aci Carbon Dioxide Duct Series Installation instructions

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 1

Version: 4.0

I0000744

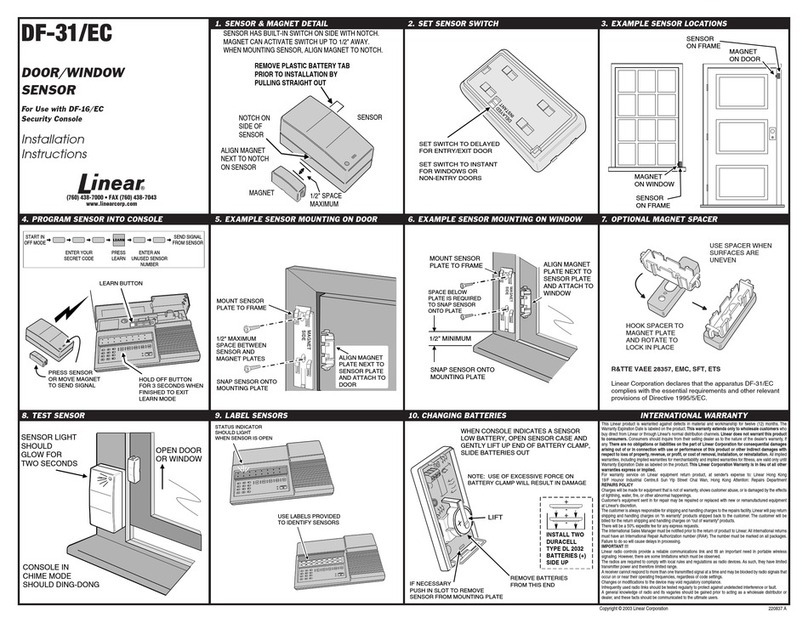

FIGURE 1: DIMENSIONS

CARBON DIOXIDE DUCT SERIES

Installation & Operation Instructions

A/CO2-DUCT

Phone: 1-888-967-5224

Website: workaci.com

GENERAL INFORMATION

The ACI Carbon Dioxide Duct Series (A/CO2-D)

monitors the carbon dioxide (CO2) levels in

industrial, commercial, school, and oce-type

environments. The concentration of CO2 is a

strong indication of the overall indoor air

quality. The A/CO2 Series is based on a single

beam, non-dispersive infrared technology

and is a cost-ecient solution for measuring

carbon dioxide levels for building climate

control. In addition, ABC software eliminates

the need for manual calibration. Carbon

Dioxide concentration is measured up to

2,000 ppm and is converted into proportional

analog outputs. The factory default output is

4-20 mA, whereas 0-5 VDC and 0-10 VDC

outputs are eld selectable via integral dip

switches. The A/CO2-D provides data which

can be used in conjunction with a Building

Automation System or Demand Control

Ventilation to decrease energy consumption while creating a healthier indoor climate.

MOUNTING INSTRUCTIONS

Since there might be a substantial pressure dierence in duct mounting applications, it is essential to avoid

ambient air from suction into the duct mounting box. For correct function it is indispensable that the

sealing of the box cover, the cable entry bushings, the cable feed through and the duct entrance are

absolutely tight.The duct entrance may need extra sealing paste in order to prevent leakage. The PCB must

be handed carefully and protected from electrostatic discharge.

• Place the O-ring around the hole at the back of the box. See figure 2.

• Electrical cable entry: The box has a factory mounted cable entry bushing. Never feed more than one

cable through each cable entry bushing, or else gas might leak through!

• Mounting the tube: Drill a 1” (25 mm) diameter hole for the sampling probe and two holes with 0.16” (4

mm) diameter for the screws (5) into the air duct and mount the tube (1) with the gasket (2). The sampling

probe should be mounted with the largest locking knob on top. The unit can be mounted with the air

coming from the left or right.

• Attaching the sensor box is made to the sampling probe by a snap-in bayonet tting. Orient the box onto

the sampling probe so that the box upside is on the same side as the largest locking knob (3). When the

probe is tted into the notches of the box, then turn the box clockwise until stop (see Figure 2). Position 1

indicates open where the box can be removed from the sampling probe. In position 2 the box is locked to

the probe.

3.31” (84mm)

5.59”

(142mm)

5.98”

(151.89mm)

8.03” (203.96mm)

1.65”

(41.91mm)

1.81”

(46mm)

WIRING

PRECAUTIONS

• Remove power before wiring. Never

connect or disconnect wiring with power

applied.

