A failure to observe the relevant information will render the manufacturer’s liability

null and void.

The safety-at-work and accident prevention regulations specific to each country must

be complied with. In particular, a person performing special work at height must be

suitably secured.

The notes on the product and its packaging must be observed.

2. Installation:

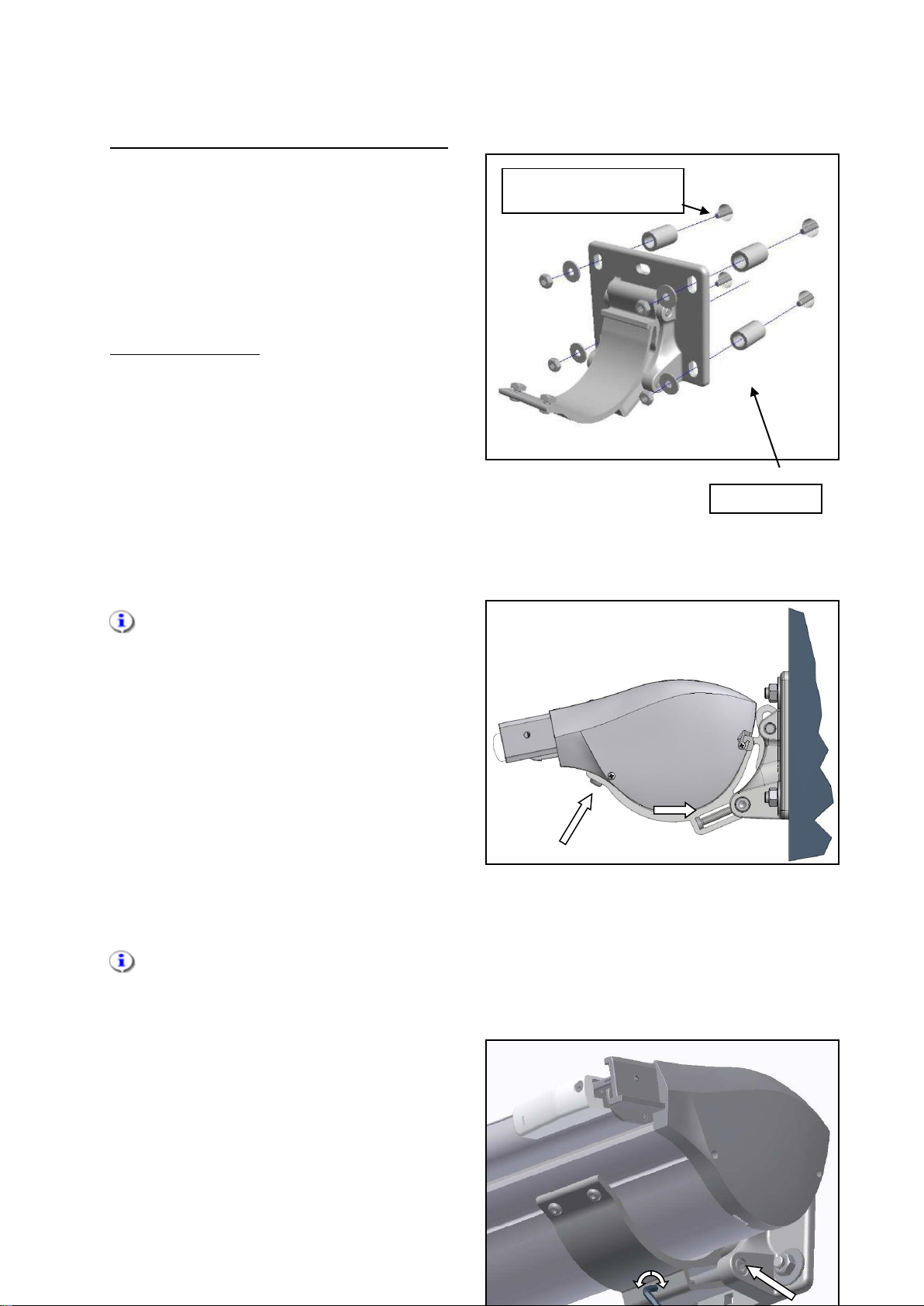

2.1. Tools, resources and materials:

•Measuring tape 10m

•(Percussion) drilling machine

•Cordless screwdriver

•Drill bits, suitable for the drilling substrate and the mounting pieces

•SW 4, SW 5; SW 6 and SW 8 Allen keys

•Torx bit Tx 25

•Ratchet (catrake) with extension and sockets, respectively ring spanners SW 13 and

