Acoustical Systems AQUILAR Series User manual

1

10” and 12” reference tonearm

©

the AOUILAR

picture by Harry Ralston

owner’s manual

picture by

Moritz Teichmann

A brief word

from the designer

My thanks and congratulations to you for choosing the AQUILAR.

The AQUILAR is the result of my more than 35 years of intimate research and

preoccupation with analog playback - with the specic focus on the interaction of the

record groove with the cartridge and tonearm.

The AQUILAR in both versions - the 10” and 12” effective length - is the direct

derivate and distillate from our 12” AXIOM tonearm introduced in 2012.

A truely universal tonearm, which offers all and every option of alignment –

while ensuring the best possible mechanical guidance for any cartridge.

Taking into account the paramount importance of energy transfer in relation to

effective moving mass.

Resulting in a level of performance only obtainable, when each and every aspect

of the analog audio tracking process is attended to with utmost attention to every

minute detail.

A level of performance, which transcends prior frontiers and opens new levels of

musical realism in the playback of recorded music.

We do share the real passion for music and I am condent that the AQUILAR will

allow you to hear and enjoy your favorite records like never before.

Please get yourself accustomed with this manual.

Make sure you familiarise yourself with each and every aspect of the AQUILAR’s

options.

Your time will be rewarded with outstanding performance, to the benet of your

whole analog set-up and ultimately your enjoyment of recorded music.

The AQUILAR is entirely designed, manufactured and assembled with care and

dedication in Bavaria, Germany.

Kind regards

D. D. Brakemeier

Content

Technical features & general design 4

Alignments 4

Step-by-step procedures 5

Single point mounting vs. SME slide base 5

Unpacking the AQUILAR 6

Mounting the AQUILAR 7

Levelling the AQUILAR’s pivot 18

Raising or lowering the pivot plane 19

Removing the ngerlift 21

Exchanging the cartridge mounting plate 22

Setting antiskating 22

Specications 23

AQUILAR alignment template 24

General note:

Technical data, minor design and specications are subject

to change without prior notice.

copyright & design: acoustical systems

Manufactured and assembled in Germany

For further infomations:

www.acoustical-systems.com, info@acoustical-systems.com

11/2017

4

Technical features

& general design

The AQUILAR is a pivot tonearm featuring a

double nano-gimbal bearing architecture.

The AQUILAR is a static, full lateral balanced

design.

The AQUILAR features an unique compound

arm wand - a combination of surface hardened

Titanium and Carbon Fiber pipes blocked

together and internally damped by an all new

design concept, a concept never before

applied in tonearm design and rst featured

in the AXIOM resulting in unmatched fast

energy transfer and total absence of any

parasitic resonances in the tonearm.

The AQUILAR was designed to explore the

possibilities of analog playback to the utmost

degree. To accomplish the best possible analog

playback performance, the AQUILAR offers an

unique complete set of alignment features.

Alignments

Leveling the bearing axis

The AQUILAR can be precisely leveled by

the user, independent from the turntable or

mounting surface. This is essential to avoid

parasitic side-forces prior to alignment and

antiskating setting.

SRA/VTA adjusted at the

cartridge

In the AQUILAR the important alignment(s)

of VTA / SRA can be made at the cartridge –

without altering the static parameters of

the tonearm, while preserving the other set

alignments and leaving the arm wand always

horizontal. This again is of paramount

importance in a static balanced design to avoid

unwanted changes in static settings (namely

tracking force) when changing tonearm height

to accommodate VTA or SRA.

Offset and Overhang

adjustment

Offset is adjusted in the prolonged and slightly

widened slots for the cartridge mounting screws.

Overhang can be adjusted at 2 spots,

both located at the head. First of course in the

prolonged 1/2” slots for the cartridge

mounting screws. Here the slots allow for up

to 5 mm adjustment in overhang and thus

effective length. The 2nd spot is at the collar

of the headshell where it is clamped to the arm

wand. This is an additional spot for further over-

hang adjustment only IF NEEDED.

The whole headshell can be moved back and

forth by up to another 5 mm in this way.

This should hardly ever be necessary.

Azimuth

The headshell’s collar is also the point for

azimuth adjustment. By loosening the clamp

screw the user may rotate the whole headshell in

either direction.

Small indication marks at the rear of the

headshell’s collar and on top of the arm wand

allow for reference and easy return to former

settings.

Dynamic anti-skating

Skating compensation – or anti-skating –

adjustment in the AQUILAR is dynamic and

follows the tangential geometry of the

AQUILAR. If carefully operated, it can be

adjusted during play. However we recommend

that you do ALL adjustment or alignment at the

AQUILAR ONLY with the cartridge / stylus

lifted off the record.

5

Tonearm height – VTA

Tonearm height can be adjusted on the main

VTA-tower of the AQUILAR.

One full turn of the large top knob adjusts

height by precisely 1 mm.

Tangential alignment

It is possible to align the AQUILAR to the

standard tangential curves of Baerwald,

Stevenson or Loefgren in any version and

standard.