• When using a shielded cable, ground the

shield only at the controller end.

Grounding both ends can cause a ground

loop.

• It is recommended you use an isolated

UL-listed class 2 transformer when

powering the unit with 24 VAC. Failure to

wire the devices with the correct polarity

when sharing transformers may result in

damage to any device powered by the

shared transformer.

• If the 24 VDC or 24VAC power is shared

with devices that have coils such as

relays, solenoids, or other inductors,

each coil must have an MOV, DC/AC

Transorb, Transient Voltage Suppressor

(ACI Part: 142583), or diode placed across

the coil or inductor. The cathode, or

banded side of the DC Transorb or diode,

connects to the positive side of the power supply. Without these snubbers, coils produce very

large voltage spikes when de-energizing that can cause malfunction or destruction of electronic

circuits.

Open the cover of the enclosure. ACI recommends 16 to 26 AWG twisted pair wires or shielded cable

for all transmitters. Refer to FIGURE 3 for wiring diagrams. All wiring must comply with all local and

National Electric Codes.

Note: The 4-20mA output requires 3 wires.

Note: When using a shielded cable, be sure to connect only (1) end of the shield to ground at the

controller. Connecting both ends of the shield to ground may cause a ground loop. When removing the

shield from the sensor end, make sure to properly trim the shield to prevent any chance of shorting.

DIP SWITCH CONFIGURATION

SW 1 sets the Output Signal.

SW2 controls the ABC Logic.

The default setting is 0-10 VDC output (switch 1 on) and ABC on (switch 2 on). For 0-5 VDC output set

switch 1 to o. The 4-20 mA output can be used with switch 1 in the on or o position.

ABC stands for automatic baseline correction, a self-calibration function for achieving maintenance-free

gas sensors. To turn o ABC, set switch 2 to o. The ABC Logic must be turned o in applications where

there is 24/7 occupancy. ie: Hospital

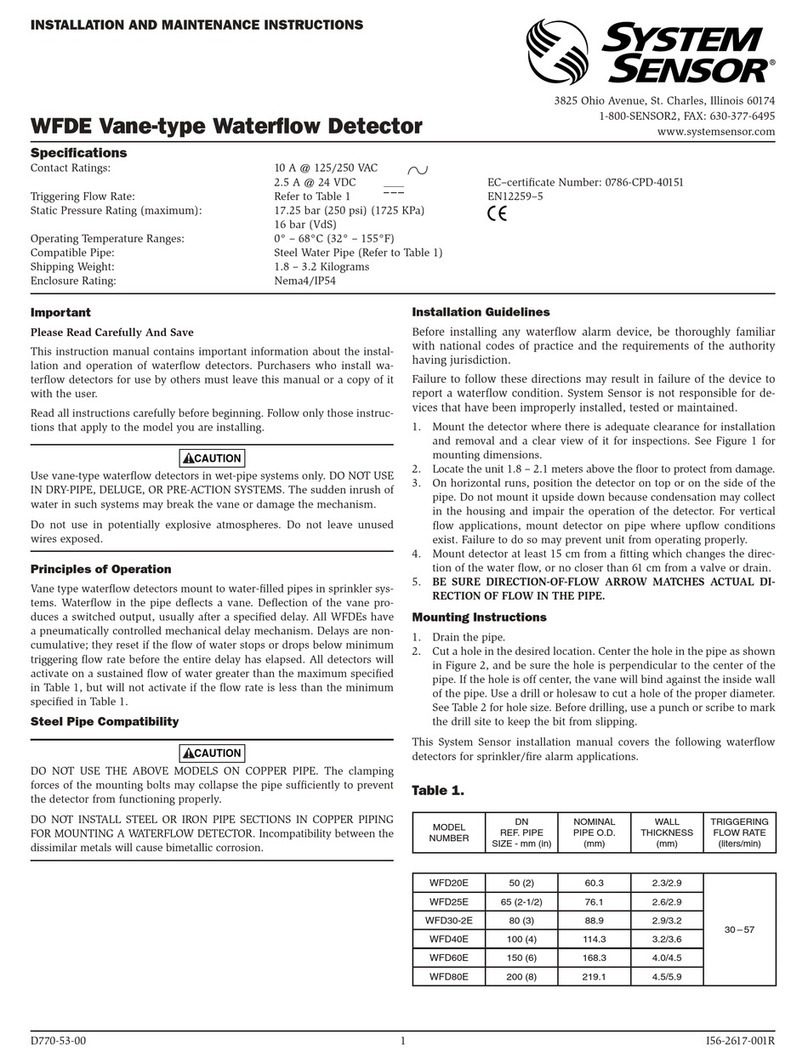

FIGURE 2: MOUNTING FIGURE 3: WIRING

0-10 or 0-5 VDC

4-20 mA

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 2

Version: 4.0

I0000744

GENERAL INFORMATION

The ACI Carbon Dioxide Duct Series (A/CO2-D)

