ACTION ELECTRONICS P94 User manual

www.action-electronics.co.uk

C 2023 Action R/C Electronics

SCHEMATIC OF INSTALLATION IN TWIN-ENGINED MODEL

Type: Dual ESC and Mixer Module. Equivalent to two fully operational ESCs and a mixer, all in the same

case. Will suit most types of DC motor used in model boats, including 7+ pole types.brushed

No of channels required: 2

Motor voltage: 6v to 24v

Maximum continuous current rating: 20A per ESC

Modes: 4 different modes of operation, selectable by user via on-board 2-way DIL switches:

Mode 1: Dual electronic speed controllers - Each ESC works from a separate channel i.e. “Tank Steering”;

Mode 2: Dual thruster mode - Controls bow and stern thrusters. Skipper selects either Traverse (where

thrusters work in the same direction and slew the model sideways) or Spin (where the

thrusters work in opposite directions and spin the model on its own axis). Selection is done by

“blipping” the rudder stick hard over and letting it go straight away. Both thrusters are also

fully speed-controlled.

Mode 3: 0% - 100% Mixer. As Mode 4, except that inboard motor can be made to spin at full speed in

reverse sense on full rudder command i.e. you can spin the model on its axis.

Mode 4: 0% - 50% Mixer. Applies differential speed control to the motors automatically as a rudder

command is give. Adjustable from 0%, where there is no mixing of rudder and throttle signals,

up to 50%, where the inboard motor just stops at full rudder command.

Other facilities:

Failsafe..........................................................

Autoset..........................................................

ESCs shut down motors on loss of signal.

Central Motor & Rudder connections..............3-pin headers provided for connecting the steering servo and a

P94 automatically sets neutral position of throttle and steering

separate speed controller to operate a centre motor.

o ing “binding” or other setting up to don power up i.e. No

Adjustable thruster output............................ Allows the operation of commercial thrusters from higher-

voltage main batteries.

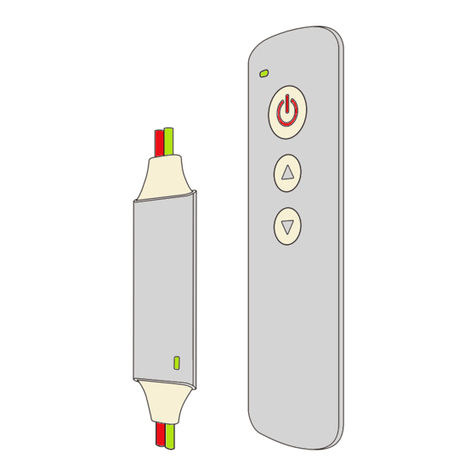

P94 DUAL ESC/MIXER MULTI CONTROLLER

CH1

CH2

BATT

Receiver

Steering Servo

ESC for motor on

Main battery

Main battery

Port Motor

centre shaft (if required)

(2 Channel Minimum)

01248 719353

Battery Eliminator (BEC)................................Built in 5V 2A (3A peak) battery eliminator

S

T

Stb’d Motor

P94 Dual ESC/Mixer Multi-controller

Installing the P94

Because of the high power of the P94 Multi-controller, care should be paid to the installation of the unit.

Each ESC circuit can deliver 20A continuously and the wiring installation should be designed with that in

mind.

Fig #4 shows a basic installation. The length of all wires should be kept to an absolute minimum, but not to

The fuse must be sized to be as small as possible without causing nuisance tripping. A 40A fuse (maximum)

should be used to protect the unit.

If more than one battery is being used for the installation, they should be connected in parallel. This is best

done by using a P103 Parallel Power Board. This will handle up to 15v @ 20A and prevents any possibility

of one battery discharging into the other and causing damage or even fire to the wiring. See Fig #6. If you

are using >15v then first connect the two battery positive terminals together and the two battery negative

terminals together and then connect each of the joined pairs to the P92 etc.

When connecting the motors, suitably rated cable must be used and the lengths kept as short as possible.

2

We recommend multi-strand cable of at least 2mm (16AWG). The wiring of the two motor connections is

reversed with respect to each other, so that they rotate in opposite directions when ahead or astern

commands are given. It is also recommended that the outputs from the ESCs are individually fused. P95

is ideal for this purpose; See Figs #1 & #2. Each fuse must be no more than 20A.

