DIAKAT BL-300 User manual

Operator’s Manual

Rev.1.0

BL-300

Floor grinder

BL

BLBL

BL

-

--

-

300

300300

300

Floor grinder

Page 1 / 9

Read the operator’s manual carefully and understand the contents before you use this equipment.

Always use the machine in accordance with all the instructions contained in this manual, in order to

ensure safe and efficient operation as well as longevity of the machine.

The manufacturer can not be held responsible for any damages or injury arising from the use of

the machine not in accordance with the instructions contained in this manual.

CONTENTS

1. SAFETY INSTRUCTION........................................................................2

1.1.

General safety instructions..................................................................................................2

1.1.1.

Qualification requirements ...................................................................................2

1.1.2.

Duties of the entrepreneur: ...................................................................................2

1.1.3.

Duties of the operator: ..........................................................................................2

1.1.4.

Using the machine ................................................................................................3

1.1.5.

Checkups, maintenance, service and repair..........................................................3

1.2.

Transporting the machine ...................................................................................................3

1.3.

Prohibited activities ............................................................................................................3

1.4.

Liquidating the machine at the end of its useful lifetime...................................................4

1.5.

Safety instruction for work with BL-300 Floor Grinder.....................................................4

2. TECHNICAL DATA AND DESCRIPTION OF THE MACHINE.............4

2.1.

Description of the machine.................................................................................................4

2.2.

Technical specifications......................................................................................................5

2.3.

Primary operative parts of the machine ..............................................................................5

2.4.

Description and designation of tools...................................................................................6

2.5.

Mounting and dismounting of tool .....................................................................................6

2.5.1.

Mounting of tool...................................................................................................7

2.5.2.

Dismounting of tool............................................................................................7

2.6.

Význam značek a piktogramůna použitých na stroji .........................................................7

3. BEFORE STARTING............................................................................8

3.1.

Visual check up of the machine state..................................................................................8

4. WORKING WITH THE MACHINE..........................................................8

4.1.

Setting of the machine , start, stop......................................................................................8

4.2.

Working with the machine..................................................................................................8

5. MAINTENANCE.....................................................................................9

5.1.

Cleaning of the machine .....................................................................................................9

5.2.

Checking screw joints.........................................................................................................9

5.3.

Tool maintenance................................................................................................................9

5.4.

Engine maintenance............................................................................................................9

BL

BLBL

BL

-

--

-

300

300300

300

Floor grinder

Page 2 / 9

1.

SAFETY INSTRUCTION

1.1. General safety instructions

1.1.1. Qualification requirements

Persons operating this machine must fulfil the following requirements:

1. The machine may be operated independently only by workers who are:

•older than 18- teen years (or as the law in the country of use prescribes)

•physically and mentally competent

•trained, who proved their ability to operate the machine safely

2. All workers who will operate this machine must make themselves familiar with all the instructions

contained in this manual and must adhere to them.

3. The operator must make himself familiar with all the safety instructions pertinent for use of this

machine (including those specific to the country of use) and must adhere to them. The familiarisation

must be documented and signed by the operator.

1.1.2. Duties of the entrepreneur:

Entrepreneur is a physical or legal entity who undertakes the work with this machine. The entrepreneur

is the guarantor of the safe use of the machine.

The entrepreneur must:

•appoint the operator and provide his training

•insure safe conditions for the use of the machine by the operator

•provide regular checks and maintenance of the machine

•ensure adherence to legal requirements for the safety of the work

•regularly check observance of safety regulations

•regularly check if the operator is using the machine in conformity with the operator’s manual

1.1.3. Duties of the operator:

Operator is a person which actually uses the machine to do the work for which the machine is designed.

The operator must fulfil the requirements as set in 1.1.1.

