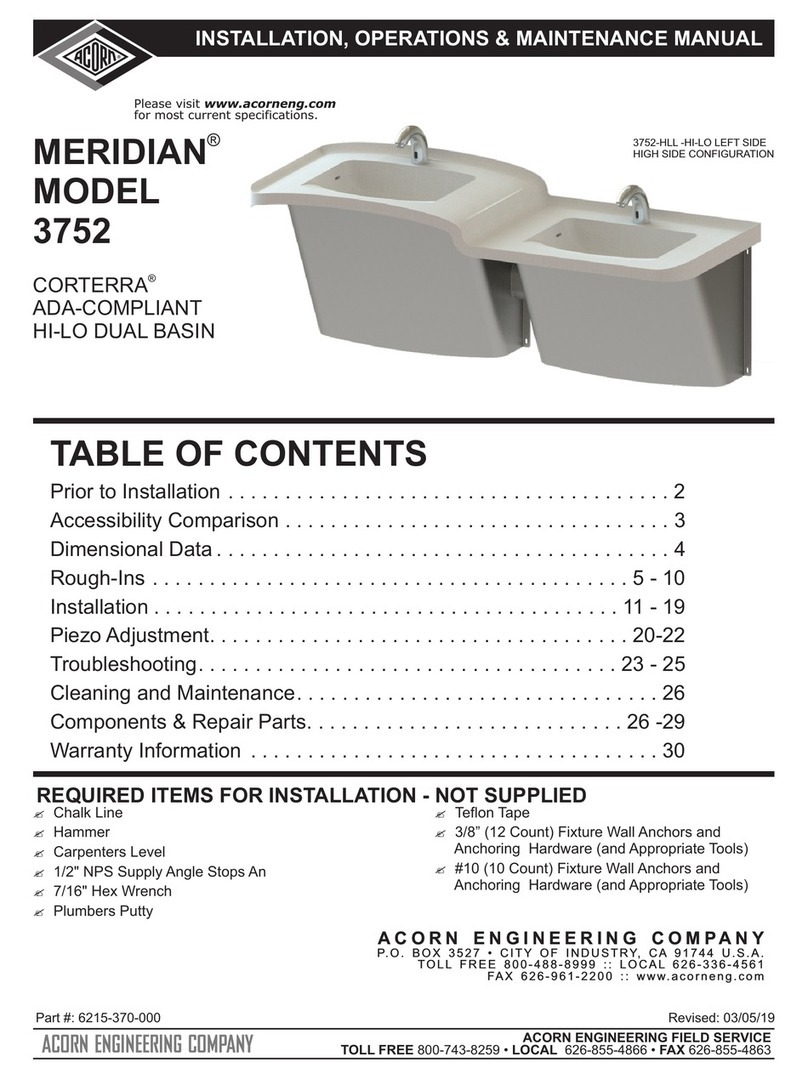

Acorn Neo-Metro WEDGE WSW130 Instruction manual

Other Acorn Plumbing Product manuals

Acorn

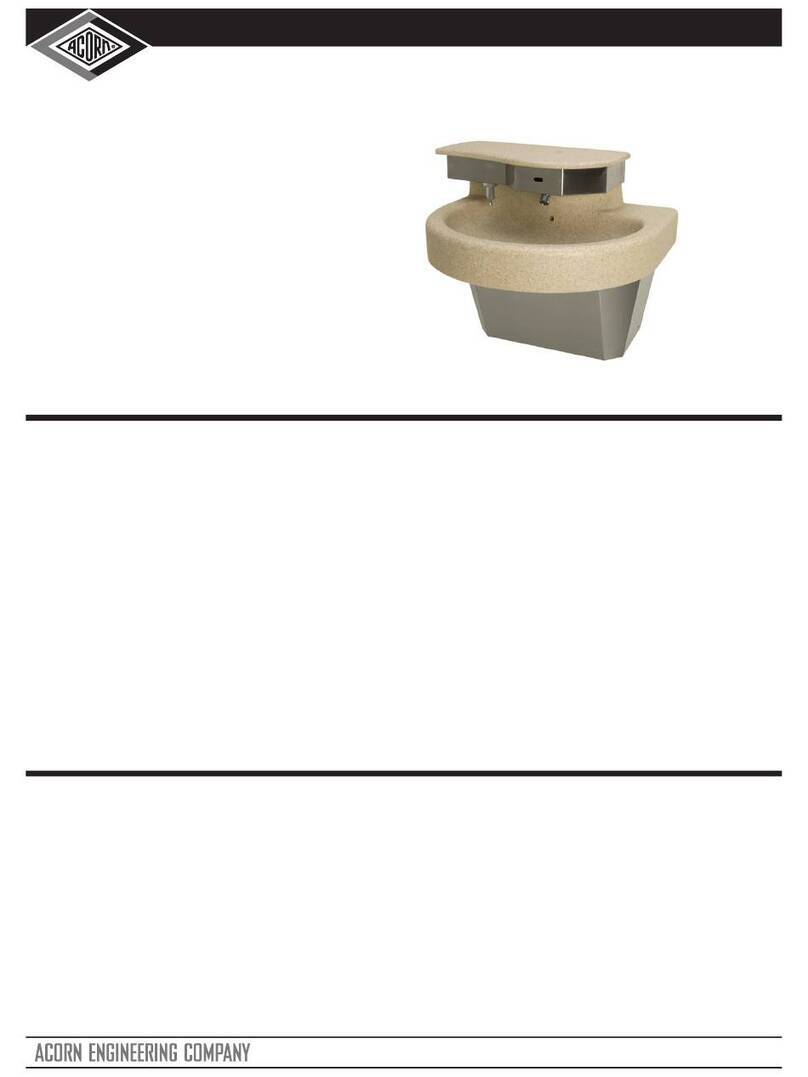

Acorn Meridian 3791-LO User manual

Acorn

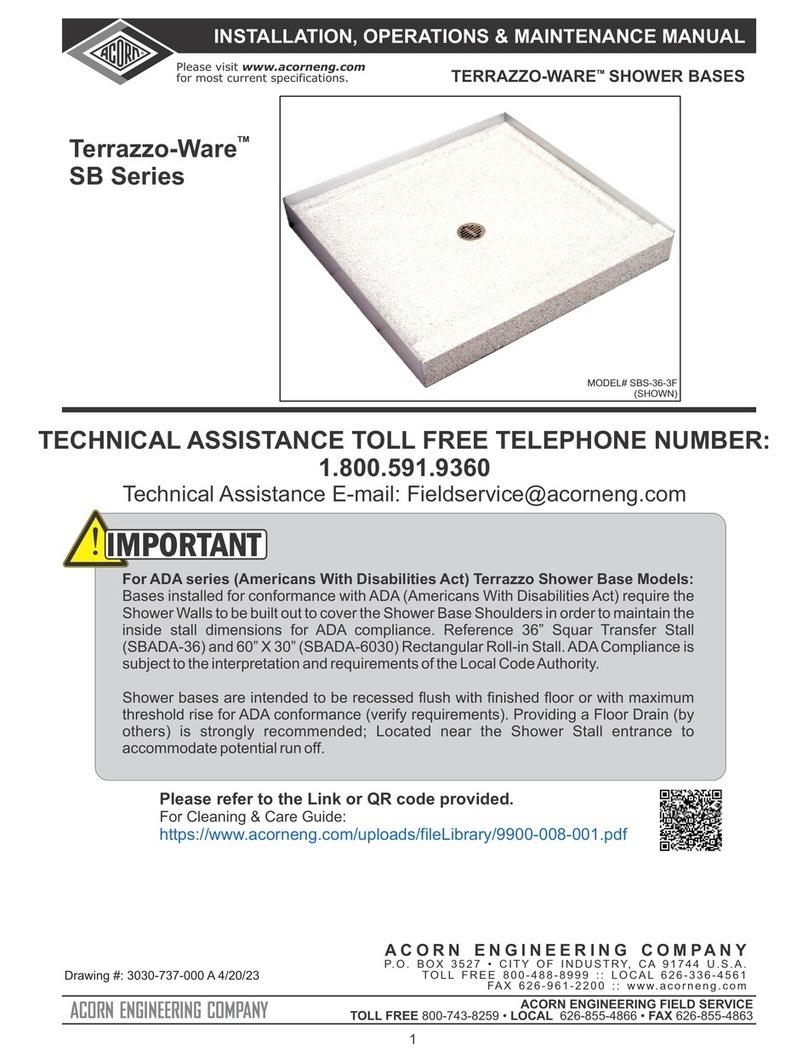

Acorn Terrazzo-Ware SB Series Instruction manual

Acorn

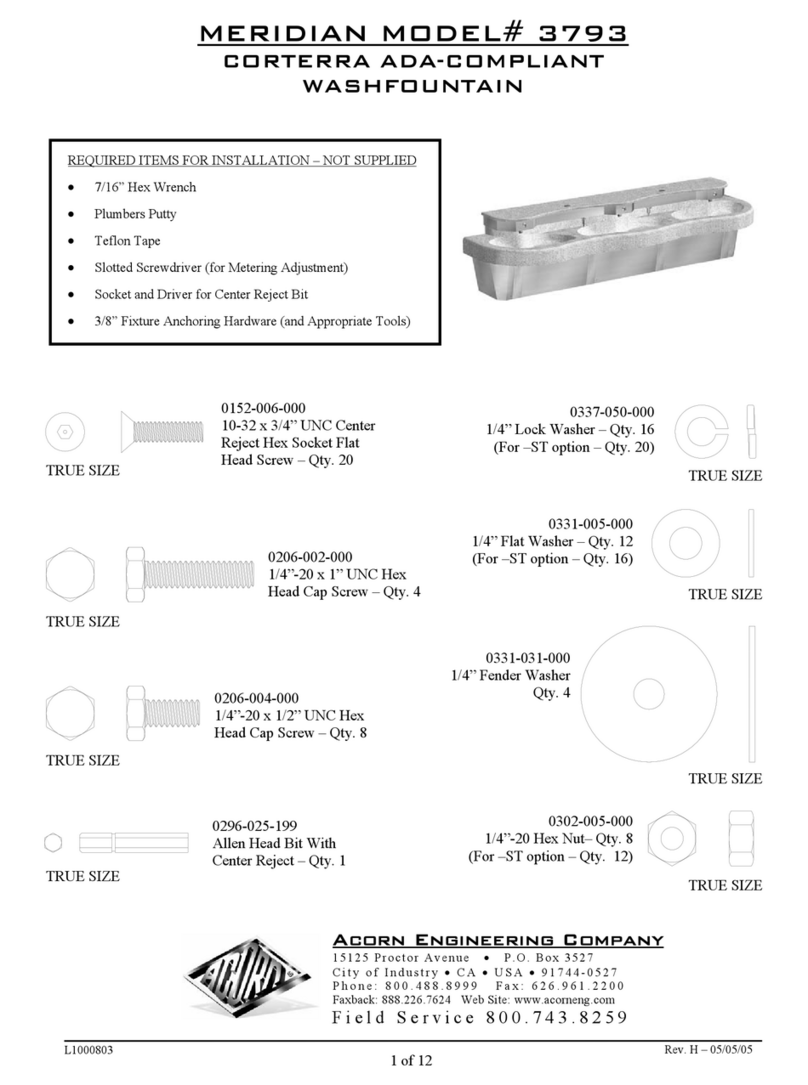

Acorn MERIDIAN 3793 User manual

