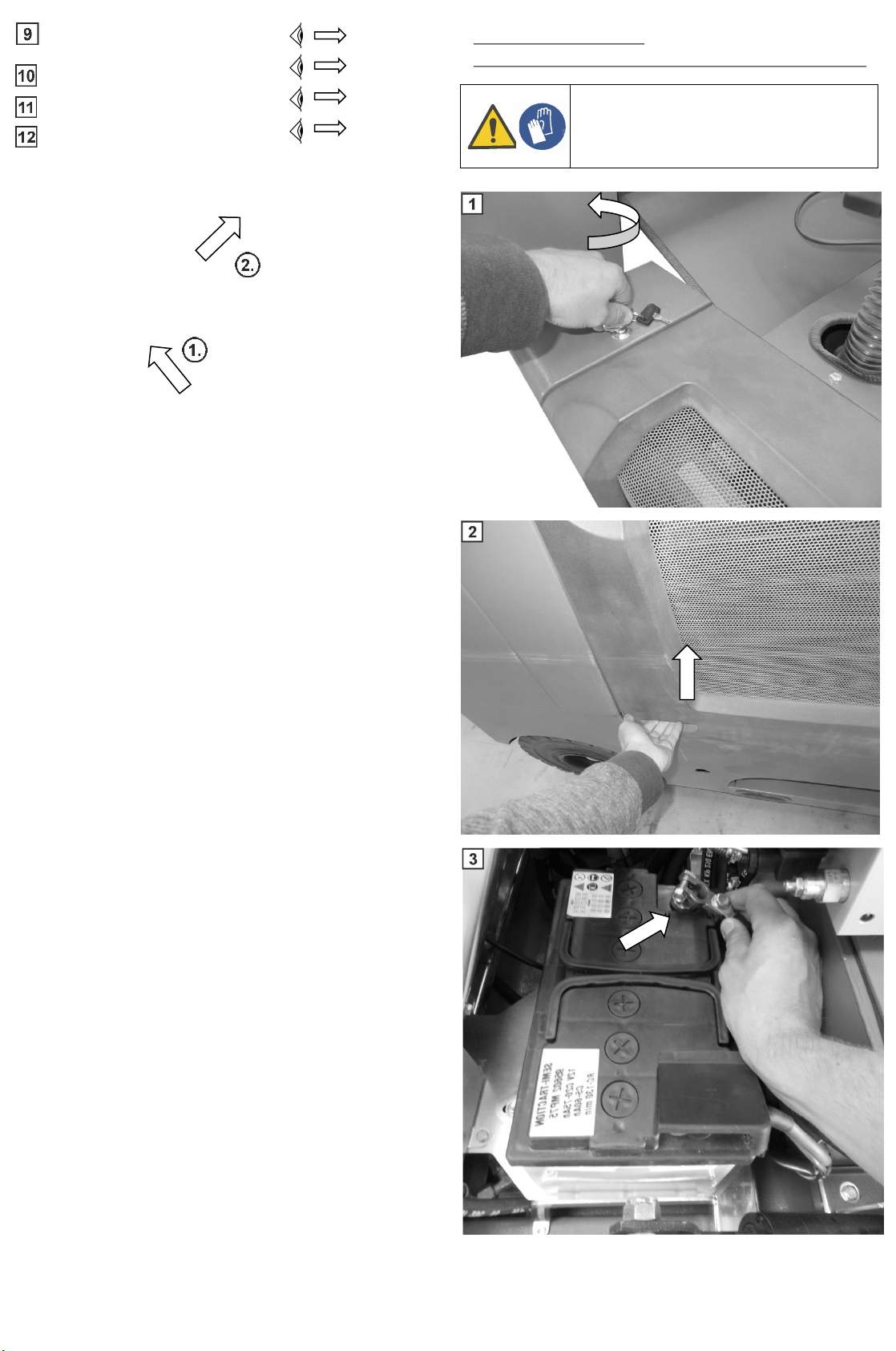

4.5.1 Establishing the machine-battery connection……9

4.5.2 Fuel fill............................................................................10

4.5.3 Gas cylinder assembly................................................10

4.5.4 Mounting the side brush......................................10

5 Operation …………….…………………………………………..………..11

5.1 Drive system……………………......................................11

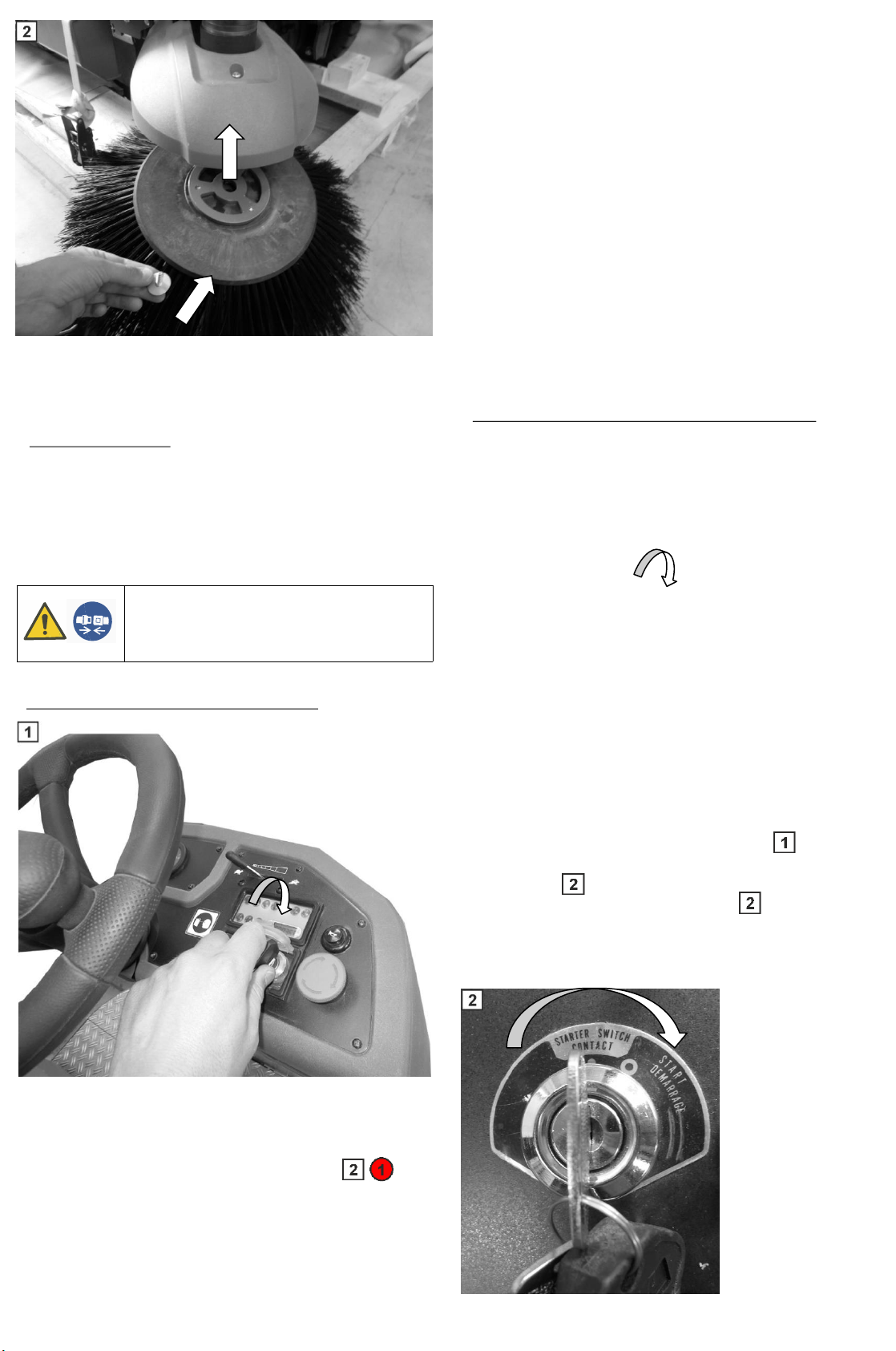

5.1.1 Starting the sweeper unit diesel.......................11

5.1.2 Starting the sweep LPG/diesel version…….……...11

5.1.2 Drive Modus ………………………………………………………12

5.1.3 Parking the sweeper....................................12

5.2 Sweeping system ……………………..………………….....13

5.2.1 Sweeping wet materials …..………………………….13

5.2.2 Height adjustment of the sweeping roller….....13

5.2.3 Operation of the sweeper roller drive…….………13

5.2.4 Dismantling of the Sweeper rollers ………….……14

5.2.5 Installation of the Sweeper rollers …….…..……16

5.2.6 Height adjustment of the side brush..…………….16

5.2.7 Operation of the side brush drive………………….17

5.2.8 Dismantling the side brush……………….………………17

5.2.9 Installation of the side brush……………………………18

5.3 Dust suction……………………………………….………….…….18

5.3.1 Operation of the fan ………..……….………………….18

5.3.2 Operation of the Filter vibrator ………….……………18

5.3.3 Dismantling the filter……..…………………………………18

5.3.4 Installation of the filter……..……...………………………19

5.3.5 Filter cleaning….………………………………………………20

