Adexa HRQ-911 User manual

Instruction Manual

Gas Solid Top with Gas Oven

operating instruction

(Read the machine before use)

Instruction Manual

In order to give full play to the performance of this product and reduce unnecessary

losses and damage, please read the product manual carefully before use, and keep it

properly for future reference.

This product is characterized by high technical content, novel design, complete

functions, convenient operation, energy saving and environmental protection, etc.,

which is a more advanced gas combined furnace in China.

warn

!Any modification, and incorrect installation, adjustment, repair or

maintenance may result in property damage or casualties, if the

adjustment or repair should be contacted with the supplier and

conducted by a trained professional.

!For your safety, please do not store or use flammable and explosive

gases, liquids or articles near this product

1. General matters

※When installing and repairing, please carefully follow the following steps to

ensure the safe use of the machine.

※Keep the instructions safe for future doubt all or left to the next

operator.

※This machine can only be operated by personnel skilled in this

machine.

※When the machine is not used or when the operator is absent, it is

necessary to turn off the machine and cut off the gas source to avoid

danger.

※The installation, initial use and maintenance of the furnace shall

be performed by professionals or qualified persons or those who have

obtained the installation operation certificate, or a concession approved

by the manufacturer.

Instruction Manual

※Remove the outer packaging, ensure the integrity of the machine, if

you have any questions, please do not use the machine, and ask experts

to consult, do not put the packaging materials, in the place where children

can get, so as not to avoid danger (materials are plastic bags, nails,

etc.)

※Repair should be repaired by the professional maintenance center

personnel, and use the original accessories. If the above requirements

are not followed, the safety performance of the machine may be endangered.

※This machine is used for a commercial use and is not suitable for other

uses, otherwise it will cause danger.

※The installation of the machine must be conducted by a professional

according to the instructions provided by the manufacturer.

※Do not rinse directly with water.

※Clean the stainless steel surface regularly and properly to prevent

surface oxidation and chemical damage to the machine.

2. Installation instructions

2.1General parameters

2.1.1 Technical parameters

Name

Gas Solid Top with Gas Ovene

Model

HRQ-911

HRQ-711

size

800×900×920

700×700×920

Intratracheal size

G 3/4〃

Gas flow rate (m3/h) (Based on the

standard condition of 15 ℃

bottled)

0.25

0.25

Use gas (see schedule)

liquefied petroleum gas

natural gas

Artificial gas

Use pressure valve

Low pressure regulating valve P≤0.05Mpa Low pressure)

Combustion value (kcal / h)

6297

Instruction Manual

2.1.2 attached list

Gas fuel classification

The basic characteristics of fuel gas are divided into four categories by the fuel gas acquisition

method

1.Natural gas (pipeline gas) 2000Pa

(1)gas well gas (2)associated(-dissolved) gas (3)mine drainage gas

2.Artificial gas (pipeline gas) 1000~1200Pa

(1)gas well gas (2)associated(-dissolved) gas (3)mine drainage gas

3.Oil to gas (pipeline gas) 2000Pa

(1)Heat storage and pyrolysis gas(2)Heat-storage and catalytic cracking gas (3)Pressure

cracking gas

4.LPG, bottled gas, 3000Pa

The above data are the industry standards for reference

Note: The gas and gas pressure used in different regions are also different,

please use the local gas pressure standard.

2.1.3 Gas, nozzle and conversion

※The gas and pressure are different in different regions. Please convert

the nozzle according to the local gas pressure

Gas

Iron plate furnace

burner (small)

Oven burner (large)

liquefied petroleum gas

Φ1.1mm

Φ1.1mm

natural gas

Φ1.8mm

Φ2.4mm

Artificial gas

Φ2.6mm

Φ3.2mm

oil gas

Φ1.7mm

Φ2.1mm

Note: This data is only for reference purposes, not for standard data.

Instruction Manual

2.1.4 Schematic diagram of the structure

Instruction Manual

3. Installation requirements and matters needing attention

※All installations and operations must be carried out by qualified

persons as required.

3.1 Installation requirements

※Because the machine is heavy, please consider the weight of the

machine when installing. We recommend that you install it on the ground.

※When installation: the machine must be 10cm away from the wall, in

case the machine needs to be installed against the wall, the wall must

be fire resistant, can not burn, the left and right side of the

non-combustible more than 10cm.