Terminal block TB1 is used for one motor or the bow thruster, and TB2 is used for the other motor or the

stern thrusters (depending on the operating mode). Do NOT allow the two heat-sink tabs to touch each

other or touch any other power wiring. Additional cooling in the form of extra heat-sinks or water-carrying

tubes can be fitted to the aluminium tabs, but they must remain electrically isolated from each other.

When connecting the receiver to other servos or speed controllers there are two “straight-through”

connections on the P94 in the form of 3-pin headers. See the Schematic Drawing on the Front Page of this

manual. These eliminate the need for Y-leads from the receiver outputs. H1 would be used conventionally

to connect the steering servo, while H2 will supply the throttle signal (unmixed) to a third electronic speed

controller e.g. for a central motor. Header pins H2 can also be used to connect a digital engine sound unit

to the system e.g. ACTion P1 0. The sound will then follow the throttle stick input and will not be affected 1

by any degree of mixing.

01248 719353

The latest version of P94 has a switch-mode voltage regulator, or Battery Eliminator Circuit (BEC) fitted.

This takes power from the main motor battery/batteries and reduces it to 5v to operate the logic circuit in

P94 and to feed the power to the receiver, also @ 5v. Unless you want to run the receiver from a

seperate battery (or the flylead from P92/P102/P107) then you MUST remove the red wires

from the two leads marked T and S. If you leave either of them connected then the receiver will be at

risk of serious damage due to being “fed” two different voltages at the same time. You can modify the

plugs easily like this:

2

1

3

Slightly lift tab

Bend and tape back RED lead

Withdraw RED (Positive) lead

Pointed blade

White/Yellow

ESC receiver lead

Red

Black

the extent that they are tight, a small amount of slack will reduce the risk of them coming loose in use.

C 2023 Action R/C Electronics

01248 719353

Important!

1. ALWAYS check your wiring before applying power to the circuit for the first time, and

ALWAYS turn off ALL power before you make ANY changes to connections or any adjustments to

switches etc. If you ignore this rule then you could cause damage to the unit.

2. Never work with a live battery in circuit, especially if the unit is out of its case. You risk

shorting out the copper tracks on the reverse of the PCB.

3. Turn on your transmitter before the receiver, and turn off the receiver before turning off the transmitter.

4. Always fit suppressor capacitors to your motors (ACTion can supply a suitable set of components).

5. When setting up Modes 3 and 4, first use the Tx Servo Reverse Switch if necessary so that the steering

servo operates the rudder(s) in the correct sense. Once you're satisfied with this, leave this switch alone

throughout the rest of the setting-up procedure. If you need to reverse the rotation of either motor then do

it by swapping over the two connections from the motor to the ESC terminals. If you find that the “wrong”

motor slows down when you apply a steering comm nd then simply swap over the two motors between a

terminals blocks TB1 and TB2.

6. If your transmitter has any form of inter-channel mixing on the steering and throttle channels, make

sure it is switched OFF for the operation of a model fitted with a P94. Also ensure that any servo throw

adjustment is set to 100% movement in both directions. See the manual for your radio for further

information.

Modes of operation

Mode 1: Dual ESC Mode (See Fig #6) Switch 1 = ON, Switch 2 = ON

Mode 2: Thruster Mode (See Fig #7) Switch 1 = ON, Switch 2 = OFF

As discussed earlier, P94 has four different modes of operation. These are selected with the small 2-way

switch which is situated on the circuit board just below the microprocessor chip. Each of the two switches

can be either ON or OFF. The unit is supplied in Mode 4 and the Mix control has been set to the optimum

position for this mode. You may need to adjust the trim lever on your Tx slightly to rudder ensure

t start together. hat the two motors exactly The indicator LEDs of P95/2 are very useful here.

The “Mix” knob controls the 'degree' of mixing. If you turn it all the way clockwise then the mixing

function in Modes 2-4 will be totally disabled. The following sections describe the four modes of operation,

in conjunction with Figs #6, 7 & 8. Note that the props are shown in outwards contra-rotating configuration

when viewed from the rear. If your model uses inward-turning props then set up the P94 as shown and, as a

last step, swap the connections between the P94 terminals and the motors to reverse their direction of rotation.

