ADA INSTRUMENTS GroundHammer-3 User manual

Operating manual

Gasoline jack hammer

Model: GroundHammer-3/4

Manufacturer Address: WWW. ADAINSTRUMENTS.COM

INSTRUMENTS

GroundHammer

INSTRUMENTS

1. Introduction .......................................................................................................................................................................................3

2. Instruction of safe operation............................................................................................................................................................3

3. Name of major part........................................................................................................................................................................5

4. Main use and feature ....................................................................................................................................................................7

5. Prepared work before using.............................................................................................................................................................7

6. Start, run and stop machine.................................................................................................................................................................9

7. Technicaldata.....................................................................................................................................................................................10

8. Failure analysis and troubleshooting methods................................................................................................................................11

9. Technical maintenance......................................................................................................................................................................12

10. Warranty ..........................................................................................................................................................................................15

11. Exceptions from responsibility .......................................................................................................................................................15

Appendix 1. Warranty card

Appendix 2.

Table of contents

MEASUREMENT FOUNDATION

GroundHammer

INSTRUMENTS

3

1. Introduction

Thanks for the purchase of ADA Instruments product. Beforer starting operation read carefully the operating manual. Keep it always at hand.

ADA Instruments product has ergonomic desing. It provides usability, high power and productivity.

Content of the operating manual may not fully correspond to the purchased instrument.

2. Instruction of safe operation

1. Only adults can use ground drill.

2. Users can’t operate ground drill if they didn’t read the operating manual.

4. Ensure that anyone who uses the instrument is familiar wi th all controls and safety precautions.

5. Wear non-slip protective shoes, protective gloves, glasses, earmuffs and helmet .

6. When you use the instrument don´t wear scarfs and jewellery.

8. Never run engine in a poorly ventilated area where the exaust fumes may be trapped and not easily taken away.

9. Move ground drill without power, detach the auger.

10. Replace auger if there are cracks and damages on it.

11. Use the mixture of fuel with octane level 92 and oil for 2 -stroke engines, in the ratio 25:1.

13. Never remove the fuel cap with the engine running. Always keep (min 3m) the instrument (before starting) from the area with spilled fuel.

14. Always keep the handles of the instrument dry and clean.

15. Before starting ensure that auger is not locked.

16. Never touch auger and don´t do servicing with engine running.

17. After you start the engine or before you stop working let the engine work at no load 2-3 min. Never stop suddenly the engine at great speed.

MEASUREMENT FOUNDATION

GroundHammer

INSTRUMENTS

4

19. Move the instrument during operation at no load.

20. Never touch the coating of spark plug or wire if the engine is running. Or electric shock may occur.

21. Store the instrument in an upright position with empty fuel tank.

22. Regularly check, adjust, repair and clean the instrument.

23. Don´t disassemble return starter. You can be seriously hurt.

24. Contact service center for maintenance that is not mentioned in this manual.

25. If your instrument is not suitable for use any more, dispose of it. Make sure that you don´t do damage to the environment.

MEASUREMENT FOUNDATION

GroundHammer

INSTRUMENTS

1

2 3 4 5

6

7

8

9

10

11

12

13

14

15

16 17

18

5

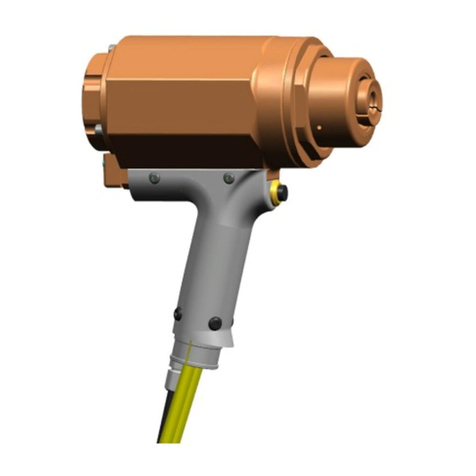

3. Name of major part

GroundHammer 3:

1. Handle

3. Stop Button

4. Throttling Handle

5. Starter Handle

6. Air Filter

7. Tank Cap

8. Spark Plug

9. Gearbox

10. Assist Handle

11. Cylinder Block

12. Drill Seat Installation Set

13. Sliding Sleeve

14. Protect Cover

15. Drill

16. Admitting Switch

17. Carburetor

18. Gearbox Cover

GroundHammer 3

MEASUREMENT FOUNDATION

6

GroundHammer

INSTRUMENTS

GroundHammer 4:

1. Combination switch

2. Stop switch

3. Starter handle

4. Adjust switch

5. Throttle switch

6. Hammer case

7. Hammer socket

8. Piling socket

9. Support plate

10. Grip

11. Damping spring

12. Positioning sleeve

13. Handle

14. Spark plug

15. Intake switch

17. Oil tank cap

18. Oil tank

19. Fuel bubble

20. Steel cover

21. Throttle cable

GroundHammer 4

4

2

1

5

13

12

11

96

10

7

15

8

14 16 17

19

20

21

3

18

MEASUREMENT FOUNDATION

GroundHammer

INSTRUMENTS

7

4. Main use and feature

Use

1. It can be used on building construction, road building project.

2. Break cornerstone for the railway road and tamp sleepers work.

3.In cold water and ice breaking region, do ice-breaking work with digging shovel so as not to destroy the hard ground.