※The installation position should be in a well-ventilated place, and

Instruction Manual

the exhaust fan should be installed to ensure that the steam and the

combustion exhaust gas are discharged during the work process.

※After the installation of the machine, must keep stable, horizontal

placement can not be tilted, also can not be shaken when used.

※Use the gas with the permission of the gas supplier first, and verify

that the supplied gas is consistent with the gas used in the future.

※Do not use other gas not conforming with the machine as fuel and high

pressure regulator.(This machine is only suitable for using the

low-pressure control valve.)

※The used voltage of the equipment must comply with the rated voltage

(do not use other power sources that do not conform to the machine)

3.2 Connect of the gas

※A quick cut air valve must be installed before installing the machine

and must be located near the machine.

※Make sure the machine is the same type of gas connected. If not, do

not connect because the gas connection pipe is painted yellow.

※The pipes connected to the machine must be connected with suitable

metal pipes.

※The machine shall be tested with LPG.

※If the pipe pressure is 10% higher than the rated pressure required

by the machine, a regulating valve is required to ensure that the rated

pressure is reached.

※After connection, test with soapy water or test whether there is air

leakage at the test pipeline connection, " do not use the fire source

ignition test!”

3.3 Electrical connection

※Users should install appropriate switch, fuse and leakage protection

near the equipment. sundries should not be stacked in front of the switch

to facilitate operation.

※The furnace body is provided with equipotential grounding bolts, and

the wire of not less than 1.5mm 2 copper conductor shall be reliably

Instruction Manual

connected with the ground wire conforming to the safety regulations.

※After the installation, check whether the wiring is loose, whether

the air pressure is normal, and whether the safe connection is reliable.

※The temperature adjustment range of the equipment baking furnace is

between 50 and 330℃, and the recommended normal use temperature is

between 180 and 250℃.

3.4 Precautions

※Do not put inflammable items (such as towels, etc.) in any position

on the furnace surface, otherwise it may cause combustion and fire

accidents.

※After using it, the gas valve should be closed immediately.

※If air leakage is found, the gas valve should be closed immediately,

open the window to strengthen ventilation. Do not switch the power supply

and electric system to be used after maintenance.

※During transportation, the stove shall be small and not inverted to

prevent damage to the product shell and interior.

※Inflammable and explosive articles should not be stored near the

installation position, the ambient temperature is lower than 45℃, and

the relative humidity is below 85%.

Special remarks:

warn!

This product must be operated by a trained chef.

Can not be disassembled or modified.

Disassembly and modification of the products can lead to serious accidents.

Before cleaning, remove the plug and cut off the power supply.

When cleaning, do not sprinkle water directly on the product.

Water will conduct electricity, and the product may cause electric shock

accidents due to electricity leakage.

Do not tap the product or place heavy objects on the product.

Abnormal operation will cause equipment damage and danger.

High temperatures can cause burns.

Instruction Manual

In the process of work and before and after, due to the high temperature

relationship, do not directly contact the box with your hands, especially in the

high temperature area.

Do not use the power supply (gas) other than the product label power supply.

Do not use the power supply knife that does not meet the safety standards and

quickly cut off the gas source valve.

pay attention to!

When the minefield is close, the power switch should be disconnected as soon as

possible.

Can avoid the electrical damage caused by lightning strike.

It is forbidden to use hard and sharp objects to destroy the furnace body surface

and enamel surface.

After the work is finished, to close the power supply knife and quickly cut off

the gas source valve.

Circuit installation and maintenance must be carried out by qualified

professional engineering personnel.

If the power cord is damaged, it must be replaced by the manufacturer or its

maintenance department or similar professional personnel to avoid danger.

3.5 Maintenance

※Clean the burner and basin regularly (once daily day)

※If not used for a long time, use the cloth coated with gasoline, clean

the stainless steel surface, put in a well-ventilated place.

※Clean the stainless steel surface with warm soapy water every day and

rinse thoroughly (do not rinse the equipment directly with a water gun).

※When cleaning equipment, do not use cleaners, brushes or scraper tools

containing wear substances to clean the stainless steel surface, as

residual iron scraps can cause rust. And wipe according to the satin

direction, do not use products containing chlorine (bleach, hydrochloric

acid, etc.) to clean the steel surface, even if these products have been

diluted, do not use.

※This product cannot be washed directly out with water.

Instruction Manual

※Do not use corrosive substances (e. g. potassium chloride) to clean

the ground under the equipment.

