Actuator Systems TCR-40C Series Parts list manual

TCR-40C-All Series-Intelligent on/off actuator usage instructions

◎Rated voltage: AC230V【AC95-265V】、AC/DC24V

◎Rated torque: 400N.m[450N.m@Max]

◎Running time: about 25s

◎Install valves: 2-way,3-way ball valve and butterfly valve

◎Wiring and feedback model:B3J、BD3J、B43J、B33J、B44J(J:Relay feedback,

synchronous feedback signal with actual arrival )

◎Alarm output: A(Relay contact feedback)

◎Direction of rotation and angle of rotation: double acting 90°

2 positions 180°, 3 positions or 4 positions

◎

Adopted high-performance brushless motor,Overload protection of internal motor

◎It can be used 20,000 times.*1

◎Two or more actuators can be used in paralle

※ Attention: Don’t use in paralle with Normal on/off actuator under control of the same contactor.

Product overview

Product features

△

0.96” double OLED screen,no visual dead angle,highly bright,energy saving and eco-friendly,real time to

show valve

opening angle and external control command.Enter sleeping state automatically after about

5 minutes,while

it could prompt location state and its control command at sleeping time.

△Original valve adjustment mode-free cover-opening and interactive:

step1:saving “anticlockwise full open position ” by using the button to control valve;

step2:saving “clockwise full close position ” by using the button to control valve;it makes valve adjustment easier.

Thoroughly eliminate the complex and inconvenience caused by mechanical positioning.

△

Adopt 16 High-performance microcontrollers,12 high-precision AD conversion,built-in unique algorithm,

thoroughly eliminate valve on/off inaccuracy caused by mechanical hysteresis,espacially suitable for 3-way

valve adjustment.

△Adopt non contact positioning,control unit moduarize design and potting processing,greatly improve product

service life;Interface uses standard connectors,convenient for installment,adjustment and replacement.

△M

enu can report real time failure,including stuck or other reasons which lead actuator fail to realize valve on/off

integrally,and output failure warning signal.

△Menu can realize valve control command exchange.

△

Menu can switch freely between remote control and local setting,and adopt button to realize valve on/off locally.

△

Menu can set valve close position deviation to on or off direction,thoroughly eliminate the complex and

inconvenience bring by “Normal On/Off mechanical positioning” to local valve adjustment.

△Menu can real-time adjust valve running speed of the actuator.

△Menu can restore factory default setting.

Success comes from our persistent pursue of perfect details.

Excellence originates from our persistence of win-win philosophy.

1

PART 2

User Manual

®

特克

.co

m

Made in china Global service

ISO9001

*1.

Test condition:Rated load,test at under 25℃working temperature and 50% humidity,lead the result from 2 times switching cycle,which will be influenced by different load

and working environment.

TCR-40C-All Series-Intelligent on/off actuator usage instructions

S3-85%(loading ≤85% rated torque refer to IEC60034-1-2017 *1)

*1

Operating mode: The testing environment temperature is 25 ℃ inside the factory. The testing standard as per IEC 60034-1-2017.The operation mode will be S3-90% if fthe

loading less than 60% rated torque..

