Adp UHRS Series User manual

Page 1

WARNING

Improper installation, adjustment, alteration, service or

maintenancecancausepropertydamage,personalinjury

or loss oflife. Installation and service must be performed

by alicensedprofessionalinstaller(orequivalent),service

agency or the gas supplier.

CAUTION

As with any mechanical equipment, personal injury can

result from contact with sharp sheet metal edges. Be

careful when you handle this equipment.

UH(RS,CM)-030/105CompactUnitDimensions..............2

Compact Unit Parts Arrangement...................................3

UH(RS,CM)-125/200Standard UnitDimensions.............4

UH(RS,CM)-250/400Standard UnitDimensions...........5

Standard Unit Parts Arrangement....................................6

Shipping...........................................................................7

Optional Accessory.........................................................7

Requirements in USA......................................................7

Requirements in Canada................................................7

Additional Requirements................................................8

Unit Heater Installation...................................................8

CombustionandVentilationAir.......................................8

Rotation ofCombustionAir Inducer - 125/150.................9

Venting.............................................................................9

ElectricalConnections...................................................14

INSTALLATION

INSTRUCTIONS

UH(RS,CM)

30,000 to 400,000 Btuh Series

UNIT HEATERS

507938-01

6/2019

Gas Connection ...................................................18

Leak Check .........................................................18

Unit Start-Up........................................................18

To Turn Off Gas toUnit ..........................................19

Heating Sequence ofOperations ............................19

Ignition Control LED..............................................20

HighAltitudeAdjustments ......................................20

Gas Flow.............................................................20

Gas PressureAdjustments.....................................20

Limit Control Switch..............................................21

Louver VaneAdjustment........................................21

Combustion AirPressure Switch.............................21

Flame Rollout Switch ............................................21

Service................................................................21

Start-Up and Performance Checklist........................22

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

WARNING

FIRE OR EXPLOSION HAZARD.

Failure to

ly could result in serious injury, death,

or property damage.

Be sure to read and understandthe

structions in thismanual.

ation, service or maintenance can cause

seriousinjury, death or property damage.

Do not store or use gasoline or other

cinity of thisor any other appliance.

formed by a qualified installer, service

agency or the gassupplier.

WHATTO DO IF YOUSMELLGAS:

Do not tryto light anyappliance.

Do not touch anyelectrical switch;do not use

any phone in your building.

Leave the building immediately.

Immediatelycall your gassupplier from a

neighbor's

structions.

If you cannot reachyour gassupplier, call the

fire department.

Table Of Contents

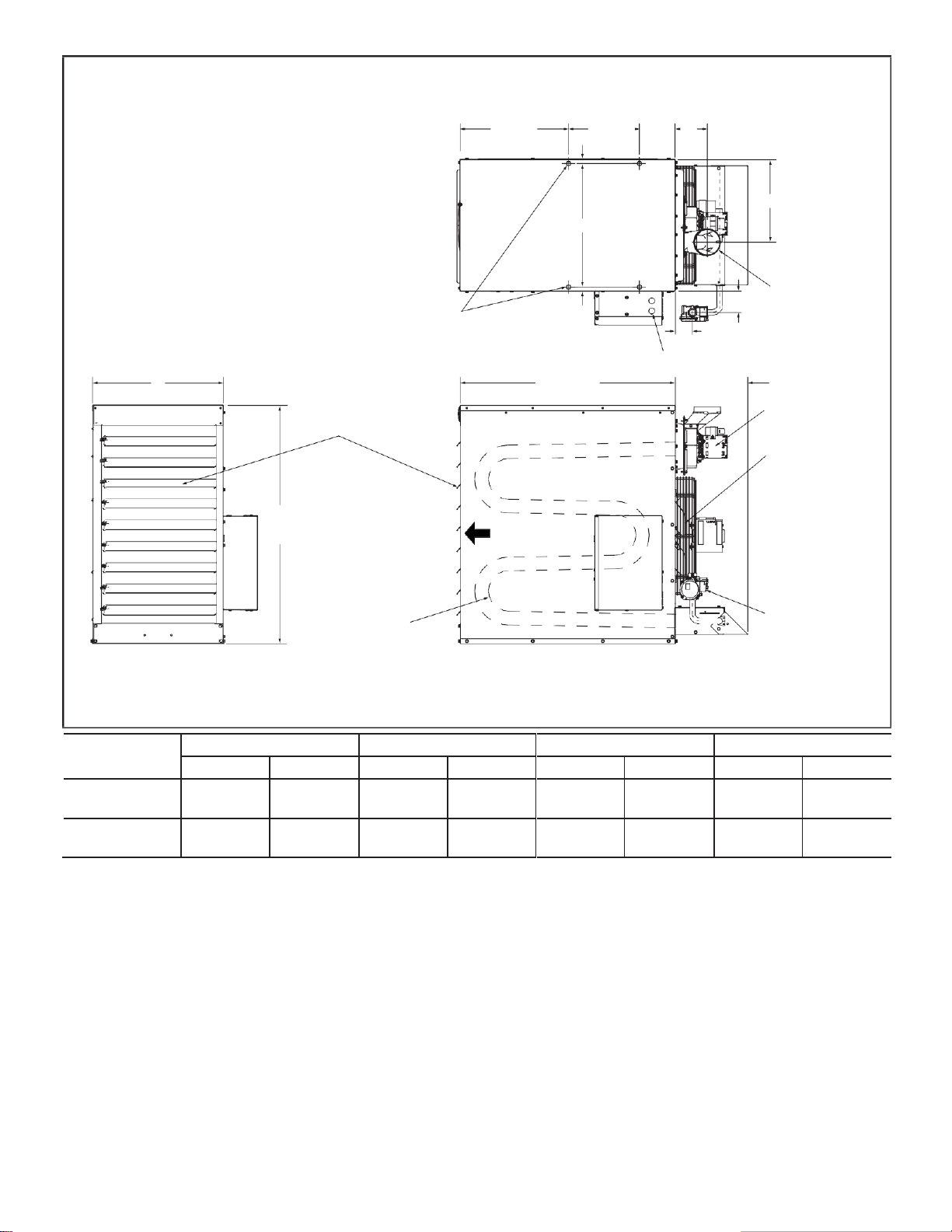

Page 2

AIR

FLOW

21

(533)

HEAT EXCHANGER

TOP VIEW

ELECTRICAL

INLET

1

(25)

29

(737)

1

(25)

B

21

(533)

HANGING

BRACKETS (2)

A

C

DIRECT

DRIVE FAN

FLUE

OUTLET

BACK VIEW

3-5/8

(92)

GAS

INLET

SERVICE

ACCESS

PANEL

ADJUSTABLE

LOUVERS

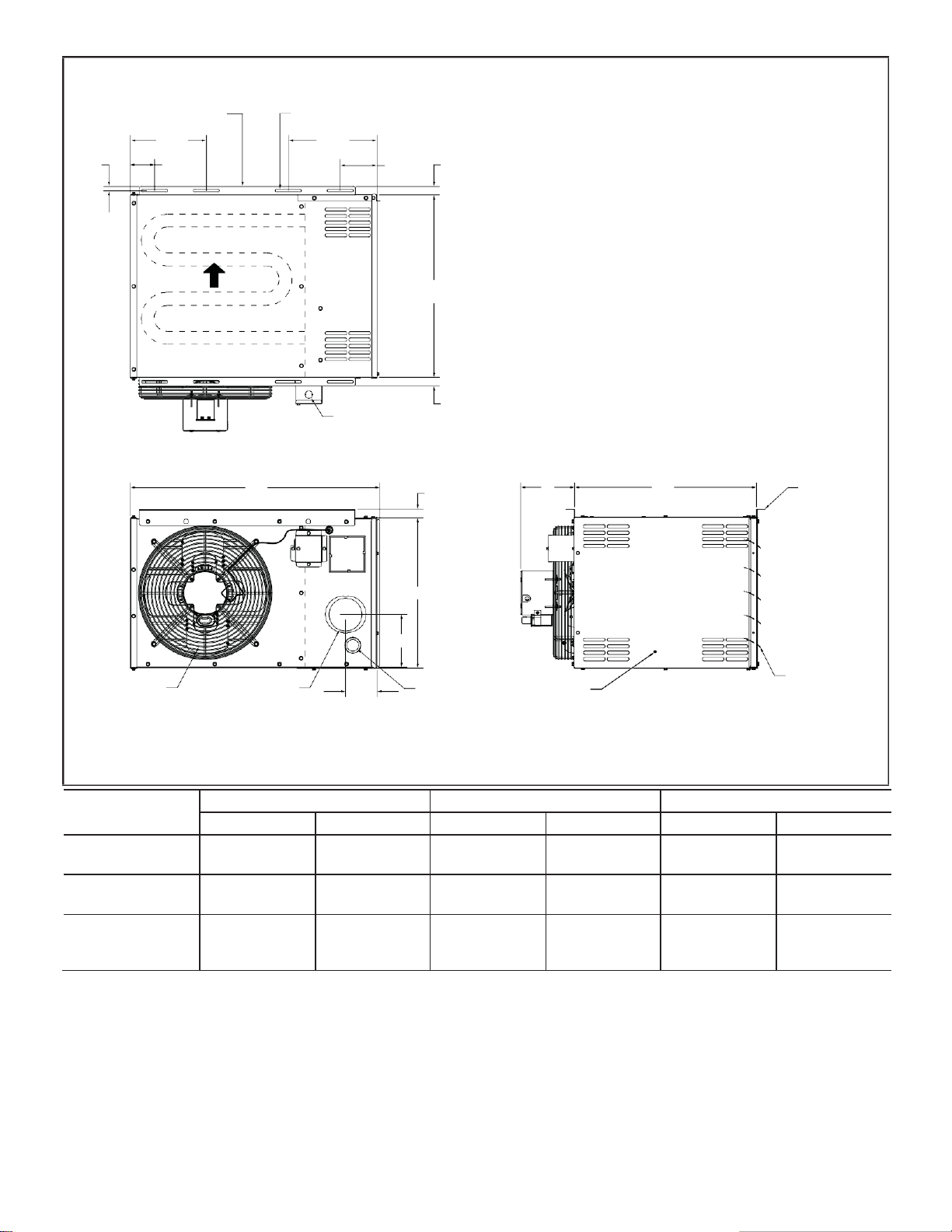

Model

No.

A

B

C

in.

mm

in.

mm

in.

mm

UHRS-030A

UHRS-045A

12-3/8

314

6-1/2

165

3-7/8

98

UHRS-060A

UHRS-075A

17-1/2

445

6-1/4

159

6-1/8

156

UHRS-090A

UHRS-105A

23

584

7-7/8

200

9-1/8

232

1/2

[13]

UHRS-030 / 105 DIMENSIONS - Inches (mm)

MOUNTING SLOTS (Typical)

5/16 x 3Inches (8 x 76mm)

10-1/2

(267)

SIDE VIEW

1

(25)

4-1/4

(108)

HANGING

BRACKETS (2)

8-3/4

(222)

2-3/4

(70)

