Page | 3

Programming Dip Switch .......................................................................................................23

Section 5.........................................................................................................................................25

Operation...................................................................................................................................25

Basic Controller Theory.......................................................................................................... 25

Linear Acceleration Option .................................................................................................... 26

Fixed Brake Option................................................................................................................. 27

Figure 5-2: Model 4000/4050 Controller Block Diagram................................................. 27

Spring Set Brake Option......................................................................................................... 28

Adjustable Brake Modification, 15-444-4 ..............................................................................28

Alternate Speed Modification, 15-444-3 ............................................................................... 28

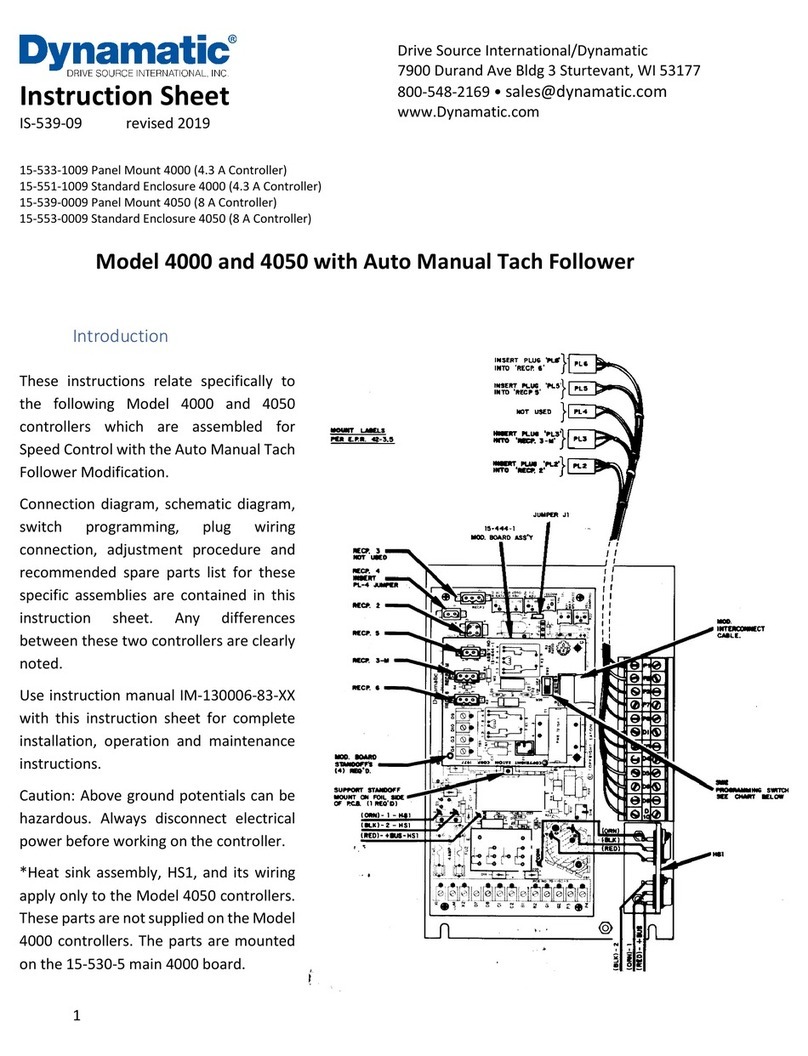

Tach Follower Modification, 15-444-1................................................................................... 29