5.4 High-dumping system …………………..………………..…..20

5.4.1 Operation of the high-dumping system .…………20

5.4.1 Cleaning the refuse container ……………..………21

5.4.2 Maintenance support….…………………..…………………21

5.5 Fuse box…………………….…………………………….……………22

6 Cleaning and maintenance……….........................………………22

6.1 Safety instructions for cleaning and maintenance…..22

6.2 General cleaning and maintenance instructions…22

7 Faults, fault indications and remedy……………………24

8 Maintenance intervals ……………………………………………25

8.1 daily maintenance instructions……………………..…25

8.2 Additionally every 50 operating hours ……………...25

8.3 Additionally every 100 operating hours………..…...25

9 Nameplate………………………………………….…………….……………25

10 Accessories and spare parts ………………………....…………….25

11 Warranty …………………………………………….……………….………25

12 Transport of the sweeper …………..…….……………….………26

13 EC Declaration of Conformity ……………..……….………..…27

Introduction/Intended use

1

This operating manual contain instructions for using the sweeper.

Our products are subject to continuous improvement. Therefore,

design changes that were made after this manual went to print could

not be incorporated.

If you have any questions, please contact our Service department.

The operating manual must be read and applied by all persons who

operate the sweeper.

Apart from the operating manual and the regulations for accident

prevention applicable in the country of use and the location of use, the

common, recognised rules for safe and technically correct

working must also be followed.

The appliance is intended exclusively for sweeping on solid surfaces

(for example.: parking areas, walkways, shop floors).

The area to be swept should not be wet.

The sweeper may only be used by reliable and instructed personnel.

Prevent use by children, teenagers and other unauthorized persons,

e.g. by removing the key after use.

Any other or additional use is considered to be improper (see. safety

instructions Ch. ). The manufacturer shall not be liable for resulting

damages.

The operator is solely responsible for the risk.

Intended use also includes compliance with the operating manual, the

safety instructions and the inspection and maintenance requirements.

Only drive on routes and places that have been expressly assigned.

Notes on appropriate surfaces (asphalt, screed, industrial flooring,

concrete, paving stones, carpets, artificial grass, etc.)

Safety instructions

2

2.1 General safety instructions

•Only use the machine in perfect condition and as

intended, while being aware of safety and dangers, and in

compliance with this operating manual!

•The machine does not have road use homologation.

•In addition to the operating manual, also note the

generally applicable statutory and other binding

regulations relating to accident prevention and

environmental protection!

•It is forbidden to sweep flammable, toxic or explosive

substances, as well as flammable gases or undiluted

acids and solvents, burning or smouldering objects!