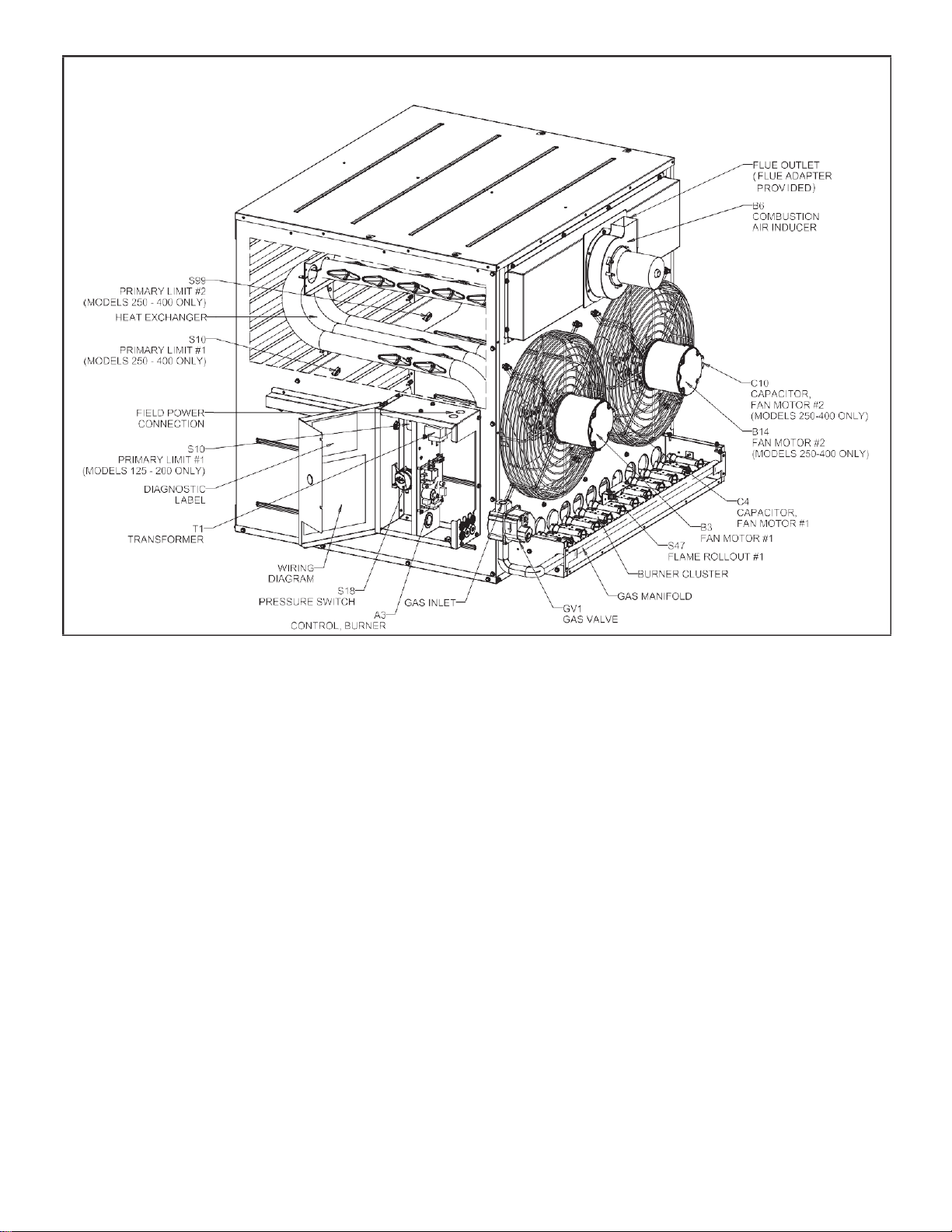

Page 3

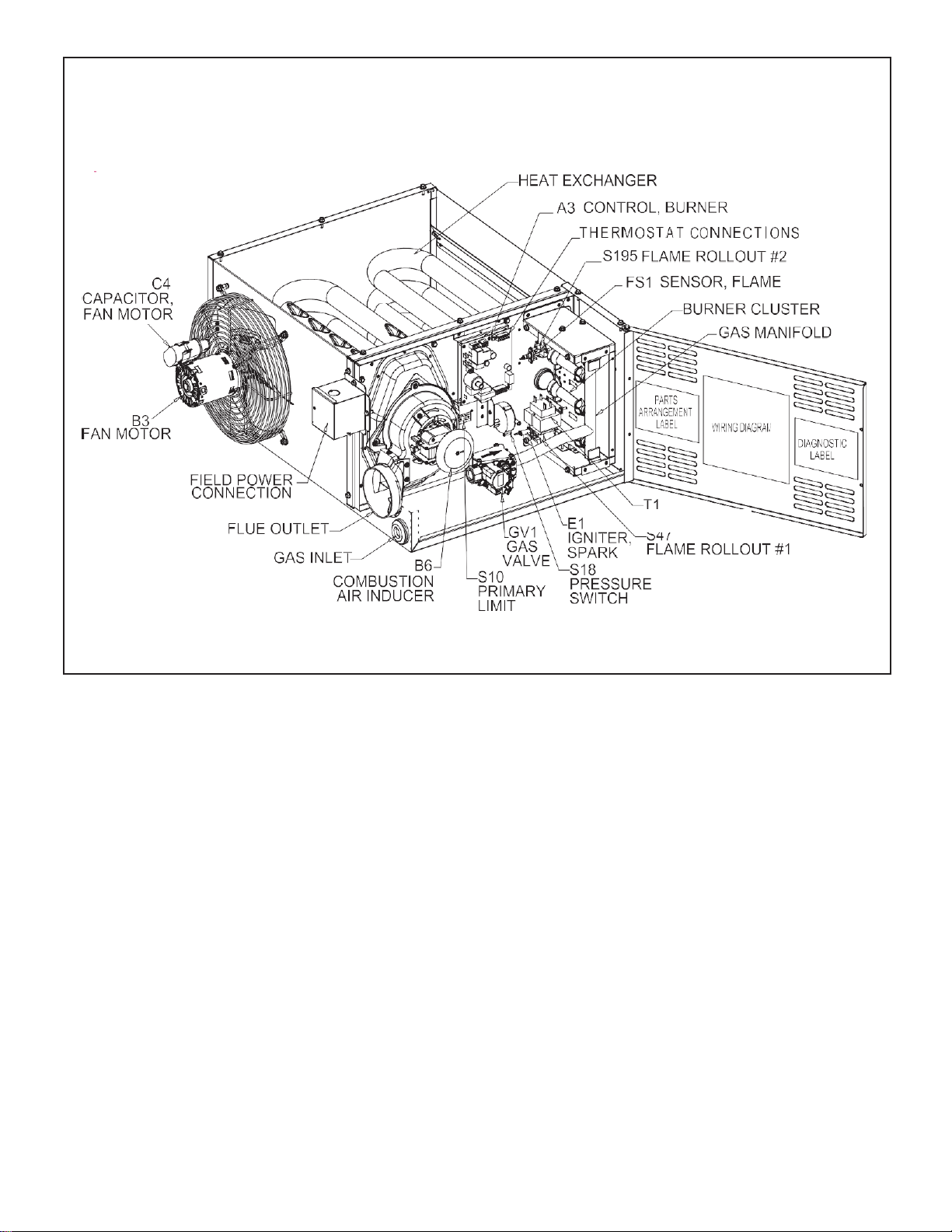

UHRS COMPACT UNIT HEATER PARTS ARRANGEMENT 030 /

105K BTUH

TRANSFORMER

Page 4

(137)

(267)

1/2 (13)

C

B

Model

No.

A

B

C

D

in.

mm

in.

mm

in.

mm

in.

mm

UHCM-125

UHCM-150

19-1/2

495

18-1/2

470

12-1/4

311

4-3/4

121

UHCM-175

UHCM-200

25

635

23-3/4

603

9-1/2

241

3

76

UHCM-125 / 200 DIMENSIONS -Inches (mm)

16 (406)

10-1/2 5-3/8 D

1/2 (13)

3-1/8 (79)

(4) 3/8-16 MOUNTING NUTS

FOR UNIT SUSPENSION

TOP VIEW

2-1/2 (64)

ELECTRICAL INLETS

ADJUSTABLE

LOUVERS

COMBUSTION AIR

INDUCER

FLUE OUTLET

A

31-7/8 (810)

10-5/8

(270)

DIRECT DRIVE FAN

35-1/4

(895)

AIR

FLOW

HEAT

EXCHANGER

GAS VALVE

FRONT VIEW

SIDE VIEW

Page 5

Model

No.

A

B

C

in.

mm

in.

mm

in.

mm

UHCM-250

UHCM-300

37-5/8

956

36-1/2

927

15-7/8

403

UHCM-350

UHCM-400

47

1194

45-3/4

1162

20-1/2

521

1/2 (13)

C

B

FLUE OUTLET

(4) 3/8-16 MOUNTINGNUTS

FOR UNIT SUSPENSION

1/2 (13)

3-1/8 (79)

DIRECT DRIVE FAN

35-1/4

(895)

AIR

FLOW

HEAT

EXCHANGER

GAS VALVE

FRONT VIEW

SIDE VIEW

10-5/8

(270) COMBUSTION AIR

INDUCER

ADJUSTABLE

LOUVERS

TOP VIEW

31-7/8 (810)

2-5/8 (67)

ELECTRICALINLETS

3

(76)

5-3/8

(137)

(267)

10-1/2

UHCM- 250 / 400 DIMENSIONS - Inches (mm)

16 (406)

A

Page 6

UHCM STANDARD UNIT HEATER PARTS ARRANGEMENT 125 /

400K BTUH

Page 7

Shipping contents includes heater, installation instruc-

tions,warrantycertificate,twomountingbrackets(shipped

loose in UH(RS,CM)-30/105 units), and a flue transition

(included in UH(RS,CM)-175/400 units only). The heater

is shipped completely assembled. Check the unitforship-

ping damage. The receiving party should contact thelast

carrier immediately if any shipping damage is found.

Units require a changeover kit when the unit is to beused

with Natural gas. The kit is ordered separately. See

Engineering Handbook.

Installation of gas unit heaters must conform with local

building codes or, in the absence oflocal codes, with the

current editionofANSIZ223.1, National Fuel Gas Code.

Installation inaircraft hangersmustbe inaccordance with

thecurrent edition of ANSI/NFPA No. 409, Standard for

Aircraft Hangers.

Installation in parking structures must be in accordance

with the current edition of ANSI/NFPA No. 88A, Standard

for Parking Structures.

Installation in repair garages must be in accordance with

the current edition of ANSI/NFPA No. 88B, Standard for

Repair Garages.

These units are approved for residential garage or non-

confined living space applications. For installation in a

residential garage or non-confined living space, unit must

be installed so that burners and ignition source are

located no less than 18” (457mm) above floor. Heater

must be located or protected to avoid physical damage

by vehicles. Referto the current edition of ANSI Z223.1,

National Fuel Gas Code.

Authorities having jurisdiction should be consulted before

installation. Airforcombustion and ventilation must con-

form tothemethods outlinedinthecurrent editionofANSI

Z223.1,Section5.3,AirforCombustionandVentilation,or

applicable provisions of local building codes.

The National Fuel Gas Code (ANSI Z223.1) is available

from:

American National Standard Institute Inc.

11 West 42nd Street

NewYork, NY 10036

These unit heaters are CSAInternational design-certified.

These unit heaters are certified for installation tocombus-

tible material as listed in Table1 and on unit rating plate.

Accessibility and service clearances must be observed in

addition to fire protection clearances.

All electrical wiring and grounding for unit must be in ac-

cordance with the regulations of the current edition of

ANSI/NFPA No. 70, National Electric Code.

The National Electric Code is available from:

National Fire Protection Association

1 Batterymarch Park

PO Box 9101

Quincy, MA 02269-9101

These instructions are intended only as a general guide

and do not supersede local codesin any way. Authorities

having jurisdictionshouldbeconsultedbeforeinstallation.

The installation must conform with localbuilding codes or,

in the absence oflocal codes, with the current edition of

CSA-B149installationcompliancecodes.Allelectricalwir-

ing and grounding for the unit must also comply with the

current edition of CSA C22.1, Canadian Electrical Code.

These unit heaters are CSA-certified for the installation

clearances listed on the rating plate and in table 1.

Adequate clearance must be provided around the appli-

ance and around air openings into the combustion cham-

ber. Provision shall be made for service accessibility.

NOTE - Fire protection clearances may be exceeded to

provide additional space for service and accessibility.

GARAGE/ WAREHOUSEINSTALLATIONS

1 - In a storage area, clearance from heaters to

combustible materials must be such that the

combustible material must not attain a temperature

above 160°F (71°C) by continuous operationofthe

unit.

WARNING

Combustible materials thatare affected by exposure to

temperatures LESS than 160°F (plastics, plastic wrap,

styrofoam, cardboard, etc.) must be stored well away

from this heater. Discharge air temperatures for these

units can approach 200°F.

2 - Maintain an 8-foot (2m) minimumclearance from the

floor to the bottom of the heater. Refer to the current

edition of CSA-B149 for installation compliance

codes. AIRCRAFT HANGER

1 - In an area where aircraft are housed or serviced, a

10-foot (3m) minimum clearance from the highest

surface ofthe aircraft to bottom of the heater must

be maintained.

2 - In other areas, an 8-foot (2m) minimum clearance

from the floor to bottom ofheater must be maintained.

3 - Heatersshould belocated sothat theyare protected

fromdamagefromaircraftorotherappliancesneeded

for servicingof aircraft. Referto requirements of the

enforcing authorities.

RESIDENTIAL

These units are approved for residential garage or non-

confined living space applications. For installation in a

residential garage or non-confined living space, unit must

be installed so that burners and ignition source are

located no less than 18” (457mm) above floor. Heater

mustbe locatedor protectedtoavoidphysical damageby

vehicles. Referto the current edition of CSA-B149 for in-

stallation compliance codes.In a confined area, the heat-

er must be installed inaccordance with the current edition

of CSA-B149 installation compliance codes. Be sure to

check withlocal codes and ordinances for additional re-

quirements.

