Adams Cleanaire CA-1000T User manual

••

.

'»'"','

•'

,'"*•

•

'^

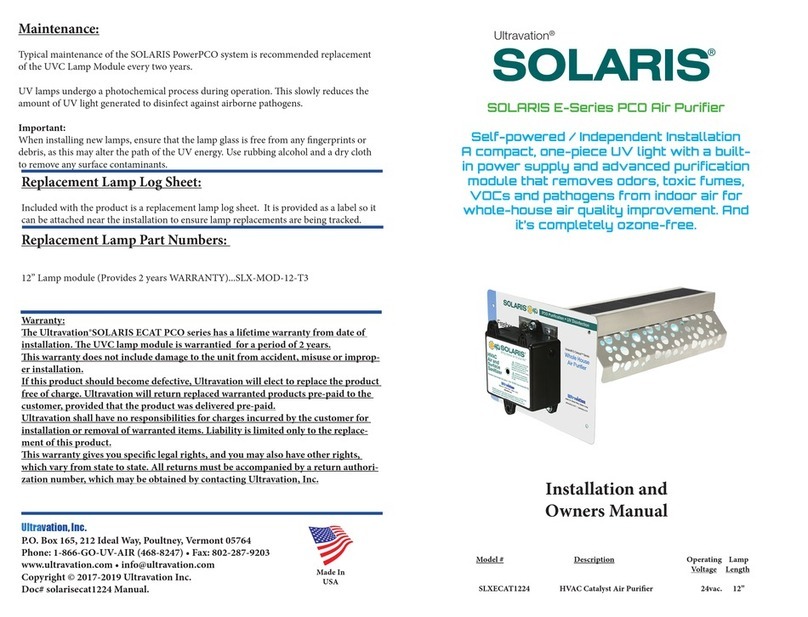

Self-contained

Ceiling

Mount

Electronic

Air

Cleaner.

Fits

T-Bardrop

ceiling

or

mounts

directly

to

standard

ceiling.

Quieter

performance*

Adjustable

discharge louvers

on

4

sides.

Cleans

ait

better.

Higher capacity.

•

Three speed fan.

•

Activated

carbon

after-filter

t&

remove

odors.

•

Decorator design

and

finish

(blends

with

most

any

decor).

INSTALLATIONMANUAL

GENERAL

This

manual

contains

information

for

location,

installation,

operation

and

service.

Before

installation

and

operation

oftheair

cleaner,

read

instructions

carefully

to

insure

safe

and

effective

operation

of

this

unit,

and

avoidunnecessary

service

cost.

Carefully

unpack

unit

and

check

for

damage

in-

curred

in

shipment.Report

any

damage

to

freight

line

immediately.

Proper

installation

procedures

for

both

T-BAR

ceiling

and

flush

mount

installation

are

pro-

vided.

Follow

method

that

bestsuites

appli-

cation

forair

cleaner.

