Lifting the granite

The granite can be either solid granite or honeycomb, the weights are as follows

Honeycomb Solid

600 Y axis 95 kg 600 Y axis 350 kg

900 Y axis 127kg 900 Yaxis 470 kg

1200 Y axis 590 kg

1500 Y axis 705 kg

Honeycomb granite will be attached to the bench with M10 studding, Solid granite will be

supported via rubber feet, also supplied will be anti tip feet.

Solid Granite

Do not attempt to manually lift solid granite, it will be necessary to use hydraulic lifting

equipment. The bench is not designed to be moved with the granite in place.

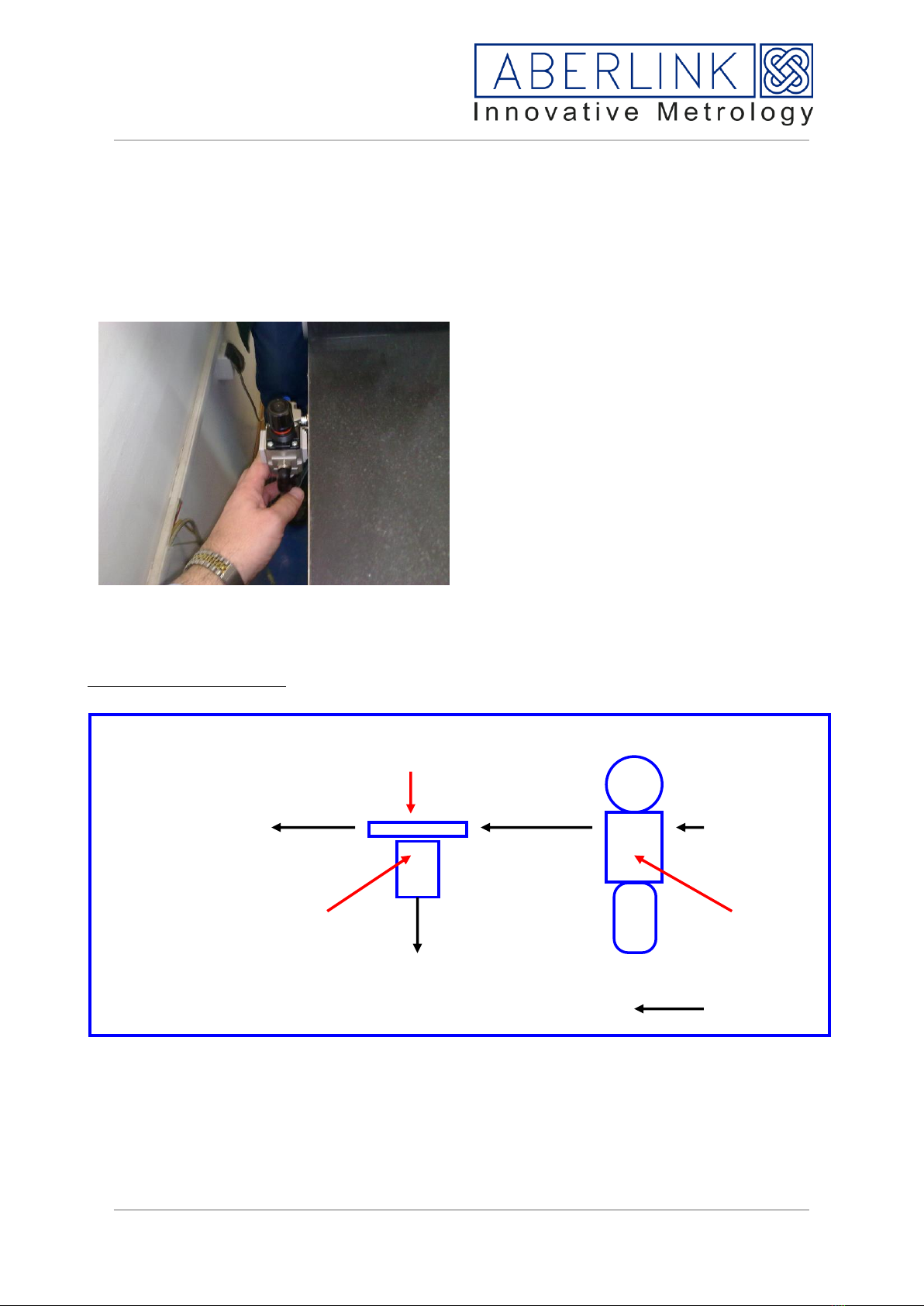

When loading the granite, be sure to set enough clearance on the feet to enable the fork

lift forks to be removed once the granite is lowered.

To aid levelling, set all feet to the same height

Have the anti-tip feet set lower than the location feet, and raise once the granite is located

and levelled.

Position the granite so the front of the granite overhangs the front by 20mm, and have the

granite located equi-distance from the left and right side.

Once in position, clean the granite and the y axis scale on the right hand side.

Honeycomb granite

The 600mm machine can be lifted quite comfortably by 4 people if necessary.

Once the granite is lifted you can locate the studding, there are two holes at the front of the

machine and one at the back in the centre position. If placing the granite onto the bench

for this task, then position on an angle to allow access.

Screw in the stud until it stops then unwind one-quarter turn, then attach and lock with the

supplied M10 nut, use 15mm spanner. Also attach another M10 nut with the flange facing

down. Set all to the same distance, allow for fork clearance if using fork lift.