WARNINGS FOR THE INSTALLER –GENERAL SAFETY OBLIGATIONS

ATTENTION! It is very important for the safety of people to follow

all instructions strictly. A wrong installation or use of the product

could cause serious damage to people.

Each automatic installation should have at least one lighting device

(i.e: flashing lights integrated in the crosshead of the bollard) and a

signal placard, along with the device quoted at point “16”

2 Read carefully this manual before starting installation and save it

for future reference.

18 In each automatic installation the installer must consider

Read carefully this manual before starting installation and save it

for future reference.

In each automatic installation the installer must consider and install

appropriate safety devices.

Packaging materials (i.e. plastic, polystyrene, etc.) must be out of

children’s reach, because potentially dangerous.

For maintenance works use only original parts supplied by AccessPRO

This product has been designed and manufactured exclusively on

the purpose indicated in this manual. Any different use not here

indicated could damage the integrity of the product and/or be

potentially dangerous.

Delos is not responsible for safety and good functioning of the

product , in case of use of components not manufactured or distributed

by Delos

Delos is not responsible for any damage caused by

improper or different use from the indicated one.

Do not apply any modification to the parts composing the

automated product AccessPRO.

Do not install the device in an explosive area: Using Inflammable

gases could be not safe.

The installer must provide the Customer with all information related to

the manual release of the automatic bollard in case of emergency and

give the User a warning manual attached to the product.

Installation must be according to the local Laws.

Do not allow children or others to stop close to the bollard during

operation.

In order to have an adequate safety level in the extra-CEE

countries, in addiction to the national laws, the above mentioned

laws must be followed.

Keep remote controls or other impulse-giving devices out of children’s

reach, in order to avoid involuntary activation.

Delos is not responsible if someone does not observes the

correct method of installation of the AccessPRO products and

related devices, included deformations coming during the use.

Thoroughfare over the AccessPRO bollard allowed only at

complete lowering of the bollard.

Before any actions on the automatic installations take power off.

Semiautomatic bollards are not adviceable for multiple installation (two

or more) on main streets where the frequent passage of vehicles over

the lowered bollards can break the lock block and make the bollard

lifting without control.