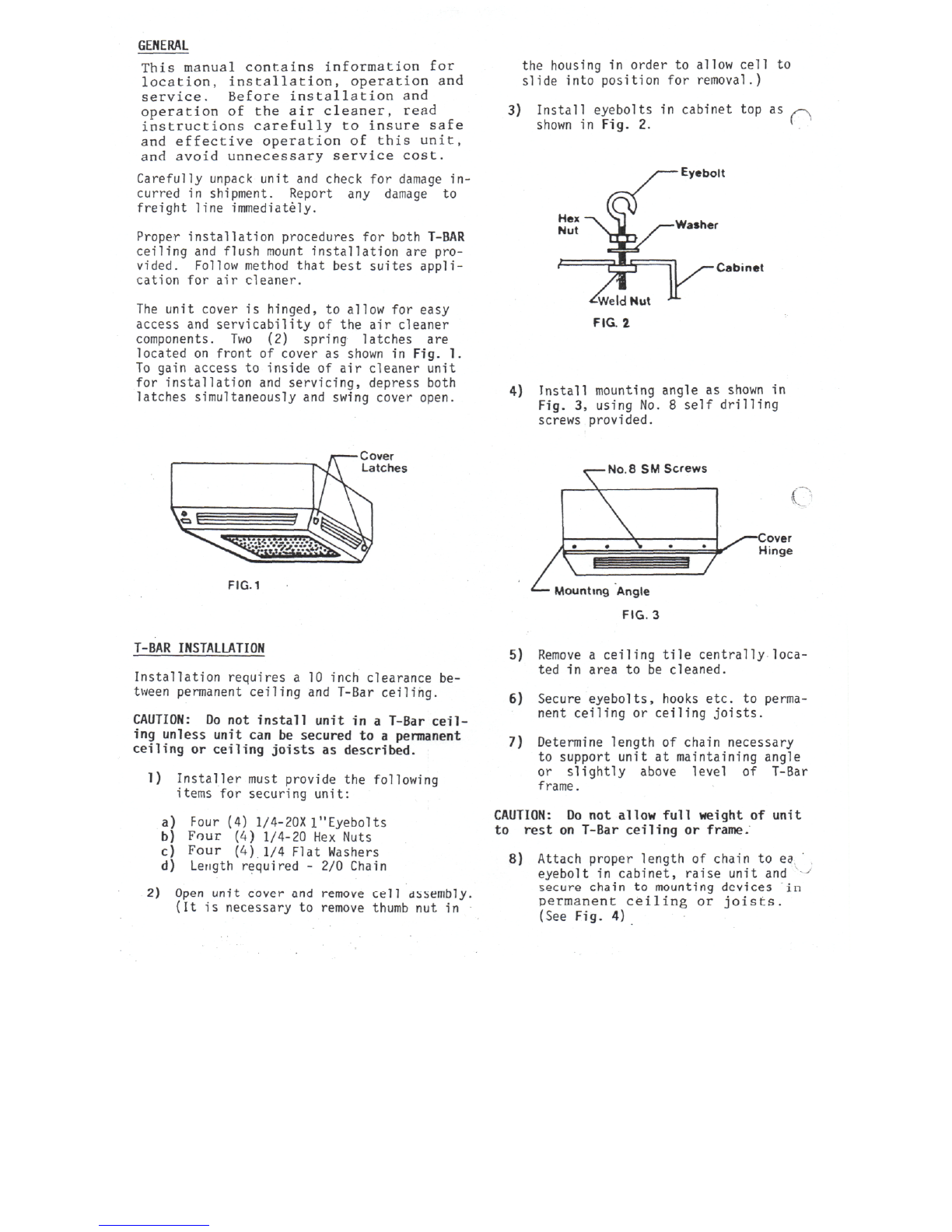

The

unit

cover

is

hinged,

to

allow

for

easy

access

and

servicability

oftheair

cleaner

components.

Two(2)

spring

latches

are

located

on

front

of

cover

as

shown

in

Fig.

1.

To

gain

access

to

inside

ofair

cleaner

unit

for

installation

and

servicing,

depress

both

latches

simultaneously

and

swing

cover

open.

the

housing

in

order

to

allow

cell

to

slide

into

position

for

removal.)