The absolute best possible performance

however is obtained only by aligning the

AQUILAR to the new UNI-DIN tangential

curve.

It’s geometric design is uniquely based on

the UNI-DIN, a tangential curve formulated

in 2011.

Step-by-step

procedures

In the next pages I would like to take you

through the mounting and alignment options of

the AQUILAR.

All procedures are illustrated step-by-step.

The pictures will give you most all of the

information you need to perfectly mount and

set-up the AQUILAR.

However, I will guide you through this with

my comments too and try to give further

information whenever the mere picture may

not tell the whole story.

We all like to get a new tool working as fast as

possible.

May I please encourage you to follow me

through this mounting and set-up procedure as

precisely as possible and to the very end - it will

be to your advantage.

This will ensure that you get the best

possible performance from your AQUILAR

and take advantage of all its features and

capabilities.

Single-point mounting vs.

SME slide base

In this manual we will cover the AQUILAR

mounting with the standard 1-point mounting.

In addition there is the option to mount the

AQUILAR easily onto any existing 9” or 10”

SME armboard.

We do offer - as a special order item - a

dedicated SME-slide base for the AQUILAR.

If interested, please ask your dealer for the

SME-slide base for the AQUILAR.

There is no difference in performance between

the 2 mounting options.

We further offer other adaptor mounting plates

for existing armboards upon your request.

If you are in need of a mounting plate for other

existing armboards - to take advantage of

existing pre-drilled armboards - please kindly

check back with your dealer who will contact

us.

GENERAL NOTE

Please make sure prior to setting up

the AQUILAR that your turntable’s

platter and armboard are dead level.

6

Unpacking the

AQUILAR

Please make sure that all parts are present

by unpacking the AQUILAR and all its tools

and accessories:

The AQUILAR suitcase

containing the following:

• the AQUILAR tonearm

• the main HD18 counter weight

• (2) Lateral balance weights

(1) stainless steel, (1) aluminum

• the AQUILAR’s accessory box

The AQUILAR’s accessory box

containing the following:

• AQUILAR alignment template

- detailed description on page 24 -

• (2) black knob ngerscrews

• (2) stainless steel countersunk screws

• (1) white knob ngerscrew with sharp tip

in 8 mm sleeve

• (1) white 20 mm POM adapter

• (2) small white 7 mm spindle hood

• (1) additional 40 mm length stainless

steel lateral rod for heavy cartridge

counterbalancing

• (1) 100 mm long, 3 mm stainless steel pin

• plastic bag with (2) distance stands

• (4) 90° Allen wrenches -

metric sizes 0.89, 1.5, 2.0 and 4.0

• (1) small diameter spirit level

for use on tonearm bearing pivot

7

• (1) 20 mm round dial scale for SRA / VTA

adjustment at headshell

• (3) special M5 mounting screws with

- (1) 20 mm length

- (1) 25 mm length

- (1) 30 mm length

• (1) set of M5 washer and spring ring

Mounting the

AQUILAR

The AQUILAR is mounted with 1 M5 screw

and 1 set of stainless steel washer and spring

ring only.

All you need is a single 5 mm hole in your

armboard to mount the AQUILAR on your

turntable.