Optional Accessory

Requirementsin USA

Requirementsin Canada

Shipping

Page 8

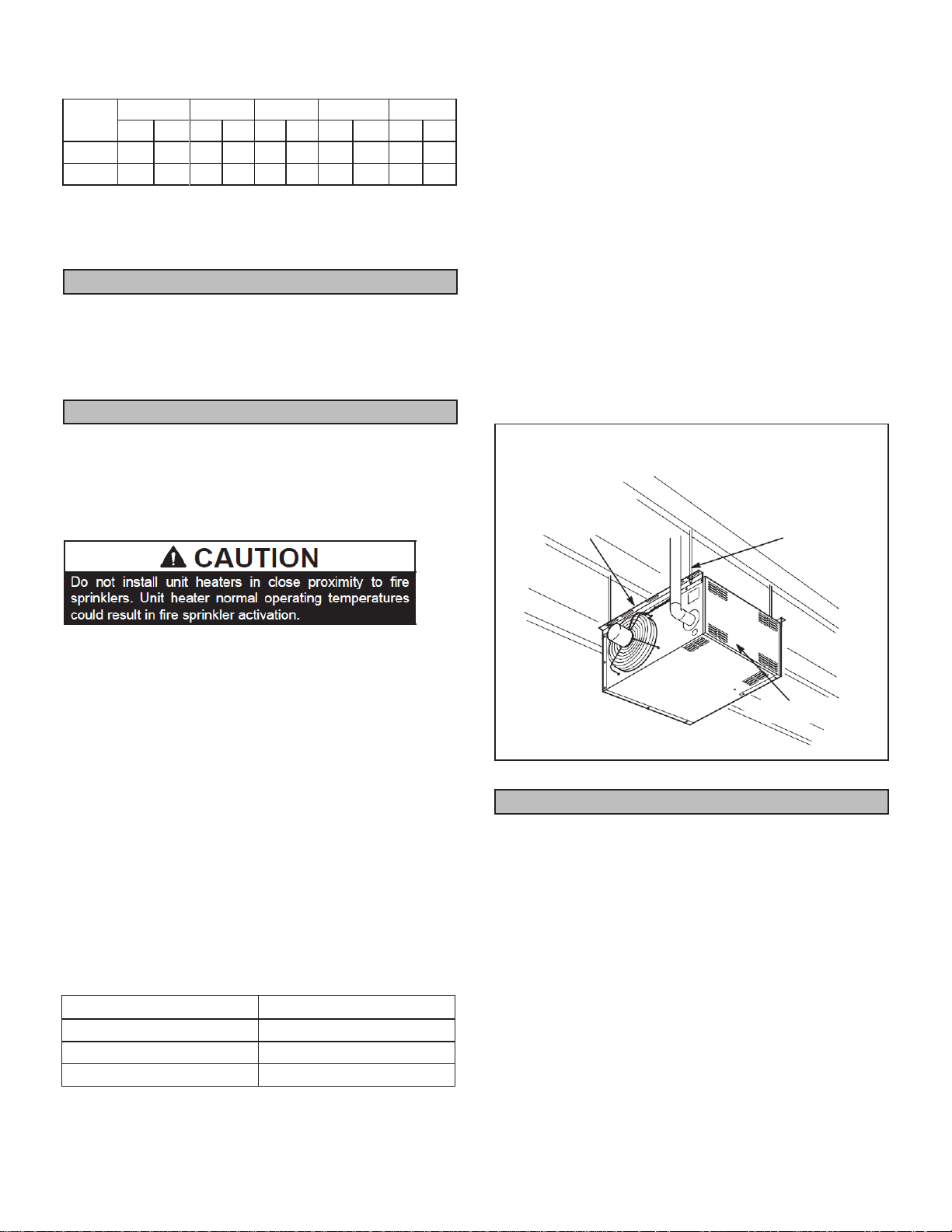

TABLE 1

UNIT CLEARANCES TO COMBUSTIBLE MATERIALS

Unit

Top

Side**

Bottom

Back

Flue

in

mm

in

mm

in

mm

in

mm

in

mm

030/105

1

25

1

25

1

25

18

457

6*

152

125/400

6

152

18

457

1

25

18

457

6

152

*6” is for single wall. Double wall B-vent clearancewill be

in accordance with the manufacturer’s listing.

**Accesspanel or controlbox side ofunit should have 24”

(610mm) clearance.

The Commonwealth ofMassachusetts stipulates the fol-

lowing additional requirements:

1 - Gas furnaces shall be installed by a licensed

plumber orgas fitteronly.

2 - The gas cock must be “T handle” type.

The appliance shall not be installed downstream from

evaporator coils or cooling units.

Install the unit in the desired location as governed by

clearances, vent connection, air direction, gas supply,

electrical supply and service accessibility.

Unit is shippedready forinstallation.

UHCM -125/400 UNITS

Four mounting nuts are furnished. Refer to dimension

illustration. Mounting nuts will accommodate 3/8” x 16

threaded rods.

1 - Push each louver to the left to depress spring and

release locking tab on the other end (locking tab

keeps the louver in place for shipping).

2 - Rotate louvers to direct airflow as desired.

3- Cut threaded rods to desired length and slide a 3/8”

nut onto the rod.

4 - Slide a flat washer onto the threaded rodAFTER the

nut (7/16” inside diameter X 1” outside diameter X

1/16” thick washer).

5 - Screwtherods (two or four) into the mounting nuts

on the unit.

6 - Tighten nuts to secure unit to rods.

TABLE 2

MAXIMUM MOUNTING HEIGHTS - 125/400

UHRS 30/105

Unit may be installed as shown in figure 1 or rotated

180°.

1 - Push each louver to the right to depress spring and

release locking tab on the other end (locking tab

keeps the louver in place for shipping).

2 - If installing unit in a rotated position - release locking

tabs in the same manner as previous step. Rotate

each louver 180° and reinstall. Remove and retain

screws securing access panel. Rotate accesspanel

180° and resecure using retained screws.

3 - Rotate louvers to direct airflow as desired.

4 - Choose location for mounting brackets.

5 - Alignmountingbracketswithpilotholes onthetop or

bottom (when rotating) edge ofthe unit. Secure with

screws provided in bag assembly.

6 - Tosupport unit, secure mounting bracket to ceiling

joist or truss. Unit may also be supported using

support rods as shown in figure 1.

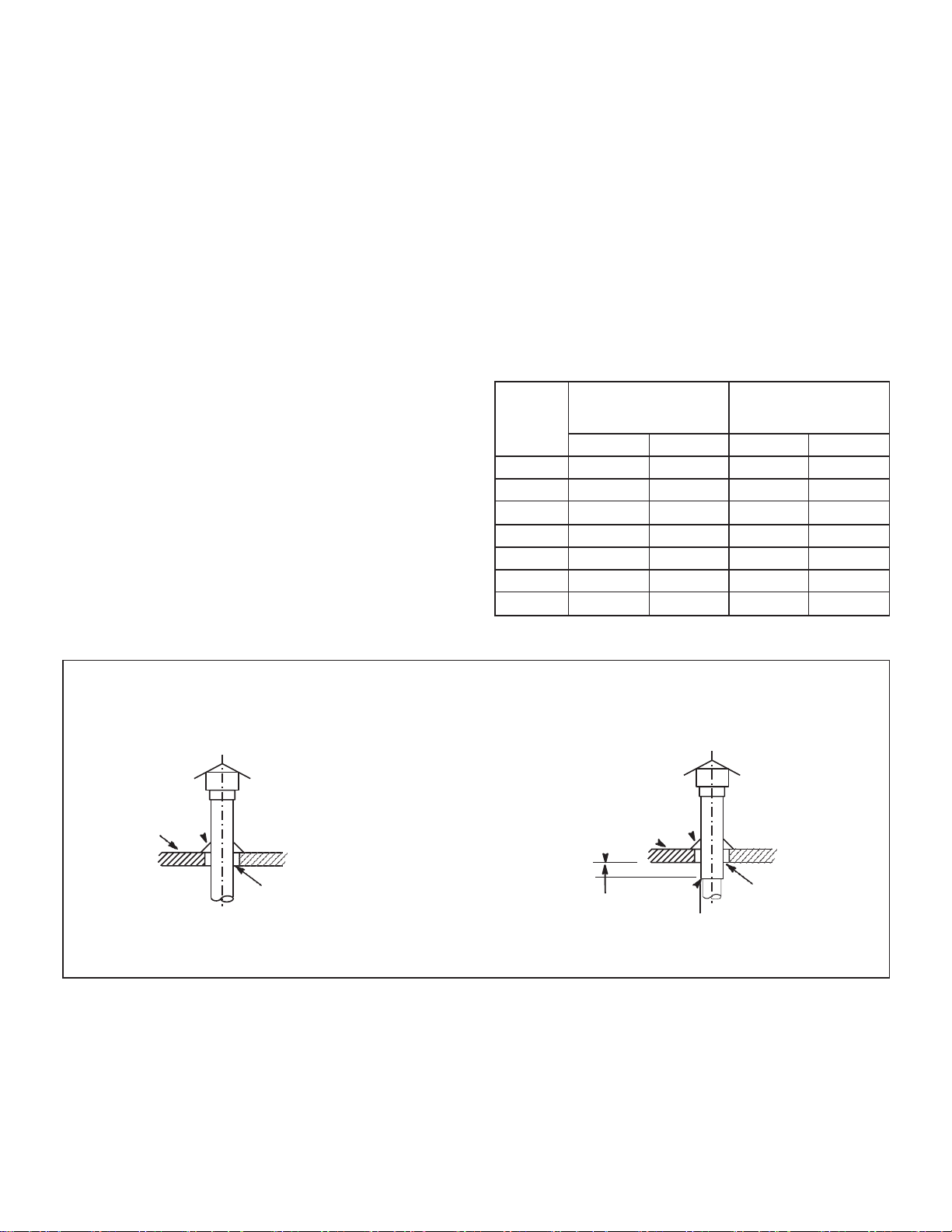

INSTALL UNIT HEATER

(030 / 105 SHOWN)

MOUNTING

BRACKETS

(2) SUPPORT

RODS

ACCESS PANEL

FIGURE 1

Adequate facilities for supplying air for combustion and

ventilation must be provided in accordance with the cur-

rent edition of ANSI Z223.1, section 5.3 and CSA-B149

installation compliance codes,or applicable provisions of

local building codes.

All gas-fired appliances require air to be used for com-

bustion. In many buildings today, there is a negative in-

door air pressure caused by exhaustfans,etc.If sufficient

quantities ofcombustion air are not available, the heater

AdditionalRequirements

Unit Heater Installation

Combustion and Ventilation Air

Unit

Feet (Meters)

UHCM-125/150

16 (4.9)

UHCM-175/200

20 (6.1)

UHCM- 250/400

30 (9.1)

Page 9

or another appliance will operate in an inefficient manner,

resulting in incomplete combustion which can result inthe

production of excessive carbon monoxide.

If indoor air is to be used for combustion, it must be

free of the following substances or the life of the heat

exchanger will be adversely affected: chlorine, car-

bon tetrachloride, cleaning solvent, halogen refriger-

ants, acids,cements and glues, printing inks, fluorides,

paint removers, varnishes, or any other corrosives.