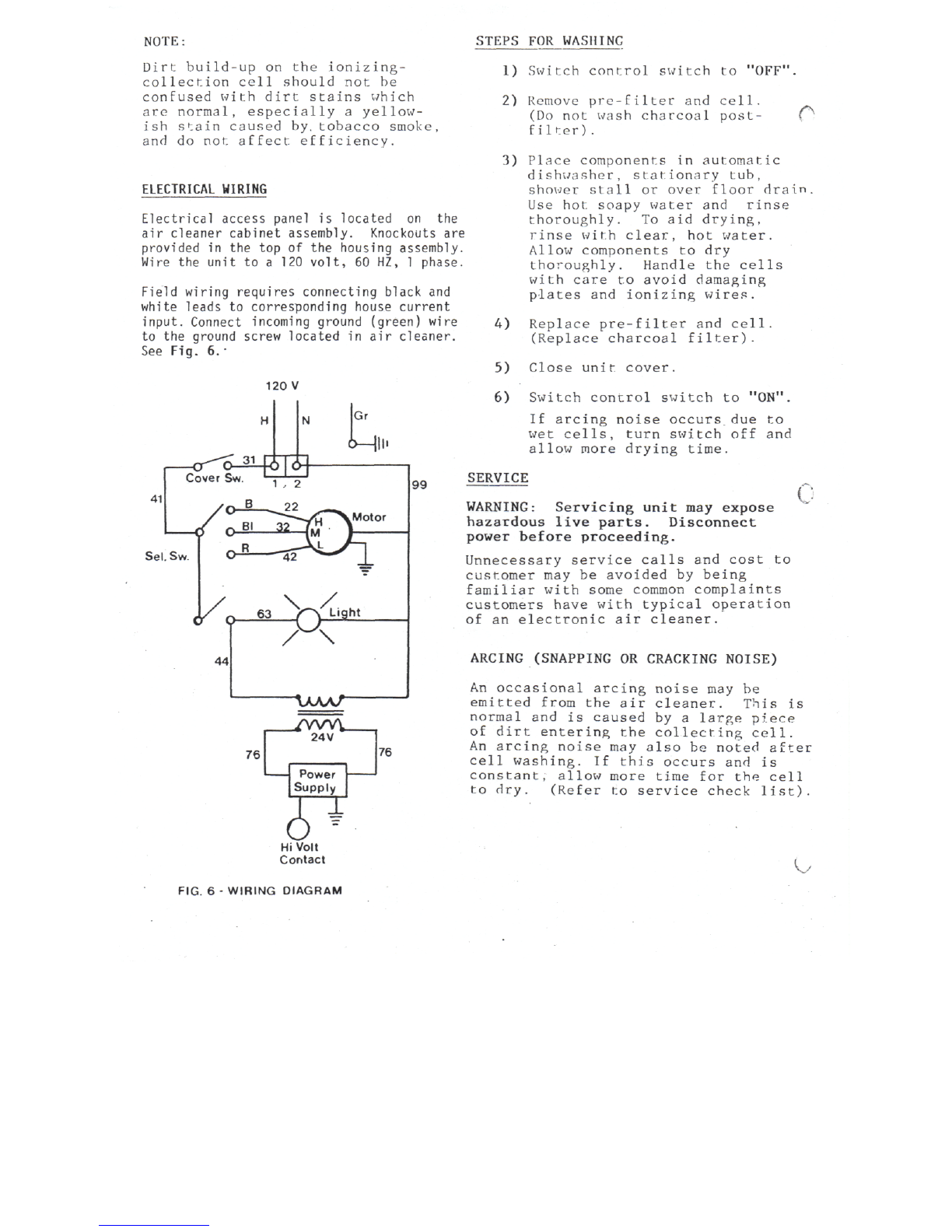

3)

Install

eyebolts

in

cabinet

topas

shown

in

Fig.

2.

Eyebolt

Cabinet

4)

Install

mounting

angle

as

shown

in

Fig.

3,

using

No.8

self

drilling

screwsprovided.

Cover

Latches

FIG.1

No.8

SM

Screws

x>ver

Hinge

Mounting

Angle

FIG.

3

T-BAR

INSTALLATION

Installation

requires

a

10

inch

clearance

be-

tweenpermanent

ceiling

and

T-Bar

ceiling.

CAUTION:

Donot

install

unit

ina

T-Bar

ceil

ing

unlessunit

canbe

secured

toa

permanent

ceiling

or

ceiling

joists

as

described.

1)

Installer

mustprovide

the

following

items

for

securingunit:

a)

Four

(4)

1/4-20X

l"Eyebolts

b)

Four

(4)

1/4-20

Hex

Nuts

c)

Four

(4)1/4

Flat

Washers

d)

Lengthrequired

- 2/0

Chain

2)

Open

unit

cover

and

remove

cell

dbsembly

(Itis

necessary

to

remove

thumb

nutin

5)

Remove

a

ceiling

tile

centrally

loca-

ted

in

area

tobe

cleaned.

6)

Secureeyebolts,hooksetc.

to

perma-

nent

ceiling

or

ceiling

joists.

7)

Determine

length

of

chainnecessary

to

supportunit

at

maintainingangle

or

slightly

above

level

of

T-Bar

frame.

CAUTION:

Donot

allow

full

weight

of

unit

to

rest

on

T-Bar

ceiling

or

frame.

8)

Attach

proper

length

of

chain

to

ea

eyebolt

in

cabinet,

raise

unit

and

'-J

secure

chain

to

mounting

devices

in

permanent

ceiling

or

joists.

(SeeFig.

4)

Permanent

Ceiling

ifff

I f

1

/ / I

/////////.

9

9

*

\ \

i

-~i

y

\

\

'

'

/

\-T-Bar

Ceiling

FIG.

