6

Eubank Wall Mount Heat Pump I&O Manual

06/2022 Rev.5

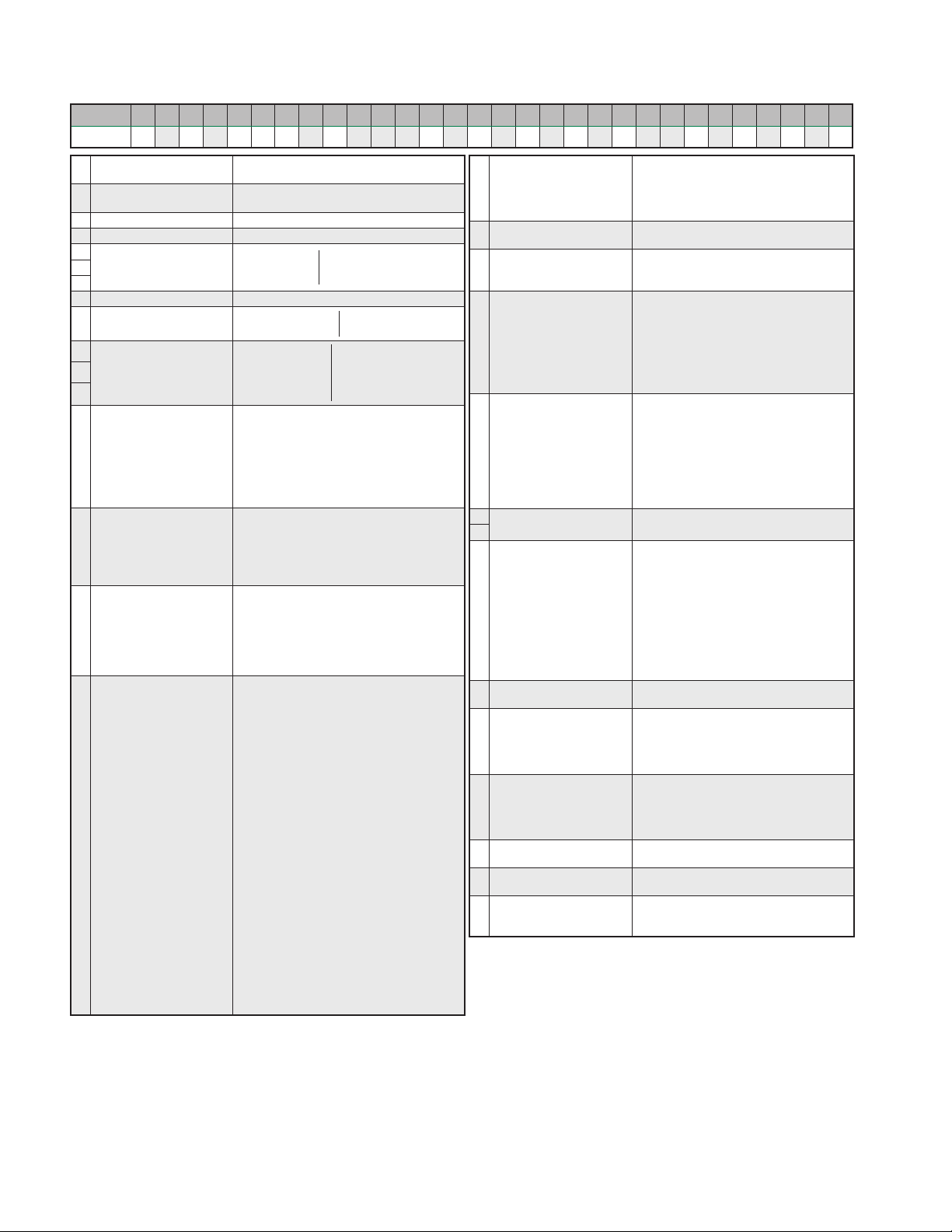

1.3 Model Identification

Example E A A 1 0 3 6 H A 0 5 0 C + + + + 1 E A + A 1 1 + + + + + +

Position 1234567891011 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

1Unit Designation/Family E = Eubank Wall Mount

S = Stock Unit

2Energy Efciency Ratio

(EER) A = 11

3Refrigerant Type A = R-410a

4Compressor Type/Quantity 1 = Single

5Unit Capacity/Nominal

Cooling (BTUH)

020 = 20,000 036 = 36,000

024 = 24,000 042 = 42,000

030 = 30,000 048 = 48,000

6

7

8System Type H = Heat Pump

9Power Supply

(Volts-Phase-Hz)

