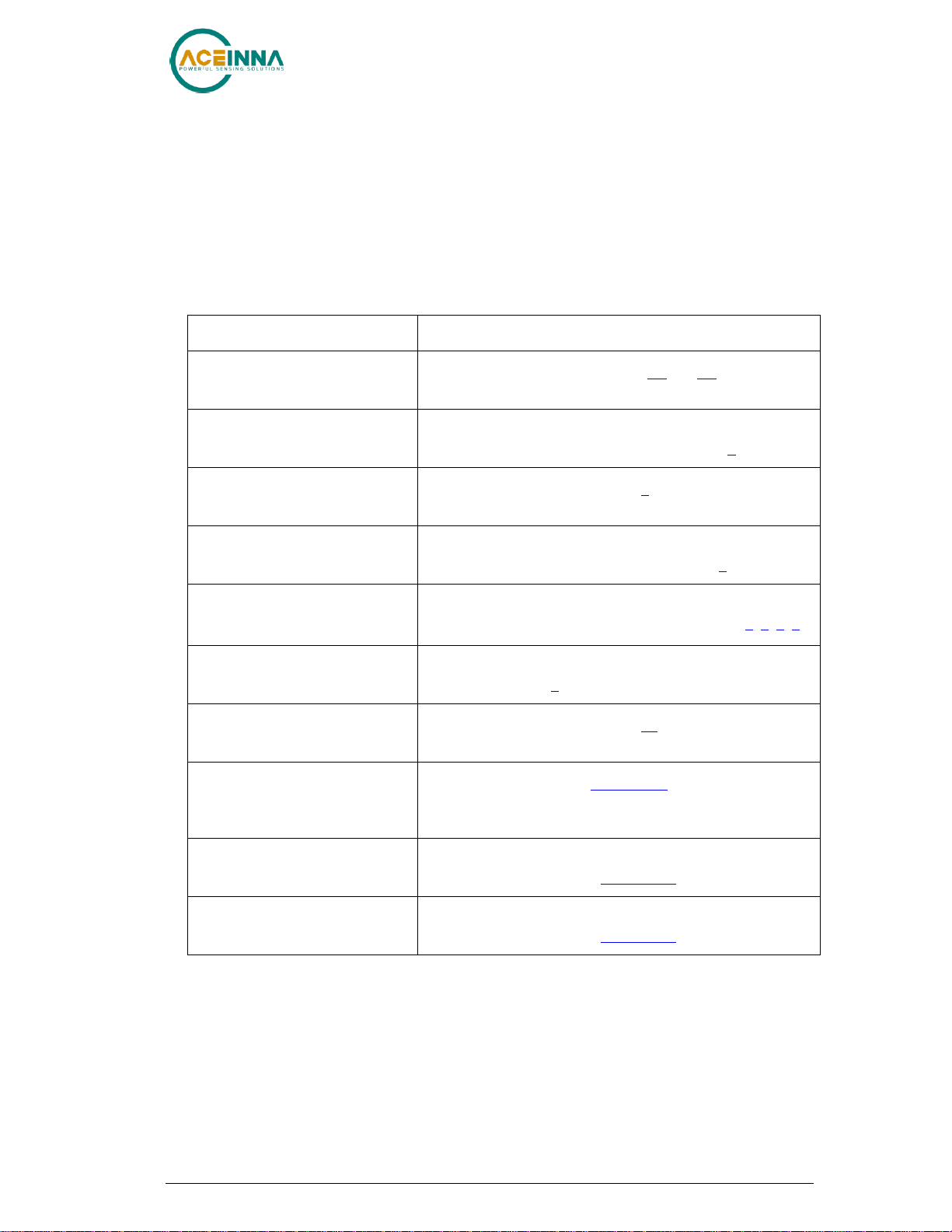

4.4.2. Output data rate..........................................................................................................31

4.4.3. Rate-Sensor scaling and Low-Pass filter....................................................................31

4.4.4. Axis orientation settings.............................................................................................33

4.4.5. Saving the configuration to EEPROM.......................................................................34

4.4.6. Sensor control registers..............................................................................................34

4.4.7. Fault detection control registers.................................................................................35

4.5. Suggested operation conditions.......................................................................................36

4.5.1. Startup timing.............................................................................................................36

4.5.2. SPI timing...................................................................................................................36

4.6. Signal synchronization....................................................................................................37

Method 1- Using the sensor sampling indicator (Pin 1).....................................................38

Method 2- Using the Timestamp registers in the Extended Burst Message........................38

4.7. Bootloader.......................................................................................................................38

5. UART interface definition......................................................................................................39

5.1. General settings...............................................................................................................39

5.2. Number formats...............................................................................................................39

5.3. Packet format...................................................................................................................40

5.3.1. Packet header..............................................................................................................40

5.3.2. Packet type .................................................................................................................40

5.3.3. Payload length............................................................................................................41

5.3.4. Payload.......................................................................................................................41

5.3.5. 16-bit CRC-CCITT ....................................................................................................41

5.3.6. Messaging overview...................................................................................................41

6. Standard UART commands and messages.............................................................................44

6.1. Link test...........................................................................................................................44

6.1.1. Ping command............................................................................................................44

6.1.3. Echo command...........................................................................................................44

6.1.4. Echo response.............................................................................................................44

6.2. Interactive commands......................................................................................................45

6.2.1. Get Packet request......................................................................................................45

6.2.2. Error response ............................................................................................................45

6.3. Output packets (Polled)...................................................................................................45

6.3.1. Identification data packet ...........................................................................................46

6.3.2. Version data packet....................................................................................................46

6.3.3. Test 0 (Detailed BIT and status) packet.....................................................................47