Actuall DoorLIFT DL-6 User manual

Owner’s Manual

KEEP THIS OWNER’S MANUAL IN VEHICLE

Need help?

For assistance with this product please visit

www.actuall.eu or contact your dealer.

Version 01-2020

2

DoorLIFT DL-6

Remote door system

Index

1Unit informaon 2

2 Safety guidelines 3

3Service book 4

4 Control devices 8

4.1 How does the remote control work 9

4.2 Programming remote control 9

5Inspecon and maintenance shuer door 10

6 Inspecon and maintenance DoorLIFT 12

7Removal motor unit 14

8How to lock the gears 16

9How to adjust the sensor 17

10 Emergency release 18

11 Basic trouble shoong 19

12 Changing DL-8001252 Tooth wheel (24) 20

13 Technical specicaons 22

DoorLIFT serial no.

Dealer

Installaon date

Door type

Door size

Door serial number

1. Unit informaon

Owner’s manual

3

DoorLIFT DL-6

Remote door system

Owner’s manual

2. Safety guidelines

Warning Safety guidelines

Aenon: Risk of injuries!

Aenon: Risk of injuries!

Never put your ngers into the

track of the door or into the pro-

le of the DoorLIFT.

Nothing should be in the range of

the shuer door when it is mo-

ving.

Slipping, tripping or falling on or

of the oor of the lorry’s goods

compartement can cause injury.

For problem-free operaon of the DoorLIFT, the lorry’s shuer door

must always be kept in good condion.

Before using the DoorLIFT:

1. Check if all the shuer doors components are rmly in

place. Loose parts must be xed or replaced if necessary.

2. Check the lorry’s shuer door is working properly.

When using the DoorLIFT:

1. No obstacles are allowed in the range of the shuer door

when it is moving!

2. If the door can be locked of bolted, do not forget to unlock

or unbolt it.

3. Check the movement of the DoorLIFT both on opening and

closing. If the DoorLIFT runs unevenly, invesgate the

cause and repair it if possible.

4. Replace damaged parts as quickly as possible.

5. Recurring stoppages or problems must be sorted out as

quickly as possible by people with the appropriate training.

Do not aempt to resolve problems yourself if you do not

have the proper training. Electronic equipment requires

specialised knowledge.

6. Take care that the rails in the doors range of movement

are not blocked.

Aer using the DoorLIFT:

1. The door should be closed properly before driving away.

2. Never drive with an open door; this will damage the Door-

LIFT.

Maintenance:

1. Damaged, loose or missing parts should be repaired or

replaced by skilled personnel. You should have checked the

DoorLIFT at least twice a year.

2. When repairing the DoorLIFT you should always disconnect

the system from the power supply.

Aenon: Electronic equipment requires specialised knowledge!

3. Do not lubricate the DoorLIFT.

4. Clean using a damp cloth. Do not use any volale substanc-

es as stac electricity may ignite them and causes an explo-

sion.

5. Use genuine DoorLIFT replacement parts.

4

3. Service Book

Type of service Date By

Notes

DoorLIFT DL-6

Remote door system

Owner’s manual

Type of service Date By

Notes

Type of service Date By

Notes

5

DoorLIFT DL-6

Remote door system

Owner’s manual

Type of service Date By

Notes

Type of service Date By

Notes

Type of service Date By

Notes

6

Type of service Date By

Notes

DoorLIFT DL-6

Remote door system

Owner’s manual

Type of service Date By

Notes

Type of service Date By

Notes

7

DoorLIFT DL-6

Remote door system

Owner’s manual

Type of service Date By

Notes

Type of service Date By

Notes

Type of service Date By

Notes

Make a copy of this page rst, this is the last blank sheet

8

DoorLIFT DL-6

Remote door system

Owner’s manual

4. Control devices

Your DoorLIFT system may be supplied with two wireless key FOB transmiers. Any

other external device like switches are provided by the er or customer.

Item Descripon Funcon

1Remote control Up/down automac

2Push buon single Up/down automac

3Push buon up Up automac

4Push buon down Down automac

5Block funcon Automac close door, block all input

Oponal funcons:

Connect auxiliary devices to the DoorLIFT control box

through the 8-lead harness using the wire chart below.

Wire Item

1Up/down input

2Up input

3Down input

4Signal block (ignion lockout)

5+ 12V output (max 250 mA)

6Door ajar output (ground)

7Cargo light output (ground)

Yellow/green Ground (max 250 mA)

The 8-pin female connector on the box comes equipped

with a plug to protect the connector from water and dirt if

the harness is not used. This plug is removed and discarded

if the harness is ulized.

1.

2.

9

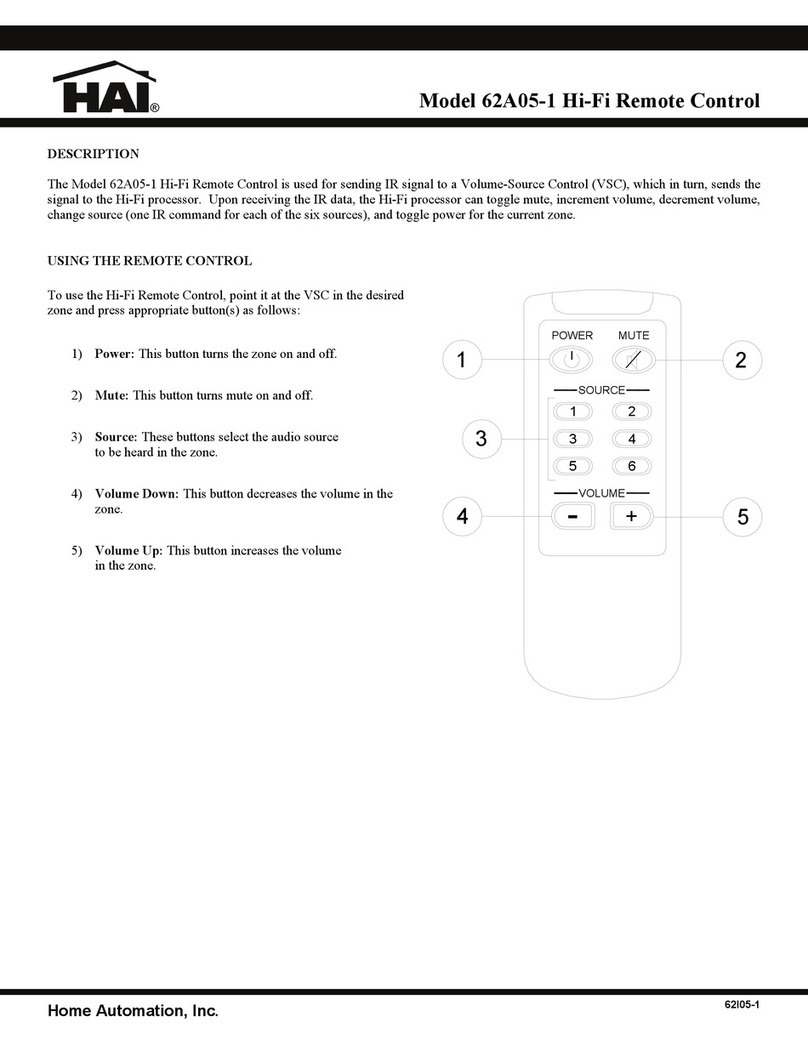

4.1 How does the remote control work

When a command is given, the LED’s will indicate the signal

was received.

- LED 2 on the control box will momentarily ash orange, as an

input signal is received either from a FOB or a switch.

- LED 1 will start to ash green as 32 VDC is sent to the motor

LED indicator

4.2 Programming remote control

2

1

1. When the power is turned on by connecng

the baery cable to the control box, within 5

seconds, press the buon 1 and 2 at the same

me. The system will then enter the code learn-

ing mode. The UNLOCK OUTPUT will trigger to

remind you that the system is in code learning

mode.

2. Within 5 seconds aer entering the code

learning mode, press any buon on the trans-

mier. The UNLOCK OUTPUT will trigger to tell

you the transmier has been recognized and is

compable with the system. A maximum of 12

transmiers can be coded per system.

3. During code learning, if there is no acon

aer 5 seconds, the system will exit learning

mode. The UNLOCK OUTPUT will be the remind-

er.

4. If old FOBs have to be erased from the re-

ceiver’s memory for any reason, program the

new FOBs with the above procedure and don’t

include the old FOBs in this procedure. This

process will erase the old FOB data from the

receiver’s memory.