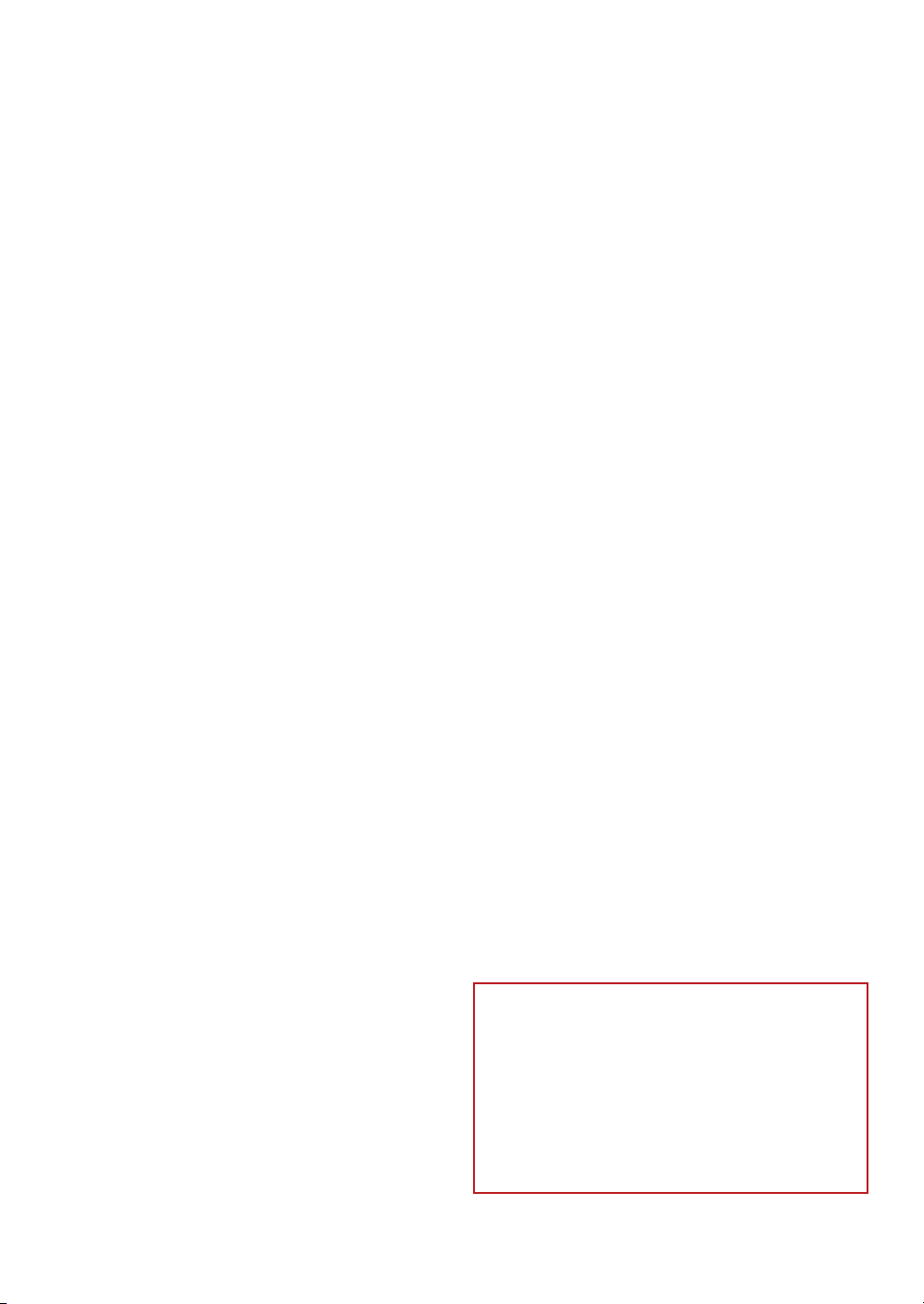

Please take the AQUILAR from its packing

and place it like pictured above.

Now remove the screw in the bottom of

the mounting plate.

Select 1 of the M5 screws in the accessory

box suitable for your armboard. The M5 screw

should be at least 8 mm (1/3”) greater in length

than your armboard’s thickness.

Now take the stainless steel lower mounting

plate and look at it.

The 3 indents have to point upward.

Please take this 50 mm lower mounting plate

and place it onto your armboard with the 3

indents pointing upwards.

The 5 mm center hole should be placed directly

over the 5 mm mounting hole.