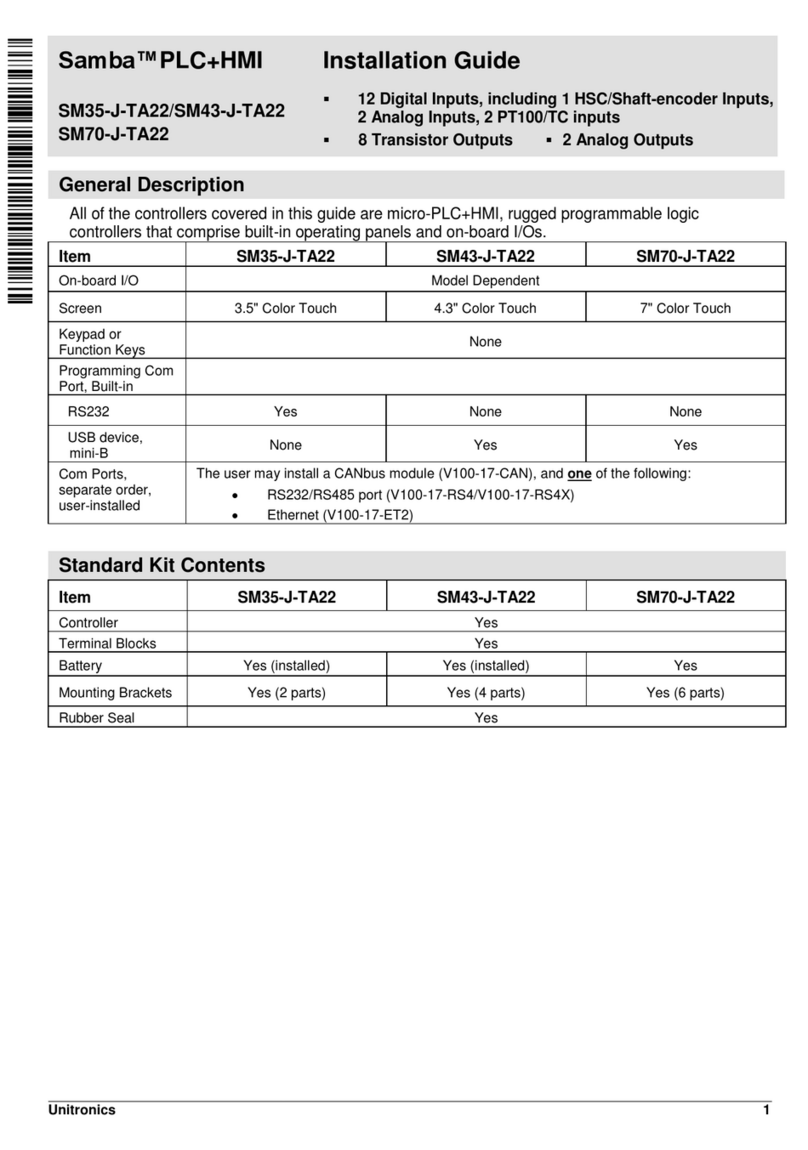

Technical data

Electrical data

Functional data

Rated voltage

Rated voltage range

Power consumption

Peak current

@Rated Voltage

Fuse

Rated torque

Angle of rotation

Max angle of rotation

Manual operation

Running time

Operating mode

Sound power level

Position indicator

Electricity safety level

Inflaming retarding level

Enclosure

Insulation resistance

Withstand voltage

Medium temperature

Working environment

Explosion-proof level

Ambient temp

Non-operation temp

Humidity

Ambient temperature*2

Working conditions

AC/DC95-265V(50/60HZ)

AC95-265V/DC100-300V

80W@MAX22W@running 5.9W@holding

0.36A/5ms@AC230V

2A

AC/DC24V

AC20-26V/DC22-30V

80W@MAX;19.2W@running 2.4W@holding

3.30A@5ms@DC24V

8A

I Type (ground protection ) III Type (ground protection )

100MΩ/500VDC

1500VAC@1Min

100MΩ/500VDC

500VAC@1Min

Connector

Success comes from our persistent pursue of perfect details.

Excellence originates from our persistence of win-win philosophy.

2

PART 2

User Manual

®

特克

.co

m

Made in china Global service

10P-5.08-500V ×(0.5-1.5)mm2 terminal

400Nm@rated voltage

90±2°

330±5°

※Matching hexagon wrench,using at no power

About 25s

65dB(A)

Mechanical and screen

1.6mmHB/UL94 test method

IP67 As Per En60529/GB4208-2008 (all directions)

F type can add dehumidifying heater

≤80°can install with actuator directly

※>80° need to install bracket or heat radiation stand

Indoor or outdoor; if exposed to the rain or sunshine,

need to install protective device for the actuator

Not explosion proof products, do not use in flammable

and explosive environment.

-15℃-+45℃(PC+PET)

≤-40℃or ≥80℃

5-95%RH non-condensing

[1]Ambient temperature <5℃,additional HTR is recommended.

[2]Ambient temperature <5 ℃and humidity>60%,

HTR +desiccant is recommended.

[3]Ambient temperature<5℃and humidity>80%,

HTR+desiccant+three preventing painting is recommended

[4]Ambient temperature>5℃and humidity>60%,

additional three preventing painting is recommended.

[5]Ambient temperature>5℃and humidity>80%,

additional desiccant+three preventing painting is recommended.

ISO9001

*2.

(1) It is customized item when used and stored under special ambient temperature of -20℃~-40℃,and special instructions are required.