In this mode the system operates as two independent ESCs, each rated at 20A. This is frequently referred

to as “Tank Steering” as it mimics the controls used by the driver of a tracked vehicle to control its direction

and speed. Many boat modellers prefer this 'manual' mode of mixing twin motors, and it is also widely used

by builders of large-scale model tanks. In this mode there is no interaction between the two channels, and

the Mix control is not used.

This mode is intended to control combined bow and stern thrusters. The thrusters can be run in the same

direction to move the model sideways in the water (“slew”), or in opposite directions to rotate it around its

own axis (“spin”). The output from terminal block TB1 is used to drive the bow thruster while TB2 controls

the stern thruster. The thruster speed/direction channel is usually the LH Tx stick. Push it to the left for a

rotation/slew to Port and to the right for a Starboard rotation/slew.

The RH side-to-side stick is the main steering control for the model and it is also used to switch the

thrusters from Spin mode to Slew mode; the stick is “blipped” to the left with the thruster speed/direction

control in the neutral position. To switch from Slew to Spin, the stick is blipped to the right. Note that the

direction is only changed if the thruster speed control is at neutral (i.e. the thruster motors are not

running) and the control is blipped to the limit for less than about 1 second. If it is held over for 1 second

or more the direction is not changed. A P95/2 in the circuit will instantly show whether or not the directions

have changed by the colour of its LEDs. Practise before you first sail the model! The changeover will only

take effect when you apply an amount of thruster speed/direction i.e. it will not be indicated when you blip

the Select stick.

The Mix control can be used to set the maximum voltage for the thrusters. This means, for example, that

you can safely run 7.2v thruster units from 12v main motor drive batteries without causing them damage;

See Fig#3. To set the thruster voltage, turn R fully clockwise. Connect a digital volt-meter across the 7

brushes of the bow thruster motor; power the system up and move the thruster control to full speed (in

either direction). Hold it there while you adjust the Mix until the meter reads the rated voltage of the thruster.

Graupner thrusters units are generally 7.2v while the Robbe ones are generally 6v.and Raboesch

Mode 3: 100% Mixer (See Fig #8) Switch 1 = OFF, Switch 2 = ON

The 100% Mixer mode is a “W-tail” type mixer. If turning to starboard, the port motor is speeded up and

the starboard motor is slowed down. If turning to port the starboard motor is speeded up and the port

motor slowed down. This mode allows the motors to reverse direction under the control of the steering

Autoset operation - Overview

Your P94 is fitted with software which now includes full ACTion ‘Autoset’. This means that P94 will automatically

detect the positions of the transmitter throttle and rudder sticks when you switch on your system, and then lock

onto them as its own neutral positions for that sailing session. The effect of this is that you will not need to adjust

the transmitter trim levers (as with earlier versions of P94) in order to stop the motors at “dead stop” command

or to start them together when you apply some throttle. It also allows the user to operate P94 with the cheaper

2.4GHz systems which have non-standard neutral signal values. We strongly recommend the fitting of spring-

centring to the throttle stick of your transmitter; your radio dealer can advise on obtaining the requisite parts or

you can contact the RC manufacturer’s local service agent to have the job done for you.

NB THIS UNIT WILL NOT OPERATE WITH FUTABA 6J OR 2.4ghz SKYSPORT RADIOS. These sets have a different

way of transmitting their signals which cannot be read by P94. The older Futaba 6EX 2.4GHz sets and the 40MHz

Skysports are both OK.

Since introducing the Autoset software to P94 it has been apparent that the back-EMF caused by the two motors

suddenly changing direction can, in some extreme circumstances, cause the power supply to the receiver to

momentarily dip below its critical value. While this has no adverse effect on the receiver it does mean that the

P94 software “thinks” that the receiver has been switched off and then back on again. It therefore goes through

its full Autoset routine all over again. Unless the transmitter sticks are in the same positions as they were when

you first switched on then this will change the neutral stick positions and make the model difficult to control.

To avoid this:

Only move the sticks gently and smoothly, especially in Mode 3 where the motors change direction very quickly

between neutral and full steering commands. Avoid just letting go of the sticks and allowing them to spring back

to neutral, or suddenly applying full throttle in one direction from either neutral or the opposite direction;

If you still have problems then we can supply a DIY-fit microprocessor with non-Autoset software. This simply

replaces the plug-in microprocessor already fitted and will be free of charge if you return the original chip

afterwards. Illustrated instructions are included to help you do what is a very straightforward job. Contact ACTion

for details.