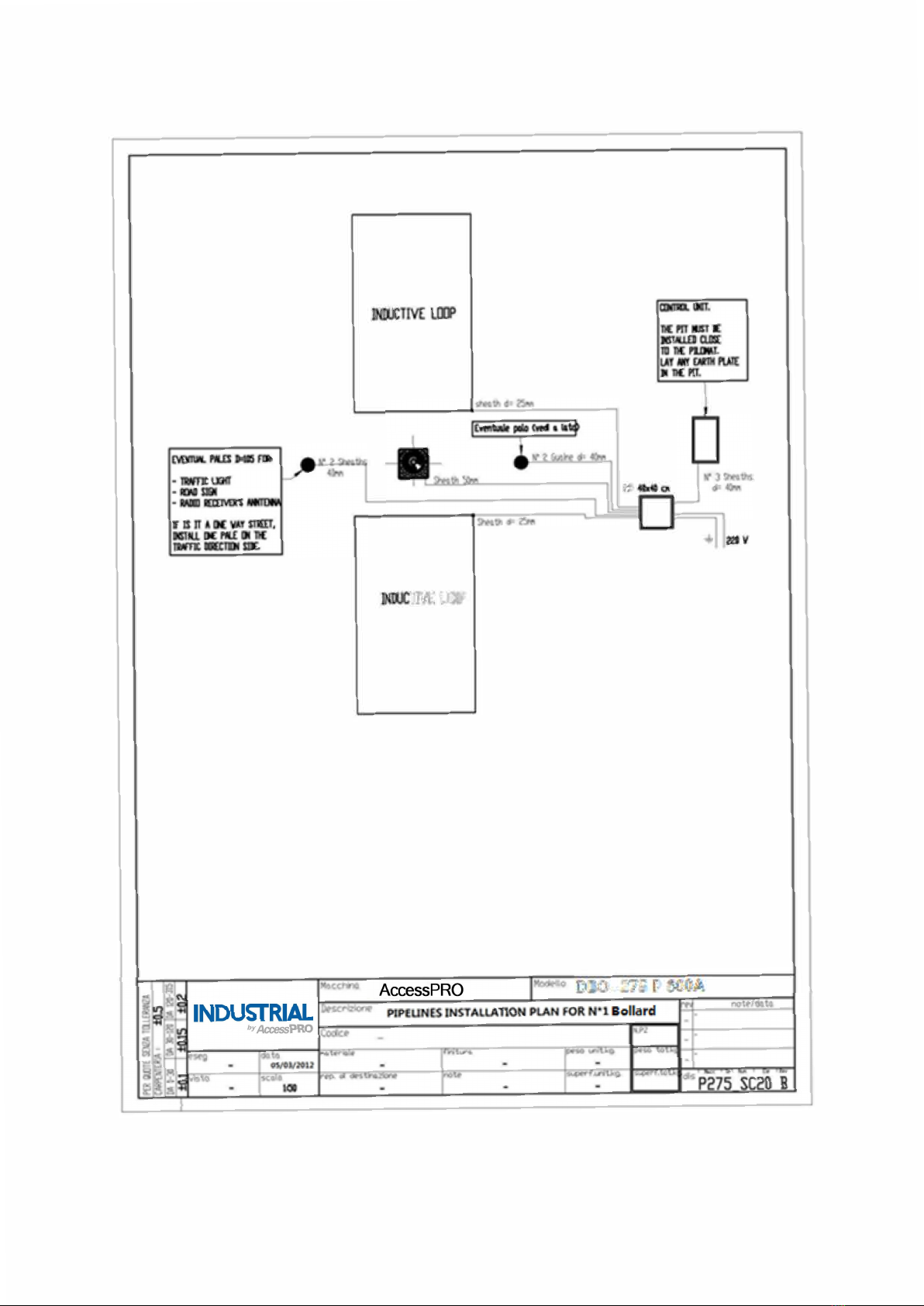

An Omni polar switch should be foreseen on the alimentation’ s net

of automatic installations. Its connections should have an opening

range of 3 mm. A magnetotermical differential with 6A Omni polar

switch is adviceable

The User must avoid any repairing actions or direct operations on the

bollard, and must address to qualified and authorized personnel only.

Assure that a differential switch with 0,03°is present at the

beginning of the automatic installation.