4

rriffiriiirii

Safety

Chain

9)

Connect

electrical

power

toair

clean-

er,

followinginstructionsunder

"Elec-

trical

Wiring".

10)

Remove

charcoal

filter

from

plastic

bag

and

install

in

channel

on

down-stream

side

of

cell.

(Arrow

on

side

of

cell

points

in

thisdirection.)

11)

Re-install

cell,

pre-filters

and

carbon

filter.

12)

Swingaccesscover

upand

snapclosed.

Unit

is

now

ready

to

place

in

opera-

tion.

FLUSH

MOUNT

INSTALLATION

Openunitcover

and

remove

the

pre-

filter

and

cell.

2)

Select

a

locationnear

the

center

of

the

area

tobe

cleaned

and

locate

the

ceiling

joists

in

thatarea.

16"

E]

>—Joist

IK

>—Ceiling

I

i

u

>—Lag

Bolts

FIG.

5

3)

Locate

four

mounting

points

(each

being

ata

joist)

and

pre-drill

holes

into

the

joist

and

unit

housing

as

shown

in

Fig.

5.

4)

Lift

unit

to

ceiling

and

secure

using

four

1/4"

X 2

1/2"

lag

bolts

as

shown

in

Fig.

5.

5)

Connect

electrical

power

to

unit.

See

Field

Wiring

Diagram.

6)

Remove

carbon

filter

from

plastic

bag

and

install

in

guide

rails

on

back

of

cell.

7)

Re-install

cell,

pre-filter

and

carbon

filter.

Replace

thumb-screws

to

secure

cell

in

position.

8)

Close

access

cover

upand

snap

closed.

Unit

is

ready

for

operation.

SYSTEM

CHECKOUT

After

assembly

ingand

installing

the

unit,

switch

the

control

switch

on.

1)The

on/off

light

should

nowbe

on.

The

light

shows

unit

has

line

voltage.

2)

Open

cell

accessdoor.

The

on/

off

light

should

go

out.

The

blower

should

also

stop.

3)

Unit

is

provided

with

three

speed

blower

switch.

Set

switch

to

speed

for

desired

air

flow.

REGULAR

MAINTENANCE

Periodically

the

dirt

collected

by

your

unit

must

be

removed.

The

frequency

of

washing

will

depend

on

the

amount

of

dirt

present

intheair

in

your

application.

The

washing

frequency

best

suited

for

your

unit

canbe

determined

by

examin-

ing

the

collector

cells

attwo

week

intervals.

Asthe

dirt

begins

to

collect,

you

willnotice

a

light

film,

then

a

verydefinite

build-up

will

be

evident

ata

later

inspection.

When

there

isa

noticeable

amount

of

dirt,

collecting

cell

must

be

washed.

In

most

areas

the

collecting

cell

should

be

washedabout

every

12

weeks.

NOTE

:

STEPS

FOR

WASHING

Dirt:

build-up

onthe

ionizing-

collection

cell

should

nothe

confused

with

dirtstains

which

are

normal,

especially

a

yellow-

ish

stain

caused

by.

tobacco

smoke,

and

donot

affect

efficiency.