※To clean the dirt on the burner and baffle in the furnace regularly

(recommended once a week)

※Do not change the ventilation space required for burning the

equipment.

※After daily work, the furnace body surface and the power cord can be

scrubbed with a wet towel without corrosive cleaner. It is strictly

prohibited to wash directly with water to prevent water infiltration,

damage the electrical performance, and cause electricity safety

accidents.

※If not used at any time, close the temperature controller and power

switch with the quick cut-off air source valve.

※When not used for a long time, the stove should be cleaned and placed

in a well-ventilated and no corrosive gas warehouse.

※Clean the stainless steel surface regularly and properly to prevent

surface oxidation and chemical damage to the machine.

※Clean before use, cut off the power supply, scrub with a wet towel

without corrosive detergent, and do not directly sprinkle water on the

product.

4. direction for use:

4.1 Upper iron plate furnace

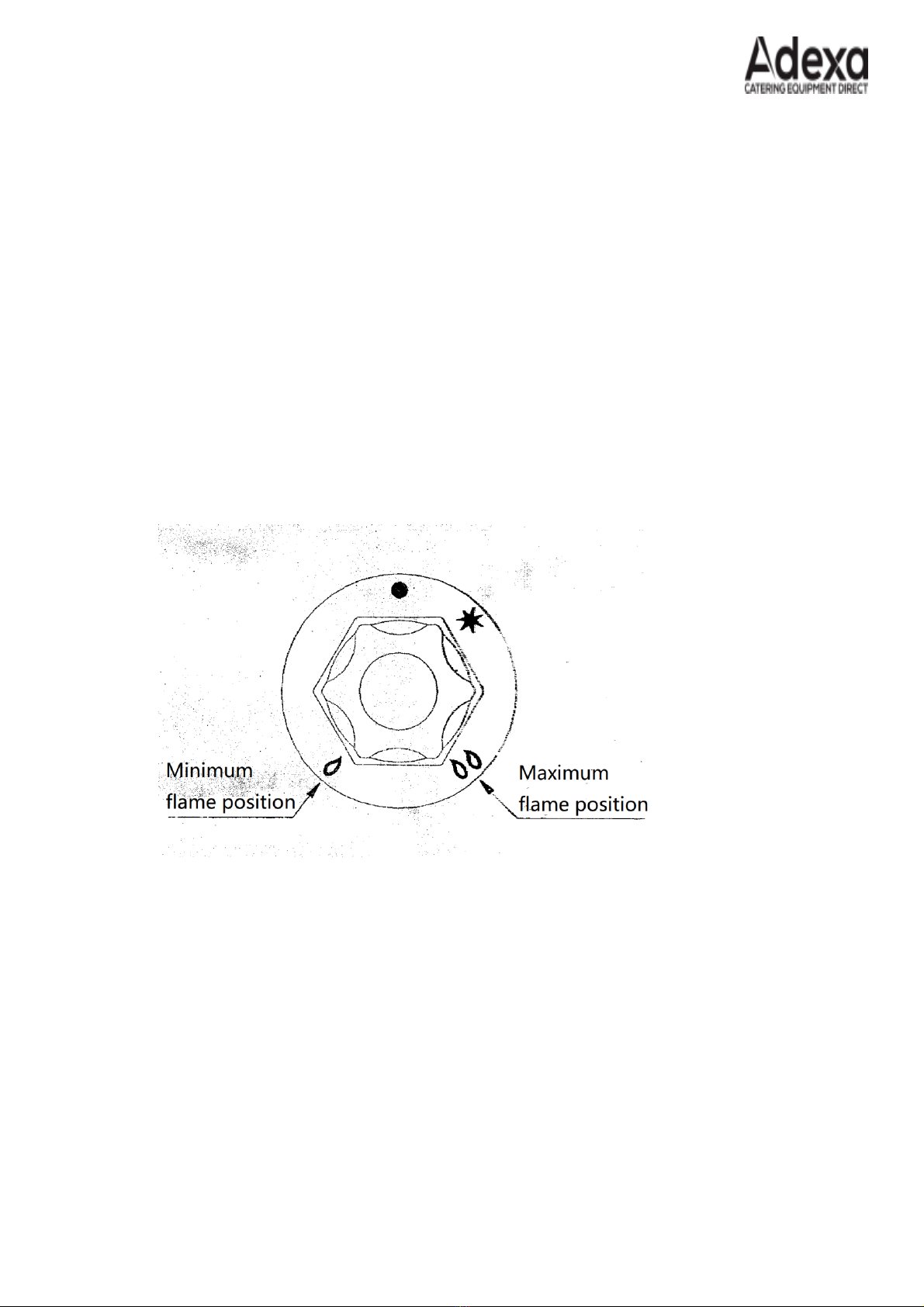

※Turn the knob counterclockwise to the "★" position, press the knob

to the bottom, and constantly press the electronic lighter to ignite the

low fire burner (fire). Press the knob down for 20 seconds; observe the

fire burner (flame). When releasing the knob, the fire burner (flame) is

ignited; if not, repeat until it is ignited. If the stove is not used for

a long time or used for the first time, it may be a little longer firing

time (about two to three minutes), which is a normal phenomenon.

※When the small fire burner (flame) is lit, then rotate the knob

Instruction Manual

counterclockwise to the maximum flame position, "00" is the maximum flame,

to ignite the main burner, it can be used.(To set the flame to the minimum,

rotate counterclockwise to the minimum flame position, and "0" is the

minimum flame.

※After use, close the main burner: rotate the knob from the maximum

flame or minimum flame position to the "★" position to close the main

burner.

※Turn off the low fire burner (fire): rotate the knob from the "★"

position to the "●" position to close the small fire burner.

※不使用此机器时,请将快速切断气源阀门关闭。

Note: Every time you rotate the knob, press the knob a little and rotate.

※Because there is gas storage in the furnace, the internal gas needs

to be discharged during the first use, and the exhaust time may be longer,

about three to five minutes.

※Exhaust method: Turn the knob from off, counterclockwise to the "

★" position and press the knob down for about three to five minutes.

Instruction Manual

4.2. Lower gas baking oven:

※position and press the knob to the bottom while constantly pressing

the electronic burner to ignite the fire burner (fire). Press the knob

down for 20 seconds; when releasing the knob, the low fire burner (flame)