Operator must:

•thoroughly familiarise himself with the Operator’s manual and all safety instruction required for the

work

•comply with all instructions and requirements set in this manual

•comply with all safety regulations set for work with machinery

•acquaint himself with the work environment including safety instructions

•pay full attention to operating the machine whilst working

•demand regular checks and maintenance of the machine as prescribed by this manual

•demand from his employer securing of conditions conductive to upkeep of safety regulations

•secure the machine against accidental movement and out of reach of unauthorised persons when not

working

BL

BLBL

BL

-

--

-

300

300300

300

Floor grinder

Page 3 / 9

1.1.4. Using the machine

When using the machine the operator must comply with the following instructions:

1. Check the machine before use.

2. Use prescribed personal safety aids while working. (Helmet, earmuffs, safety shoes, goggles,

respirator, gloves…).

3. While working monitor the machine for unusual sounds or smoke which may indicate defect. When

defect is indicated immediately stop the machine and call for expert repair.

4. It is necessary to provide an adequate supply of fresh air for the operator, when using the machine

in enclosed areas (tunnels etc.).

5. When grinding creates dust, connect machine to adequate dust collector.

6. When finish working, switch off the motor and move the machine the secure place and insure

against unauthorized use.

1.1.5. Checkups, maintenance, service and repair.

•regularly check the technical state of the machine.

•if fault or damage is discovered ensure expert repair.

•repair or service may bee carried out only by qualified personnel from a manufacturer’s service

organisation.

•it is prohibited to carry repairs or service at places where the safety of work is not ensured and can

be affected by outside impingement, such as falling objects, collision with other machinery etc.

•changes and alteration to the machine can be carried out only with the explicit agreement of the

manufacturer!

1.2. Transporting the machine

1. Transporting or lifting the machine must be carried out only

by equipment of appropriate bearing or lifting capacity.

2. When transporting secure the machine against

overturning, moving or falling off.

3. It is advantageous to fold the handlebars to Compact

transport mode whilst transporting see pic. 1.

Pic.1 Compact transport mode

Remark: Handlebars can be easy lowered after loosening of two

M10 screws place on the rest side of the frame.

1.3. Prohibited activities

When using the machine it is forbidden:

1. Using the machine for work other then for which is designed.

2. Operating the machine in other manners then those described in this manual.

3. Using the machine under influence of alcohol, narcotics or drugs and medicaments.

BL

BLBL

BL

-

--

-

300

300300

300

Floor grinder

Page 4 / 9

4. Using the machine whilst its running may endanger the safety or persons, property or traffic.

5. Bring in to operation and work with the machine if any of the safety features are dismounted or

damaged. (Tool cover, rubber cover etc.).

6. Leave running or unsecured machine with out safeguarding it against unauthorised use.

7. Using machine whilst oil leakage, gas leakage or any other content leakage occur

8. Apply additional weight to area around main shaft.

9. Cleaning the machine while it is running.

10. Cleaning the machine with high pressure water.

1.4. Liquidating the machine at the end of its useful lifetime

When liquidating or disposing of the machine it is absolutely necessary to adhere to all rules or

legislation pertinent to the country where the machine have been is used.

The manufacturer can not be held responsible for damages to health or environment in cases where all

the above mentioned principles where not adhered to.

1.5. Safety instruction for work with BL-300 Floor Grinder

When working with the machine the following instructions must be complied with:

1. It is prohibited to work with the machine with out the tool cover (including the rubber collar).

2. No person except the operator is permitted within the danger perimeter of the machine.

3. Start the machine always tilted over its rear wheels with the tool a safe distance above the ground –

use quick-lift shank device.

4. Observe all general rules of safe work.

2.