4. It can be used on pipe laying, drainage construction and harbor construction.

Features

1. It is the world’s lightest weight, lowest displacement engine type handheld gasoline hammer.

shovel digging a 360 degree rotation.

3. It can regulate the number of impact energy and impact, apply for a variety of materials suitable for construction.

4. Applications: Our machine is suit in many kinds of situations, such as crashing project in road-building, electric power, telecom, and cable, ditch.

5. The handle of machine has rubber coating. It greatly reduces the recoil force of the machine, and improves the comfortable for the user.

5. Prepared work before using

Installation the drill

1. Lubricating the drill.

2. Clean the chisel and gripping chuck with the cloth to remove

old lubricant with dust.

Important: put the lubricant on the back part of the chisel. Other-

wise it will runout very fast. Move up the gripping chuck, insert

the drill into the drill seat then release the gripping chuck, make

Fuel

The general gasoline and the two-stroke oil mix. Fig.1

MEASUREMENT FOUNDATION

GroundHammer

INSTRUMENTS

8

Fig.2

Recommended mixing ratio:

Conditions gasoline : engine oil

Work within 20 hours 20:1

Work after 20 hours 25:1

1. Prohibit the use of pure gasoline (no refueling

two-stroke engine oil) for fuel.

2. Add fuel in the well-ventilated place.

the neck. If any fuel spill, please completely remove

or evaporate before starting the gasoline engine

4. After refueling, tighten the fuel tank cap.

MEASUREMENT FOUNDATION

9

GroundHammer

INSTRUMENTS

6. Start, run and stop machine

with fuel.

Close the air vent when the engine is in the state of cooling, but

open the air vent only when the engine is heated.

the operation handle with one of your hands and quickly pull

the pulling handle with the other hand. Do not let the pulling

handle go back freely in your repeat pulling, but hold it and put

it down with its resilience to protect the starter.

3. Open the air vent completely when the gasoline engine is

started.

Air vent

Start

Fuel

bubble

Fig.3

Run

1. Let the engine warm up at low speed for at least 5 minutes before the operation.

2. Prohibit use gasoline hammer under the non-breaking with high speed operation.

Stop machine

1. Release the gas handle.

2. Press the red button to stop.

MEASUREMENT FOUNDATION

GroundHammer

INSTRUMENTS

10

7. Technical data

GroundHammer-3 GroundHammer-4

Engine type Single cylinder, air cooling, 2 stroke

LxWxH (mm) 603x280x375

Fuel mixing oil (gasoline 25, two-stroke engine oil 1)

Fuel tank capacity 0.9 L 1.2 L

Weight 10.5 Kg 13 Kg

Displacement 42.5 CC

Max power and speed 0.9 KW/6500 r/min 1.2 KW/6500 r/min

Max torque and speed 1.45 N.m/5000 r/min

Consumption rate

Impact frequency 1700~2230 BpM

Impact energy 25~45 J

Spark plug type L6 L6T

Starter system Hand pull start

MEASUREMENT FOUNDATION

11

GroundHammer

INSTRUMENTS

Whether fuel runs out or the Carburetor is blocked

Too much carbon deposit in igniter plug Remove carbon deposit

Example 3: Reluctance in speeding and weakness in power

Carbon deposit cover the entrance of the cylinder or silencer Remove carbon deposit

Whether the oil tube and the air vent on the fuel Tank cover is

blocked

Clean

8. Failure analysis and troubleshooting methods

Whether the spark plug is moisture Dry the igniter plug

Whether the spark plug produces electric spark Replace the igniter plug

Too much fuel absorbed Lessen the fuel supply

MEASUREMENT FOUNDATION

12

GroundHammer

INSTRUMENTS

Example 4: Abnormal sound

Carbon deposit found in combustion chamber Remove carbon deposit

Serious abrasion in active components Replace

The head of the chisel is attrited badly Replace or renew

Please contact with Sales Agency of the Crusher if your machine needs further mending.

9. Technical maintenance

Technical maintenance, replacement or repair must be carried out in the service centers.

DAILY TECHNICAL MAINTENANCE

1. Check the centering of the instrument. Check it for the sharpness and presence of cracks. Chisel with improper centering has strong

vibration and it can damage the instrument.