must be lit; if not, repeat this.(In an emergency, rotate the knob to the

"★" position and press to the bottom, through the lower monitoring mouth

of the furnace, light the small fire burner with a lighter, so that the

manual ignition can ignite the small fire burner). If the stove is not

used for a long time or used for the first time, the ignition time may

be a little longer, about two to three minutes, which is a normal

phenomenon.

※Turn the knob counterclockwise to the "C" position point burner and

then to the desired temperature position to reach the desired temperature

Degree, then it can be used. This equipment is equipped with temperature

regulating valve, which can automatically temperature the oven.

※After use, close the main burner: rotate the knob clockwise to the

"★" position to close the main burner. Turn off the low fire burner (fire):

rotate the knob from the "★" position to the "●" position to close the

small fire burner.

※Close the quick cut-off air supply valve without using this machine.

Note: Every time the knob is rotated, press the rotation slightly,

and then rotate.

190

260

C

120

330

Instruction Manual

※The first use of the need to release the internal air, the release

time may be longer, about three to five minutes.

※Passing method: Turn the knob from the off state, press

counterclockwise to the "★" position, and press the knob down for about

three to five minutes.

5. Daily inspection:

※Check the machine status before and after use every day

※Before use

Is the machine tilted?

Is the power cord aged, cracked or broken?

Is the control panel so damaged?

※in use

Is there a burnt bad smell, a bad smell?

Can the temperature control be heated at the same time?

Is the temperature out of control or leakage leakage?

warn!

Routine inspections must be performed frequently.

Check the product regularly to prevent serious accidents.

If you feel that the circuit and machine are faulty, stop using them.

Inform the professional and technical personnel for inspection and repair as soon as possible.

If the product fails and the user cannot be eliminated, we can

contact our factory or dealer to solve the problem and repair it free

within half a year after-sale. Where not according to the instructions

for the wiring, improper use, transportation collision and other damage,

need to replace the parts of the product, the factory only recover the

parts fee.

This manual suits for next models

1

Other Adexa Oven manuals

Popular Oven manuals by other brands

Gaggenau

Gaggenau BO 450 Installation instruction

Indesit

Indesit FIM 51 K.A S operating instructions

Siemens

Siemens HB976GM 1 Series User manual and installation instructions

VWR International

VWR International 89508-426 Operating and maintenance manuall

Siemens

Siemens HB26D555W instruction manual

Zanussi

Zanussi ZOHEE2K2 user manual