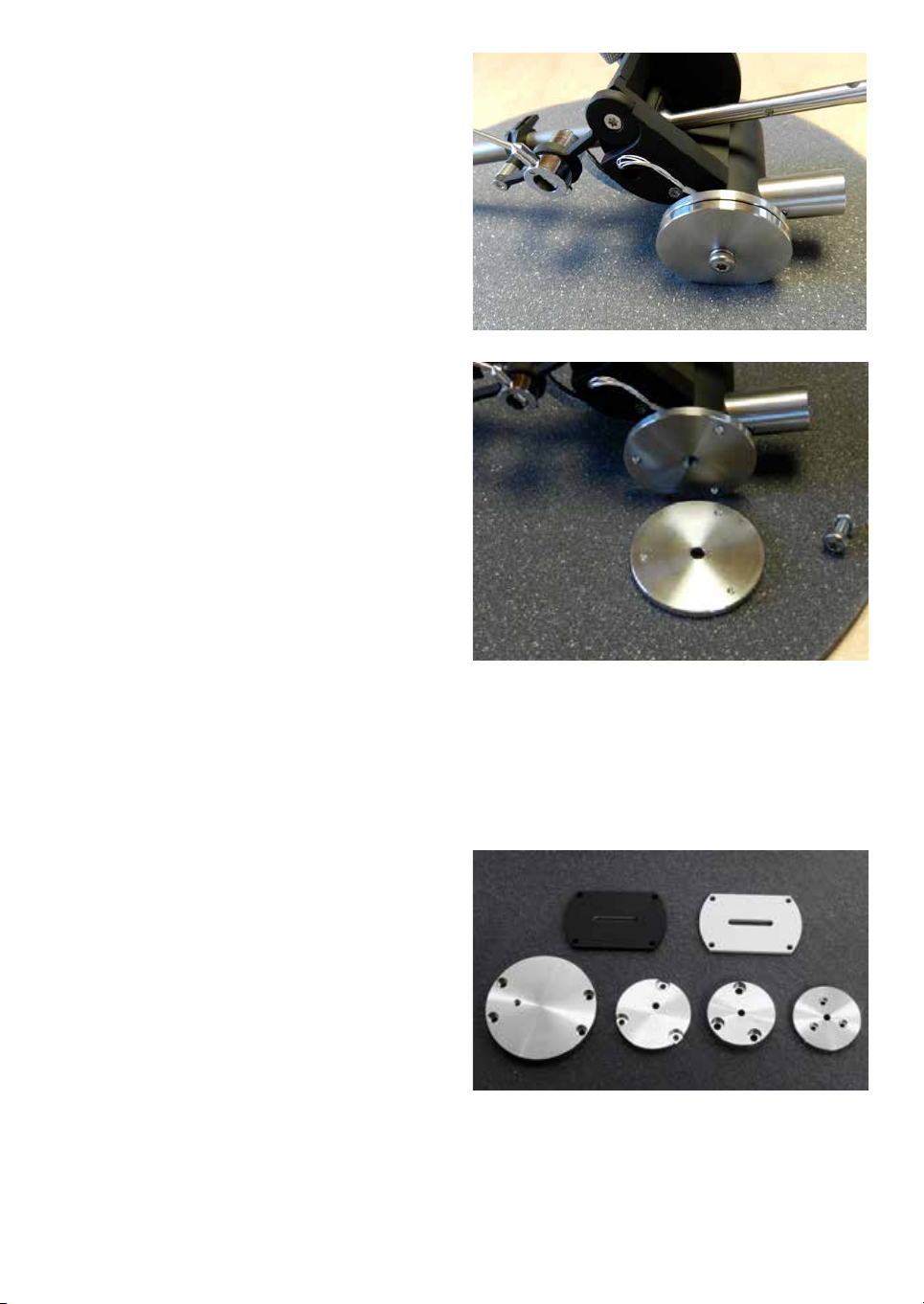

Please note: There is a selection of

mounting plates available to accommo-

date existing arm boards - please ask your

dealer for details.

upper row: SME - slide base

lower row: mounting plates for

Kronos, Jelco, Tri-Planar and Brinkmann

8

Take the selected 20 - 30 mm length M5 screw

with spring ring and washer attached.

Put it up through the suitable center hole on

the turntable mounting board and through

the center hole in the stainless steel lower

mounting plate (3).

Place the whole AQUILAR assembly directly

on top of the M5 screw and secure it in place

by screwing the M5 screw upwards through the

hole in armboard, through the lower mounting

plate into the center pillar of the AQUILAR.

Make sure to position the lower mounting plate

with the indents as pictured (4).

That way you can easily align the 3 levelling

spikes in the upper mounting plate in the

correct position towards the matching indents in

the lower mounting plate.

PLEASE NOTE

The 3 spikes MUST sit in the matching

indentions in the lower mounting plate.

Now tighten the mounting screw JUST A BIT -

not anywhere near maximum strength.

Do not use maximum force, just make sure it is

loosely tightened so that the mounting plate can

still be rotated in the horizontal plane.

The mounting screw will be xed

during levelling the pivot plane.

The AQUILAR is now sitting in place.

If you use the AQUILAR’s alignment

template - detailed description on page 24 -

to determine the mounting distance, please insert

the 100 mm stainless steel pin careful into the

dedicated hole next to the thread for the position-

ing screw. Sharp tip downwards - open M3 thread

pointing upwards (1).

The pin has a sharp tip - be careful! -

this can be used to mark the desiered spot on the

armboard. A controlled gentle hit with a small

hammer on the end of the pin will do (2).