2. Check the stability and tightening of the instrument.

WEEKLY TECHNICAL MAINTENANCE

1. Check the starter, especially cord and pull-back spring.

2. Clean the outside surface of the spark plug.

3. Check the gear-box unit for the presence of lubricant.

MEASUREMENT FOUNDATION

13

GroundHammer

INSTRUMENTS

MONTHLY TECHNICAL MAINTENANCE

1. Wash the fuel tank with the fuel.

2. Clean the outside surface of the carburetor and the area around it.

3. Clean the outside surfaces.

The following Data are given for common use of the prod-

uct. Suppose it is in worse working condition, such as thick

dust in the air or much longer work hours for Crusher, the

maintenance cycle should be shortened correspondingly.

Before

work

After

work or

every day

After Fill-

ing oil

Every

Week

Every

Month

Broken

Down

If neces-

sary

The whole machine

outlook check (state,

stabilities of screws) x x

Cleaning x

Control handle/stop button function check x x

Air Filter Clean x x

Replace x

Fuel Filter Check x

Replace x

Petrol Tank/Petrol Tank

cover

Clean x x

Check x x

Tighten x

MEASUREMENT FOUNDATION

14

GroundHammer

INSTRUMENTS

Gear Box/Hammer Box Clean x

Add oil x

Chisel Check Sharpness x

Sharpen or Forge x

Replace x

Silencer Check x

Remove carbon deposit x

Cylinder Cooling Fin Check x

Clean x

Spark Plug Check/Adjust Customize

the distance between

electrodes

x

Replace x

Screw and Nut Check x x

Tighten x

MEASUREMENT FOUNDATION

GroundHammer

INSTRUMENTS

15

Warranty

This product is warranted by the manufacturer to the original purchaser to be free from defects in material and workmanship under

normal use for a period of one (1) year from the date of purchase.

During the warranty period, and upon proof of purchase, the product will be repaired or replaced (with the same or similar model at

manufactures option), without charge for either parts of labour.

Warranty also applies to spare parts. In case of a defect please contact the dealer where you originally purchased this product. The

warranty will not apply to this product if it has been misused, abused or altered. Without limiting the foregoing, leakage of the bat-

tery, bending or dropping the unit are presumed to be defects resulting from misuse or abuse.

To get warranty support, apply service center: in full complete set; with warranty card; with rest of the fuel (no less 100 ml) in fuel tank.

The instrument must be clean. Service center can refuse warranty support in case of non-observance of these claims.

Exceptions from responsibility

The user of this product is expected to follow the instructions given in operators’ manual.

Although all instruments left our warehouse in perfect condition and adjustment the user is expected to carry out periodic checks of

the product’s accuracy and general performance.

The manufacturer, or its representatives, assumes no responsibility of results of a faulty or intentional usage or misuse including any

of data and interruption of business etc., caused by using the product or an unusable product.

explained in the users’ manual.

The manufacturer, or its representatives, assumes no responsibility for damage caused by wrong movement or action due to connect-

ing with other products.

WARRANTY DOESN’T EXTEND TO FOLLOWING CASES:

- damage to products or parts caused by misuse, including, without limitation, misapplication or nrgligence of the terms of service

exposed to the self-dependent repair or disassembling during warranty period;

- the instrument that has damages, defects because of outer mechanical, thermal, chemical effects, unproper maintenance, storage or

acts of God;

- defects caused by reasons that are not depended on the manufacturer, such as usage of fuel that has inadmissible state standard, usage

of oil and mixture of inadmissible quality, and also voltage drop of power;

- instrument has damages caused by presence of any liquids and foreign objects inside the product. Ventiducts, fuel and oil holes are

clogged up;

- normal runout of the instrument, inner or outer clogging;

- the instrument is overload (continuous operation with max load) that leads to the breakage of piston-cylinder-unit;

- the instrument with breakage of piston-cylinder-unit because of continious operation at idle;

than an authorized service center;

- if the standard or serial product number will be changed, erased, removed or will be unreadable;

regular maintenance of the instrument.

For more information you can visit our website WWW.ADAINSTRUMENTS.COM

WARRANTY CARD

Name and model of the product ________________________________________________

Serial number ________________date of sale_______________________

Name of commercial organization _____________________stamp of commercial organization

Warranty period for the instrument explotation is 12 months after the date of original retail purchase.

During this warranty period the owner of the product has the right for free repair of his instrument in case of manufacturing defects.

occur in the result of the instrument outage.

The product is received in the state of operability, without any visible damages, in full completeness. It is tested in my presence. I have no

complaints to the product quality. I am familiar with the conditions of qarranty service and i agree.

purchaser signature _______________________________

Before operating you should read service instruction!

If you have any questions about the warranty service and technical support contact seller of this product

__________________________________________________________________________

__________________________________________________________________________

name and model of the instrument

Corresponds to ______________________________________________________________

designation of standard and technical requirements

Data of issue _______________________________________________________________

Stamp of quality control department

Price

Sold ___________________________________ Date of sale ______________________

name of commercial establishment

Отбойный молоток

Руководство по эксплуатации

Отбойный молоток

INSTRUMENTS

GroundHammer

INSTRUMENTS

Приложение 1.

Приложение 2.

Содержание

This manual suits for next models

1

Table of contents

Languages: