GWA – 250

page 8 of 8

Technical data

Auxiliary power supply

Permitted supply voltage: 20 V to 253 V AC / DC 48...62 Hz,reverse polarity protected

Power consumption: ≤2,5 VA / 1,75 W

Overvoltage category: II acc. to DIN EN 61010-1

Protection classification: II double or reinforced insulation

Isolation voltage: 4kV~ Auxiliary power to relay outputs to signal inputs

Galvanic isolation: All supply, input and output channels among each other as well as both relay outputs

from each other are safe galvanically isolated.

Relay outputs

Function: 2x potential-free changeover contact

Switching power of the contacts: U~ maximum 253 V AC

I~ maximum 6 A AC (maximum switch-on current 10A)

P~ maximum 1500 VA at ohmic load / 300 VA at cos ≥0,7

at U- maximum I- maximum P-

30 V 6 A 180 W

110 V 0,3 A 33 W

220 V 0,12 A 26,4 W

Minimum switching load: ≥50mW (0,5 V / 1 mA)

Switching cycles: ≥100.000 switching cycles at maximum contact load

Delay time: ≤0,4s ±0,1s resp. ≤4s ±1s

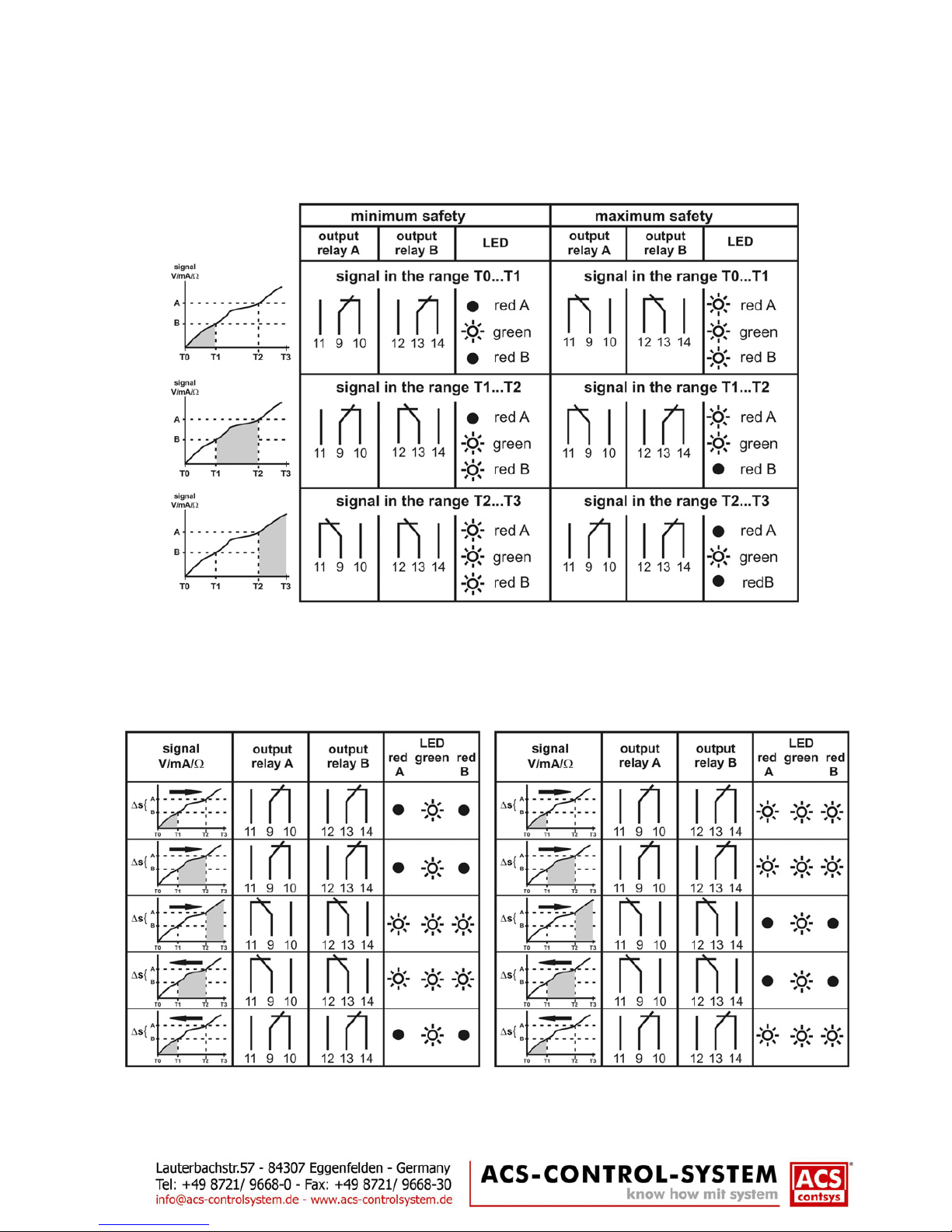

Switching hysteresis 0,5% ±0,2% / at two-position-control ∆s: limit value A – limit value B

Signal input GWA – 250

Direct voltage: 0…10 V / maximum 50V / input resistance 100kΩ

Direct current: 0…20mA / 4…20mA / maximum 400mA at 30V – self resetting fuse

Input resistance 50Ω+ 0,2V

Measuring deviation: ≤0,4% of nominal measuring range

Temperature deviation: ≤0,2% / 10 K of nominal measuring range

Measurand transmitter supply: overload and short circuit protected

3-wire-sensor: ≥21,2V at 20mA ≥20,7V at 27,5mA min. 27,5mA / max. 25V

2-wire-sensor: ≥20,0V at 20mA ≥19,0V at 27,5mA min. 27,5mA / max. 25V

Signal input GWAP – 250

Temperature resistor Pt100: 3-wire- / 2-wire-measuring, resistance linear, measuring current 2 x 0,515mA ±10µA

Measuring range: Zero value: –50°C, 0°C +50°C / range: 30 Kelvin, 50 Kelvin, 100 Kelvin, 600 Kelvin

Measuring deviation: ≤0,4% (at zero value –50 / +50°C end value error ≤2%) of nominal meas. range

Temperature deviation: ≤0,2% / 10 K of nominal measuring range

Wire resistance: ≤40 Ωper wire

Error supervising: At wire break / short circuit of one or multiple Pt100 connection wires the output

relays are switched off (at safety function minimum safety). At short circuit resp.

wire link between terminals 1 and 2 the device operates in 2-wire-measuring

Materials

Connection housing: PA – polyamide

Terminal housing: PA – polyamide

Sticker: PE – polyester

Connection terminals

Number: 3 resp. 4 terminal blocks with each 4 terminals, everlasting screws

Connection cross-section: maximum 1 x 2,5 mm or 2 x 1,5 mm

Housing style

Housing: Series installation housing, 22,5mm wide

Weight: 100 g

Environmental conditions

Environmental temperature: Single installation – 40°C...+85°C

Series installation – 40°C...+70°C

Climatic classification: 3K3 resp. 3M2 DIN EN 60721-3-3

Protection classification: IP20 DIN EN 60529

EM – compatibility: emission DIN EN 61326-1 operation device class B

immunity DIN EN 61326-1 industrial range