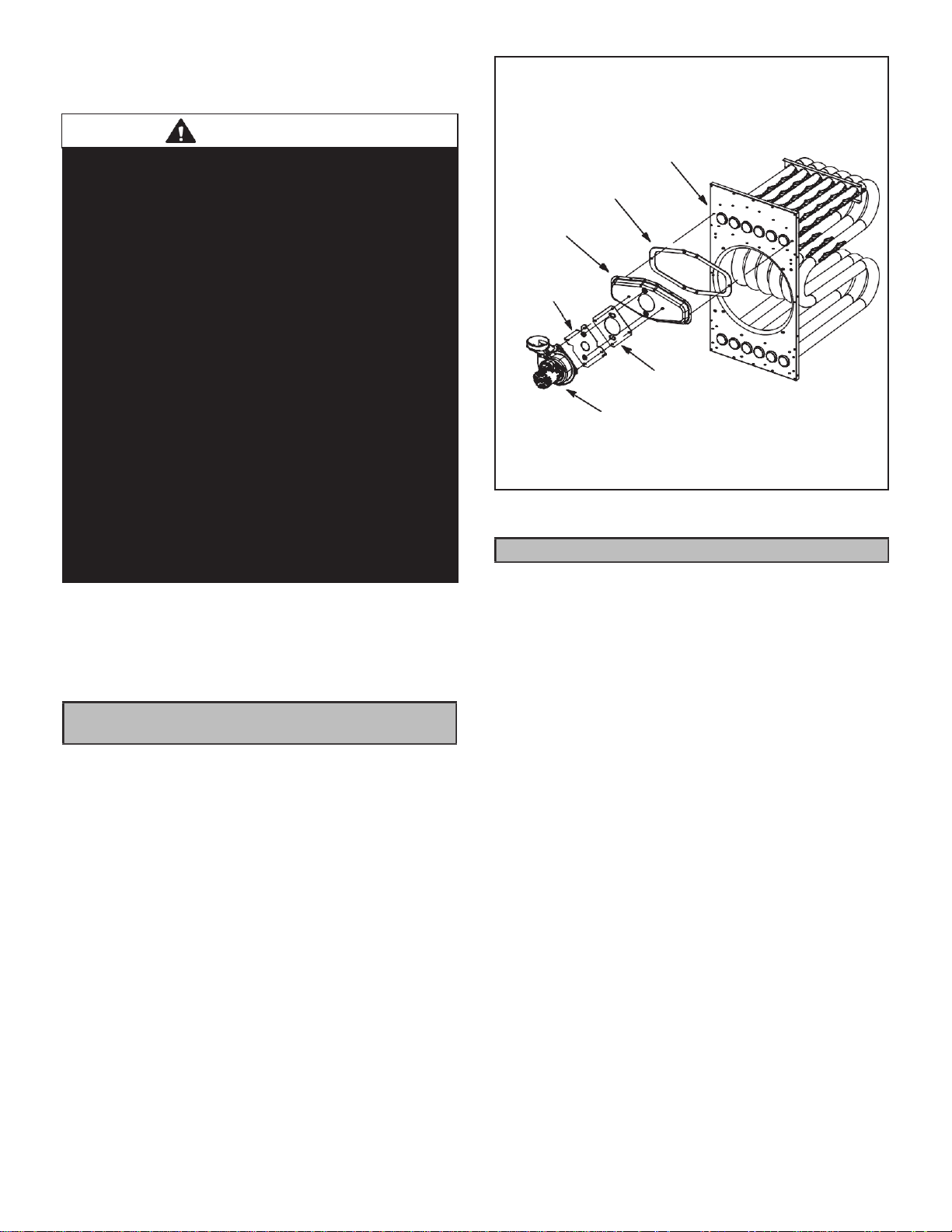

Rotation of Combustion Air Inducer (UHCM) -125 & 150

Only)

The combustion air inducer on UHCM -125 & 150 may

be rotated 90° either to the left or right of the original

vertical position in order to better suit the application.

NOTE - It is not permissible to rotate the combustion air

inducer on UHRS -030/105 and UHCM -175/400.

Rotate the combustion air inducer assembly as follows:

1 - Remove the heater from the carton. Decide the best

unit heaterorientation. The vent can be installed in

one of three discharge positions: up, left, orright.

2 - If the inducer is to be rotated, follow the instructions

in this section; otherwise, referto instructions under

“Venting” section.

3 - Before making an electricalorgas connections, use

a socket toremove the four screws which secure the

combustion air inducerto the flue box.See figure 2.

4 - Rotate the inducer 90° to the desired position.

Reinsert and tighten the inducer securing screws.

5 - The unit heater is now ready for installation as

described in the Venting section.

Venting

NOTE - The vent is a passageway, vertical or nearly so,

used to convey flue gases from an appliance, or its vent

connector,totheoutsideatmosphere. Theventconnector

is the pipe orduct that connects a fuel-gas-burning appli-

ance to a vent or chimney.

NOTE - Local codes may supersede any of these provisions.

GENERAL RECOMMENDATIONS AND

REQUIREMENTS

Unit heaters must be vented in compliance with the lat-

est edition of the National Fuel Gas Code (NFPA 54 /

ANSI Z223.1) in the USA and with CSA-B149.1 codes in

Canada, as well as applicableprovisions oflocal building

codes, and the following instructions.

030-150 Units - The transitionisa part of the combus-

tion air blower.

175-400 Units - A stamped/extruded metal transition

issuppliedwiththiscertifiedunit. Itmustnot be mod-

ified or altered and must be installed on the outlet

of the combustion air inducer assembly prior to the

installation of the vent connector.Failure to comply

with thisrequirement willvoidthe certification of the

unit by the approval agencies.

A single-wall vent connector may be used between the

furnace and the vertical vent pipe in all applications;how-

ever, single-wall vent material cannot be used for

vertical vent piping inresidentialapplications. UL-ap-

proved Category IIIventing materials must be used

in all residentialapplicationswhich venthorizontally.

WARNING

Insufficient combustion air can cause headaches,

nausea, dizziness or asphyxiation. It will also cause

excess water in the heat exchanger resulting in rusting

and premature heat exchanger failure. Excessive

exposure to contaminated combustion air will result

in safety and performance related problems. Avoid

exposure to the following substancesin the combustion

air supply:

Permanent wave solutions

Chlorinated waxes and cleaners

Chlorine base swimming pool chemicals

Water softening chemicals

De-icing salts or chemicals

Carbon tetrachloride

Halogen type refrigerants

Cleaning solvents (such as perchloroethylene)

Printinginks, paintremovers, varnishes, etc.

Hydrochloric acid

Cements and glues

Antistatic fabric softeners forclothesdryers

Masonry acid washing materials

FLUEBOX AND COMBUSTION AIR

INDUCER ASSEMBLY

125/150

VEST PANEL

FLUE BOX

GASKET

FLUE BOX

ORIFICE

PLATE

ORIFICE

PLATEGASKET

COMBUSTION

AIR INDUCER

FIGURE 2

Page 10

A single-wall vent pipe used as a vent connector in resi-

dential or commercial applications, oras a vertical vent in

commercial applications, musthave all seams and joints

sealed with pressure-sensitive aluminum tape or silicone

rubber sealant. Aluminumtapemust meetthe provisions

of SMACNAAFTS-100-73 Standards.The aluminum tape

must have a temperatureratingof400°F(204°C). Silicone

rubber sealant must have a temperature rating of 482°F

(250°C), i.e., Dow Corning RTV-736 or equivalent. All

jointsmustbesecuredwithatleasttwocorrosion-resistant

screws. All joints must be checked for gas tightness after

installation. Single-wallvent pipe used as vertical vent in

commercial applicationsmust not pass through anyattic,

interior wall, concealed space, or floor.

VERTICAL VENTS USING METAL VENT PIPE -

COMMERCIAL AND RESIDENTIAL INSTALLATIONS

These compact unit heaters are listed as Category 1

appliances for vertical vent installations.

1 - These unit heaters are to be used with NFPA- or

ANSI-approved chimneys or U.L.-listed type B-1

gas vents, orlisted chimney lining systems for gas

ventingwhere applicable,aswellas themodifications

and limitationslistedinfigure3. Sealsingle-wall vent

material according to General Recommendations

and Requirements section.

2 - The vent connector shall be 4” (102mm) diameter

on 30K, 45K, 60K, 75K,090,105K, 125K,and 150K

Btuh

units; 5” (127mm) diameter on 175K, 200K, 250K,

& 300K Btuh units; 6” (152mm) on 360 & 400K Btuh

units. On 175-400 units, a flue transition piece

(supplied) is required to fit over the outlet of the

induced draft assembly on the appliance.

NOTE - If needed, loosen the upper right two or three

screws securing thecombustion air blower. Slide thetran-

sition into place and secure loosened screws.

3 - Keepthevent connector runs as short as possible

with a minimum number of elbows. Refer to the

current edition of ANSI Z223.1 or CSA-B149

installationcompliance codes for maximum ventand

vent connector lengths.

4 - The entirelengthofasingle-wallmetalventconnector

shall be readily accessible for inspection, cleaning

and replacement.

5 - Single-wall vent pipe used as vertical vent in

commercial applicationsmust not pass through any

attic, interior wall, concealed space, or floor.

TABLE 3

MAXIMUM HORIZONTAL VENT CONNECTOR AND

HORIZONTAL VENT PIPE LENGTHS

No. of

Elbows

30, 45,60, 75,090, 105,

100,115, 145, 175, 200,

360, 400

250 & 300

ft

m

ft

m

1

25

7.6

35

10.7

2

20

6.1

30

9.1

3

15

4.6

25

7.6

4

10

3.0

20

6.1

5

5

1.5

15

4.6

6

-

-

10

3.0

7

-

-

5

1.5

VENT TERMINATION ON SINGLE-WALL VERTICAL VENT RUNS

Commercial Application Only

SINGLE-WALL VENTPIPE WITH SINGLE-WALL VENT PIPE WITH

SINGLE-WALL TERMINATION DOUBLE-WALL (TYPE B-1) TERMINATION

ROOF FLASHING ROOF FLASHING

ROOF PITCHED

ROOF PITCHED FROM 0” TO 45”

FROM 0” TO 45”

12”MAX CLEARANCE TO BE

2” CLEARANCE AS SPECIFIED ON

THIMBLE TYPE “B” VENT PIPE.

SEAL JOINT BETWEENSINGLE-WALL VENT AND “B” VENT TERMINATION

AND THE OPEN SPACE BETWEEN THE SINGLE WALL VENT PIPE AND

THE OUTER PIPE OF THE “B” VENT TERMINATION.

FIGURE 3

Page 11

6 - The unit may beventedverticallyasasingleappliance

or ina common vent with other gas-fired appliances.

In common venting situations, vent connectors for

otherappliancesmustmaintaina4” (102mm)vertical

separation between the vent connectors. Refer to

common venting tables in the current editions of

ANSIZ223.1 or CSA-B149 installation compliance

codes for proper vent size.

7 - Clearance to combustible material is 6” (152mm)

for single-wall vent material except where a listed

clearance thimble is used. Clearance tocombustible

material for type B-1 vent or factory-built chimneyis

per manufacturer’s instructions.

8 - The vent connector shall be supported without any

dips or sags. Vertical vents shall be supported in

accordance with their listing and manufacturers’

instructions. All horizontal vent connectorruns shall

have a slope up to the vertical vent of at least 1/4”

per foot (1mm per 50mm).

9 - All vertical type B-1 vents, single-wall vertical vents

(commercial applications), or listed chimney lining

systemsmustbeterminatedwithaUL-listed(orother

equivalent agency) vent cap orlisted roofassembly.

10- The vent must extend at least 3 feet (1m) above

the highest point where it passes through a roof

of a building. The vent must also extend at least 2

feet (1m)higher thanany part of a building within a

horizontal distance of10 feet (3m) unless otherwise

specified by ANSI Z223.1 or CSA-B149 installation

compliance codes. Thevent must extend at least 5

feet (2m) above the highest connected equipment

flue collar HORIZONTAL VENTING

NOTE - Commonventingisnot allowed when horizontally

venting the unit heater.

If the UH(RS,CM) unit heater is to be horizontally vented,

a positive pressure may be created in the vent. The unit

heater,wheninstalled withhorizontal venting,will perform

as a category III appliance.

1 - In residential applications which vent horizontally,

use only special vent materials approved for use

with Category III appliances.

2 - The vent pipe diameter for horizontal installations

shall be 4” (102mm) diameter on 30K, 45K, 60K,

75K, 090, 105K, 125K, and 150K Btuh units; 5”

(127mm) diameter on 175K, 200K, 250K, & 300K

Btuh units; 6” (152mm) on 350 & 400K Btuh units.

On175-400units, a flue transition piece (supplied)

is required to fit over the outlet of the induced draft

assembly on the appliance.

3 - The minimum horizontal vent length is 5 feet (2m).

4 - Refer totable3for maximumhorizontalventlengths.

5 - If possible, do not terminate the horizontal vent

through a wall that is exposed to prevailing wind.

Exposure to excessive winds can affect unit

performance. If such a termination is necessary,use

a wind block to protect the vent termination from

direct winds.

6 - Horizontal vent termination must be free from

obstructions and at least 12” (305mm) above grade

level and maximum snow height.

7 - Do not install a horizontal vent termination directly

below roof eaves or above a public walkway, or

any other area where condensate dripping may be

troublesome and may cause some staining. Avoid

windows where steam may cause fogging or ice

buildup.

8 - Minimum clearance for horizontal vent termination

from any door, window, gravity air inlet, gas or

electric meter,regulators, and relief equipment is 4

feet (1m) for United States installations. In Canada,

horizontal vent termination must have a minimum 6-

foot horizontal clearance from gas and electric

meters and relief devices.

Refer tolatesteditionsoftheANSIZ223.1orCSA-B149

forinstallationcompliancecodesandwithlocalauthor-

ities with jurisdiction.

9 - Vent termination must be a minimum of 4 feet (1m)

below, or4feet (1m) horizontally, from any soffit or

under-eave vent.

10 - Vent must be a minimum of 6 feet (2m) from an

inside corner formed by two exterior walls. If

possible, leave a 10-foot (3m) clearance.