Autoset operation - Procedure

Follow the procedure shown in the diagrams below. Note that P94 will Autoset every time you switch on the radio;

it isn’t a one-off “binding” or “setting up” procedure. It is important not to move the transmitter sticks while the

autoset is running or the system may not work correctly. After a few seconds - depending on how long your

receiver and transmitter take to ‘bind’ - the relays will click rapidly several times and it is then OK to operate the

transmitter as normal. If the model goes out of range then P94 will stop both of the motors, but when the model

comes back into range then P94 will resume with the same neutral positions that it had when you first switched

on i.e. It will NOT autoset again.

Mode 4: 50% Mixer (See Fig #8) Switch 1 = OFF, Switch 2 = OFF

command. The amount by which the motors change speed is controlled by the Mix knob; turn it anti-clockwise

to increase the degree of opposite rotation of the inboard motor at full rudder command. Note that if you

apply a rudder command any throttle then the motors will go to full speed in forward+reverse; this without

allows you to spin the model on its axis with no forward speed.

The main throttle output from the receiver connects to P94 lead marked “T” with the steering output

connected to lead marked “S”. The rudder servo itself should be connected to header pins H1. If the model

has a three-motor setup, the ESC to drive the third motor should be connected to header pins H2. Note

that both of these connections are made with the Black (negative) wire in the plug onto the outer pins i.e.

nearest the edge of the circuit board. 100% mixing is more suited to slow moving vessels that require the

maximum degree of manoeuverability e.g. tugs, ferries, fishing vessels and other work-boats.

The 50% Mixer mode is more complex than the 100% mixing function, and is more suited to faster

vessels e.g. fast luxury cruisers, MTBs and modern lifeboats. In this mode, the outer motor in the turn is

not speeded up (unlike the 100% mix). The inner motor is slowed down - the amount by which is determined by

the rudder input, but it is not allowed to change direction unless reverse throttle command is given. The sensitivity

of the system to the rudder input is set using the Mix control; turn it anti-clockwise to increase the amount of

mixing. The connections for Mode 4 are the same as for Mode 3. Note that rudder command with no throttle will

NOT start the motors in this mode.

ON

ON

12

“Click” “Click”

“Click” “Click”

Switch ON transmitter Switch ON / connect

4

After relays stop clicking

Wait until relays ”click” rapidly

OK to move sticks

6v to 12v BATTERY

+ve -ve

main battery

01248 719353

C 2023 Action R/C Electronics

FIG #2: DUAL THRUSTER CONNECTIONS (MODE 2)

(Power connections omitted for clarity)

BOW

Commercial thruster units

STERN

Suppressor

ACTion RFI

Kits

FIG #1: TYPICAL TWIN MOTOR CONNECTIONS (MODES 1, 3 &4)

Mix control - See diagrams above

thruster e.g. Graupner

movement to thruster

clockwise

turned fully

Start with Mix

and adjust Mix slowly

= 7.2v, Robbe = 6v

that specified for the

until Voltage reaches

Apply full stick

0 - 20V across thruster

read 0v - 20v

set scale to

motor brushes;

multimeter

Connect digital

ACTion RFI Suppressor Kit

(Power connections omitted for clarity)

when the main drive motors rotate in opposite direction e.g. At Full Ahead speed.

When connected as shown, the LEDs will both glow the same colour

MOTOR #2

MOTOR #1

"+ve"

"+ve"

STARBOARD

PORT

ADJUSTING Mix control where

Main battery voltage is greater

"+ve"

"+ve"

ACTion P95/2 Indicator

Fuse Board

ACTion P95/2 Indicator

Fuse Board

C 2023 Action R/C Electronics Original drawing by Dave Milbourn

P94

Adjust rudder trim lever of transmitter until the two LEDs “fire up” together when

slight forward throttle command is given (does not apply to Mode 1).

than bow thruster voltage.

2023 updates by Iain Lewis

Recovery Service.

A recovery or repairs service means that you will not be left with a dead unit for any reason.

The cost of this service (as of March 2023) is £19.95 which includes the return shipping costs to any UK

address.

Should you need a repair, please contact us before sending your unit & we will explain the steps.