SW 17

•Steel drill bits, diameter 4.5mm and 5.5mm

•Spirit level and string for alignment of the brackets

•Test cable, resp. adjustment set (for initial operation)

•Aluminium chop saw to shorten the posts

2.2. Preparing the installation:

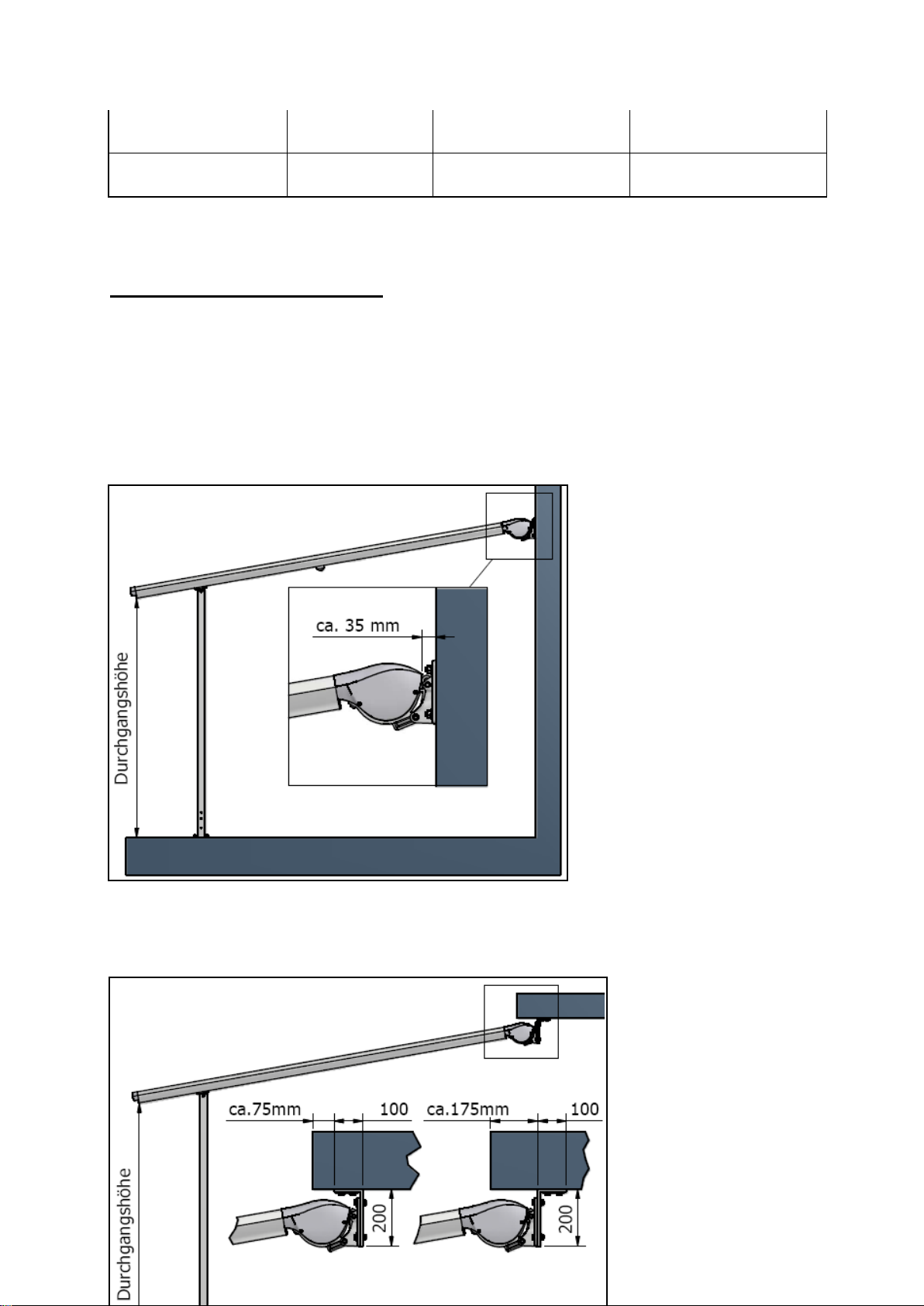

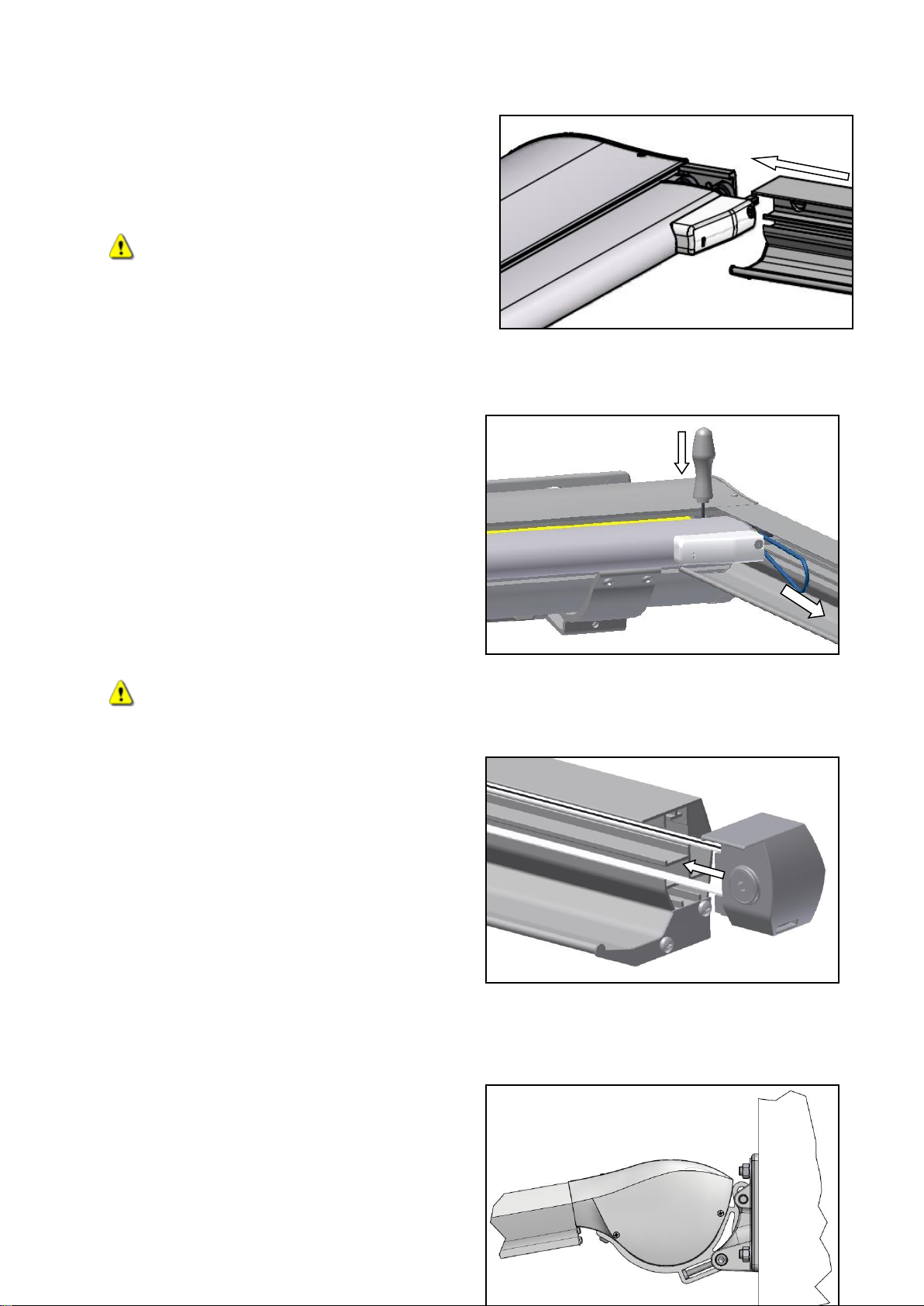

Transport the awning to the site of installation, ensuring that the orientation is

correct. The location of the drive side is indicated on the packaging.

Secure the installation zone (the secured zone must be at least equivalent to the size

of the fully deployed awning).

If the awning is hoisted to higher installation positions with ropes, the awning must

be removed from the packaging.

When attaching the hoisting ropes, ensure that the awning is properly fastened, but

not damaged. Hoist the awning exclusively in horizontal position and evenly.

If the information above is not observed, the awning system may fall down and put

the health of persons at risk!

2.3. Wind resistance classes:

Definition:

DIN EN 13561 Item 4.3. defines different wind resistance classes for awnings. The

classification depends on the quality of the product. The higher the class, the better the

quality of the product.