monitors the carbon dioxide (CO2) levels in

industrial, commercial, school, and oce-type

environments. The concentration of CO2 is a

strong indication of the overall indoor air

quality. The A/CO2 Series is based on a single

beam, non-dispersive infrared technology

and is a cost-ecient solution for measuring

carbon dioxide levels for building climate

control. In addition, ABC software eliminates

the need for manual calibration. Carbon

Dioxide concentration is measured up to

2,000 ppm and is converted into proportional

analog outputs. The factory default output is

4-20 mA, whereas 0-5 VDC and 0-10 VDC

outputs are eld selectable via integral dip

switches. The A/CO2-D provides data which

can be used in conjunction with a Building

Automation System or Demand Control

Ventilation to decrease energy consumption while creating a healthier indoor climate.

MOUNTING INSTRUCTIONS

Since there might be a substantial pressure dierence in duct mounting applications, it is essential to avoid

ambient air from suction into the duct mounting box. For correct function it is indispensable that the

sealing of the box cover, the cable entry bushings, the cable feed through and the duct entrance are

absolutely tight.The duct entrance may need extra sealing paste in order to prevent leakage. The PCB must

be handed carefully and protected from electrostatic discharge.

• Place the O-ring around the hole at the back of the box. See figure 2.

• Electrical cable entry: The box has a factory mounted cable entry bushing. Never feed more than one

cable through each cable entry bushing, or else gas might leak through!

• Mounting the tube: Drill a 1” (25 mm) diameter hole for the sampling probe and two holes with 0.16” (4

mm) diameter for the screws (5) into the air duct and mount the tube (1) with the gasket (2). The sampling

probe should be mounted with the largest locking knob on top. The unit can be mounted with the air

coming from the left or right.

• Attaching the sensor box is made to the sampling probe by a snap-in bayonet tting. Orient the box onto

the sampling probe so that the box upside is on the same side as the largest locking knob (3). When the

probe is tted into the notches of the box, then turn the box clockwise until stop (see Figure 2). Position 1

indicates open where the box can be removed from the sampling probe. In position 2 the box is locked to

the probe.

+24 VDC or 24 VAC

Supply Voltage

Ground or Signal Common

0-5 or 0-10 VDC Output

+24 VDC or 24 VAC

Supply Voltage

Ground or Signal Common

4-20mA Output

WIRING

PRECAUTIONS

• Remove power before wiring. Never

connect or disconnect wiring with power

applied.

• When using a shielded cable, ground the

shield only at the controller end.

Grounding both ends can cause a ground

loop.

• It is recommended you use an isolated

UL-listed class 2 transformer when

powering the unit with 24 VAC. Failure to

wire the devices with the correct polarity

when sharing transformers may result in

damage to any device powered by the

shared transformer.

• If the 24 VDC or 24VAC power is shared

with devices that have coils such as

relays, solenoids, or other inductors,

each coil must have an MOV, DC/AC

Transorb, Transient Voltage Suppressor

(ACI Part: 142583), or diode placed across

the coil or inductor. The cathode, or

banded side of the DC Transorb or diode,

connects to the positive side of the power supply. Without these snubbers, coils produce very

large voltage spikes when de-energizing that can cause malfunction or destruction of electronic

circuits.

Open the cover of the enclosure. ACI recommends 16 to 26 AWG twisted pair wires or shielded cable

for all transmitters. Refer to FIGURE 3 for wiring diagrams. All wiring must comply with all local and

National Electric Codes.

Note: The 4-20mA output requires 3 wires.

NES

SW POT

4-20mA VIN COM

NES

VOUT

SW POT

Note: When using a shielded cable, be sure to connect only (1) end of the shield to ground at the

controller. Connecting both ends of the shield to ground may cause a ground loop. When removing the

shield from the sensor end, make sure to properly trim the shield to prevent any chance of shorting.