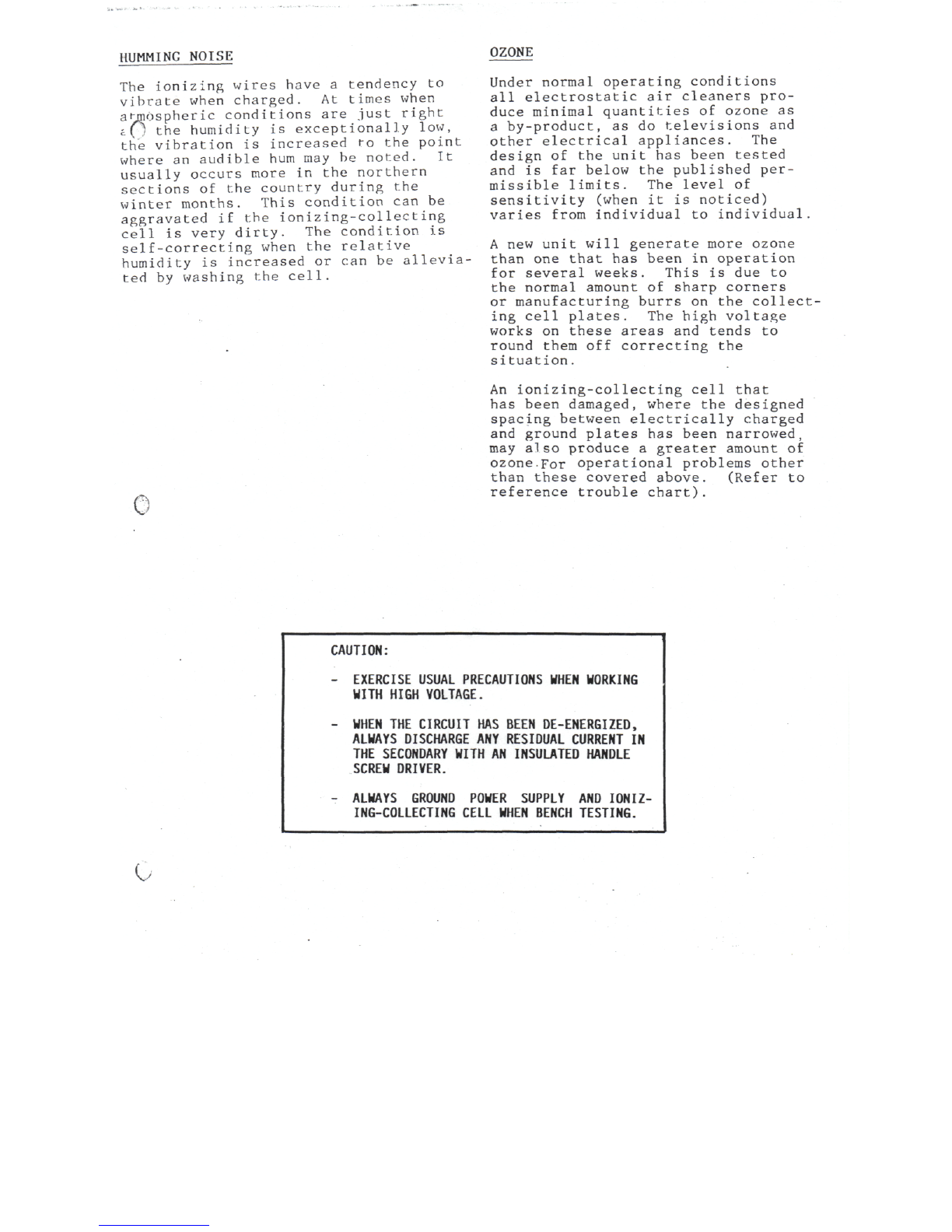

ELECTRICALWIRING

Electrical

access

panel

is

located

onthe

air

cleanercabinet

assembly.

Knockouts

are

provided

inthetopofthe

housing

assembly.

Wire

the

unit

toa

120

volt,

60HZ,1

phase.

Field

wiring

requires

connectingblack

and

white

leads

to

corresponding

house

current

input.

Connect

incomingground(green)wire

tothe

ground

screw

located

inair

cleaner.

See

Fig.

6.•

120V

Sel.

Sw.

76

24V

Power

Supply

76

1)

Switch

controlswitch

to

"OFF".

2)

Remove

pre-filter

and

cell.

(Donot

washcharcoalpost-

(

filter).

3)

Placecomponents

in

automatic

dishwasher,

stationary

tub,

shower

stall

or

over

floordrain.

Use

hot

soapywater

and

rinse

thoroughly.

Toaid

drying,

rinse

withclear,

hot

water.

Allowcomponents

todry

thoroughly.Handle

the

cells

with

care

to

avoiddamaging

plates

and

ionizing

wires.

4)

Replacepre-filter

and

cell.

(Replacecharcoalfilter).

5)

Closeunitcover.

6)

Switch

control

switch

to

"ON".

If

arcingnoiseoccurs

dueto

wet

cells,turnswitch

offand

allow

more

dryingtime.

SERVICE

WARNING:

Servicingunit

may

expose

hazardouslive

parts.

Disconnect

powerbeforeproceeding.

0

Unnecessary

servicecalls

and

cost

to

customer

maybe

avoided

by

being

familiar

with

some

common

complaints

customers

havewithtypical

operation

ofan

electronic

air

cleaner.