DoorLIFT DL-6

Remote door system

Owner’s manual

Note: if the FOB baery

has to be replaced for any

reason, the baery is a 12

Volt A-23 dry cell type

10

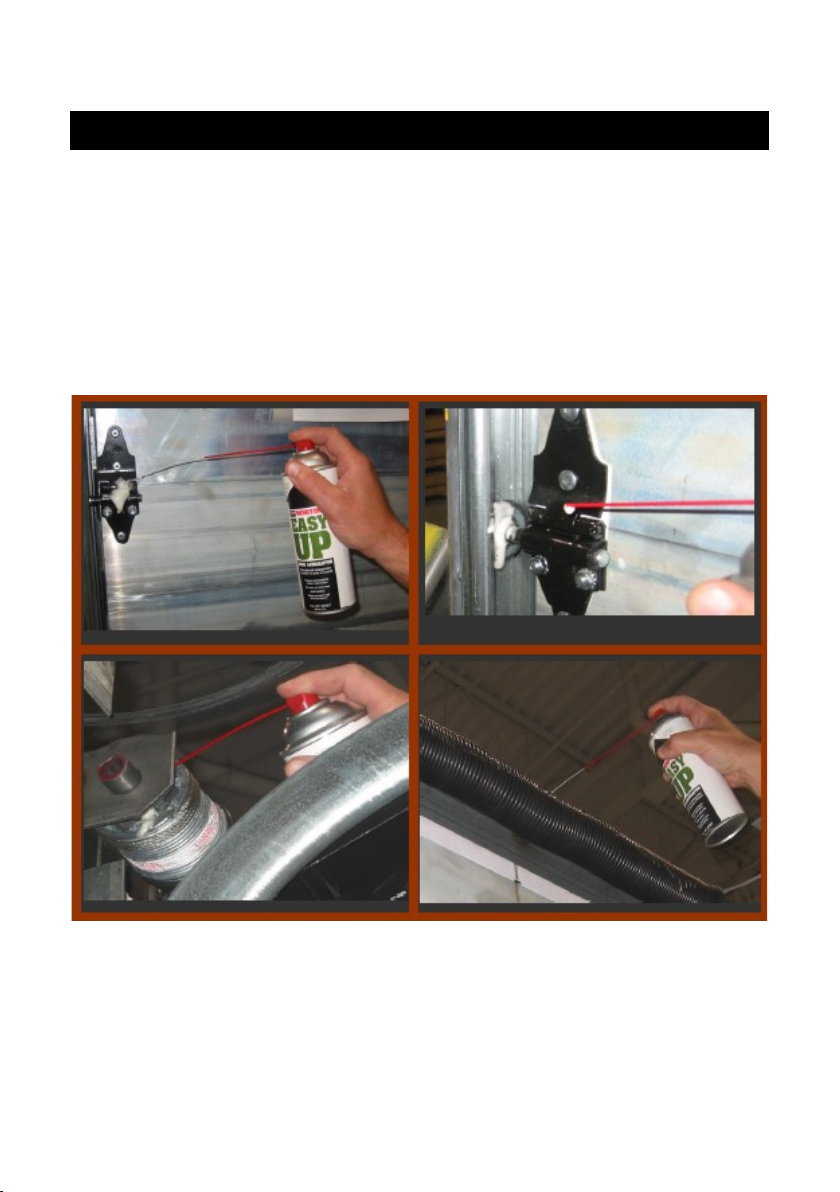

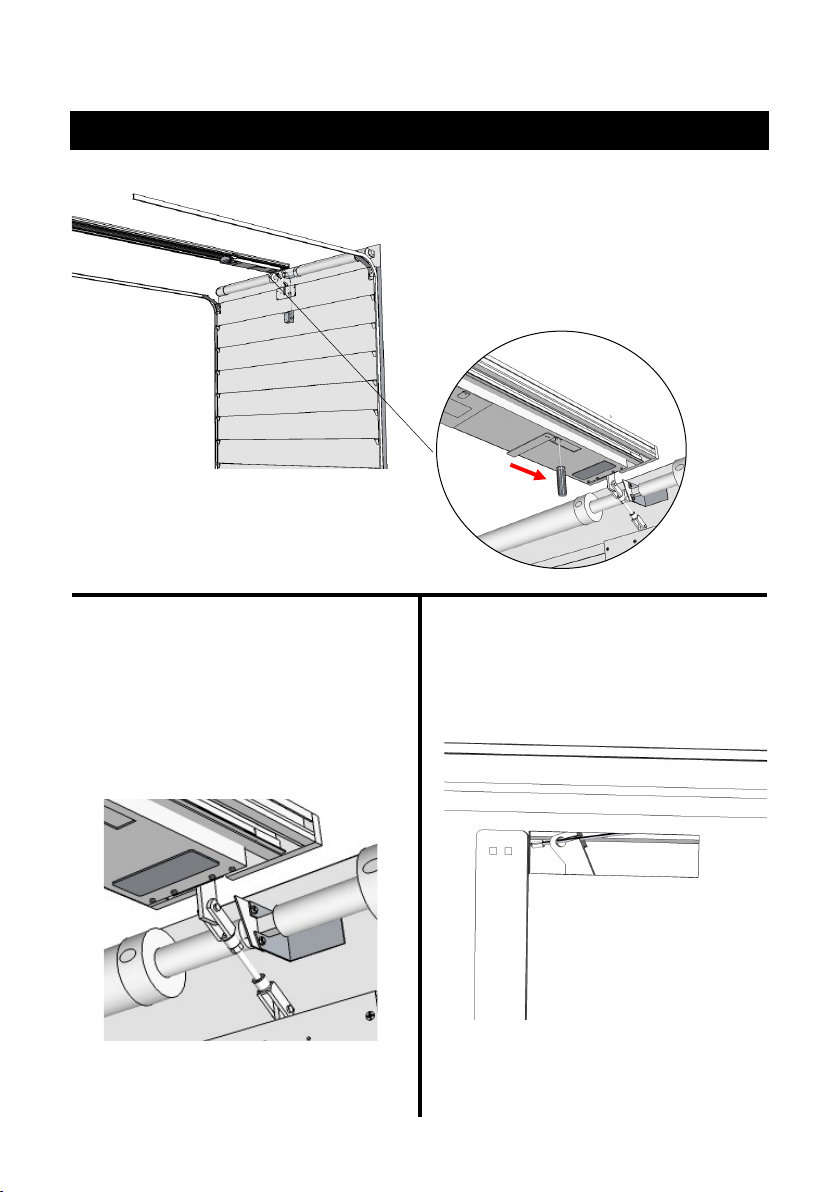

5. Inspecon and maintenance shuer door

Maintain the shuer door every 3 months:

1. Lubricaon shuer door

2. Balancer maintenance and adjustment

3. Check if all the shuer doors components are rmly in place.

1. Lubricate the roller bearings and shas, hinge pins and cable drum bearings as

per the illustraon below.

DO NOT USE GREASE OF ANY KIND

Grease sits on the surfaces and aracts dust, dirt and salt.

DoorLIFT DL-6

Remote door system

Owner’s manual

11

2. Check to make sure the shuer door is properly balanced.

ALWAYS lubricate your shuer door, prior to checking the balance of the door.

The DoorLIFT will operate the shuer door provided a force of no more than 35Kg

to open or close the door. Ensure that the force required to li the door is equal to

the force required to close the door.

• If the door requires more force to open than it does to close, increase the

tension on the balancer.

• If the door requires more force to close than it does to open, decrease the

tension on the balancer.

Addional info:

Time and the elements aect the tension on the spring that lis the door. Over

me, the spring wire will corrode and loose eecve wire diameter. The springs

themselves also get red and loose their tensile strength. An average balancer on a

door will last approximately 15,000 to 25,000 cycles.

Adjusng and maintaining the proper door balance:

CAUTION—work on doors and related parts can be dangerous. It is strongly recom-

mended that repair service work be preformed by persons who have successfully

completed appropriate training.

1. For adjusng the spring, please consult your shuer manual for brand spe-

cic instrucons.

DoorLIFT DL-6

Remote door system

Owner’s manual

12

6. Inspecon and maintenance DoorLIFT

Pre-condions:

• Maintenance should be performed by qualied (trained) sta.

• Maintenance of the DoorLIFT should always be done in conjuncon with

maintenance of the shuer door.