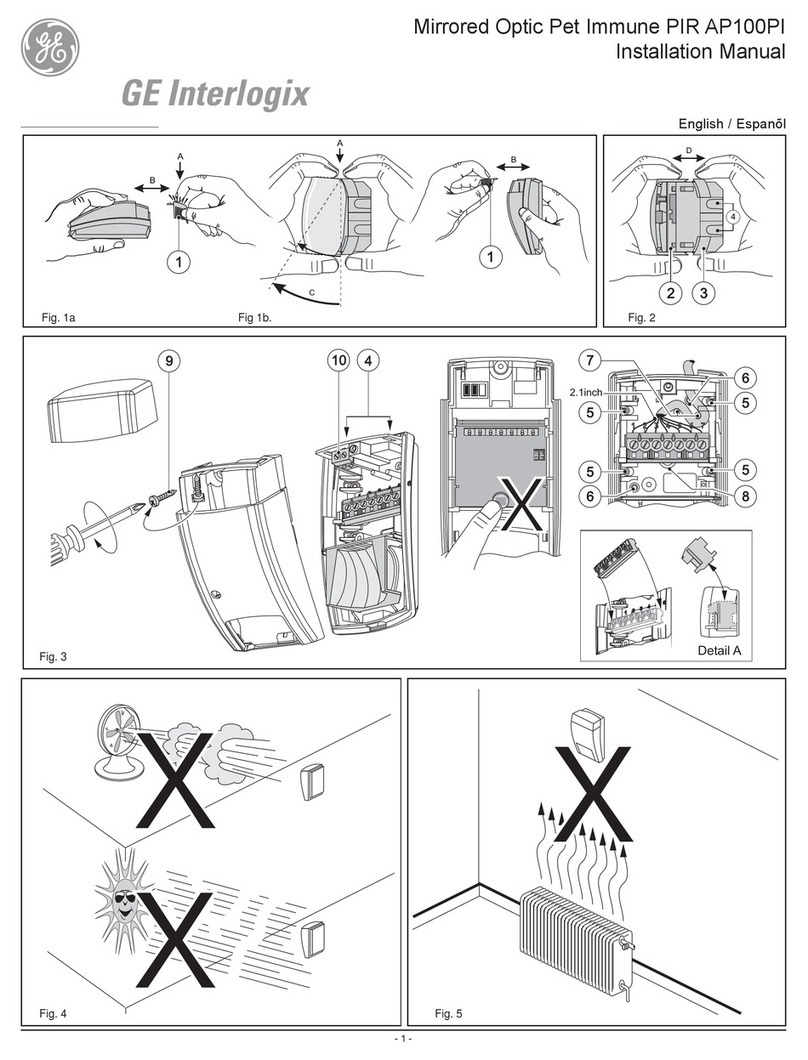

DIP SWITCH CONFIGURATION

SW 1 sets the Output Signal.

SW2 controls the ABC Logic.

The default setting is 0-10 VDC output (switch 1 on) and ABC on (switch 2 on). For 0-5 VDC output set

switch 1 to o. The 4-20 mA output can be used with switch 1 in the on or o position.

ABC stands for automatic baseline correction, a self-calibration function for achieving maintenance-free

gas sensors. To turn o ABC, set switch 2 to o. The ABC Logic must be turned o in applications where

there is 24/7 occupancy. ie: Hospital

4-20mA VIN COM VOUT

GENERAL INFORMATION

The ACI Carbon Dioxide Duct Series (A/CO2-D)

monitors the carbon dioxide (CO2) levels in

industrial, commercial, school, and oce-type

environments. The concentration of CO2 is a

strong indication of the overall indoor air

quality. The A/CO2 Series is based on a single

beam, non-dispersive infrared technology

and is a cost-ecient solution for measuring

carbon dioxide levels for building climate

control. In addition, ABC software eliminates

the need for manual calibration. Carbon

Dioxide concentration is measured up to

2,000 ppm and is converted into proportional

analog outputs. The factory default output is

4-20 mA, whereas 0-5 VDC and 0-10 VDC

outputs are eld selectable via integral dip

switches. The A/CO2-D provides data which

can be used in conjunction with a Building

Automation System or Demand Control

Ventilation to decrease energy consumption while creating a healthier indoor climate.

MOUNTING INSTRUCTIONS

Since there might be a substantial pressure dierence in duct mounting applications, it is essential to avoid

ambient air from suction into the duct mounting box. For correct function it is indispensable that the

sealing of the box cover, the cable entry bushings, the cable feed through and the duct entrance are

absolutely tight.The duct entrance may need extra sealing paste in order to prevent leakage. The PCB must

be handed carefully and protected from electrostatic discharge.