11- Ventterminationmustbeaminimumof10feet (3m)

from any forcedair inlet (includes fresh air inlet for

other appliances, such as a dryer).

12 - When termination is routed through combustible

wall, vent termination must be supported using a

firestop to maintain clearances specified on unit

rating plate. Inside edge of vent termination must

be at least 16” (406mm) from outside wall

13 - All horizontal vents which use special vent pipe for

use with Category III appliances must terminate

with an approved Category III tee. Opening end

must face downward.

14 - For horizontal venting, the vent pipe shall be

supported with hangers no more than 3 feet (1m)

apart to prevent movement after installation.

15 - Selectawallterminationpointthatwillmaintain1/4”

(6mm)riseper foot(305mm)slopeofhorizontalrun

of vent pipe.

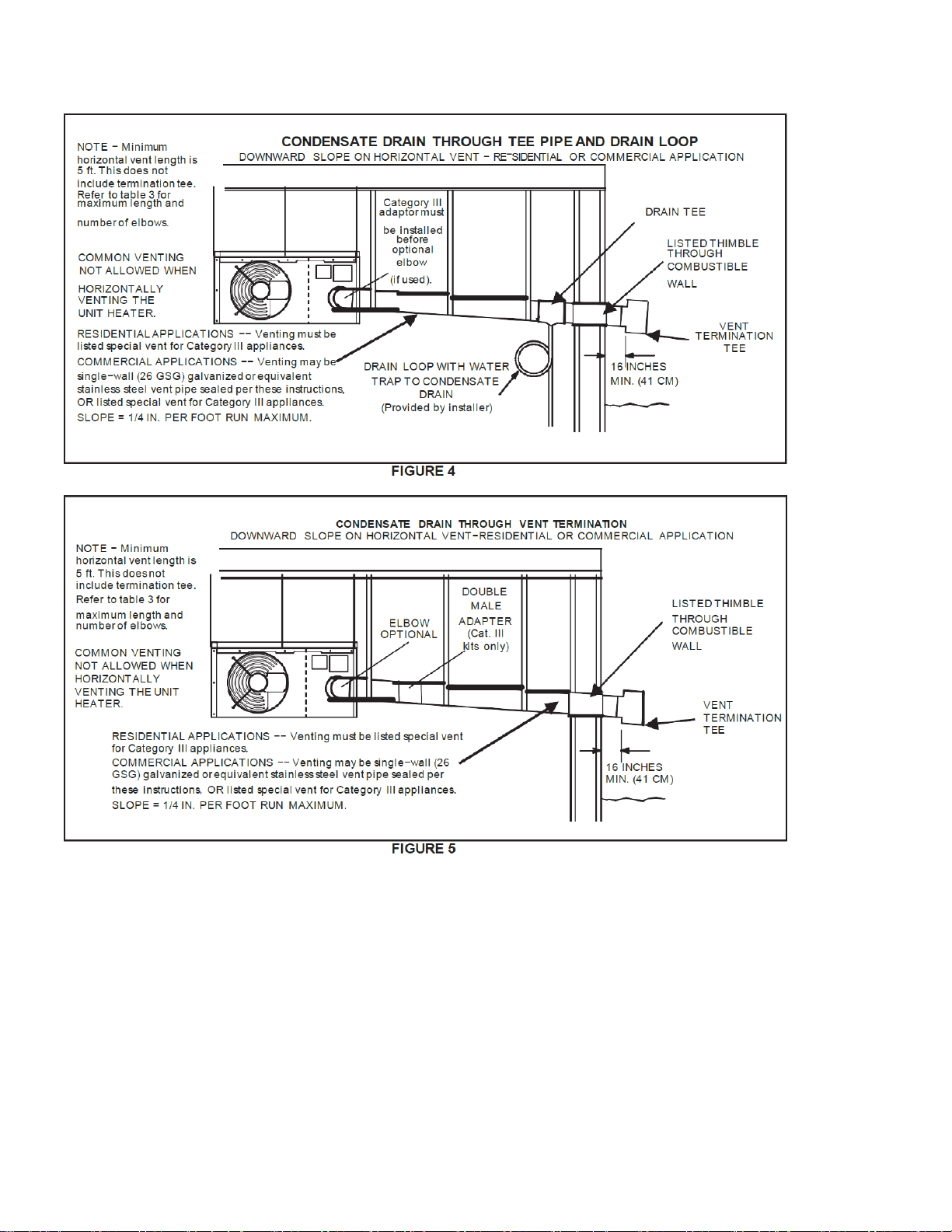

16 - For upward sloped vent, a condensate tee and

drain must be installed within the first 5 feet (2m)

from the unit heater to protect the appliance. If a

flexible condensate drain line is used, the drain

line must include a loop filled with water to prevent

combustion products from entering the structure. If

the unit is shut down for an extended period oftime

and will be exposed to sub-freezing temperatures,

the condensate may freeze.

17 - Selectawallterminationpointthatwillmaintain1/4”

rise per foot slope of horizontal run of vent pipe. In

areas where authorities having jurisdiction permit,

a downward slope of maximum 1/4” per foot is also

acceptable. Condensate drainage can be collected

ina teepipesection(figure4)withdrain loopsimilar

to one used for upward slope vent, or allowed to

drip through the vent termination, if permitted by

authorities (figure 5).

Page 12

Page 13

FIGURE 6

TABLE 4

Category III Horizontal Venting Components²

(Required for Horizontal Vent Applications)

UH(RS,CM) Unit

Vent

Diameter (in.)

Upslope Vent

Kit / Cat. No.

Downslope Vent

Kit / Cat. No.

45° Elbow Kit /

Cat. No. (optional)

90° Elbow Kit /

Cat. No. (optional)

¹Min. Vent Length

(ft.)

30, 40, 45, 60, 75,

90, 105, 125, 150

4

C5VENT4KU /

75W63

C5VENT4KD /

75W67

C5VENT4E45 /

87W80

C5VENT4E /

75W71

5

175, 200, 250,

300

5

C5VENT5KU /

75W64

C5VENT5KD /

75W68

C5VENT5E45 /

87W81

C5VENT5E /

75W72

350, 400

6

C5VENT6KU /

75W65

C5VENT6KD /

75W69

C5VENT5645 /

87W82

C5VENT6E /

75W73

¹Length doesnot include termination (orelbowwhere applicable).

NOTE - Elbowisrequired where shown to facilitate connection of horizontalvent kit to flue outlet.

²Referto EHB forvent pipe part numbers.

VENTING USING A MASONRYCHIMNEY

The following additional requirements apply when a lined

masonry chimneyis being used to vent the compact unit

heater.

IMPORTANT

Single appliance venting of a fan-assisted unit heater

intoatilelinedmasonrychimney(interiororoutsidewall)

is prohibited. The chimney mustfirst be lined witheither

type “B-1“ vent or an insulated single-wall flexible vent

lining system, sized in accordance with venting tables in

the ANSI Z223.1, or CSA-B149 installation compliance

codes.

1 - Masonry chimneys used to vent Category I units

heatersmustbeeithertile-linedorlinedwitha listed

metal lining systemor dedicated gas vent. Unlined

masonry chimneys are prohibited. A category I

appliance must never be connected to a chimney

that is servicing a solid fuel appliance. If a fireplace

chimney flue is used to vent this appliance, the

fireplace opening must be permanently sealed.

2 - A fan-assisted unit heater maybe commonlyvented

into an existing lined masonry chimney provided:

a. The chimney is currently serving at least one draft-hood

equipped appliance.

b. The vent connector and chimney are sized in accordance

with venting tables.

3 - A “B1” double-wall vent or masonry chimney liner

shall terminate above the roof surface with a listed

cap or a listed roof assembly in accordance with

the terms of their respective listings and the vent

manufacturer’s instructions.

4 - Do not install a manual damper, barometric draft

regulator, or flue restrictor between the unit heater

and the chimney.

5 - If type“B1” double-wallventisusedinsideachimney,

no otherappliance can be vented into the chimney.

Outer wall oftype “B” vent pipe must not be exposed

to flue products.

6 - Insulation for the flexible vent pipe must be an

encapsulated fiberglass sleeve recommended by

the flexible vent pipe manufacturer.

7 - The space between liner and chimney wall should

NOTbeinsulatedwithpuffedmicaorany other loose

granular insulating material.

16 INCHES

MIN. (41 CM)

VENT

TEE

RESIDENTIALAPPLICATIONS −− Venting must be listed special vent

for Category III appliances.

COMMERCIAL APPLICATIONS −− Venting may be single−wall (26

GSG) galvanized or equivalent stainless steel vent pipe sealed per

these instructions, OR listed special vent for Category III appliances.

SLOPE = 1/4 IN. PER FOOT RUN MAXIMUM.

LISTED THIMBLE

THROUGH

COMBUSTIBLE

WALL

(Cat. III

kits only)

COMMON VENTING

NOT ALLOWED WHEN

HORIZONTALLY

VENTING THE UNIT

HEATER.

ELBOW

MALE

NOTE − Minimum

horizontal vent length is

5 ft. This does not

include terminationtee.

Refer to table 3 for

maximum length and

number of elbows.

CONDENSATE DRAIN THROUGH VENT TERMINATION

DOWNWARD SLOPE ON HORIZONTALVENT−RESIDENTIAL OR COMMERCIAL APPLICATION

Page 14

8 - If B-1 vent or an insulated flexible vent pipe cannot

be used as liners, the chimney must be rebuilt

to accommodate one of these methods or some

alternateapproved methodmust befoundtovent the

appliance. When inspection reveals that an existing

chimney is not safe for the intended purpose, it

shall be rebuilt to conform to nationally recognized

standards, lined or relined with suitable materials

or replacedwith a gas vent or chimney suitable for

venting unit heaters. Thechimney passagewaymust

be checked periodically to ensure that it is clear and

free of obstructions.

REMOVAL OF UNIT FROM COMMON VENT

In the event that an existing unit heateris removed from a

venting systemcommonlyrunwithseparategas applianc-

es, the venting systemis likely to be too large to properly

vent theremainingattachedappliances.Thefollowingtest

should be conducted while each appliance isin operation

and the other appliances are not in operation, yet remain

connected to the common venting system. If the venting

system has been installed improperly, the systemmust be

corrected.

1 - Seal any unused openings in the common venting

system.

2 - Visually inspecttheventingsystemforpropersizeand

horizontal pitch. Determine there is no blockage or

restriction, leakage,corrosion, or other deficiencies

which could cause an unsafe condition.

3 - In so far as is practical, close all building doors and

windows andall doors between the space in which

the appliances remaining connected to the common

venting systemare located and other spaces of the

building. Turn on clothes dryersand any appliances

not connected to the common venting system. Turn

on any exhaust fans, such as range hoods and

bathroomexhausts,sotheywilloperateatmaximum

speed. Do not operate a summer exhaust fan. Close

fireplace dampers.

4 - Followthe lighting instructions. Place the appliance

being inspected in operation. Adjust thermostat so

appliance will operate continuously.

5 - Test for spillage at the draft hood reliefopening after

five minutes ofmain burner operation. Use the flame

of a match or candle, or smoke from a cigarette,

cigar, or pipe.

6 - After it has been determined that each appliance

remaining connected to the common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, fireplace dampers

andany othergas-burningappliancetotheirprevious

condition of use.

7 - If improperventing isobserved during any of the above

tests, the common venting systemmust be corrected.

The common venting system should be resized to ap-

proach the minimum size as determined by using the

appropriatetablesinAppendixGinthecurrenteditions

of theANSIZ223-1, or the appropriate Category I Nat-

ural Gas and Propane appliances venting sizing tables

in the current standards of the CSA-B149 for installa-

tion compliance codes.

NOTE - Local codes maysupersede anyofthe provisions

outlined in this instruction.