(2) At the ambient temperature of - 40 ℃, power on is required for more than 15 minutes (30 minutes is recommended) before use. The higher the ambient temperature is,

the shorter the power on time can be.

(3) If user use the product at the ambient temperature of -40℃for long time, it needs to be insulated.For example,add heating cable around the actuator.If the ambient

temperature is over -20℃,then the heating cable can be canceled.

7*0.5mm² cable, voltage withstand AC300V (Length 800mm)

9*0.5mm² cable, voltage withstand AC300V (Length 800mm)

TCR-40C-All Series-Intelligent on/off actuator usage instructions

Success comes from our persistent pursue of perfect details.

Excellence originates from our persistence of win-win philosophy.

3

PART 2

User Manual

®

特克

.co

m

Made in china Global service

ISO9001

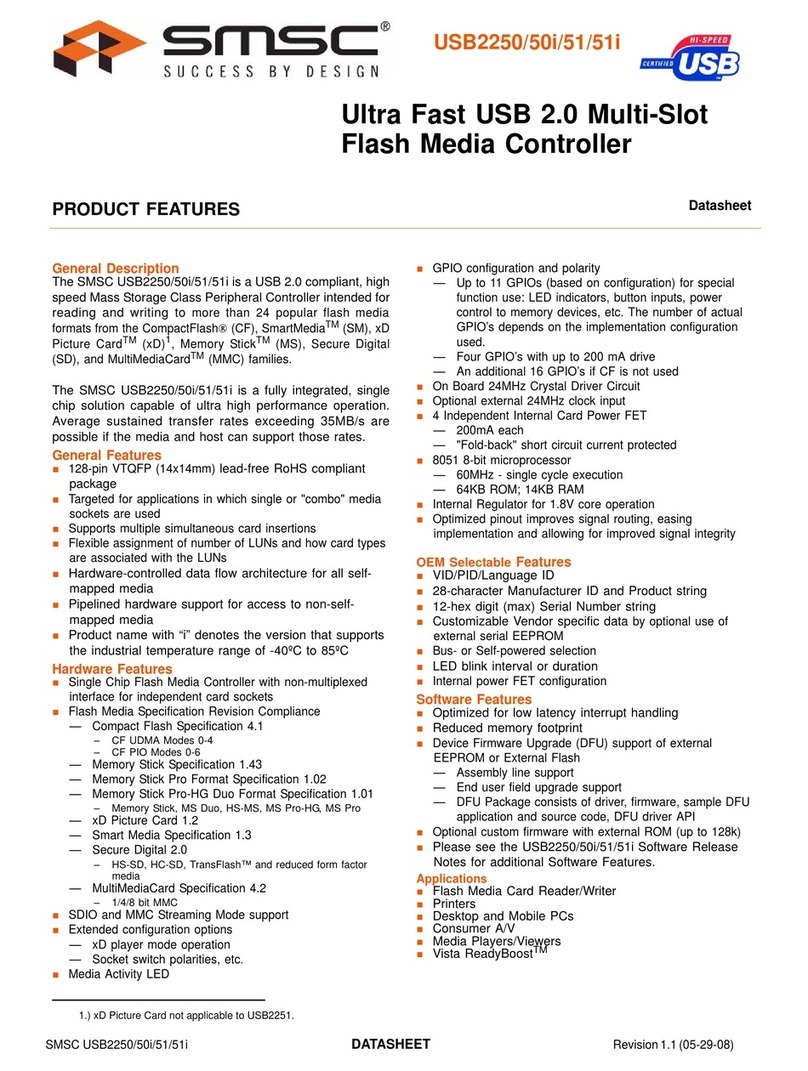

Main parts

Dimension 【

Female octagonal

】

1

2

3

4

5

6

7

Parts Material

Actuator

Indicator

Transparent AS

PC+PET

Screwx4

304

Manual shaft

304

LED

Transparent PC

8

9

10

11

Parts Material

Wrench fixed

ABS

Hexagon wrench

Tool steel

Waterproof cable

connector

NiLon

seal part between up

and down cover

Terminal cover

NBR

PC+PET

Clutch

Polyoxymethylene

POM

Height 30 mm

Unit:mm

Anti-condensation heater 【Accessory 】

Temperature Switch

Heating Resistor

※ Notice 1: The range of power is 2W-3W;

※ Notice 2:The range of constant temperature heating is 25℃±20%.

