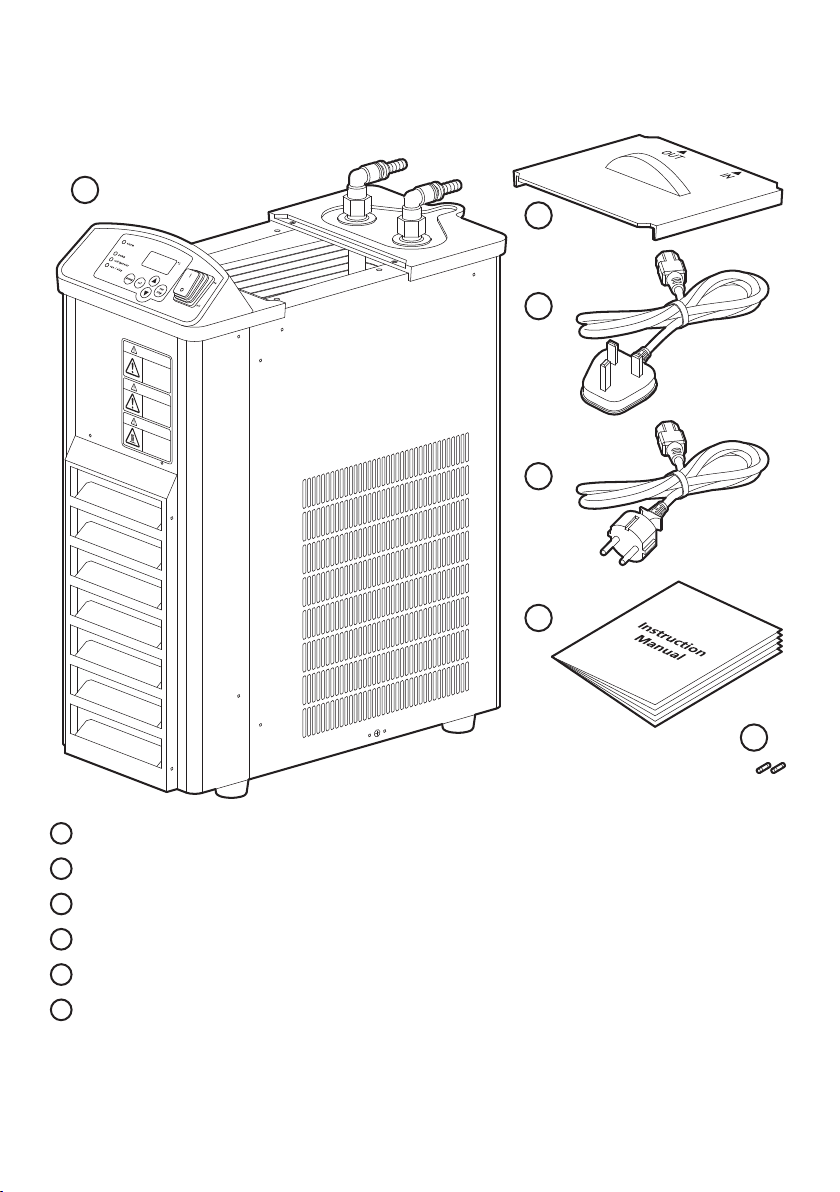

2

Section 1 - Introduction

Thank you for purchasing this Cole-Parmer product. To get the best performance from the equipment, and

for your own safety, please read these instructions carefully before use.