• Maintenance schedule is based on 40 cycles per day, 5 days a week. At high-

er frequency, you may need to do the inspecon more oen.

• Maintenance schedule is based on a well maintained, well balanced and

manual operable shuer door.

• When repairing the DoorLIFT you should always disconnect the system from

the power supply.

• DO NOT GREASE OR LUBRICATE THE DoorLIFT. Clean using a damp cloth.

• Use only genuine DoorLIFT replacement parts.

DoorLIFT DL-6

Remote door system

Owner’s manual

13

Maintenance acvies Six months Yearly

Check the operaon by opening and closing the system with

the door aached

XX

Check the balancing of the door with the DoorLIFT discon-

nected

XX

Ensure that all parts are properly ghtened. Damaged, loose

or lost parts should be repaired or replaced

XX

Inspect the aluminum track XX

Lubricate and test the emergency unlocking system XX

Perform door maintenance as instructed in Step 5 XX

Check all electrical connecons for ghtness and corrosion X

Disconnect the motor-unit and take it out of the track for

inspecon

X

Do a visual inspecon of the motor-unit gears and guide

wheels

X

Check the cable of the emergency unlocking mechanism

and replace if damaged.

X

Replace the four guiding blocks (part number: DL-8001254). X

Replace the baery of the remote control FOB if needed X

Place service scker X

Expected me for maintenance service of DoorLIFTs excluding door

maintenance and inspecno:

Six months :30 minutes.

Annual :60 minutes.

Replace the motor-unit aer 5 years or 160.000 cycles

DoorLIFT DL-6

Remote door system

Owner’s manual

14

7. Removal motor unit

1. Use a screw driver and insert this in

the lever, located in the motor unit.

Move the lever towards the shuer

door. Your are now able to open and

close the door by hand.

2. Remove the clevis pin on the turn

buckle. This will disconnect the motor-

unit from the door.

3. Remove the cable from the lever

DoorLIFT DL-6

Remote door system

Owner’s manual

15

4. Remove the cable from the cable

tube in the motor-unit.

5. Remove the cover from the track.

6. Cut the zip e retaining the yellow

cable to the slider cover. Unscrew the

slider cover bolts and remove it.

Unplug the yellow cable harness from

the motor connector within the box.

7. Slide the motor-unit out of the

track.

DoorLIFT DL-6

Remote door system

Owner’s manual

16

“click”

Using a screw driver, insert the p in the

lever located in the motor-unit.

Move the lever towards the Baery icon

unl you hear a rm “click” meaning the

gears are meshed with the linear track

gears.