ARCING

(SNAPPING

OR

CRACKING

NOISE)

An

occasional

arcing

emitted

from

theair

normal

andis

caused

of

dirt

entering

the

An

arcingnoise

may

noise

maybe

cleaner.This

is

by

a

largepiece

collect

ing

cell,

also

be

notedafter

cell

washing.

If

this

occurs

andis

constant,allow

more

time

forthe

cell

to

dry.(Refer

to

servicechecklist).

Hi

Volt

Contact

FIG.

6 -

WIRING

DIAGRAM

HUMMING

NOISE

OZONE

The

ionizing

wireshave

a

tendency

to

vibrate

when

charged.

At

timeswhen

atmospheric

conditions

are

just

right

c.

O

the

humidity

is

exceptionally

low,

the

vibration

is

increased

tothe

point

where

an

audible

hummaybe

noted.

It

usually

occursmore

inthe

northern

sections

ofthe

countryduring

the

wintermonths.Thiscondition

canbe

aggravated

ifthe

ionizing-collecting

cell

is

verydirty.

The

condition

is

self-correcting

when

the

relative

humidity

is

increased

orcanbe

allevia

ted

by

washing

the

cell.

Under

normaloperatingconditions

all

electrostatic

air

cleanerspro-

duceminimalquantities

of

ozone

as

a

by-product,

asdo

televisions

and

otherelectricalappliances.

The

design

ofthe

unit

has

beentested

and

isfar

below

the

publishedper-

missible

limits.

The

level

of

sensitivity

(when

itis

noticed)

varies

fromindividual

to

individual.

A

new

unitwillgeneratemoreozone

than

one

that

has

been

in

operation

for

severalweeks.This

isdueto

the

normal

amount

of

sharp

corners

or

manufacturing

burrs

onthe

collect-

ing

cellplates.

The

highvoltage

works

on

theseareas

and

tends

to

roundthem

off

correcting

the

situation.

An

ionizing-collectingcellthat

has

beendamaged,where

the

designed

spacingbetweenelectricallycharged

and

groundplates

has

been

narrowed,

may

alsoproduce

a

greater

amount

of

ozone.For

operationalproblemsother

thanthesecovered

above.

(Refer

to

referencetrouble

chart).

CAUTION:

-

EXERCISEUSUALPRECAUTIONS

WHEN

WORKING

WITH

HIGH

VOLTAGE.

-

WHEN

THE

CIRCUIT

HAS

BEEN

DE-ENERGIZED,

ALWAYSDISCHARGE

ANY

RESIDUALCURRENT

IN

THE

SECONDARY

WITH

AN

INSULATED

HANDLE

SCREWDRIVER.

-

ALWAYSGROUNDPOWERSUPPLY

AND

IONIZ-

ING-COLLECTIN6CELLWHENBENCH

TESTING.