M20X1.5

water-proof lock nut

172

22

160

270

Ø70

Ø102

4-M8

Height 10mm

4-M10

Height 15mm

⑩

①

②

③

④

⑧

⑦

11

⑤

⑥

⑨

Dimensions / weight

Vibration Shock

Vibration amplitude

Installation notes

Maintenance

Certification

Dimensions (LXWXH)

Connection standard

Output axis specification

Hole deepness

Weight

≤5g

※10 to 55 Hz, 1.5 mm double amplitude

Mechanical indication is required to be upward, and manual

operation or wiring space shall be reserved

Free maintenance

CE

See “Dimensions”

ISO5211

F07、F10

Female octagonal

≤30mm(Female octagonal)

PC+PET material 6.0kg

TCR-40C-All Series-Intelligent on/off actuator usage instructions

Success comes from our persistent pursue of perfect details.

Excellence originates from our persistence of win-win philosophy.

4

PART 2

User Manual

®

特克

.co

m

Made in china Global service

ISO9001

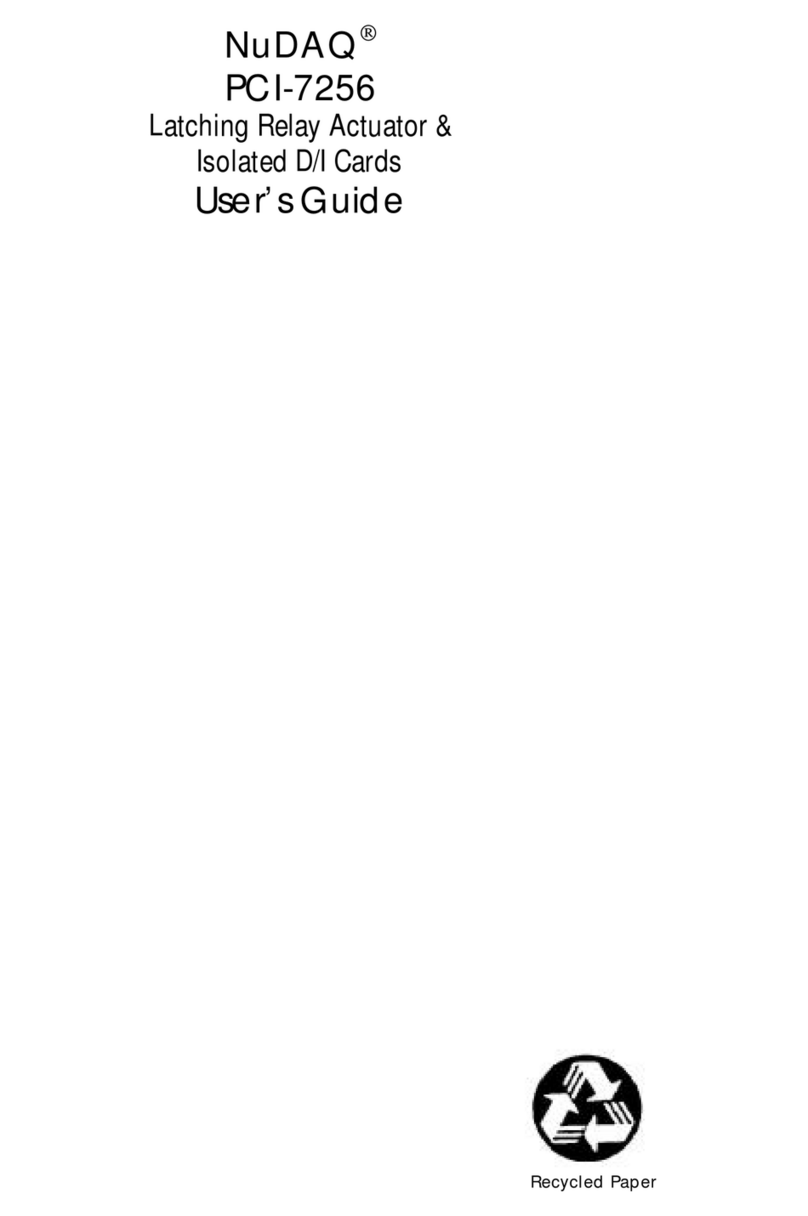

Wiring diagrams

B3JA/B3JA(KT)