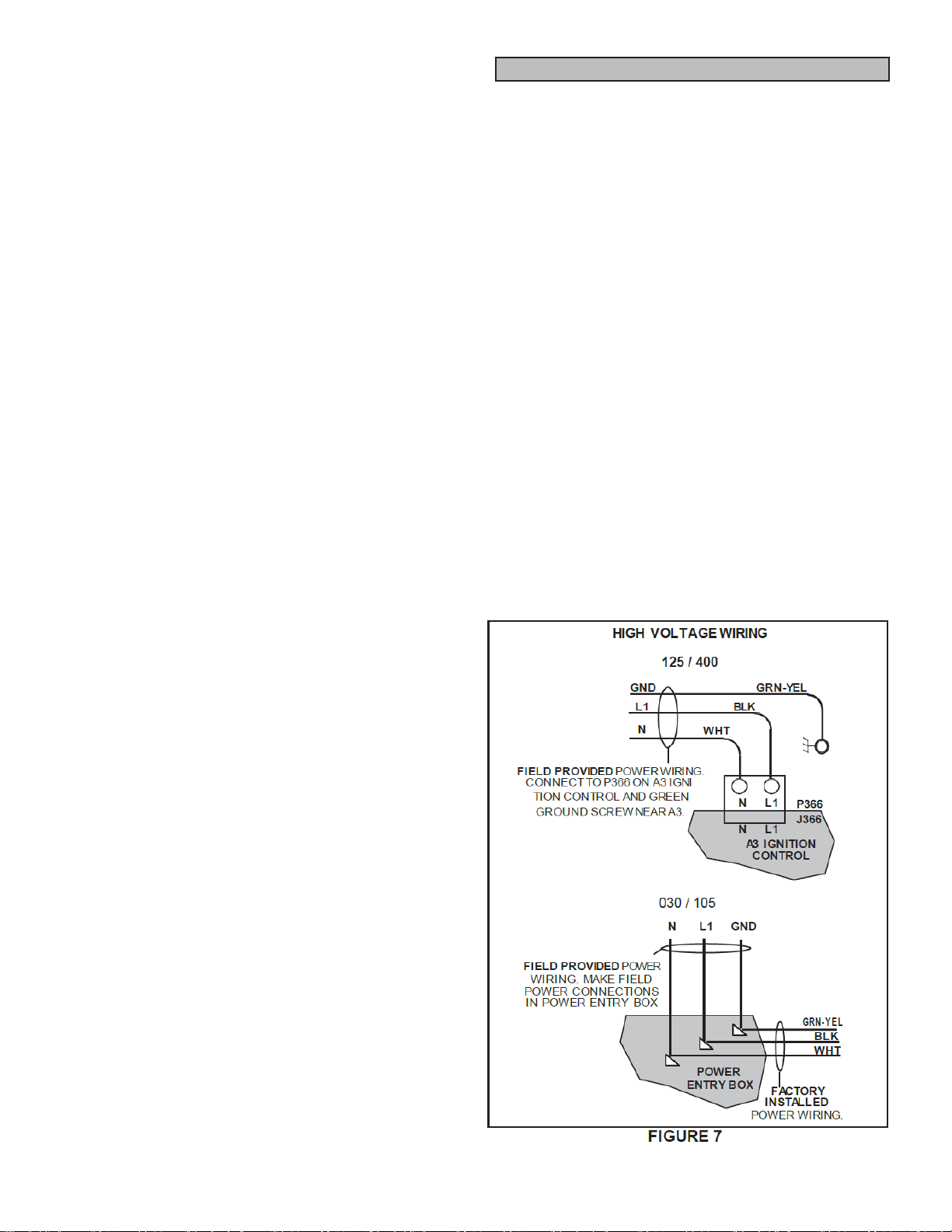

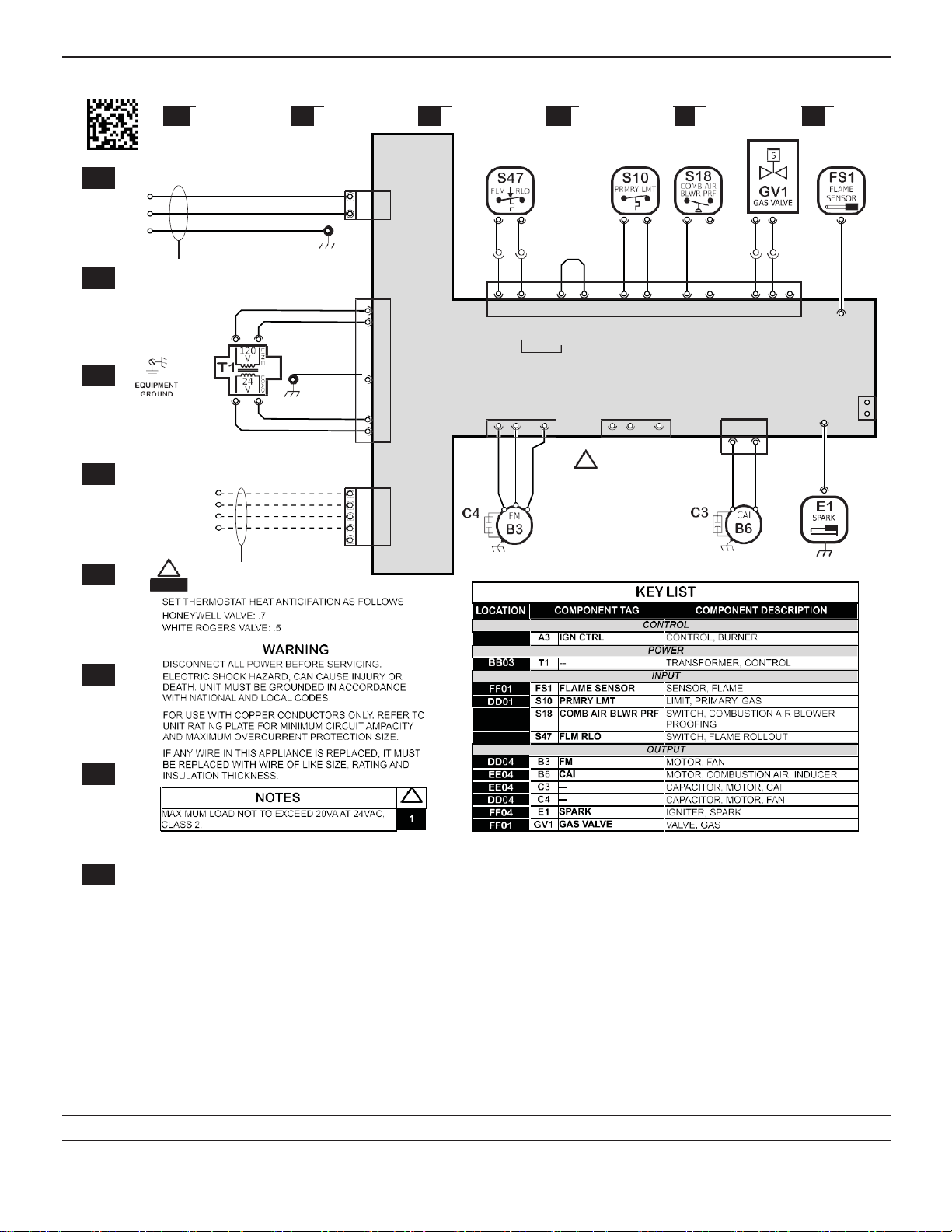

The UH(RS,CM) series unit heaters use a direct spark

ignition system. There is no pilot necessary as the spark

lights the main burner as the gas valve is turned on. The

direct spark ignition controlboard emits radio noise asthe

sparkingprocessis under way. The level of energy may

be sufficient to disturb a logic circuitin a microprocessor

controlled thermostat. It is recommended that an isola-

tion relay be used when connecting the unit heaters to a

microprocessor controlled thermostat. Install the thermo-

stat accordingto instructionsprovided. Install a separate

fused disconnect switch, with the fuse sized according to

blower motor size. Connect wiring through knockout on

the junction box located on the side ofthe unit heater. Re-

fertodimensions inthefrontof thisinstructionforlocation.

Refertoheaterwiring diagramfor connectioninformation.

Use18 gauge wire or larger for thermostat connections.

NOTE - Electricallyground unit in accordance with local

codes or, in the absence of local codes, in accordance

with thecurrent editions of the ANSI/NFPA No. 70, Na-

tional Electrical Code orCSA C22.1,Canadian Electrical

Code, Part 1.

NOTE - Uninsulated ground wires must be wrapped in

electrical tape to avoid damage to the electrical system.

Make line voltage connectionsas shown in figure 7. Con-

nect field wiring as shown on wiring diagram on unit. Also

refer to typical diagram in this manual.An additional ther-

mostat wire must be run to terminal “G” on heater when

continuous blower is desired.

Electrical Connections

Page 15

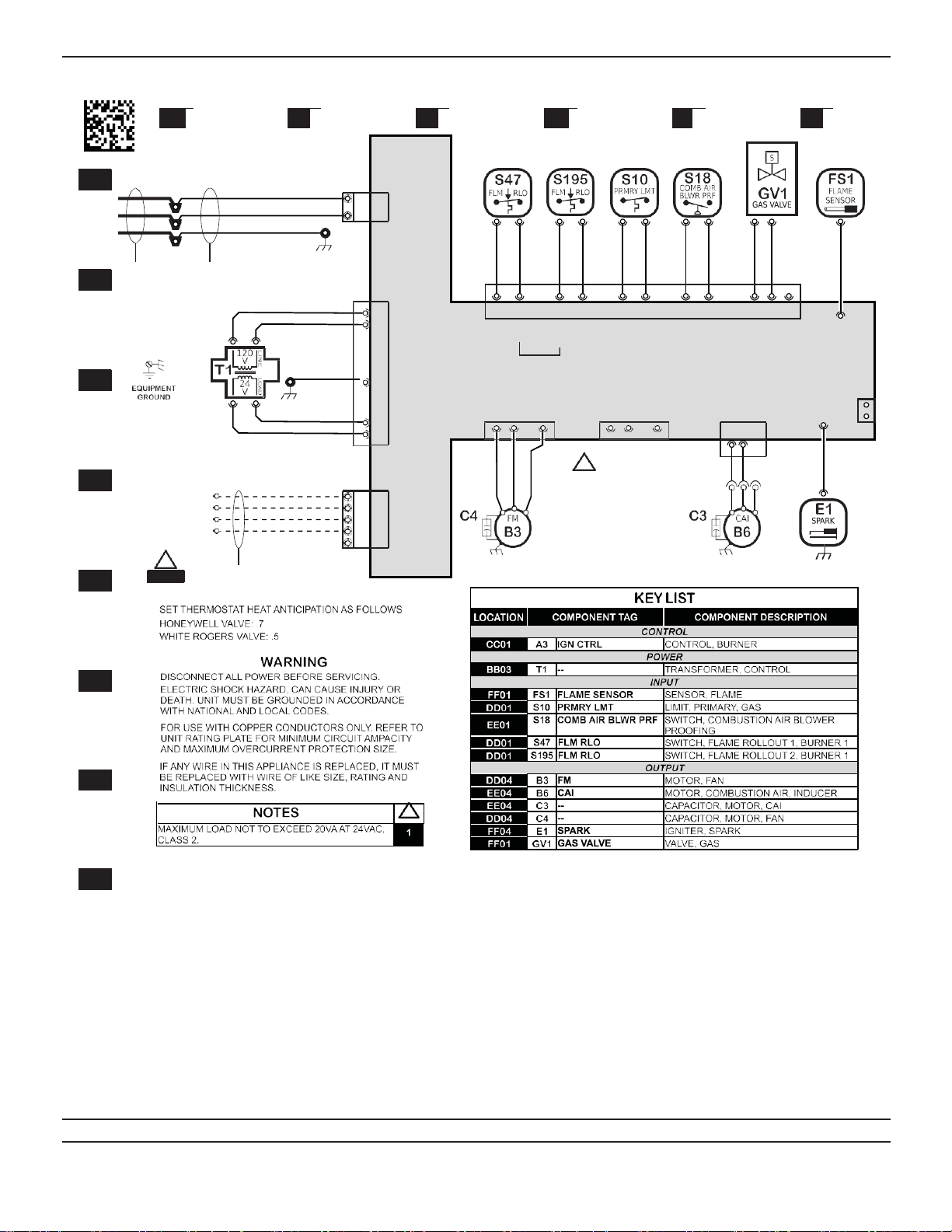

P19 J19

WHT WHT

BLK BLK

FAC RUN TEST

5

537992-01

AA BB CC DD EE FF

A3

HIGH VOLTAGE POWER CONNECTIONS I GN CTRL

L1

N

GND

BLK

WHT

GRN- YEL

L1 L1

N N

NO COM

FIELD PROVIDED

POWER WIRING.

MAKE FIELD POWER

CONNECTIONS IN

POWER ENTRY BOX.