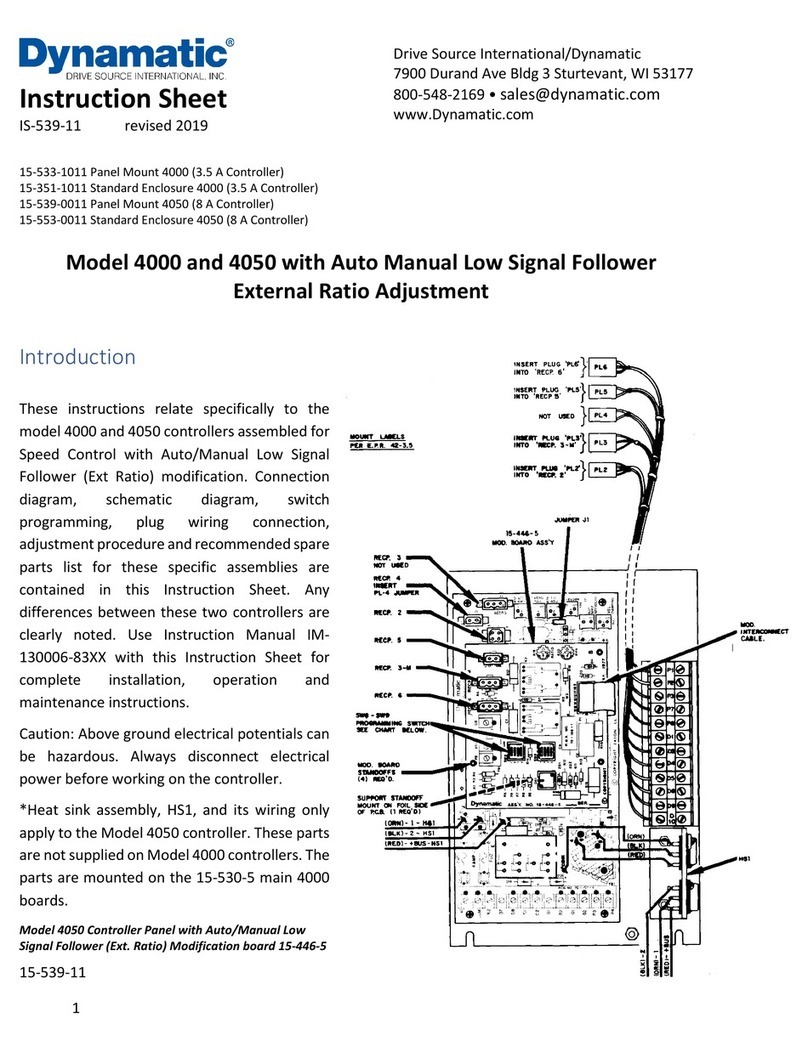

Low signal Follower Modification 15-446-1/5/101 ...............................................................29

Torque/Speed Modification, 15-444-5 ..................................................................................29

Torque Limit Modification, 15-444-2..................................................................................... 30

Dancer Position Modification, 15-444-7................................................................................ 30

Figure 5-3: Model 4000 Controller Schematic with 15-530-5 Main Assembly ................ 31

Figure 5-4: Model 4050 Controller Schematic with 15-530-6 Main PCB Assembly........... 32

Mutuatrol® Modification, 15-446-2....................................................................................... 33

Variable Air Volume Modification (VAV), 15-446-3/102 ....................................................... 33

Linear Accel/Decel Modification, 15-446-4 ...........................................................................33

Section 6.........................................................................................................................................34

Start-Up and Adjustments .........................................................................................................34

Tools Required .......................................................................................................................35

Power Off Tests......................................................................................................................35

Power on Tests....................................................................................................................... 36

Set-Up of Main PCB Assembly ...............................................................................................37

Basic Speed Control ............................................................................................................... 37

LED Set-Up ............................................................................................................................. 38

Zero Adjust R19 with LED monitor- ................................................................................... 38

Zero Adjust R19, Alternate Method- .................................................................................38

Max Speed/Volts R21.........................................................................................................39

Max Speed/Volts R21 with LED Monitor ........................................................................... 39

Max Speed/Volts R21, Alternate Methods-.......................................................................39

Time Constant (TC) Adjust R26-.........................................................................................40

Accel Rate R18 ...................................................................................................................40