A= 208/230-1-60 D= 460-3-60

C= 208/230-3-60

10

Heat Designation

@ Rated Voltage

000 = No Heat 090 = 9KW

040 = 4KW 100 = 10KW

050 = 5KW 120 = 12KW

060 = 6KW 150 = 15KW

080 = 8KW

11

12

13 Ventilation

Conguration

N = Barometric Damper w/15% OSA

Y = Manual Damper w/No Pressure Relief

Z = Manual Damper w/Pressure Relief

D = Motorized Damper w/Pressure Relief

C = Economizer

H = GreenWheel®

+ = None

$ = Special

14 Dehumidication

G = Hot Gas Reheat

R = Electric Reheat

T = Electric Reheat w/Humidity Control

G = Hot Gas Reheat

+ = None

$ = Special

15 Controls

A = Power Fail Alarm w/Additional Lockouts

C = 24V EMS Relay Kit

D = 24V EMS Relay Kit w/Factory

Installed T-Stat

E = Factory Installed T-Stat

+ = None

$ = Special

16 Operating Condition

A = Evaporator Freeze Sensor (EFS)

C = EFS w/Hot Gas Bypass

D = Desert Duty

E = Extreme Duty

F = Desert Duty w/Hard Start

G = Desert Duty w/EFS

H = Desert Duty w/Hard Start & EFS

J = Extreme Duty w/Hard Start

K = Extreme Duty w/EFS

M = Extreme Duty w/Hard Start & EFS

N = Hard Start

P = Hard Start w/Low Ambient & CCH

Q = Hard Start w/Low Ambient &

Fan Cycle Control (FCC)

R = Crank Case Heater (CCH)

T = Hard Start w/EFS

U = Hard Start w/Hot Gas Bypass

V = Hard Start w/Low Ambient & CCH & EFS

W = Low Ambient w/CCH

X = Hot Gas Bypass

Y = Low Ambient w/CCH & FCC

Z = Low Ambient w/CCH & EFS

1 = Low Ambient w/FCC

2 = Low Ambient w/FCC & EFS

3 = CCH w/Hot Gas Bypass

+ = None

$ = Special

17 Indoor Air Quality Features

D = Dry Bulb Sensor

E = Dry Bulb Sensor w/Dirty Filter

G = Dirty Filter Sensor

+ = None

$ = Special

18 Air Flow 1 = Top Supply/Bottom Return

$ = Special

19 Compressor Location

C= Center - All 6 ton units and above

D= Left Hand - All 31/2 to 5 ton units

E= Right Hand - All 11/2 to 3 ton units

20 Filter Option

A = 2” Pleated (MERV 8, AC/HP-C)

C = 2” Charcoal

D = MERV 11 High Filtration Package

E = MERV 13 High Filtration Package

F = Filter Access Through Return Air Grille

W = Aluminum Washable

+ = None

$ = Special

21 Corrosion Protection

A = Condenser Coil Only

C = Evaporator Coil Only

D = Both Coils Condenser & Evaporator

E = All Coils Cond/Evap/Reheat

F = Coat All

G = Coastal Package & Evaporator Coil

K = Coastal Package

+ = None

$ = Special

22 Engineering Revision

Level A1

23

24 Cabinet Color

1 = Beige (Standard Eubank)

2 = Gray

3 = Carlsbad Canyon

4 = White

5 = Stainless Steel Exterior

6 = Dark Bronze

7 = .050 Aluminum Stucco

8 = Mesa Tan

9 = Pebble Gray

A = Stainless Steel - Unit

$ = Custom Color (Powder Coat)

25 Sound Attenuation 2 = Compressor Blanket

+ = None

26 Security Option

A = Lockable Access Plate/Tamper Proof

C = Tamper Proof Screws

D = Lockable Access Plate w/Tamper Proof

+ = None

$ = Special

27 Fastener/Drain Pan Option

A = Stainless Steel Fasteners

C = Stainless Steel Drain Pan

D = Stainless Steel Fasteners & Drain Pan

+ = None

$ = Special

28 Unused + = None

$ = Special

29 Unused + = None

$ = Special

30 Special Variation

+ = None

$ = Special Conguration Not Covered by

Model Nomenclature

Note: Not all options are available with all congurations.

Contact your Eubank sales representative for conguration

details and feature compatibility.

1.4 Air Flow, Weights and Filter Sizes.