FACTORY INSTALLED POWER

WIRING

BLK

1 1 XFMR- L1

3 3 XFMR- N

P368 8 2 7 1

J368 8 2 7 1

9 3 5 4

9 3 5 4

11 6

11

12

6 12

GRN- YEL 4 4

GND WIRE

ATTACHED TO

XFMR MOUNTI NG

GND- BOARD P373

1

SCREW 5 XFMR- COM

6P364 P365 2

J 374 4 1

BLU 6 XFMR- 24VAC 2 5 8 2 5 8

LOW VOLTAGE THERMOSTAT CONNECTIONS

24V POWER (R) R R

24V COMMON (C) C C

P365 AND P364

ARE ENERGIZED

SIMULT A N E O U SL Y

P374 4 1

1 3

BLOWER (G) G G

HEAT (W1) W1 W1

W2 W2

FIELD PROVIDED

CLASS II 24VAC

THERMOSTAT WIRING

Model: UHRS Unit Heater; SeparatedCombustion Unit Heater Heat Input -

030k-105k BTUH

Voltage: 120/60/1

Supersedes: N/A Form No: 537992-01 Rev: 0

06

07

08

05

04

YEL

03

WHT

02

01

0

CO

P366

J 366

P367

J367

P363

J 363

WHT

GRN- YEL

BLK

WHT

S47

FAN1- N

FAN1- GND

24VAC-IN

WHT

S47

FAN1- L1

WHT

S195

WHT

S195

- OUT

FAN2- N

FAN2- GND

BLU

S10

24VAC-IN

BLU

S10

- OUT

FAN2- L1

PNK

S18

24VAC-IN

BRN

S18

- OUT

CA I - N

CA I - L1

COM

M

GRY

WHT

GV-C

GV- M

GV- H

RED

GRY

SPARK

FLA ME SENS

WHT- RED

!

1

Page 16

FAC RUN TEST

538025-01

AA BB CC DD EE FF

A3

HI GH VOLTAGE POWERCONNECTI ONS I GN CTRL

L1

N

GND

BLK

WHT

GRN- YEL

FIELD PROVIDED POWER WIRING.

CONNECT TO P366 AND GREEN GROUND

SCREW LOCATED INSIDE UNIT.

L1 L1

N N

1 2

1 2 WHT

NO COM

3 4

3 4

BLK 1 1 XFMR- L1

3 3 XFMR- N

P368 8 2

J368 8 2

7 1 9 3 5 4

7 1 9 3 5 4

11 6

11

12

6 12

GRN-YEL 4 4

GND WIRE

ATTACHED TO

XFMR MOUNTING

GND- BOARD P373

1

BLU

SCREW 5 5 XFMR- COM

6 6 XFMR- 24VAC P364 25 8 P365 2

2

5 8 J374 1 4

LOW VOLTAGE THERMOSTAT CONNECTIONS

24V POWER (R)

24V COMMON (C)

BLOWER (G)

HEAT (W1)

R R

C C

G G

W1 W1

W2 W2

P365 AND P364

ARE ENERGIZED

SIMULT A N E O U SL Y

P374 1 4

FIELD PROVIDED

CLASS II 24VAC

THERMOSTAT WIRING

Model: UHRS Unit Heater; SeparatedCombustion Unit Heater Heat Input -

125k-200k BTUH

Supersedes: N/A Form No: 538025-01 Rev: 0

02

120/60/1

Voltage:

08

07

06

05

04

03

01

YEL

WHT

0

P366

J 366

P367

J367

P363

J 363

WHT

WHT

S47

FAN1- N

FAN1- GND

24VAC-I N

GRN- YEL

WHT

S47

BLK

FAN1- L1

S195

S195

- OUT

FAN2- N

FAN2- GND

S10

BLU

24VAC-I N

BLU

S10

- OUT

FAN2- L1

PNK

S18

24VAC-I N

BRN

S18

- OUT

BLK

CA I - L1

COM

M

WHT

GRY

WHT

CA I - N

GV-C

GV- M

GV- H

GRY

SPARK

FLA ME SENS

WHT- RED

!

1

Page 17

FAC RUN TEST

5

AA BB CC DD EE FF

A3

538024-01

L1

N

GND

HIGH VOLTAGE POWER CONNECTIONS

BLK L1

WHT N

GRN- YEL

FIELD PROVIDED POWER WIRING.

CONNECT TO P366 AND GREEN GROUND

SCREW LOCATED INSIDE UNIT.

I GN CTRL

L1

N

1 2

1 2

BLU

BLU

NO COM

3 4 5

3 4 5

BLK 1 1 XFMR- L1

3 3 XFMR- N

P368 8 2

J368 8 2

7 1 9 3 5 4

7 1 9 3 5 4

11 6

11

12

6 12

GRN- YEL 4 4

GND WIRE

ATTACHED TO

XFMR MOUNTI NG

GND- BOARD P373

1

SCREW

BLU

LOW VOLTAGE THERMOSTAT CONNECTIONS

24V POWER (R)

24V COMMON (C)

5 XFMR- COM

6 6 XFMR- 24VAC

R R

C C

P364 2 5 8 P365

2 5 8

2

J374 1 4

P374 1 4

BLOWER (G) G G

HEAT (W1)

HEAT (W2)

1FIELD PROVIDED

CLASS II 24VAC

THERMOSTAT WIRING

W1 W1

W2 W2

Model: UHCM Unit Heater; Separated Combustion Unit Heater Heat Input -

250k-400k BTUH

Voltage: 120/60/1

Supersedes: N/A Form No: 538024-01 Rev: 0

01

WHT

06

07

08

05

04

03

02

YEL

WHT

0

P366

J366

P367

J367

P363

J363

WHT

GRN- YEL

BLK

WHT

S47

FAN1- N

FAN1- GND

24VAC-I N

WHT

S47

FAN1- L1

S195

S195

- OUT

WHT

S10

FAN2- N

FAN2- GND

24VAC-I N

GRN- YEL

BLK

BLU

S10

- OUT

FAN2- L1

PNK

S18

24VAC-I N

BRN

S18

- OUT

BLK

CA I - L1

COM

M

HI

WHT

GRY

CA I - N

GV-C

GV- M

GV- H

WHT

BRN

GRY

SPARK

FLA ME SENS

WHT- RED

Page 18

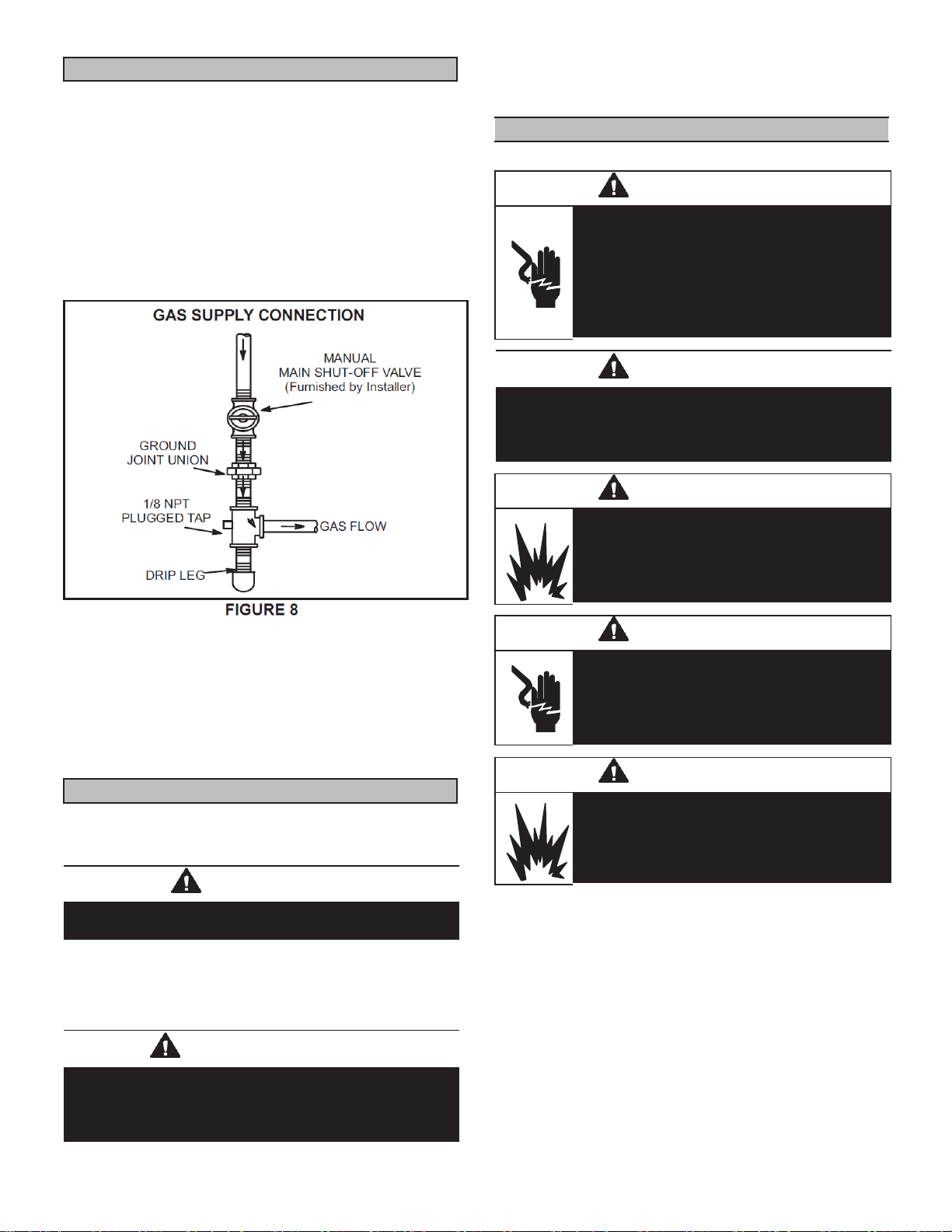

When connectinggas supply, the length of the run from

themetermustbeconsidered indeterminingthepipesize

to avoid excessive pressure drop. A line pressure of 7”

w.g. (178mm w.g.) for natural gas should be maintained

when sizingpiping. Forcorrect sizingofpiping,consultthe

utility having jurisdiction.

A drip leg should be installed in the vertical pipe run

to the unit. In some localities, codes may require that

a manual main shutoff valve and union (furnished by

installer) be installed external to the unit. Union must be

of the ground joint type. A drip leg should be readily ac-

cessible to permit cleaning and emptying. See figure 8.

NOTE - If a switch box is mounted over electrical knock-

outs on back of unit, leave a minimum of 4” (102mm)

clearance between switch box and drip leg.

A1/8” NPT plugged tap shall be installed immediately up-

stream of the gas supply connection to the heater.

NOTE - Compounds usedon threaded joints of gas pip-

ing must be resistant to the actions of liquefied petroleum

gases.

Aftergas piping is completed, carefully check all piping

connections,(field and factory), for gas leaks. Use asoap

solution or other preferred means.

CAUTION

DO NOT use matches, candles,flame orother sources

of ignition to check for gas leaks.

The appliancemust beisolatedfromthegas supply piping

system byclosingits individual manual gas shutoff valve

during any pressure testing ofthe gas supply system at

testpressuresequaltoorgreaterthan1/2psig(3.45kPa).

NOTE - In case emergency shutdown is required, shut

down main gas valve and disconnect main power to unit.

These devices should be properly labeled by the installer.

Unit Start-Up

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING

Electric shock hazard. Can cause injury

or death. Do not use this unit if any part

has been under water. Immediately call a

qualified service technician to inspect the

unit and to replace any part of the control

system and any gas control which hasbeen

under water.

WARNING

Install, operate and maintain unit in accordance with

manufacturer’s instructions to avoid exposure to fuel

substances or substances from incomplete combustion

which can cause death or serious illness.

WARNING

Danger of explosion. Can cause injury or

product or property damage. If overheating

occurs orifgas supply fails to shut off, shut

off the manual gas valve to the appliance

before shutting off electrical supply.

WARNING

Electric shock hazard. Can cause injury or

death. Before attempting to perform any

service or maintenance, turn the electrical

power to unit OFF at disconnectswitch(es).

Unit may have multiple power supplies.

WARNING

Danger of explosion. Can cause injury or

productorproperty damage.Youmustfollow

these instructions exactly.

BEFORE LIGHTINGsmell all around the appliance area

for gas. Be sure to smell next to the floor because some

gas is heavier than air and will settle on the floor.

Use only your hand to move the lever. Never use tools. If

thelever willnot move byhand, donottrytorepair it,calla

qualifiedservicetechnician.Forceorattemptedrepairmay

result in a fire orexplosion.

IMPORTANT

The heater and its individual shut off valve must be

disconnected from the gas supply piping system during

any pressuretesting ofthat system at testpressures in

excess of 1/2 psig (3.45kPa). See figure 9.