N /V-

L /V+

M

1.3”

OLED

Screen

Signal

Acquisition

Voltage

Regulator

Pos_Sensor

16Byte

MCU

SW

Close

Open

Relay

Relay

Relay

3

5

6

1

2

7

8

9

AC-DC

PE

Motor

Driver

M

BD3JA/BD3JA(KT)

N /V-

L /V+

M

1.3”

OLED

Screen

Signal

Acquisition

Voltage

Regulator

Pos_Sensor

16Byte

MCU

Relay

Relay

Relay

AC-DC

PE

Open Close

SW

Motor

Driver

M3

5

6

1

2

7

8

9

B33JA/B33JA(KT)

10 10

BU

RD

BK

Y/G

GN

PL

GY

BN

WT

N /V-

L /V+

M

1.3”

OLED

Screen

Signal

Acquisition

Voltage

Regulator

Pos_Sensor

16Byte

MCU

Relay

Relay

Relay

Li_Battery

Protection

AC-DC

PE

Motor

Driver SW1

SW2

M3

5

6

1

2

7

8

9

10

B43JA/B43JA(KT)

N /V-

L /V+

M

1.3”

OLED

Screen

Signal

Acquisition

Voltage

Regulator

Pos_Sensor

16Byte

MCU

FK_3

FK_2

FK_1

FK_COM

Relay

Relay

Relay

Li_Battery

Protection

AC-DC

PE

signal common end

Motor

Driver SW1

SW2

M3

5

4

6

1

2

7

8

9

10

Super

Capacitor Super

Capacitor

Super

Capacitor

Super

Capacitor

PE

FK_Alert(optional)

FK_Open

no connection(spare terminal)

FK_Closed

FK_COM

BU

RD

BK

Y/G

GN

PL

GY

BN

WT

BU

RD

BK

Y/G

GN

PL

GY

BN

WT

BU

RD

BK

OG

Y/G

GN

PL

GY

BN

WT

PE

FK_Alert(optional)

FK_Open

no connection(spare terminal)

FK_Closed

FK_COM

PE

FK_Alert(optional)

FK_Open

no connection(spare terminal)

FK_Closed

FK_COM

PE

no connection(spare terminal)

Control instructions:

□

SW is connected with CLOSE,

the actuator will rotate clockwise . When the valve is closed,

is connect with ,giving signal of closing.

□

SW is connected with OPEN ,the actuator will rotate anticlockwise . When the valve is open,

is connect with ,giving signal of opening.

※Notice 1

:

is not connected with and , when the actuator is rotating.

※

Notice 2

:

After power cut,the feedback and fault signal will disappear,

is not connected with

and

.

10

9

10 8

10 9 8

10 9 8

Control instructions:

□

SW is connected with CLOSE,

the actuator will rotate clockwise . When the valve is closed,

is connect with ,giving signal of closing.

□

SW is connected with OPEN ,the actuator will rotate anticlockwise . When the valve is open,

is connect with ,giving signal of opening.

※Notice 1

:

is not connected with and , when the actuator is rotating.

※

Notice 2

:

After power cut,the feedback and fault signal will disappear,

is not connected with

and

.

10

9

10 8

10 9 8

10 9 8

※

Notice 3:For the actuator with failsafe function,the actuator will rotate forward to the set direction after supply power

fails and it will stop automatically when it arrive set position .

SW1 Flow direction

0°

90°

mid position

(could be free set by menu)

SW2

Control instructions:

connect

connect

disconnectconnect

connect

disconnect

Feedback signal

connect with

connect with

connect with

9

10

8

10

9810

Alarm single(optional)7

10 connect with

connect connect

connect

connect

disconnect

disconnect

disconnect

disconnect

SW1 Flow direction

1th positon

2th positon

3th positon

4th positon

SW2

Control instructions:

Feedback signal

Alert status and feedback

signal are setted by menu

Success comes from our persistent pursue of perfect details.

Excellence originates from our persistence of win-win philosophy.

