10

Inner Bowl Removal Instructions

This procedure requires a set of retaining ring plyers and safety glasses to complete. If you do not have

retaining ring plyers they can be purchased at Lowes, Home Depot, Harbor Freight and other tool stores

for about $20.

1) Unplug machine from power source.

2) Place handle in straight up position and lock in place using the quick release pin.

3) Using the handle, tilt machine sideways until handle is resting on the floor to one side.

4) Remove tools from machine.

5) Remove the (9) ¼-20 hex bolts and lock washers from the perimeter of the cover plate. Remove plate

from machine.

6) Vacuum dust and debris from inner bowl.

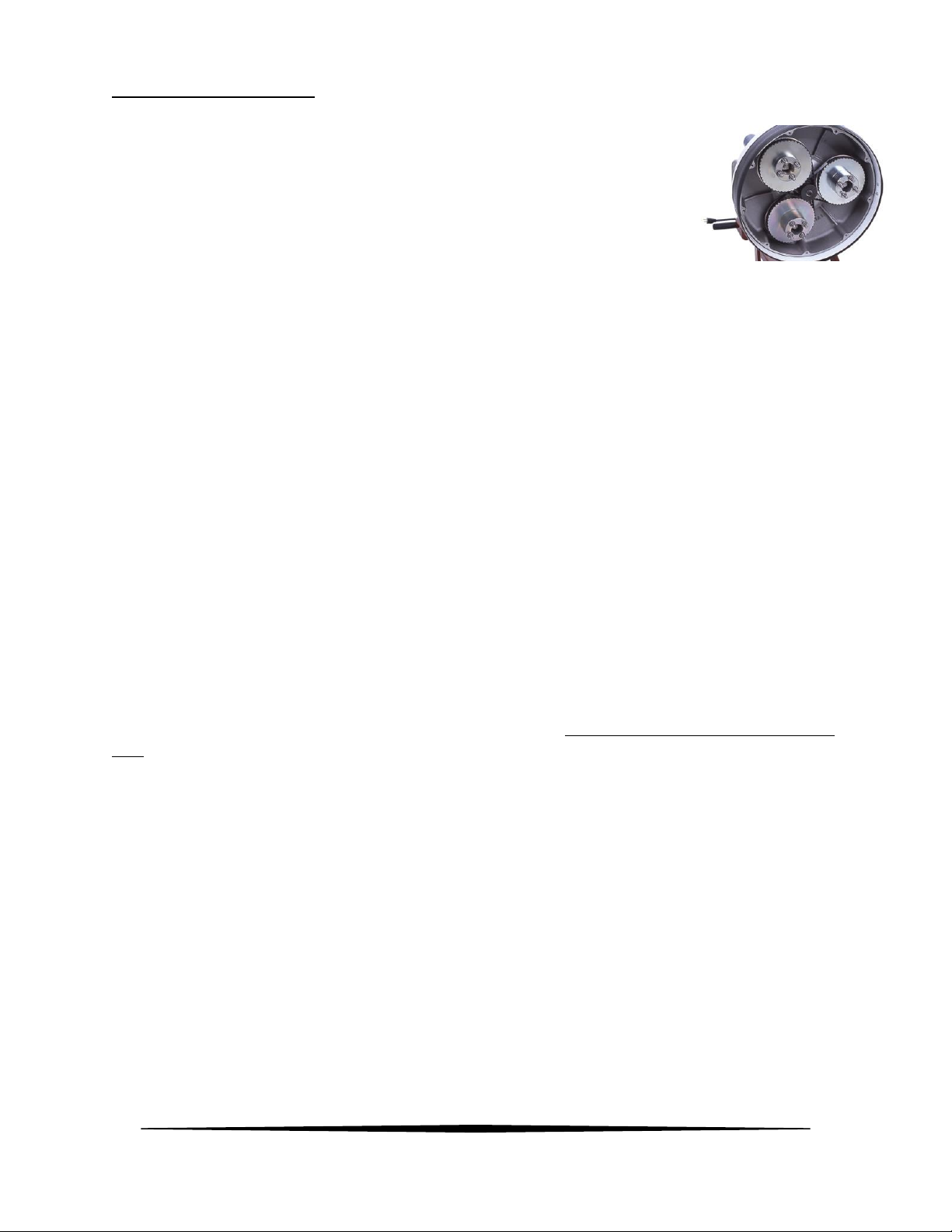

7) Locate bolt in center of center driving pulley. While holding one of the large driven pulleys to prevent

rotation, remove this center bolt and its flat washer. On some machines this removal requires a hex

(Allen) wrench while later machines require a 7/16 wrench or socket.

8) On some older machines, retaining plates were not used on the face of the driven pulleys. If your

machine is configured this way go to step 11.

9) On machines with old style plates, each driven pulley has (3) Allen socket screws holding the retainer

plates in place. Remove these (9) screws and (3) retaining plates then go to step 11.

10) On machines with newer retaining plate design, only remove the single ¼-20 hex bolt from each of

the driven pulleys. Then rotate the retaining plate slightly until keyhole openings in plate allow removal.

If plate will not rotate, loosen button head screws slightly and rotate plate. There is no need to remove

button head screws.

11) With retaining plates removed and using gloves, pull the belt away from large pulley using a flat

screwdriver while slowly rotating the pulley. Be careful not to pinch fingers between belt and pulley.

Repeat until belt is off pulley. Repeat this process until all three belts have been removed.

12) Remove center driving pulley from motor shaft. This may require prying behind pulley(s) with a large

flat screwdriver or a small pry bar. In some extreme cases it may even require the use of a pulley puller

tool. Also remove square key.

13) With center pulley removed, locate retaining ring at center of bowl (just behind where center pulley

was before removal). Wear safety glasses. Using a pair of retaining ring plyers, remove this retaining

ring.

14) Using a clean cloth, wipe away any dust or dirt from the groove where retaining ring was located.

15) Using two of the large pulleys as handles, pull away from machine. This should allow entire inner

bowl with large pulleys intact to slide out of machine. If bowl will not slide out try lifting up on pulleys at

the same time while pulling away from machine. In rare instances it may require renting a Harmonic

Balancer Removal tool from an auto parts store to extract the bowl. If this type of difficulty is

experienced contact factory for further guidance.