1

2

3

4

9

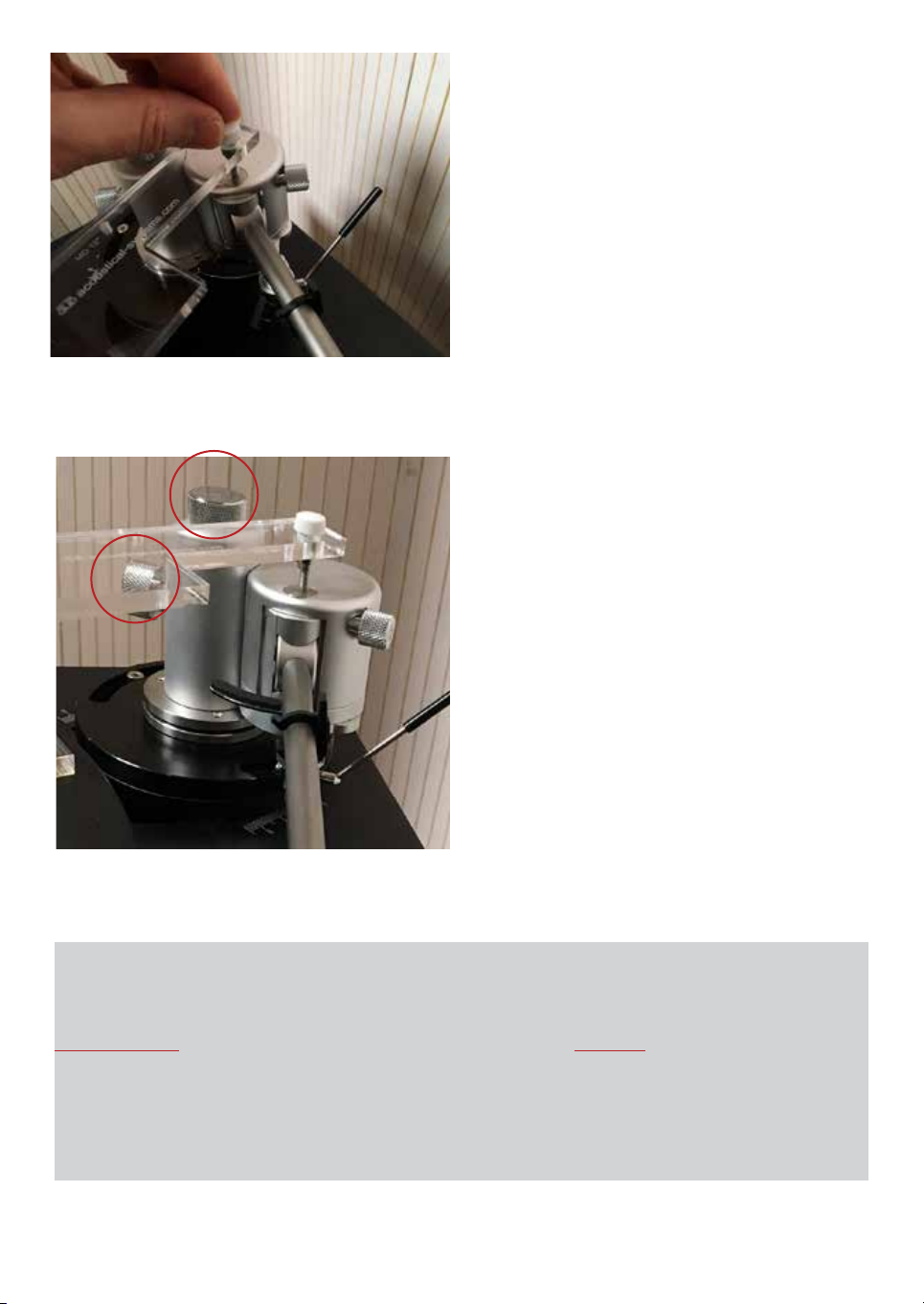

Now use the AQUILAR’s dedicated

alignment template (description on

page 24).

Please see picture for reference - you will

nd all needed mounting gear and tools in the

accessory box.

On top of the AQUILAR’s bearing house is a

12 mm diameter stainless steel plate with a

small center hole. This center hole clearly marks

the pivot center of the AQUILAR (1).

First place the AQUILAR’s alignment

template - with 20 mm white POM spindle ring

in place in the hole in the mirrored tangential

template - onto the spindle of your turntable

(2 + 3).

In its resting position, the inside of the

AQUILAR’s headshell should be

approximately 2” or 5 cm away from the outer

rim of the turntable’s platter.

Now take one of the 2 small 7 mm spindle

adapter hood and SLOWLY and CAREFULLY

place it on top of the spindle and ever so slightly

press down (4). Check which one ts better.

IMPORTANT - be careful!!

DO NOT press down the spindle adapter any

more than 1-2 mm. If you press too hard, you

will have a very hard time getting the white

20 mm POM ring off your spindle again (5).

The 7 mm spindle adapter allows the

precise centering of the alignment tool on a

wide range of spindle diameters.

Remember

Please be careful and do not use any excessive

force. Pushing down realy hard creates a VERY

tight lock which you will have big problems

loosening up again.

1

3

4

5

2

10

Now slide the alignment template into place

with the 8 mm hole thread at the end of its

outward positioning beam over the pivot

locating plate on the AQUILAR.

Now take the white knob ngerscrew and put it

into the 8 mm hole with the tip downwards.

The tip must meet the indention in the center of

the 12 mm pivot plate.

The AQUILAR should be positioned, so that

the underside of the armwand is approximately

2.5 cm / 1” above the turntable’s platter surface.

First you have to unlock the knob screw at

the inward side of the VTA tower by turning it

ONLY 1/4 revolutions anti-clockwise (A).

If you need to adjust for the above desired

height by lifting the AQUILAR in height above

the arm board, adjust the height using the top

VTA knob (B).

A

B

Important:

Always loose locking screw A rst (1/4 turn

only) before doing any height adjustment at

top knob B !

11

Before you proceed to mount the cartridge of

your choice, you rst have to attach the main

counterweight and the lateral weight assembly

to the AQUILAR.

Please remove the lateral weight assembly

as well as the airplane-nose shaped HD18

counterweight from the AQUILAR’s box.

Next take the metric 1,5 Allen key and slightly

turn the screw in the counterbar’s end

anti-clockwise - only about 1-2 revolutions (1).

Now please take the HD18 counterweight and

slide it - narrow head to the front - onto the

stainless steel counterbar (2).

laretal

weights

main

conterweight

2ndary

for 12” 2ndary

for 10”

12

12

Consider a preliminary position like

pictured (1).

You may - even so slightly!! - x the PTFE-

sleeve on the counterbar attending 1 of the 2 M2

grub screws with the 0.89/90 Allen key (2).

In the next step please loosen booth lateral

weights from the 4 mm diameter stainless steel

rod (3).

Select 1 of the 2 lateral weights:

For a cartridge weight of approx.14 grams

or less, please use the aluminium cylinder

(matt silver in color and light weight).