5

PART 2

User Manual

®

特克

.co

m

Made in china Global service

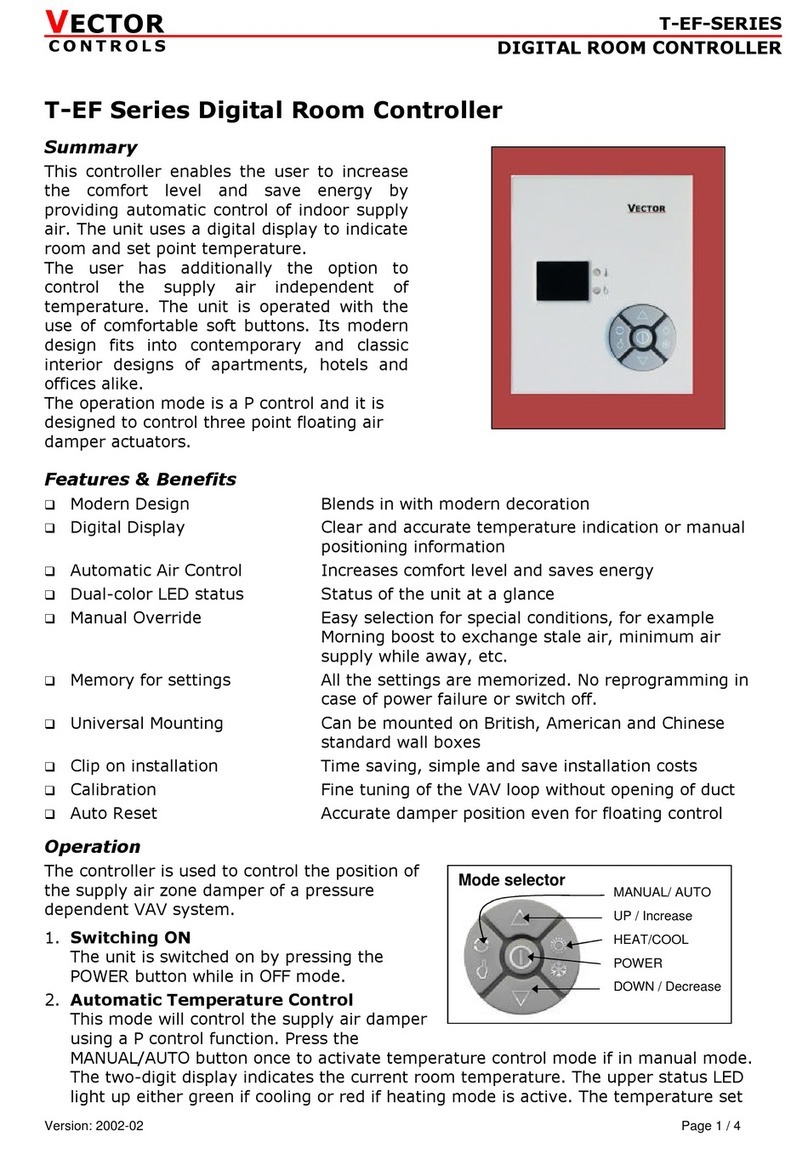

Right wiring

M

1.3”

OLED

Screen

16Byte

MCU

Motor

Control

AC-DC

M

1.3”

OLED

Screen

16Byte

MCU

Motor

Control

AC-DC

AC Power

Intelligent on/off actuator

Intelligent on/off actuator

Error wiring

XNormal on/off actuator

Intelligent on/off actuator

1

M

1.3”

OLED

Screen

16Byte

MCU

Motor

Control

AC-DC

AC Power

Wire notice

※Note:Don’t use in paralle with Normal on/off actuator under control of the same contactor.

Wiring diagrams

TCR-40C-All Series-Intelligent on/off actuator usage instructions ISO9001

Terminal block of the product without cable.

20C/40C-95-265V terminal block

20C/40C-12/24V terminal block

12345 678910

12345 678910

Test terminal for the cable end_wiring instruction

1.Fuse:please refer to manual for more parameters.

2.SW switching capability:please refer to manual for more parameters.

3.Feedback signal contact load capacity:0.1A/250VAC 0.5A/30VDC.

4.Please make sure actuator connect ground reliably

5.Some products adopt wiring box ,user could wiring according to the

order of number.

Cable terminal for test

(actuator with Alarm function)

(User could cut out the cable terminal

as it is only used for factory test)

OG

BK

RD

BU

GY

WT

BN

PL

Y/G

Cable terminal for test

(General specification)

(User could cut out the cable terminal

as it is only used for factory test)

BK

RD

BU

GY

WT

BN

Y/G

Terminal block for product without cable

_Wiring instruction

1.Fuse:please refer to manual for more parameters.