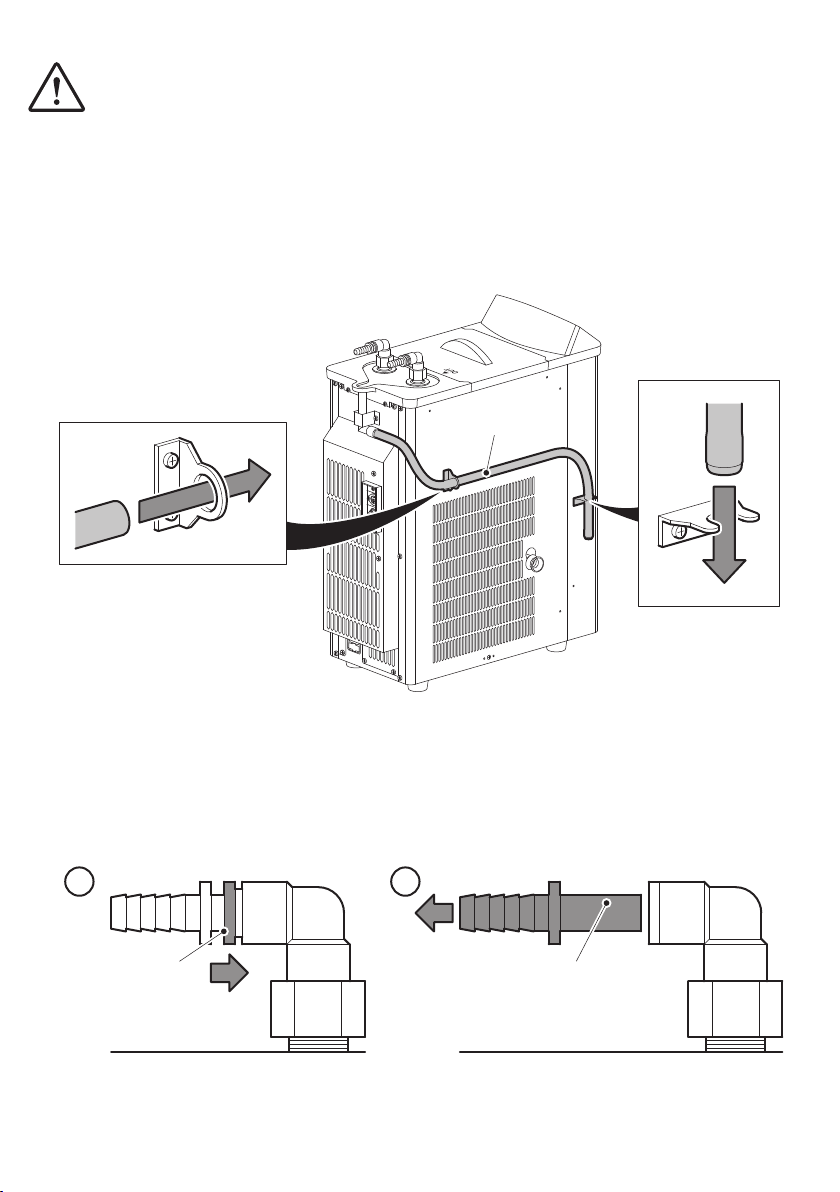

If the equipment is not used in the manner described in this manual and with accessories other than

those recommended by the manufacturer, the protection provided may be impaired.

1.1 General Description

A Recirculating Cooler offers a powerful cooling for an external device. By accurately controlling the temperature

of your cooling medium down to -20°C, efciency of operations such as condensing can be greatly improved. A

recirculating cooler is not only much more powerful than conventional water cooling, but is also an ideal

alternative when water consumption is an issue for economical, environmental or practical reasons.