For a cartridge body weight of 15 to 25

grams please select the stainless steel lateral

weight (higher weight).

For a cartridge weight of 26 to 31 grams,

please select the extra long rod from the

accessory box and use both lateral weights.

Such a weight is unlikely, nevertheless it can

be accomodated as described in detail later

in this manual.

Fix the aluminum (or stainless steel) cylinder

again at the end of the rod.

Now slide the rod into the inward pointing side

of the through hole in the end of the

counterbar.

This position ensures perfect lateral balance

with the geometry of the AQUILAR.

1

2

3

13

Please x the rod - with the end just meeting the

opening of the through hole - by attending again

to the M3 grub screw at the end (1).

Settings in pictures (2 + 3) and (4 + 5) are both

possible and correct.

1

2 3

4 5

14

In case you are working with an unusually

heavy cartridge weighing in at more than

25 grams, you may need to use both lateral

weights to counterbalance that cartridge.

It is unlikely, that such a cartridge is used -

however we never know what the future brings

and your AQUILAR is able to counterbalance

a wider range of cartridge weights than most

other tonearms.

Now position the aluminum lateral weight left

(outward - A) of the counterbar and the

stainless steel lateral weight right (inward - B)

onto the 4 mm rod.

The aluminum lateral weight has to be

positioned as pictured, otherwise there is no

perfect lateral balance possible. AB

15

How to mount your cartridge

of choice for best performance

Here are just some standard recommendations:

For mounting your cartridge, please use

NON- magnetic M2.5 screws and plastic

washers under the screws head. We recommend

using Titanium screws.

If you can’t use Titanium screws, please use

brass/gun metal M2.5 screws. They are non-

magnetic and provide good energy transfer.

Aluminum is too soft and does not give enough

coupling for perfect energy transfer.

Stainless steel screws always have a minimum

of magnetism - do not use them. You will loose

sound quality.

Do use, if possible, a torque driver with

precisely adjustable settings.

For M2.5 cartridge screws please use torque

settings according to 80-90% of maximum as

recommended by German engineering norm for

DIN 912.

This ensures perfect energy transfer - and

thus gives you the most dynamic and detailed,

uncolored sound from your cartridge.

Detailed recommendations regarding mounting

screws, settings and special tools are available

from acoustical-systems upon your request.

Recommended torque values for

cartridge mounting screws for

optimum energy transfer

M2.5 torque

Titanium 0.75 Nm = 75 cNm

Stainless steel 0.58 Nm = 58 cNm

Brass 0.45 Nm = 45 cNm

Aluminium 0.35 Nm = 35 cNm

Recommended top quality torque drivers

left: xed torque

middle and right: adjustable torque

Best sonic results can be obtained with the

special SMARTscrews made out of Titanium

Timet 1100 (if you are interested please ask

your dealer).