2.SW switching capability:please refer to manual for more parameters.

3.Feedback signal contact load capacity:0.1A/250VAC 0.5A/30VDC.

4.Please make sure actuator connect ground reliably.

5. Orange terminal is for the product in 95-265V (include 220V).

Black terminal is for the product DC12V/DC24V.

6. Some products adopt wiring box ,user could wiring according to the order of number.

TCR-40C-All Series-Intelligent on/off actuator usage instructions ISO9001

Diagram1 UPVC plastic ball valve+bracket assembly,Diagram2 3piece stainless steel ball valve assembly

Diagram3 3piece stainless steel 3way ball valve assembly

Mounting instructions

Notice:

※

1.When assembly with valve,it's suggest to use spring washer add

flat washer in order to fasten the screw and nut.

※

2.It's recommend to use 704 silica gel or instant cement instead of

anaerobic adhesive and UV glue.

※

3.Pls keep the actuator housing away from organic solvents,such as:

kerosene,butanone ,tetrachlormethane etc.,or the housing will crack.

Diagram1(With bracket) Diagram2(Direct mount) Diagram3(Direct mount)

Success comes from our persistent pursue of perfect details.

Excellence originates from our persistence of win-win philosophy.

6

PART 2

User Manual

®

特克

.co

m

Made in china Global service

Installed valve technical requirements

□1.

If the ball valve is out of operation for a long time, and the torque value

of

first on or off is the max torque

□2.

When installing direct mount model valve, the hole deep

≤30

mm. It requires cutting if the output shaft is longer than

30

mm.

□3. Pls pay attention to the following items if you install the bracket and coupling by yourself:

※

The intensity of bracket should meet the using requirements: the bracket twisting extent ≤0.2mm in the process of on or off.

※The parallelism of bracket ≤0.5mm.

※

When processing the shaft hole at both end of the coupling, it is necessary to ensure the accuracy and concentricity. The

purpose is to make sure the mechanical hysteresis ≤10°, otherwise it will cause the actuator unable to work.

□4.

Screw should be installed spring washer、flat washer, and we suggest you daub some glue cement around the screw in

case of screw loosening.

□5.

After installation, user should switch the valve on and off one time with handle device first. Modifying the valve after make

sure it works well.

Valve type Recommend install condition

wafer butterfly valve

flange butterfly valve

metal ball valve

plastic ball valve

actuator rate torque≥2times valve max torque

actuator rate torque≥1.7times valve max torque

actuator rate torque≥1.7times valve max torque

actuator rate torque≥1.5times valve max torque

ISO9001

TCR-40C-All Series-Intelligent on/off actuator usage instructions

Working environment

Safety notice

□ Indoor and outdoor are both optional.

□ Not explosion proof products, do not use them in flammable and explosive environment.

□ You need to install protective device for the actuator,if it is exposed to the rain or sunshine .

□ Please pay attention to the ambient temp.

□ When installing, you need to consider the reserved space for wiring and repairing.

□ When power on, it is not allowed to dismantle actuator and valve.

□ When power on, it is not allowed to do wiring.

□ ※Absolutely no falling down the ground, which will hit the device and lead to improper operation.

□ ※Absolutely no standing on the device, which will cause device malfunction or personal accident.

□ ※It is forbidden to do wiring project in rainy day or when there is water splash.

□ In order to use the device safely for a long term, please pre-read the manual carefully to ensure correct use.

□

Notice item: Please understand the product specification and using method clearly to prevent persona safety

danger or device damage.

□ In order to indicate damage and danger, here we classify them as “warning ” and “notice ※”.

□ Both of contents are very important, which should be obeyed strictly.

“Warning ”: It will cause death or serious injury if not obeyed.

“Notice ※”: It will cause slight injury or device damage if not obeyed.

□ Su bject to technical changes.