TECHNICAL DATA AND DESCRIPTION OF THE MACHINE

2.1. Description of the machine

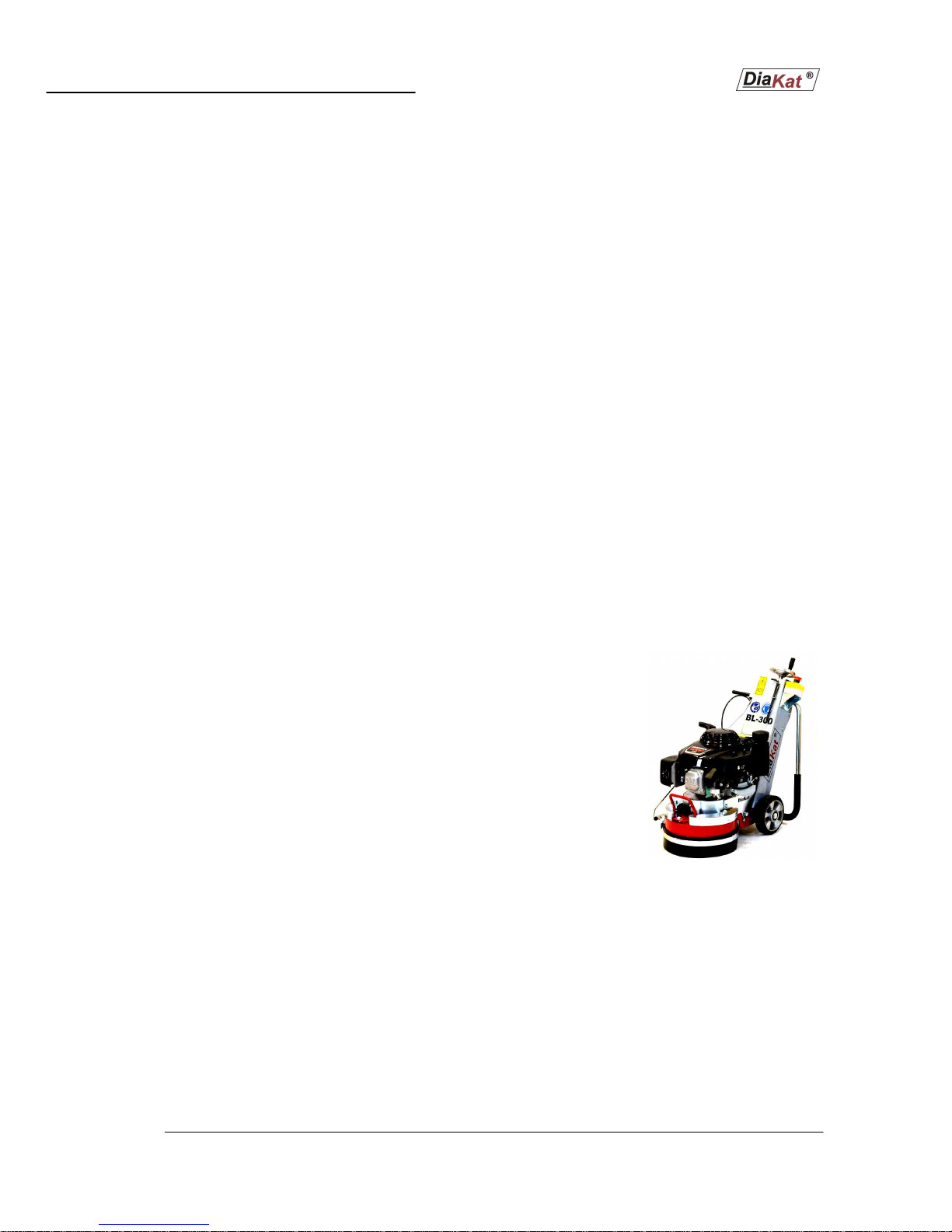

The BL-300 DiaKat Floor Grinder is designed for grinding small bumps and slight unevenness of

horizontal floor areas. It find its widest use in grinding and levelling of smaller concrete, anhydride and

screeded floor areas with diamond or Tc tipped grinding tools The BL -300 is primarily intended for a

“dry grinding” with the option of dust removing.