16

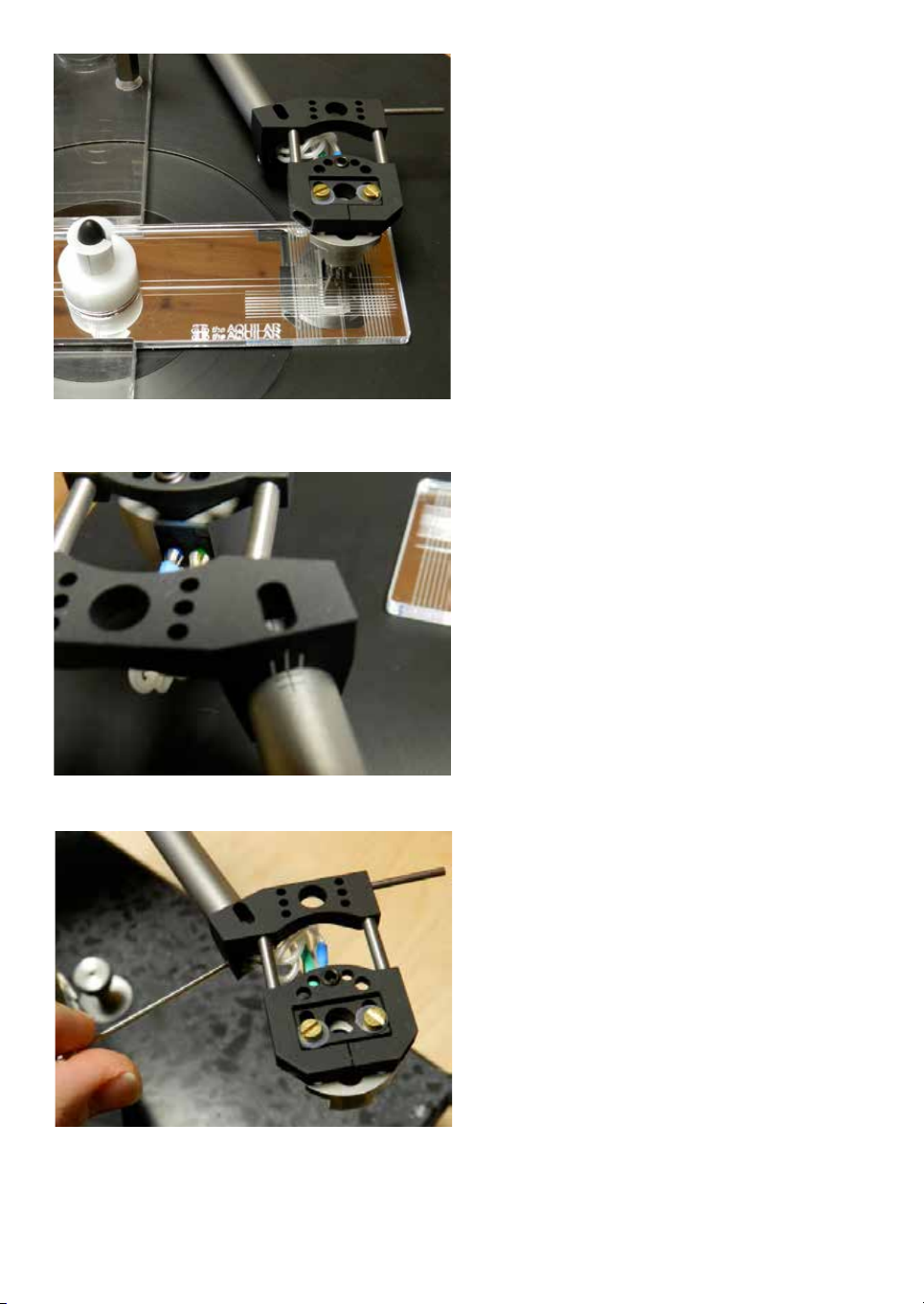

The AQUILAR’s mirrored alignment

template ensures a super precise 1-point

alignment to the UNI-DIN tangential curve.

The AQUILAR’s geometry is tailored to the

UNI-DIN geometry designed and introduced by

acoustical systems in 2011.

If you are interested in the background of this

all-new tangential alignment - please check back

on acoustical-systems.com website for an essay

I have written about UNI-DIN and its unique

features.

Make sure that the stylus meets the single point

sweet spot in the mirrored template while your

cartridge’s cantilever is in line with the center

line behind the sweet spot.

The template features the same precision and

construction as our SMARTractor universal

alignment tool.

Should you need to adjust azimuth, please look

at the rear collar of the AQUILAR’s headshell.

The markings will allow easy return to former

settings and give you a good indication of

direction and position.

You need to completely loosen the inward

pointing lockscrew on the left hand lower side

of the headshell’s collar, using the long silver

Allen key.

The question will come - thus I will answer

it right here: Why is the headshell lock screw

located left side for left hand operation and not

right (outward) side?

Well, why not? - Actually half the world’s

population is left handed .... as is the majority

of our staff!

Do lock the screw again after nding the right

azimuth.

17

The AQUILAR is one of only two tonearms on

the market - the other being it’s “brother” the

AXIOM - allowing you to set SRA and VTA at

the cartridge without altering static settings.

If you need to adjust SRA / VTA, rst loosen

the hidden screw on the left front side in the

AQUILAR’s headshell.

This screw actually tightens a clamp xing the

mounting plate in place.

Untighten this clamp by turning the screw

anti-clockwise for half a revolution - 180° turn

of the 1.5 Allen wrench.

Now take the 2.0 Allen key in the

accessory box for adjusting the grub screw at

the rear top end of the headshell.

Clockwise rotation will turn down the tail of the

cartridge and thus will decrease the SRA°.

The total mounting plate angle allows for freely

changing SRA for most all cartridges from 97°

down to 84°.

To accomplish this for other 10” tonearms you

would need to move them up and down their

towers by more than 2.5” up and 2.5” down -

practically impossible.

Likewise this change in SRA will of course also

inuence the VTA angle of your cantilever.

To raise the SRA° make some “room” rst by

turning the set screw up to the desired position.

Now with 1 nger carefully press the rear

bottom of your cartridge upwards.

When done, please tighten the headshell clamp

again by turning the screw clockwise.

You can use the 20 mm round scale to return

to former settings and keep track of SRA

adjustment.

18

Levelling the

AQUILAR’s pivot

Another very important feature in the

AQUILAR which is rarely found in tonearm

designs: The AQUILAR allows the precise

levelling of the horizontal pivot plane -

independent from the armboard or turntable

plinth.

This is where the 3 spikes in the upper

mounting plate come into action.

Please take the long sliver ball-head 2.0 mm

Allen key and position the small blue precision

spirit level on top of the 12 mm pivot plate.

Adjust the position of the spikes so that the

spirit level bubble is centered. The 3 spikes in

120° on a circle to each other allow for precise

levelling. Adjusting the top of the spike

clockwise makes it go down, thus lifting up that

part of the upper mounting plate and results in

the bubble moving towards that spike.

After a few moments you will get used to this

procedure and will have no problems getting

perfect level of your pivot in just 1-2 minutes.

Peek at the spirit level from directly above the

pivot by using only your dominant eye while

closing the other.

This is to make sure you have no parallax error

in your sight during this setting.