0

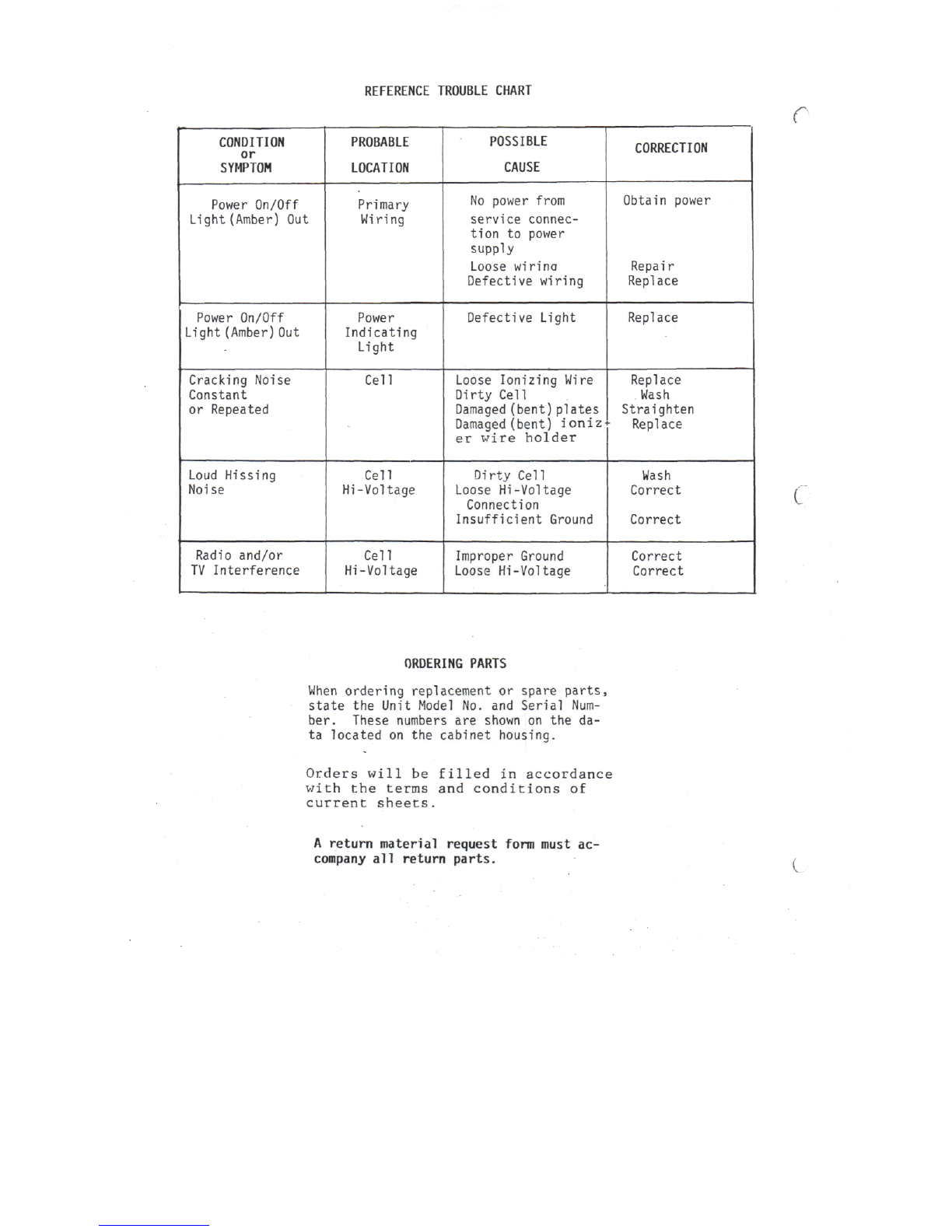

REFERENCETROUBLECHART

r

CONDITION

or

SYMPTOM

Power

On/Off

Light

(Amber)

Out

Power

On/Off

Light

(Amber)

Out

Cracking

Noise

Constant

or

Repeated

Loud

Hissing

Noise

Radio

and/or

TV

Interference

PROBABLE

LOCATION

Primary

Wiring

Power

Indicating

Light

Cell

Cell

Hi-Voltage

Cell

Hi

-Voltage

POSSIBLE

CAUSE

No

powerfrom

serviceconnec-

tion

to

power

supply

Loose

wirina

Defectivewiring

DefectiveLight

LooseIonizingWire

Dirty

Cell

Damaged

(bent)plates

Damaged

(bent)

ioniz

er

wire

holder

Dirty

Cell

Loose

Hi-Voltage

Connection

InsufficientGround

Improper

Ground

Loose

Hi-Voltage

CORRECTION

Obtain

power

Repair

Replace

Replace

Replace

Wash

Straighten

Replace

Wash

Correct

Correct

Correct

Correct

(

ORDERING

PARTS

When

ordering

replacement

or

spare

parts,

state

the

Unit

Model

No.and

Serial

Num-

ber.

These

numbers

are

shown

ontheda-

ta

located

onthe

cabinet

housing.

Orders

will

be

filled

in

accordance

with

the

terms

and

conditions

of

currentsheets.

A

return

material

request

form

must

ac-

company

all

return

parts.

c

r

u

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

PARTSLIST

DESCRIPTION

CabinetCover

CollectorCell

Light

SelectorSwitch

Knob

Latch

LatchActuator

Pre-Filter

Motor

Fan

Blade

Power

Supply

CoverPlate

Ionizing

Wire

Charcoal

Filter

LouvreAssy.

PARTSNUMBER

C21121

C21123

H472

C21112

C21130

C21111

C21110

C21113

'

C21124

C21125

AP24

C21134

C21056

C21114

C21122

QUANTITY

1

1

1

1

1

2

2

1

1

1

1

1

16

1

4

Table of contents