The grinder is powered by 3,2 kW Honda petrol engine. The engine is mounted on a rigid frame and is

connected to the drive spindle by means of a flexible ring coupling. This configuration enables the tool

to cope with floor unevenness and ensures smooth transfer of torque. The undercarriage consist of

height adjustable rear wheels, with which the depth of cut can de adjusted and an adjustable front wheel

with which the depth of cut can be restricted. The front wheel also provides easier transport. The

machine is manipulated by means of adjustable handlebars.

BL

BLBL

BL

-

--

-

300

300300

300

Floor grinder

Page 5 / 9

2.2. Technical specifications

Weight

62+6 kg

Tool diameter

300 mm

Max. depth of cut

0,5-1,5 mm

Main spindle RPM's

1800 rot.min

-1

Depth of cut adjusting manual

Engine

HONDA GXV160

Engine RPM's

3000 ot.min

-1

Max.output

4.0 kW (by 3600 rot.min-

1

)

2.3. Primary operative parts of the machine

Pic. 2 Description of operative parts

1 – Hanlebars

2 – STOP button

3 – Tightener (tool, handlebars,etc.)

4 – Safety rubber

5 – Additional weights

6 – Front wheel

7 – Quick-lift shank device

8 – shank device Controller

9 – Depth restriction setting wheel

10 – Throttle controller

BL

BLBL

BL

-

--

-

300

300300

300

Floor grinder

Page 6 / 9

2.4. Description and designation of tools

Description

TCT cutters carrier 3bars x 4 x 46 / 6 Ø 300 mm

Usage * reducing of surface to desired depth

* grinding of small bumps

* surface roughening

* tile's holding glue removal

Depth of cut 1 - 3 mm

Material

* asphalt

* concrete

* cemented spawns and screeds

Description

DIAMONDS Ø 300 mm (coarse, medium, fine)

Usage * grinding of surface to desired roughness

* small unlevelnesses removal

* removal of old paintings

Depth of cut 0,5 - 1,5 mm

Material

* asphalt

* concrete

* cemented spawns and screeds

Description

Grinding disc TC Ø 300 mm

Usage * grinding of surface to desired roughness

* small unlevelnesses removal

* removal of old paintings, glues

Depth of cut 0,2 - 0,5 mm

Material * asphalt

* concrete

* cemented spawns and screeds

* epoxy paintings

Description

Grinding disc - sandpaper (emery discs)

Usage * grinding of surface to desired roughness

* dirty removal

* removal of old paintings

Depth of cut 0,5 - 1,5 mm

Material

* asphalt

* concrete

* cemented spawns and screeds

Description

Polishing disc - Velcro attached polishing blocks

Usage * concrete polishing

Depth of cut N/A

Material * Concrete

Mounting and dismounting of tool

!ATTENTION! Always follow the instructions below when mounting or dismounting tool! (Only

then you can set up the machine with tool correctly and safely.) The machine must be always secured

against movement and the motor switched off when changing tool!

BL

BLBL

BL

-

--

-

300

300300

300

Floor grinder

Page 7 / 9

2.4.1. Mounting of tool

1. Bring the machine to standstill and secure it.

2. Tilt the machine over its rear wheels and rest it on the handlebars.

4. .Set the tool with its centre hole on to the collar of the tool carrier; align the screw holes in the tool

with the threaded holes in the carrier.

5. Hold the tool on the carrier and secure it with three high tensile screws with CSK head.

6. Tighten the screws on rota basis.

7. Make sure that the tool hole fit fully on to the collar of the carrier.

2.4.2. Dismounting of tool

Similarly dismount the tool.

2.5. Význam značek a piktogramůna použitých na stroji

BL-300 floor grinder is complient with EU law and is marked with following stickers with following

meaning:

Symbol / Sticker

Sticker meaning

ATTENTION! Read the manual before use and follow the manual!

!ATTENTION! The Operator is obliged to use safety breath

respirator whilst using machine.