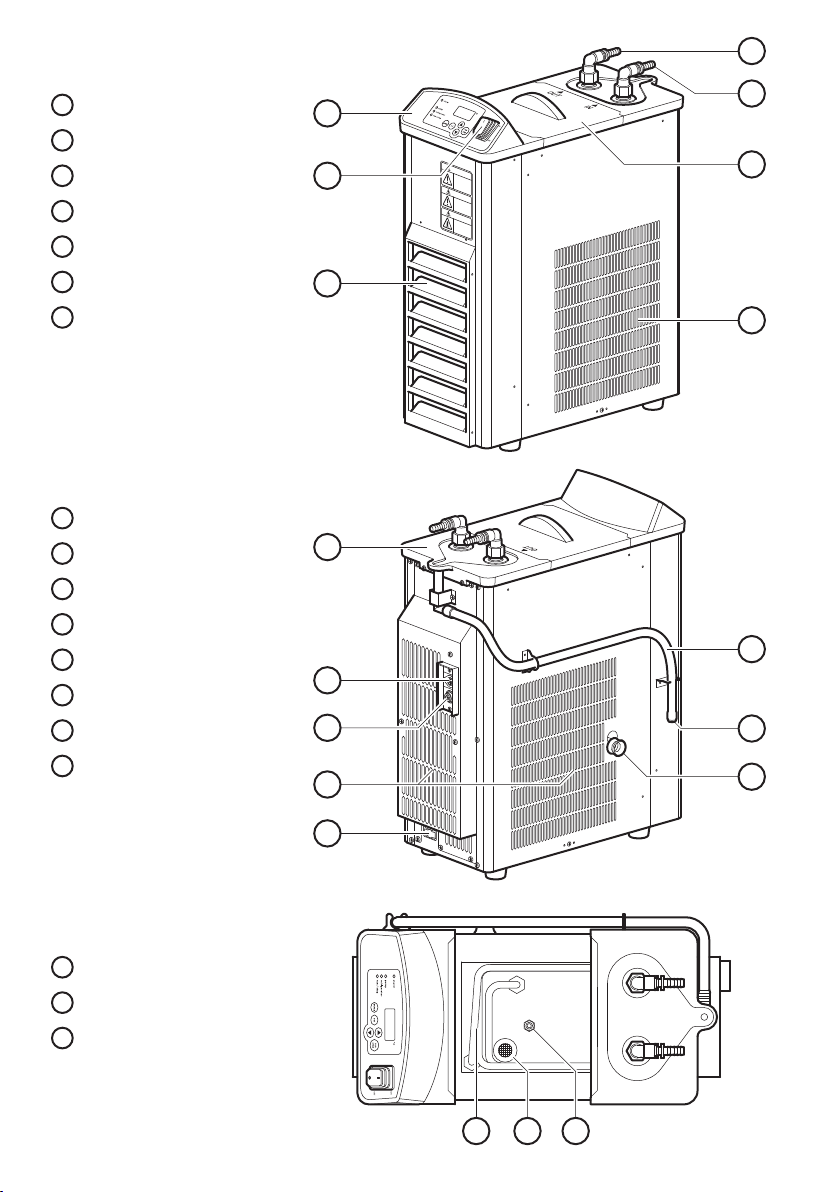

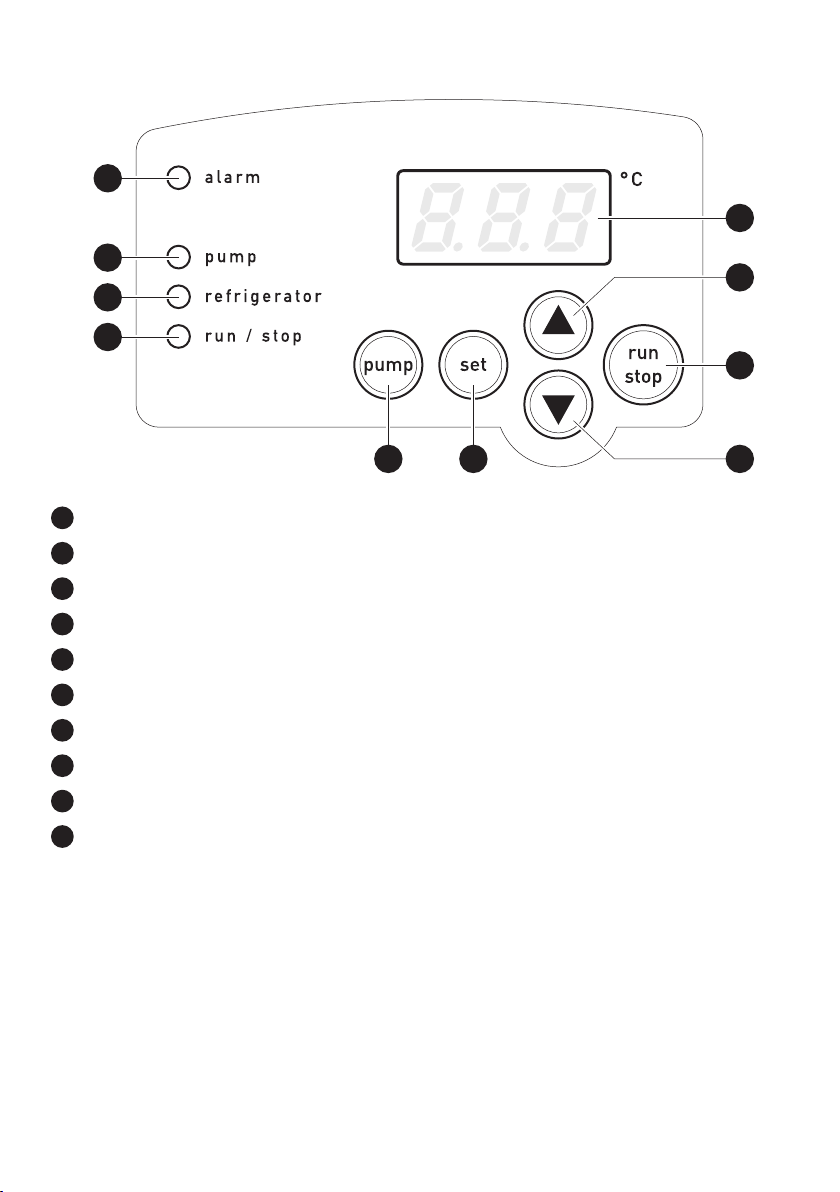

The RC-200-3 provides a powerful cooler with a compact footprint suitable for mounting on or under a bench. The LED

digital display clearly shows the current temperature of the cooling medium to ±2°C, while the set temperature is

revealed by a one button press.

The unit has a dedicated drain for easy emptying and cleaning. It also incorporates a built in safety alarm to indicate

an overload relay for the refrigeration unit. A dust lter is incorporated and can be accessed without tools via the

hinged front panel.

1.2 Important Safety Advice

Users should be aware of the following safety advice:

❖SHOCK HAZARDS OR UNSAFE PRACTICES ARE DANGEROUS as they can cause severe personal injury, re

or death.

❖DO NOT use combustible substances near hot objects.

❖DO NOT cover any of the ventilation panels.

❖DO NOT use the equipment in hazardous atmospheres.

❖DO NOT operate or handle any part of the equipment with wet hands or use on surfaces that may become ooded.

❖NEVER move the equipment while still connected to the power supply.

❖HIGH TEMPERATURES ARE DANGEROUS as they can cause serious burns to operators and ignite combustible

material.

❖USE CARE AND WEAR PROTECTIVE GLOVES TO PROTECT HANDS.

❖NEVER lift or carry the equipment during operation.

❖ DO NOT position the equipment unit so that it is difcult to disconnect from the mains supply using the mains

plug.

❖ The mains outlet socket used should be located close to the equipment and readily identiable and accessible

to users.

❖DO NOT leave equipment switched on and it is not recommended to leave any heating apparatus unattended

during operation.

❖ The equipment should be transported and installed with a minimum of two people.

❖ The equipment is tted with a power outage recovery mode. In case of mains interruption you can choose if

you want the recirculating cooler to continue or stop once the power is restored, see section 4.3.

❖DO NOT use the equipment with distilled or deionised water