Either contact us by phone, or e-mail to info@component-shop.co.uk

www.action-electronics.co.uk

01248 719353

C 2023 Action R/C Electronics

+ve

FIG #3: BASIC INSTALLATION WITH SINGLE BATTERY

-ve

ON/OFF Switch

40A

ACTion H/Duty

In-Line fuse holder

40 Amp connector

6v - 24v battery

(max)

Red

Black

P94

Page 2

This wiring layout may also be used for a P94 Lite

installation. Motor current should not exceed 10A

each and a 20A fuse (max) should be used.

*15

25

*15

+ve -ve

FIG #4: USING POWER DISTRIBUTION BOARD P92 OR P102

(Receiver & motor connections omitted for clarity)

6v - v battery15

Max Voltage is 24v for P102

ON/OFF Switch

ACTion P92 Power

*Use 10A fuses for P94 Lite

Distribution Board

(Receiver & motor connections omitted for clarity)

ON/OFF Switch

Batteries must be same type, voltage and capacity(<15v)

15

15

15

+ve

-ve

ACTion P92 or P102 Power D/B

6v - v batteries to suit15

P103 Parallel

Power Board

(Receiver & motor connections omitted for clarity)

FIG #5: TWO BATTERIES CONNECTED IN PARALLEL

+ve +ve

-ve -ve

www.action-electronics.co.uk

01248 719353

Original drawing by Dave Milbourn

2023 updates by Iain Lewis

Red

Black

Red

Black

P94

BOTH AHEAD

BOTH ASTERN AHEAD

ASTERN

ASTERN

AHEAD

P94 "S" connection

P94 "S"

Steering Servo

P94 "T" connection

P94 "T"

RECEIVER CONNECTIONS FOR

RECEIVER CONNECTIONS FOR

MODE 1 (Futaba convention for

MODE 2 (Futaba convention for

numbering channels is shown)

numbering channels is shown)

Steering = RH stick Side/Side

Spin/Slew Select = RH stick Side/Side

Port Throttle = LH stick Up/Down

Speed & Direction = LH stick Side/Side

Stb’d Throttle = RH stick Up/Down

Connect Steering Servo to H1 on P94

5

B/8

1

3

2

4

6

7

5

B/8

1

3

2

4

6

7

Spin Mode Spin Mode

Slew Mode Slew Mode

“Blip” Tx stick to Left <

1 second to change

from Spin to Slew mode

and to the Right to

change back.

NB Thruster speed on

LH stick MUST be at the

neutral position when

switching modes.

www.action-electronics.co.uk

C 2023 Action R/C Electronics

FIG #6: 7 MODE 1 “TANK STEERING”

FIG #7: MODE 2 DUAL THRUSTERS

Page 3

MODE 1

MODE 1

MODE 2

01248 719353

Original drawing by Dave Milbourn

2023 updates by Iain Lewis

MODE 4

MODE 3

MODE 4

MODE 3

MODE 4

MODE 3

MODE 4

MODE 3

BOTH AHEAD

BOTH ASTERN

ASTERN

AHEAD

STOP

AND

AND

AHEAD STOP

AHEAD

ASTERN

ASTERN

MODE 4

MODE 3

AHEAD

AHEAD

ASTERN

STOP

MODE 4

MODE 3

ASTERN

ASTERN

AHEAD

STOP

MODE 1 AND MODE 3 AND MODE 4

STOP STOP

P94 "S" connector

P94 "T" connector

CH1

CH2

CH3

CH4

RECEIVER CONNECTIONS FOR

MODES 3 and 4 (Futaba convention for

numbering channels is shown)

Steering = RH stick Side/Side

Throttle = LH stick Up/Down

5

B/8

1

3

2

4

6

7

P94

www.action-electronics.co.uk

C 2023 Action R/C Electronics

FIG # : 8 MODES 3/4; 100% & 50% MIXERS

Page 4

01248 719353

Original drawing by Dave Milbourn

2023 updates by Iain Lewis

Table of contents

Popular Controllers manuals by other brands

Barber-Colman

Barber-Colman DYN1-10704 Series Service information

PEITIAN ROBOTICS

PEITIAN ROBOTICS ARC4-50 manual

ZKTeco

ZKTeco C5S110 Installation and connection guide

KAESER KOMPRESSOREN

KAESER KOMPRESSOREN SIGMA CONTROL 2 user manual

Mitsubishi Electric

Mitsubishi Electric AT-50B installation manual

AUMA

AUMA SGM 04.1 Operation instructions