Acorn

Acorn Meridian 3792 Instruction manual

Acorn

Acorn TERRAZZO-WARE Series Configuration guide

Acorn

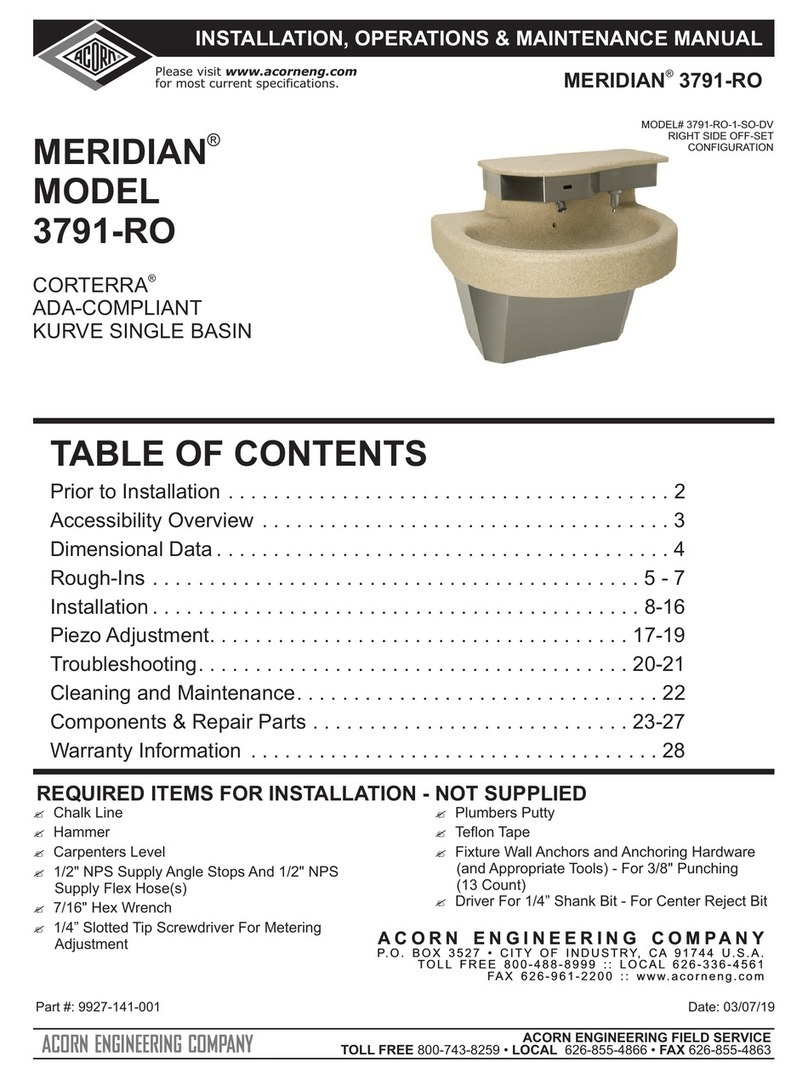

Acorn MERIDIAN 3791-RO Instruction manual

Acorn

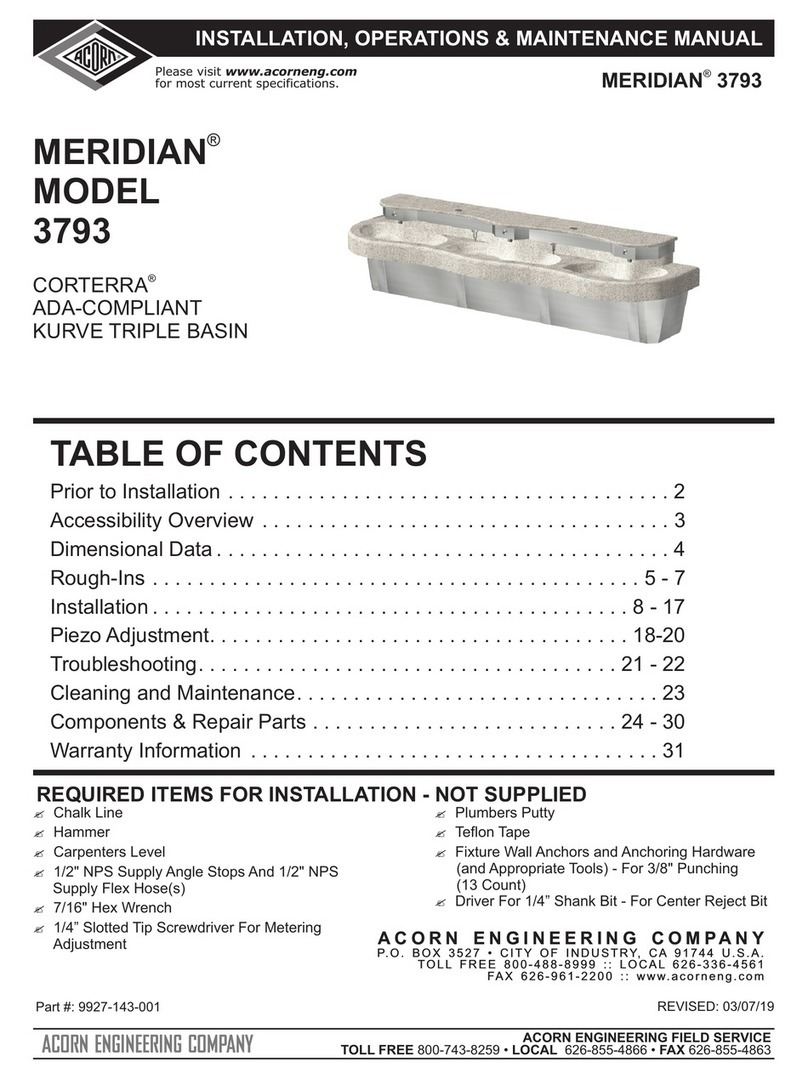

Acorn MERIDIAN 3793 Instruction manual

Acorn

Acorn MERIDIAN 3753-HLH User manual

Acorn

Acorn Meridian Corterra 3751 Instruction manual

Acorn

Acorn NEO-METRO SLAB-EDGE 3802 Instruction manual

Popular Plumbing Product manuals by other brands

Weka

Weka 506.2020.00E ASSEMBLY, USER AND MAINTENANCE INSTRUCTIONS

American Standard

American Standard DetectLink 6072121 manual

Kohler

Kohler K-6228 Installation and care guide

Uponor

Uponor Contec TS Mounting instructions

Pfister

Pfister Selia 49-SL Quick installation guide

Fortis

Fortis VITRINA 6068700 quick start guide

Elkay

Elkay EDF15AC Installation, care & use manual

Hans Grohe

Hans Grohe AXOR Citterio E 36702000 Instructions for use/assembly instructions

baliv

baliv WT-140 manual

Kohler

Kohler Mira Eco Installation & user guide

BELLOSTA

BELLOSTA romina 0308/CC Installation instruction

Bristan

Bristan PS2 BAS C D2 Installation instructions & user guide