8. How to lock the gears

DoorLIFT DL-6

Remote door system

Owner’s manual

17

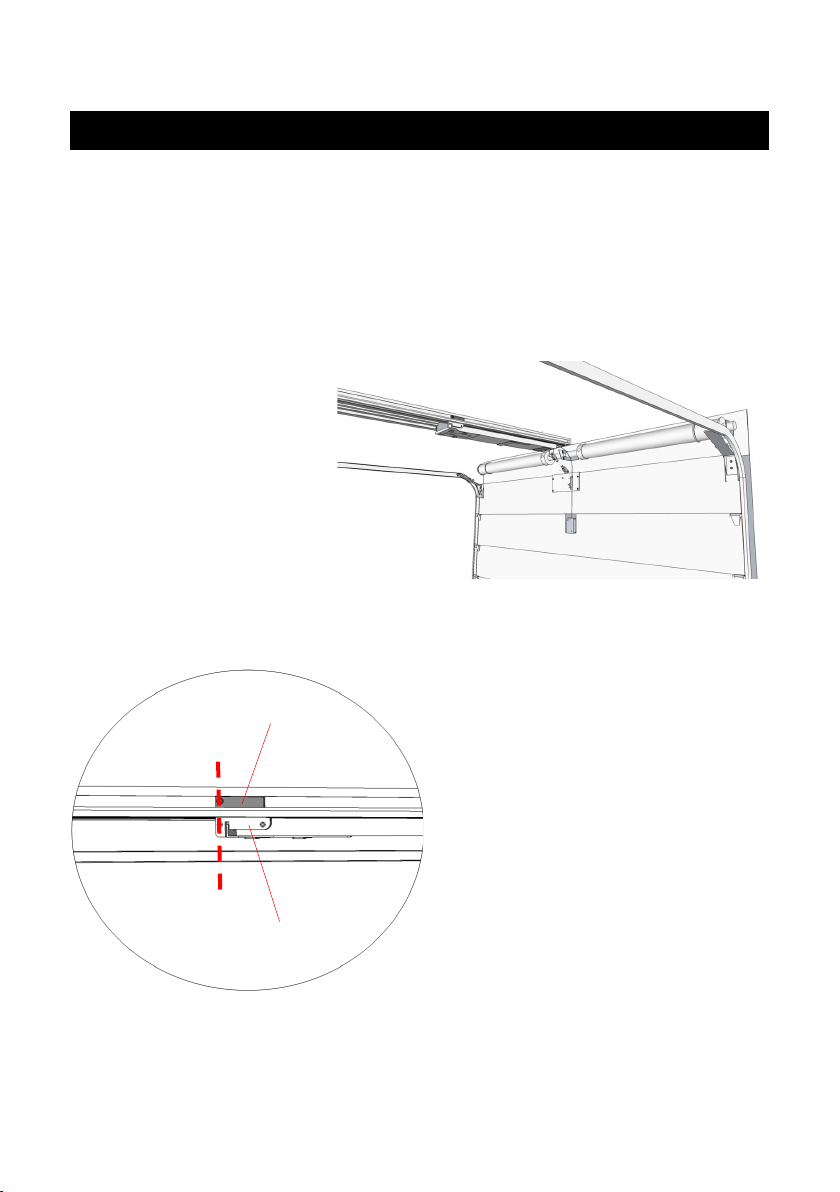

9. How to adjust the sensors

A

B

The sensor switch for the CLOSED posion is set at the factory, but may need ad-

justment depending on the header size and turnbuckle length.

Note: to gain acces to the Close switch, the track trim can be slid on the track to

gain access.

1. Disengage motor. Close

the door fully by hand.

2. Set the sensor (A) sideways to

match the cable slider (B). Both screw

heads should be in line, see picture

The cable slider holds a magnet.