• Place the O-ring around the hole at the back of the box. See figure 2.

• Electrical cable entry: The box has a factory mounted cable entry bushing. Never feed more than one

cable through each cable entry bushing, or else gas might leak through!

• Mounting the tube: Drill a 1” (25 mm) diameter hole for the sampling probe and two holes with 0.16” (4

mm) diameter for the screws (5) into the air duct and mount the tube (1) with the gasket (2). The sampling

probe should be mounted with the largest locking knob on top. The unit can be mounted with the air

coming from the left or right.

• Attaching the sensor box is made to the sampling probe by a snap-in bayonet tting. Orient the box onto

the sampling probe so that the box upside is on the same side as the largest locking knob (3). When the

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 3

Version: 4.0

I0000744

probe is tted into the notches of the box, then turn the box clockwise until stop (see Figure 2). Position 1

indicates open where the box can be removed from the sampling probe. In position 2 the box is locked to

the probe.

WIRING

PRECAUTIONS

• Remove power before wiring. Never

connect or disconnect wiring with power

applied.

• When using a shielded cable, ground the

shield only at the controller end.

Grounding both ends can cause a ground

loop.

• It is recommended you use an isolated

UL-listed class 2 transformer when

powering the unit with 24 VAC. Failure to

wire the devices with the correct polarity

when sharing transformers may result in

damage to any device powered by the

shared transformer.

• If the 24 VDC or 24VAC power is shared

with devices that have coils such as

relays, solenoids, or other inductors,

each coil must have an MOV, DC/AC

Transorb, Transient Voltage Suppressor

(ACI Part: 142583), or diode placed across

the coil or inductor. The cathode, or

banded side of the DC Transorb or diode,

connects to the positive side of the power supply. Without these snubbers, coils produce very

large voltage spikes when de-energizing that can cause malfunction or destruction of electronic

circuits.

Open the cover of the enclosure. ACI recommends 16 to 26 AWG twisted pair wires or shielded cable

for all transmitters. Refer to FIGURE 3 for wiring diagrams. All wiring must comply with all local and

National Electric Codes.

Note: The 4-20mA output requires 3 wires.

Note: When using a shielded cable, be sure to connect only (1) end of the shield to ground at the

controller. Connecting both ends of the shield to ground may cause a ground loop. When removing the

shield from the sensor end, make sure to properly trim the shield to prevent any chance of shorting.