Do not waste exhausted batteries in the garbage, but dispose them in

the apposite containers to allow recycling. Disposal costs have already

been paid by the manufacturer

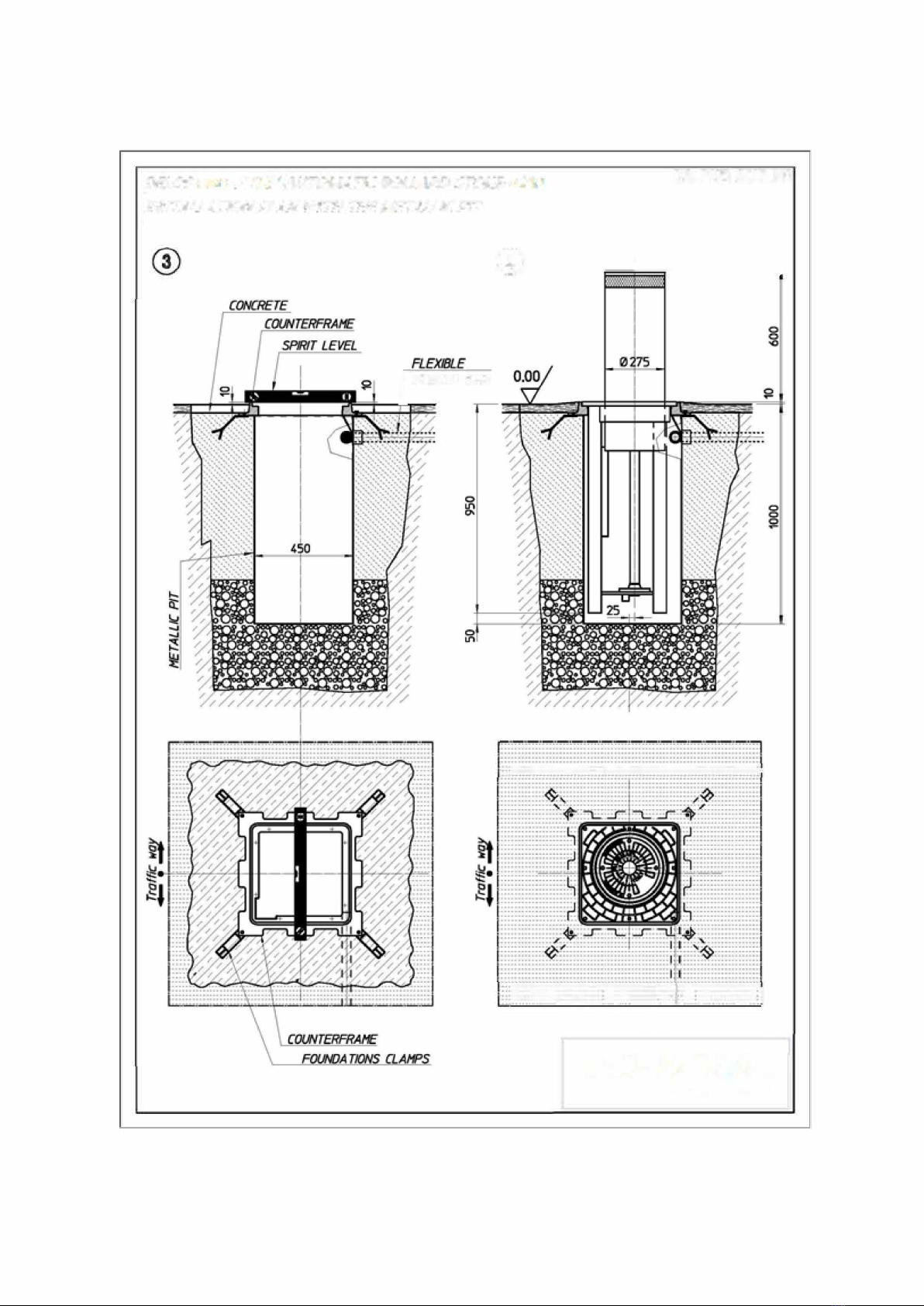

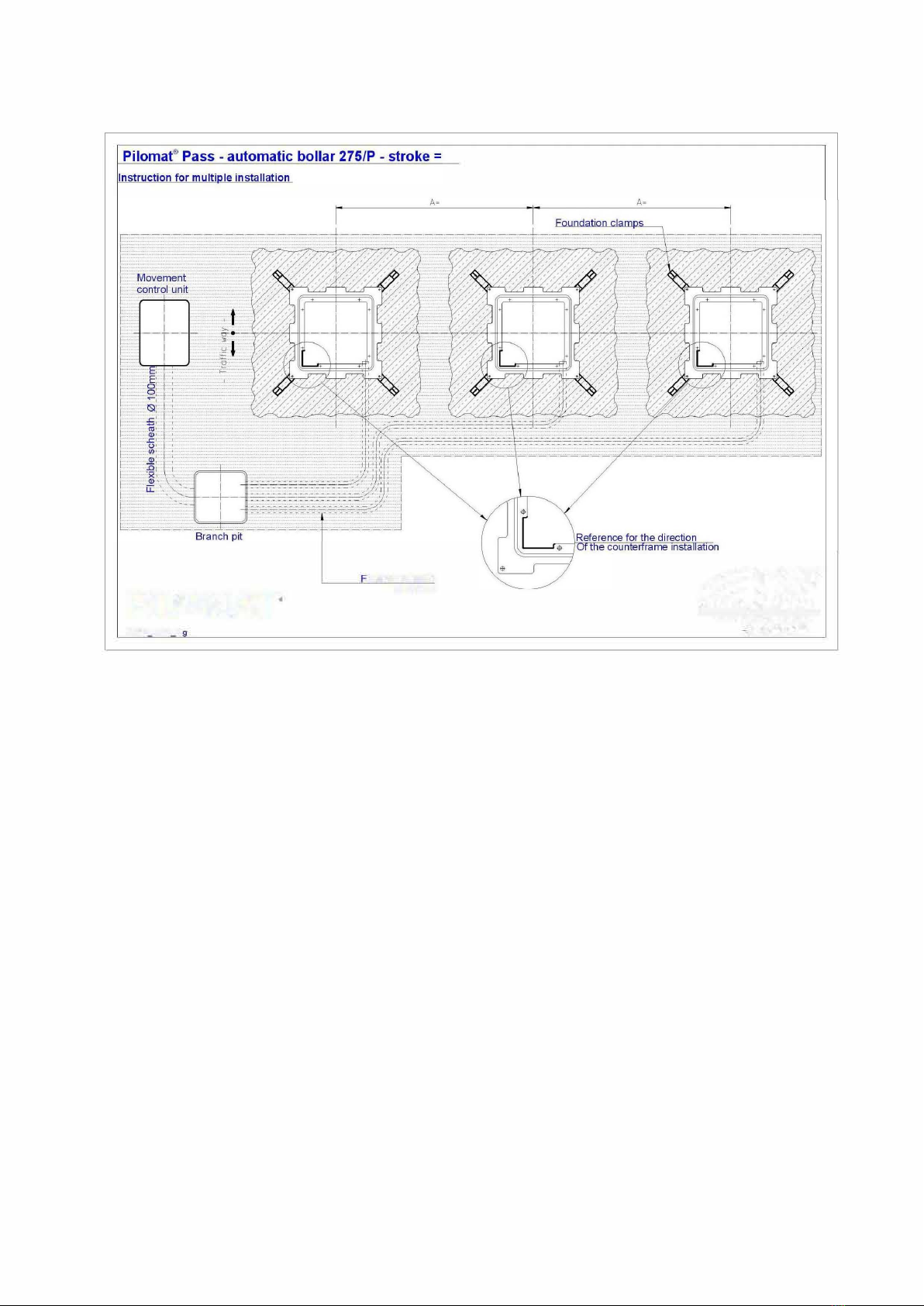

The main electrical alimentation of the control unit of automatic

installations must be connected directly to at the beginning of the

apposite principal switch set inside the control unit; use anti-flame

cables approved by at least one of the European Institutes. The

dimension of the first alimentation line must be minimum

3x2,5mm,but evaluated by the installer according to the number of

Delos bollards (400W each AccessPRO bollard) and the distance

from the output point in order to guarantee a correct alimentation

(230V +/- 10% for moving AccessPRO bollard).

The product is packaged on Euro pallet; use pallets’ movers or

shunters for movement; handle with care.

Test that the earthing is workmanlike and connect the metallic

parts.

The product has been manufactured with IP 56 protection’s level, and

could therefore be stored everywhere; storage in internal or covered

places is anyway preferable.

The automatic installations include a standard safety device: an

inversion pressure switch in case of at least 40 kg of load. It is

anyway necessary to test the activation level every six months,

according to what laws establish.

The product does not require availability of spare parts;

AccessPRO’s warehouse can send by express any needed

spare parts.

Safety devices (Law EN 12978) allow protection of potentially

dangerous areas where activities such as squashing, conveyance,

shearing are possible to occur.

In case of maintenance and/or reparation, Pay attention not to give

improper raising signals; to avoid any problems, disconnect the

bollard’s moving by the switch set inside the control management

station.

Everything not mentioned in this manual is not allowed