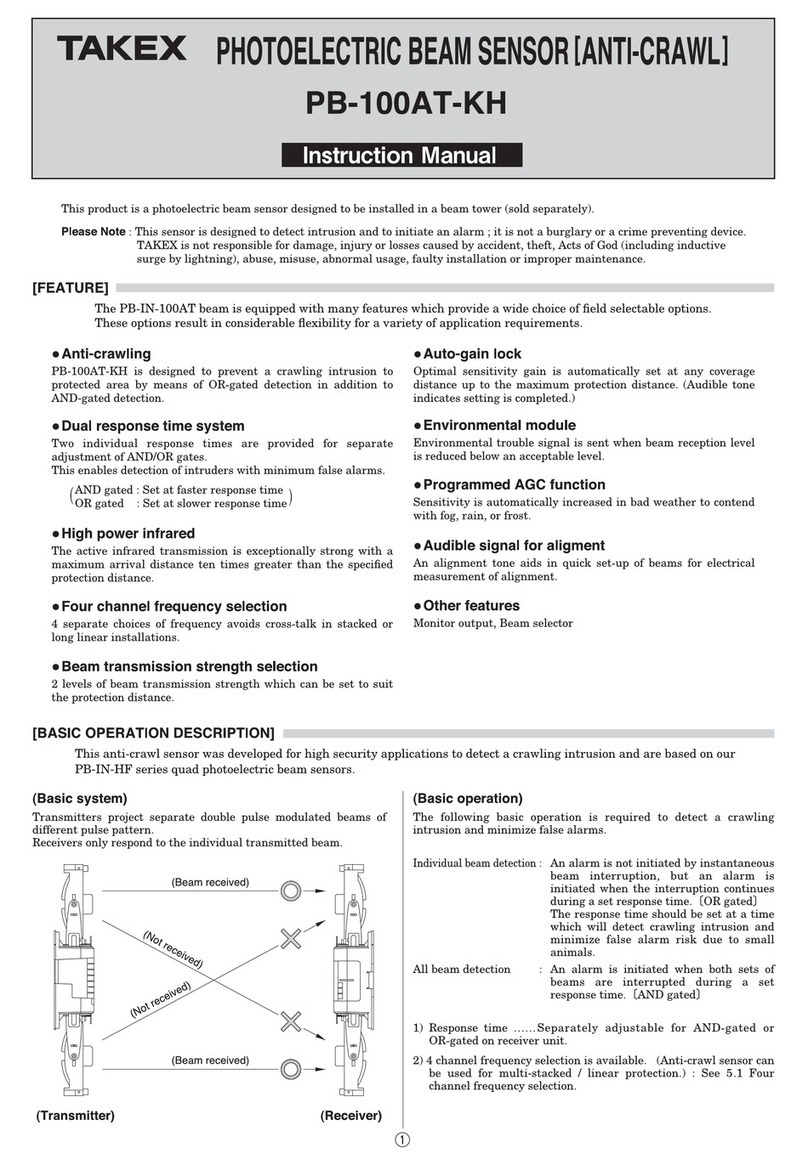

Symptoms Possible cause Remedy

Operation LED 1. Disruption of power or inadequate power 1. Correct power source

does not light 2. Bad wiring connection or broken wire, short 2. Check and correct wiring

Receiver Alarm 1. Disruption of power or inadequate power 1. Correct power source

LED does not 2. Bad wiring connection or broken wire, short 2. Check and correct wiring

light when the 3. Reflection of beam is flooding receiver and 3. Remove reflecting object. Set beam power to

beam is broken sent into the receiver Low. Contact TAKEX for further remedies

4. Four beams are not broken simultaneously 4. Ensure all beams are broken at same time

5. Beam interruption time is shorter than response time 5. Adjust response time

Receiver Alarm 1. Alignment is off 1. Check and adjust

LED stays on 2. Shading object between transmitter and receiver 2. Check site/remove any possible obstacles

3. Optics of units are soiled 3. Clean the optics with a soft cloth

4. Frequency channel setting on transmitter 4. Readjust to be the same channel

does not match with that on receiver

Intermittent alarm 1. Bad wiring connection 1. Check again

2. Change of supply voltage 2. Stabilise supply voltage

3. Shading object between transmitter and receiver 3. Remove the shading object

4. The wiring of power machine is located nearby 4. Change the place for installation

transmitter and receiver

5. Stabilise 5. Unstable installation of transmitter and receiver

6. Optics of units are soiled 6. Clean the optics with soft cloth

7. Improper alignment 7. Check and re-adjust

8. Small animals may pass through the 4 beams 8. Change environments or the place for installation

9. Beam power switch is set at L, which does not 9. Set beam power switch at H and make the unit

keep enough sensitivity allowance gain-locked with receiver cover detached

Model PB-IN-50HF PB-IN-100HF PB-IN-200HF

Detection System Near infrared beam interruption system

(TR. - RE. 4 beams simultaneous interruption)

Infrared beam Double modulation pulsed beam by LED

Protection Outdoor 165’ Outdoor 330’ Outdoor 660’

distance (50m) or less (100m) or less (200m) or less

Max. arrival Tenfold Tenfold ) Tenfold

distance 1640’ (500m) 3280’ (1000m) 6560’(2000m)

Response time 50msec. to 700msec variable (Standard: 50msec.)

Power Supply 12V to 30V DC (non-polarity)

Current 60mA or less 70mA or less 85mA or less

consumption at protection at protection at protection

(Max. 95mA (Max. 105mA (Max. 120mA

or less) or less) or less)

Alarm Output Dry contact relay output 1c

Reset: interruption time + off-delay (Approx. 1.5 sec.)

Contact capacity: 30V AC/DC, 1A or less

Environmental Dry contact relay: 1a or 1b (switchover)

output Contact operation: Output when weather condition gets worse

Contact capacity: 30V AC/DC,1A or less

Tamper output Dry contact relay: 1b

Contact operation: Output when receiver cover is detached

Contact capacity: 30V AC/DC, 0.1 A or less

Alarm LED Red LED (receiver) lights when an alarm is initiated

Sensitivity Red LED (receiver) lights when beam reception is attenuated

attenuation LED

Functions Modulated beam frequency selection, Tone indicator,

Environmental module, Beam power selection,

Alarm memory indication, Programmed AGC. Auto-gain lock

function. Monitor jack.

Beam adjustment Horizontal: ±90˚, Vertical: ±10˚

Ambient temperature -31˚F to + 151˚F (-35˚C to +66˚C)

Mounting position Outdoor, Indoor

Wiring Terminals

Weight Transmitter: 42 oz (1200g) Receiver : 45.5 oz (1300g)

Appearance PC resin (wine red)

8.

(Units should be tested on a regular weekly basis)