Fault phenomenon

Actuator no action

△1power not connected

△2voltage below level or incorrect

△3overload protection of motor after 3s

△4terminal loose or poor contact

△5starting capacitance poor run

□

1

Actuator interior water

ingress

△1OD of incoming line cable non-standard

△2waterproof treatment of incomingline incomplete

△3actuator lens wearout

△4screws on connection cover/head cover /slide cover loose

□

4

Actuator not fully closed

□

3

No feedback signal △1line barrier of user acquisition signal

△2actuator is cut off the power

□

2

Fault cause Processing methods

Receive feedback signal doesn’t mean

actuator is fully closed, so don’t cut power off

△2return difference increases due to abrasion between

actuator and valve rod

△1use feedback signal to control actuator

Contact the manufacturer to get repair

Check whether valve gets stuck or torque value is too big

Connect power

Check whether voltage is within the normal range

Check and correctly connect terminal

Contact the manufacturer to get repair

Connect user acquisition signal

Connect power and signal will be normal

1

Adjust valve-off position to realize deviation by the menu

2 Contact the manufacturer to get repair

Common failures and processing methods

ver:20161015

ISO9001ISO9001

Success comes from our persistent pursue of perfect details.

Excellence originates from our persistence of win-win philosophy.

7

PART 2

User Manual

®

特克

.co

m

Made in china Global service

Table of contents

Popular Controllers manuals by other brands

Tech Controllers

Tech Controllers EU-81zPID user manual

JLCooper Electronics

JLCooper Electronics SharpShot user manual

Truma

Truma DuoControl vertical operating instructions

Hunter

Hunter Eco-Logic 6 Owners manual and programming instructions

Autonics

Autonics TZN Series manual

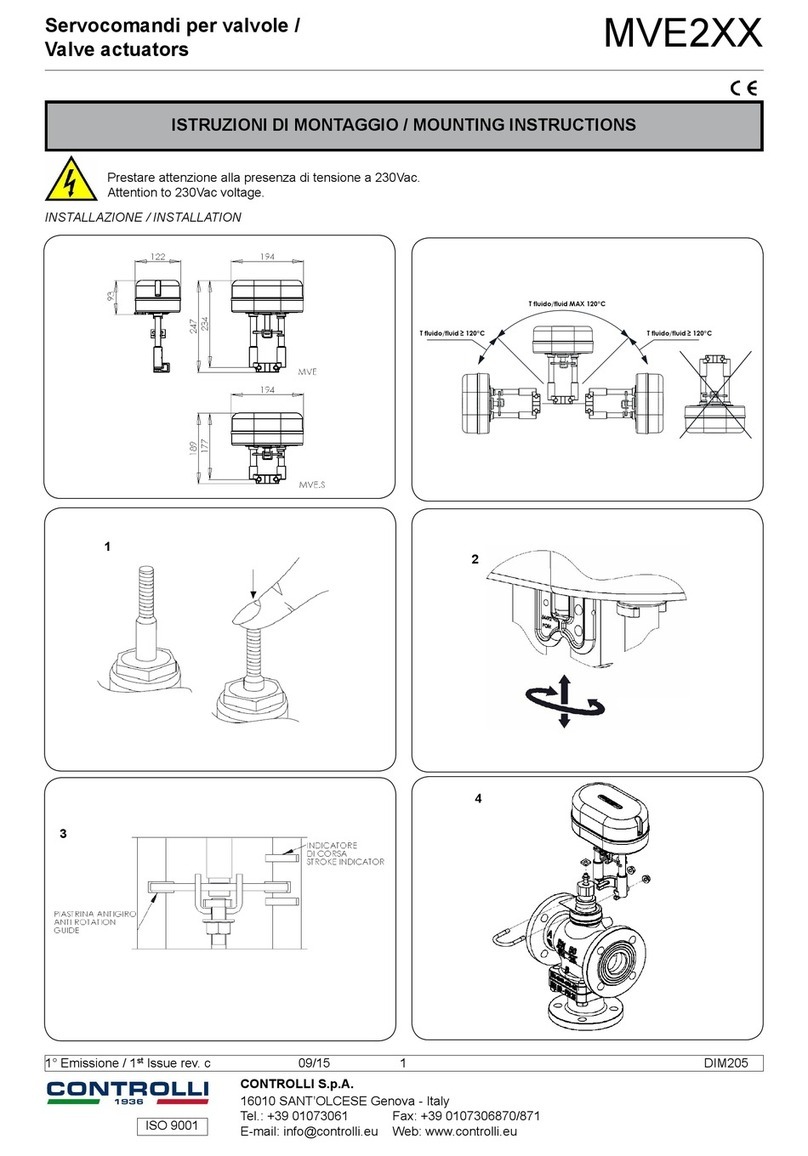

Controlli

Controlli MVE2XX Mounting instructions