DoorLIFT DL-6

Remote door system

Owner’s manual

18

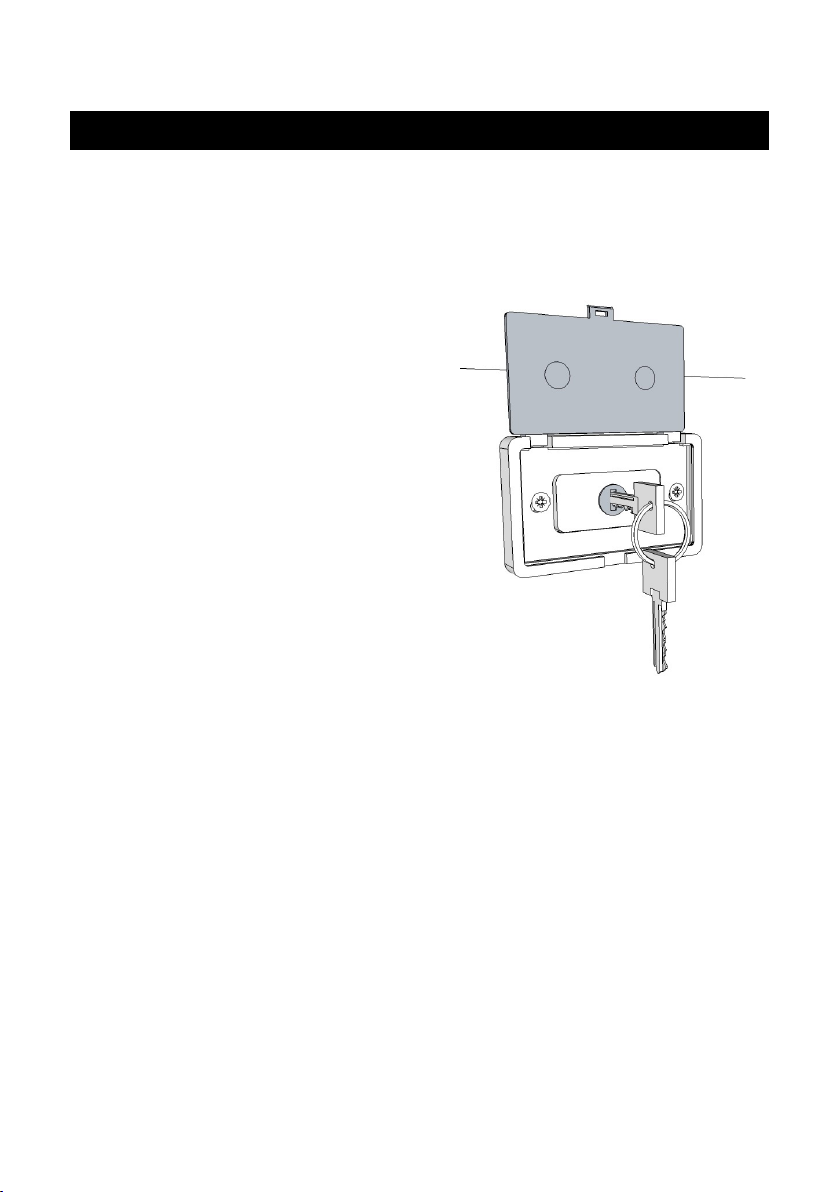

10. Emergency release

You may be occasionally required to release the DoorLIFT from the door, in order to

operate the shuer door manually. DoorLIFT can be released from the drive system

in the following way:

Using the exterior EMERGENCY release

1. Insert the DoorLIFT key into the lock

cylinder located in the center of the

second shuer door panel, on the

outside of the door.

2. Turn the key 90 degrees clockwise

and pull the lock and connecng

cable from the lock cylinder. Pull the

lock assembly rmly and the Door-

LIFT will be released from the drive

system.

3. Reinsert the cable and lock cylinder

back into the lock housing on the

door. The shuer door can now be

operated manually.

DoorLIFT DL-6

Remote door system

Owner’s manual

19

11. Basic trouble shoong

When your system isn't working properly or not at all, pleas check

the following:

1. Check for visible damage or obstrucon

2. Try if a dierent control device is working

3. Check the control box and see what the LED’s are telling you

LED Colour Sequence Issue/Funcon Explanaon

LED 1 Red Flash Low voltage input (during operaon) A

LED 1 Green Solid Power in B

LED 1 Green Flash In operaon C

LED 2 Orange Flash Signal received D

LED 2 Orange Solid Warning, overload motor-unit / obstrucon E

LED 2 Red Solid Error, me out door travel F

LED 1 None NA No input power G

LED Explanaon

A. The input on the systems is too low. Check the voltage and capacity of the baery. Also

check the cables from the baery to the control box for any damage or weary.

B. The control box has a power coming in

C. The control box has received the signal and is sending power out to the motor-unit. If

the motor-unit is sll not running, please see if the power is geng to the motor-unit by

taking of the cap (chapter 7, step 6) and measure the voltage in the connector on the

spiral cable.

Also check the motor-unit for any damage on wiring or gears.

D. The control box has received a signal from the control device. If you are using a remote

control and LED 1 is not starng to ash; try to reprogram the remote control to the

control box rst. If aer that, or when you use push buons, the LED 1 is sll not ash-

ing; the control box is not working.

E. The control box has detected a abnormality in the form of an obstrucon or overload on

the motor-unit. In both case, the currents got too high and the control box shuts o.

Check if there is nothing blocking the door from going up/down.

Check if the door closed sensor is adjusted right and the motor-unit reaches it.

Check if the motor-unit is running with normal speed and doesn't make a strange noise.

These are signs that the motor-unit is damaged and draws too much amperage from the

system.

F. The system took too long to get to the next point in the cycle. This might either be a

slow motor-unit (because the motors are not strong enough anymore) or the system is

not reaching one of the sensors in me.

G. The control box has no input power. Please check the fuse on the baery cable, the

baery and the cable itself.

DoorLIFT DL-6

Remote door system

Owner’s manual

20

12. Changing DL-8002152 Tooth wheel (24)

DoorLIFT DL-6

Remote door system

Owner’s manual

Take o the circlip Take o the tooth

wheel

Place the new tooth

wheel

Return the circlip

1. 2.

3. 4.

For all other repairs, please contact your dealer for support. Do not try to repair

the DoorLIFT by yourself, this requires specic knowledge and training.

Other manuals for DoorLIFT DL-6

1

Table of contents