!ATTENTION! The Operator is obliged to use ear protection

whilst using machine.

INFORMATION! Arrow shows sense of tool rotation.

BL

BLBL

BL

-

--

-

300

300300

300

Floor grinder

Page 8 / 9

3.

BEFORE STARTING

3.1.Visual check up of the machine state

Regularly (before commencing work) check:

•all covers and safety features

•all screwed joints (especially tool mounting screws)

•state of tool’s wear

4.

WORKING WITH THE MACHINE

!ATTENTION! Always use adequate dust collector when grinding in enclosed area.

4.1. Setting of the machine , start, stop

!ATTENTION! never start the machine if the tool is touching the floor.

1. With the aid of front and rear setting wheels set the machine that the tool (machine frame) is

parallel to the working surface and the tool is lightly touching the floor.

2. Set the depth of cut by the front setting wheel and tighten the check nut. By using the rear setting

wheel again level the machine. Lock the rear setting wheel.

3. Set the machine to idle position by quick-lift controller so that the tool is in safe height above the

ground.

4. Start-up the engine.

5. When reaching maximal engine RPM’s lower the tool carefully on the ground.

6. According to the type of grinded material and requested pressure add corresponding additional

weights (always same qty on each side of the machine) so that engine’s RPM are sustained during

work.

!ATTENTION! Select such a depth of cut (depending on the material grinded) so that the machine is

not overloaded (the motor must not slow down or stall – danger of damage to the motor).

4.2. Working with the machine

If all settings are correct the machine is moving over the surface easily. In order to achieve the best

flatness of the grounded surface move the machine evenly from side to side in arches and at the same

time move slowly forward. Regularly check the state of wear of the grinding tool and clogging by dirt

of the TCT cutters! Clogged tool can not work properly, it wears unevenly and clogging can

eventually lead to damage or destruction of carrier and cutters.

BL

BLBL

BL

-

--

-

300

300300

300

Floor grinder

Page 9 / 9

5.

MAINTENANCE

The basic steps of preventive maintenance described in this manual can be carried out by the operator

appointed by the entrepreneur. We recommend that all repairs and adjustments beyond the scope of this

manual are carried out by authorised service centre.

!ATTENTION! In the guarantee period it is prohibited to interfere with the engine and power

transmitting components in any manner whatsoever!

5.1. Cleaning of the machine

Regular cleaning prolong the life of the machine its components and tools. After finishing work clean

the machine from dust and dirt by wet cloth or air before storing. Never use pressurised water for

cleaning.

5.2. Checking screw joints

Check the tightness of screw joints before every start of the machine. Regularly check the tightness of

the tool securing screws.

5.3. Tool maintenance

Regularly check the wear and soiling of tools. If the diamond segments are almost worn off, change the

tool. If the TCT cutters are clogged with dust and dirt and can not rotate freely loosen them by light

taping of the hammer and pressurised air.

5.4. Engine maintenance

Follow the manual for Honda petrol engine!

Table of contents

Other DIAKAT Floor Machine manuals

Popular Floor Machine manuals by other brands

Hoover

Hoover CH83020 Safety, operation and maintenance manual with parts list

Windsor

Windsor Armada BRC 40/22 120V operating instructions

Nilfisk-Advance

Nilfisk-Advance ES300 Instructions for use

Windsor

Windsor Mini Pro operating instructions

Windsor

Windsor 10080220 operating instructions

KENT

KENT SelecTrac 17 Operator's manual

Kent Euroclean

Kent Euroclean 20 Instructions for use

Minuteman

Minuteman Mirage M220021K17 Operation service parts care

NSS Enterprises

NSS Enterprises Galaxy Operation manual

Isoplam

Isoplam L010001 Use and maintenance manual

BETCO

BETCO STEALTH ASD20B Operator and parts manual

Nilfisk-Advance

Nilfisk-Advance SW900 Use and maintenance