19

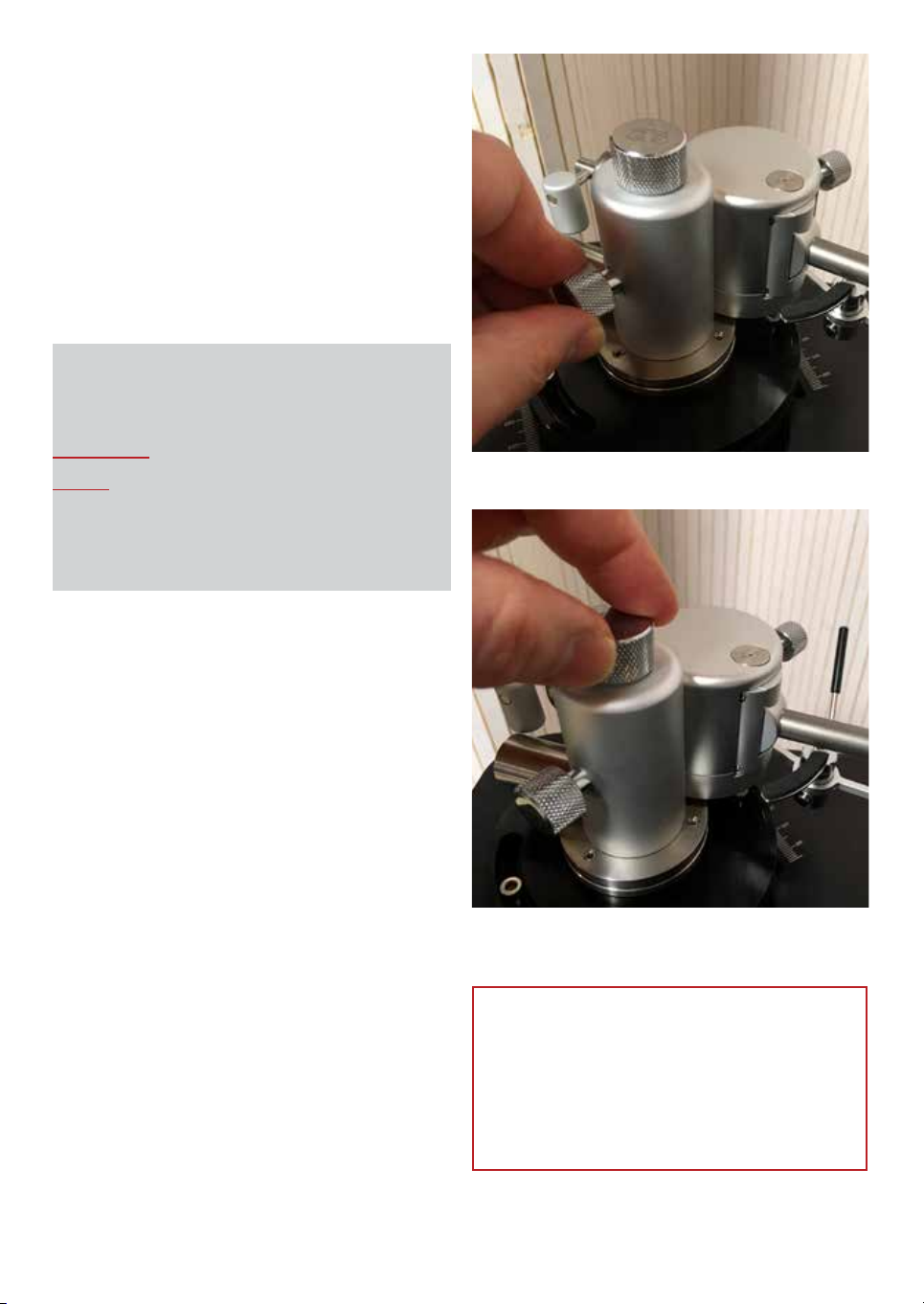

Raising or lowering the

AQUILAR’s pivot plane

Unscrew the lock screw on the inward

side of the VTA tower by turning it 90°

anti-clockwise.

Just a quarter of a revolution of the lock screw -

90° - is enough.

Now you can lower or lift the AQUILAR by

turning the top screw.

After you have reached the desired height,

please - gently!! - fasten the side lock screw

again.

Excessive force is never needed anywhere on

the AQUILAR. And it has absolutely no benet

whatsoever.

IMPORTANT - PLEASE NOTE

We always recommend doing all

adjustments requiring hand action

only while the stylus is lifted off the

groove.

Important:

Always loose locking screw A

rst (1/4 turn only) before

doing any height adjustment

at top knob B !

A

B

20

The AQUILAR features (2) laser engraved

height scales in its inner stainless steel pillar.

One height scale is visible from the front and

the other is visible from the inward side.

If you muse to mount the AQUILAR as a

“secondary” tonearm on a turntable featuring 2

or more armbases, know that we have specially

catered for this by providing this additional

feature of the 2nd scale on the inward pointing

side.

This manual suits for next models

2

Table of contents

Other Acoustical Systems Accessories manuals