Hardware and physical integration guideline PCR Sensor A111

Page 3 of 32

2019-12-04 Tel: 0755-2328 2845 深圳市佰誉达科技有限公司

Table of Contents

1 Introduction..................................................................................................................................... 4

1.1 Radar loop equation................................................................................................................. 4

1.2 Radar radiation pattern............................................................................................................ 5

2 HW Integration - Schematics .......................................................................................................... 6

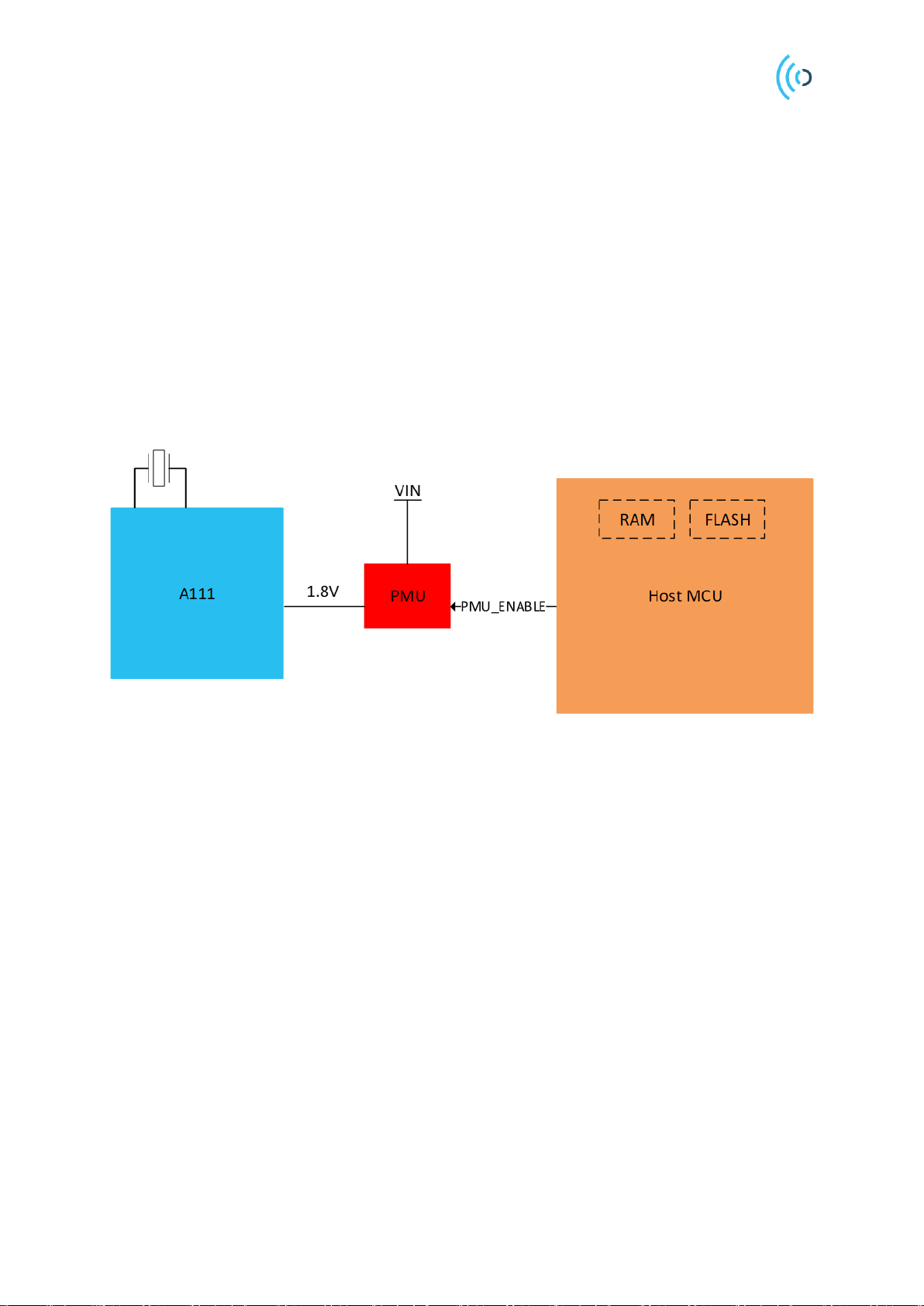

2.1 Power....................................................................................................................................... 6

2.2 SPI Interface............................................................................................................................ 7

3 HW Integration - PCB..................................................................................................................... 8

3.1 Sensor ground plane................................................................................................................ 8

3.2 Sensor underfill ....................................................................................................................... 9

3.3 Integration with other components.......................................................................................... 9

3.4 A111 Decoupling capacitors ................................................................................................. 10

3.5 A111 Crystal.......................................................................................................................... 11

4 Physical Integration....................................................................................................................... 13

4.1 Radome integration ............................................................................................................... 13

4.2 Radome thickness.................................................................................................................. 15

4.3 Radome distance.................................................................................................................... 16

4.4 Impact on the radiation pattern.............................................................................................. 18

4.5 Multi-layer radome integration.............................................................................................. 20

5 Physical Integration - Lens............................................................................................................ 22

5.1 Focal distance........................................................................................................................ 23

5.2 Radiation pattern................................................................................................................... 25

5.3 FZP Lens Design................................................................................................................... 26

6 Appendix A: Materials.................................................................................................................. 29

7 References..................................................................................................................................... 30

8 Revision......................................................................................................................................... 31

Disclaimer ............................................................................................................................................. 32