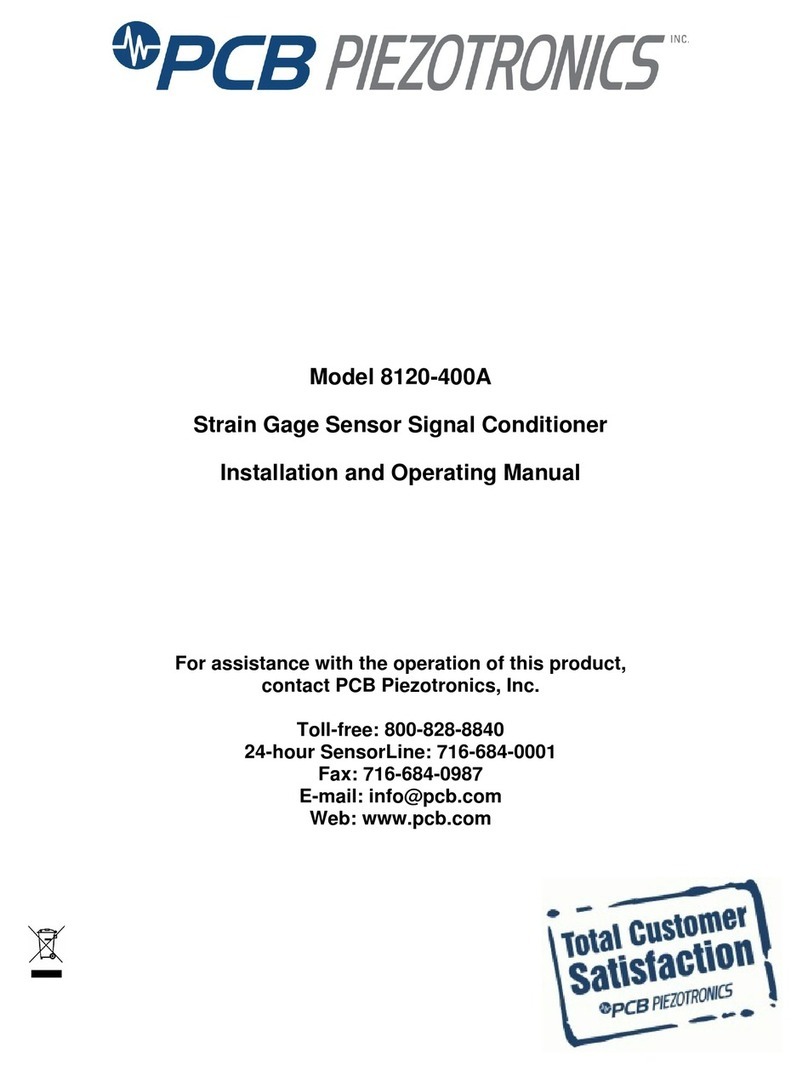

DIP SWITCH CONFIGURATION

SW 1 sets the Output Signal.

SW2 controls the ABC Logic.

The default setting is 0-10 VDC output (switch 1 on) and ABC on (switch 2 on). For 0-5 VDC output set

switch 1 to o. The 4-20 mA output can be used with switch 1 in the on or o position.

ABC stands for automatic baseline correction, a self-calibration function for achieving maintenance-free

gas sensors. To turn o ABC, set switch 2 to o. The ABC Logic must be turned o in applications where

there is 24/7 occupancy. ie: Hospital

FIGURE 4: DIP SWITCH SETTINGS

4-20mA VIN COM VOUT

ON

1 2

DIP SWITCH

PRODUCT SPECIFICATIONS

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 4

Version: 4.0

I0000744

WARRANTY

The A/CO2-DUCT Series is covered by ACI’s Five (5) Year Limited Warranty, which is located in the front of ACI’S

SENSORS & TRANSMITTERS CATALOG or can be found on ACI’s website: www.workaci.com.

24 VAC +/-20%, 50/60 Hz (half-wave rectier) | 16.5-40 VDC Max.

3 VA for 24 VAC, 3W for 24 VDC (peak); <0.9W (average)

Single beam infrared sensing technology (NDIR)

Diusion

0 to 2,000 ppm

Up to 10,000 ppm (factory set)

+/- 30 ppm and +/- 5% of reading

Output 1: 0-5 VDC or 0-10 VDC (Default) | Output 2: 4-20 mA (500 Ohm Load maximum)

Polarity protected

+/- 40 ppm +/- 3% of reading (@ 15-35°C; 20-70% RH and 101.3 kPa)

+ 1.6% reading per kPa (deviation from standard pressure 101.3 kPa)

≤ 2 minutes, diusion

< 1 minute (@ full specs < 15 minutes)

Various (see ordering grid)

+/- 1°F (+/- 0.6ºC)

32 to 122ºF (0 to 50ºC)

0 to 95%, non-condensing

Duct Box: PC & ABS blend, Flammability Rating UL94V-0

Cover: Makrolon® 6555 plastic, Flammability Rating UL94V-0

Pipe: PC & ABS blend, Flammability Rating UL94V-0

7,500 sq. ft maximum

4-6 ft

> 15 years (typical)

ABC algorithm (Automatic Baseline Correction)

NON-SPECIFIC INFORMATION

Supply Voltage:

Power Consumption:

Sensing Technology:

Sensing Method:

Measurement Range Default:

Extended CO2 Ranges:

Extended Range Accuracy:

CO2 Output Signal:

Fail Safe:

CO2 Accuracy :

Pressure Dependence:

Response Time:

Warm-Up Time:

Temperature Output Range:

Temperature Accuracy:

Operating Temperature Range:

Operating Humidity Range:

Enclosure:

Sensor Coverage Area:

Mounting Height:

Sensor Life :

Calibration

Note : Accuracy is dered after minimum three (3) ABC periods (1 period = 8 days) of continous operations | Note : In normal indoor air

quality (IAQ) applications | Corrosive environments are excluded | Note : Building CO2 levels must drop to 400 ppm same time during the

week for ABC to work properly | If the building is occupied 24 hours / day, ABC must be turned o

This manual suits for next models

1

Other aci Security Sensor manuals

Popular Security Sensor manuals by other brands

System Sensor

System Sensor WFDE Series Installation and maintenance instructions

PCB Piezotronics

PCB Piezotronics 8120-400A Installation and operating manual

Axis

Axis F1004 installation guide

Wren

Wren HYPERION HYP-PP180R-B installation guide

Honeywell

Honeywell Miller Revolution Harness manual

MSA

MSA General Monitors TL105 instruction manual