GasConnection

Leak Check

Page 19

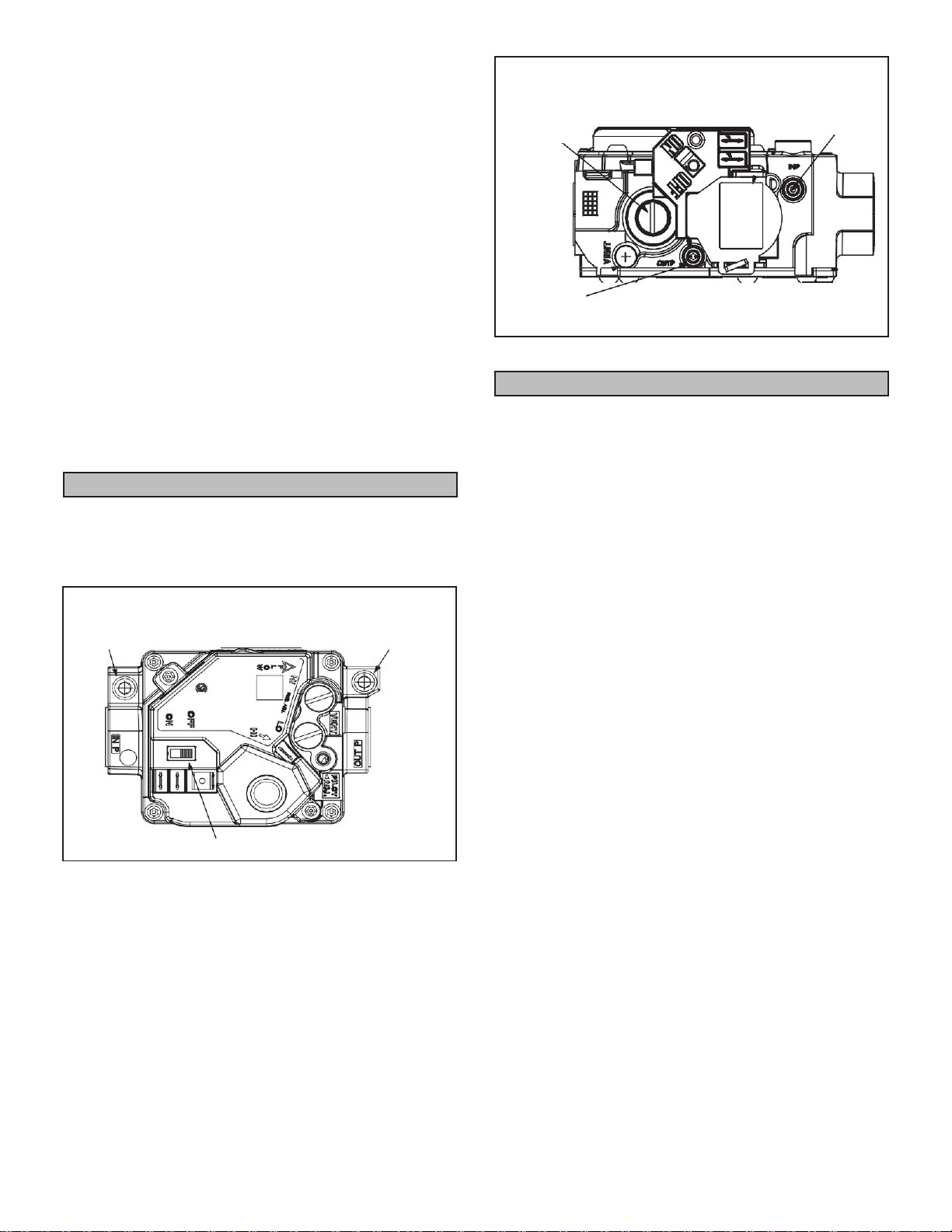

OPERATIONOFWHITERODGERS36HSERIES VALVE

(FIGURE9)AND WHITERODGERS 36G SERIES GAS

VALVE (FIGURE 10)

NOTE - STOP! Read the safety information at the begin-

ning of this section.

1 - Set thermostat to lowest setting.

2 - Turn off all electrical power to appliance.

3 - This appliance is equipped with an ignition device

whichautomatically lightsburners. DONOTattempt

to light the burners manually.

4 - Move lever to OFF.

5 - Wait five minutes to clear out any gas. If you then

smell gas, STOP! Immediatelycall yourgassupplier

from a neighbor’s phone. Follow the gas supplier’s

instructions. Ifyou do not smell gas, go to nextstep.

6 - Move lever to ON.

7 - Turn on all electric power to unit.

8 - Set thermostatto desiredsetting.

9 - If appliancestillwillnotoperate,followtheinstructions

“To Turn Off Gas to Unit” and call your service

technician or gas supplier.

1 - Set thermostat to lowest level.

2 - Turn off all electrical powerto unit if service is to be

performed.

3 - Move lever to OFF

WHITE RODGERS 36H SERIES GAS VALVE

INLET Two-Stage MANIFOLD

PRESSURE PRESSURE

PORT OUTLET

MANIFOLD

PRESSURE

ADJUSTMENT

SCREW

GAS VALVE SWITCH SHOWN IN OFF POSITION

FIGURE 9

WHITE RODGERS 36 GAS VALVE

MANIFOLD Single-Stage INLET

PRESSURE PRESSURE

ADJUSTMENT PORT

SCREW

MANIFOLD

PRESSURE

OUTLET GAS VALVE SWITCHSHOWNIN OFF POSITION.

FIGURE 10

1 - When thethermostat callsforheat, the combustion

air inducer starts immediately.

2 - Combustion air pressure switch proves inducer

operation before allowing ignition sequence to

start. This switch is factory set and no adjustmentis

necessary.

3 - After pre-purge of approximately 30 seconds, the

spark ignition is energized and the solenoid valves

open in the gas valve.

4 - The spark then ignites the gas, the ignition sensor

proves the flame and the combustion process

continues.

5 - In the event that the flame is not detected after the

first 10-second trial for ignition, the controller will

repeat steps 3 and 4 an additional two times before

locking out the gas valve. Ignition control will then

automatically repeat steps 3, 4, and 5 after 60

minutes.

NOTE - Tointerrupt the 60-minute lockout period, move

thermostatfrom“Heat” to“OFF” thenbackto“Heat.” Heat-

ing sequence then restarts at step 1.

6 - The burners must light withoutnoticeable crossover

delay. There must be no flame lifting from theburner

heads, flashback or burning within the burner. The

flames should be predominantly blue in color and

should be approximatelycentered in the tubes with

no apparent impingement taking place.

7 - Theignitioncontrolwillenergizethefanapproximately

30 seconds after ignition is established.

8 - After the thermostat demand is satisfied the gas

valve is closed. Thirtyseconds after the demand is

satisfied, the combustion air inducer is shut off.

9 - The ignition control will shut off the system fan

approximately150secondsafterthegas valve is de-

energize.

To Turn Off Gasto Unit

Heating Sequence of Operation

Page 20

The ignition control contains a green LED which indicates

the following: TABLE5

IGNITION CONTROL LED

LED

UNIT OPERATION

Slow Flash*

Normal Operation - No call for heat

Fast Flash

Normal Operation - Call for heat

2 Flashes

Systemlockout - failed to detect or sustain flame

3 Flashes

Pressure switch failed closed before CAI

is energized or failed open after CAI is

energized

4 Flashes

High limit (S10) or rollout switch open

5 Flashes

Flame sensed and gas valve (GV1) not energized

6 Flashes

On-board microprocessor fault.

7 Flashes

Pressure switch (S18) closed with inducer off.

8 Flashes

Rollout switch(S47/S195) open. Cycle-power to reset.

Steady On

Control board (A3) failure

Steady Off

Internal control board (A3) failture or not power.

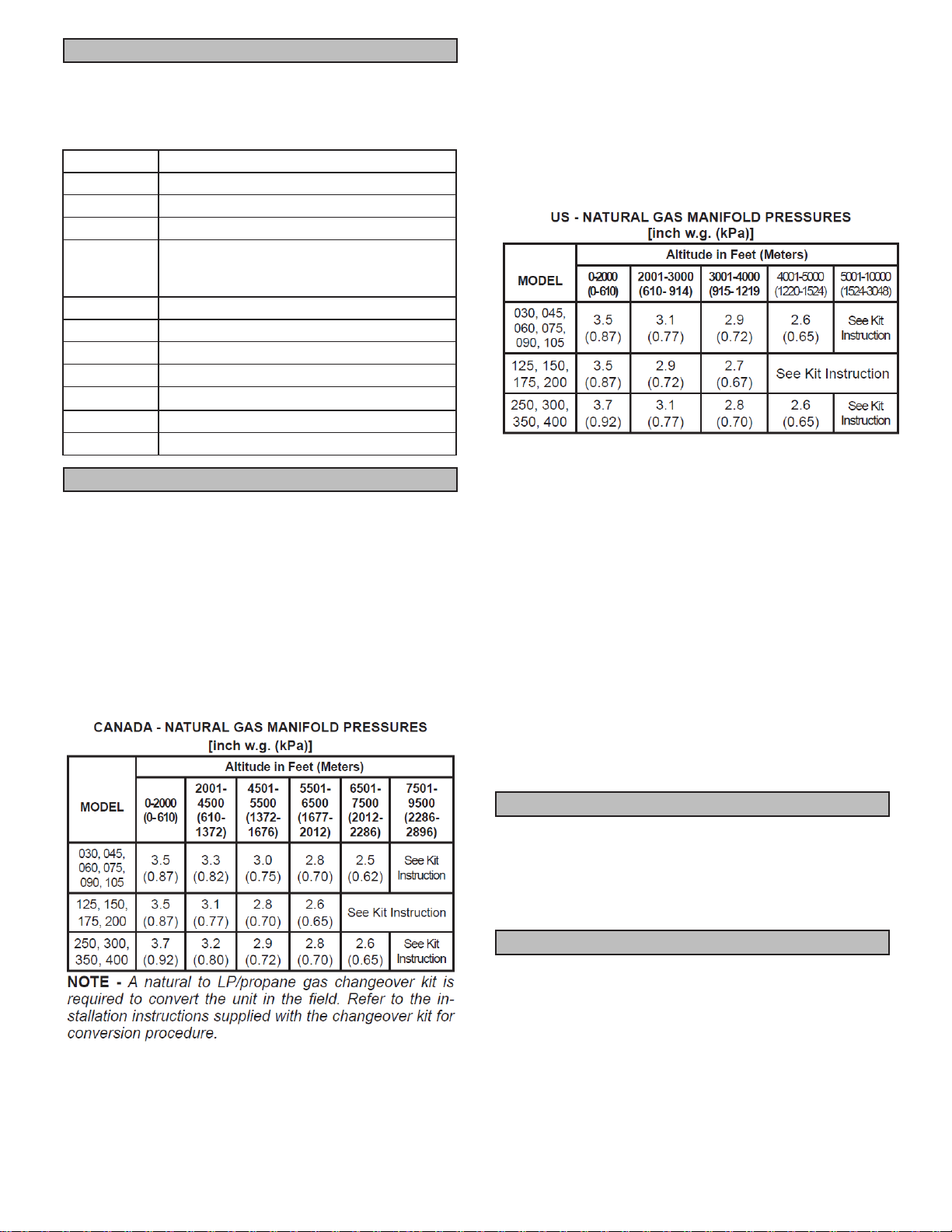

In Canada, certification for installation at altitudes

over 4500 feet (1372m) above sea level is the

jurisdiction of local authorities. ADP recommends

derating 4%/1000 feet above 4,500 feet. Refer to

table 6 for natural gas manifold pressures and the

Engineering Handbook for high altitude kit part

numbers.

Units may be fired at full input up to 2000 feet.

(610m) above sea level. Above 2000 feet (610m),

manifold pressure must be adjusted.Adjust pressure

regulator to pressure shown in table 6.

In the US, units may befired at full input up to 2000 feet

(610m) above sea level. Above 2000 feet (610m), unit

must be de-rated by four percent per1000 feet for instal-

lation above 2000 feet.The de-rate may be accomplished

by adjusting the manifold pressure. See table 7. See the

Engineering Handbook forhigh altitude kit part numbers.

TABLE 7

TABLE 6 In some cases, it is necessary to change the pressure switch to

ensure proper operation at higher altitudes. See EHBfor high

altitude pressure switch kits.

The combustion air inducerproving switch is factory set.

No adjustment is necessary.

To check for proper gas flowto the combustion chamber,

determine the Btu inputfrom the appliance rating plate.Di-

vide this input rating by the Btu per cubicfeet of available

gas. Result is the required number of cubic feet per hour.

Determine theflow of gas through the gas meter for two

minutes and multiply by 30 toget the hourly flow ofgas.

1 - Check gas line pressure with unit firing at maximum

rate. A minimum of the following should be

maintained for proper unit operation:

030-105KBTUH - 5” (127mm) w.c. for natural gas

125-400KBTUH - 6” (152mm) w.c. for natural gas

030-105KBTUH - 10.5” (267mm) w.c. for LP/propane gas

125-400KBTUH -11.0” (279mm) w.c. for LP/propane gas

Ignition ControlLED

High Altitude Adjustments

GasFlow

GasPressure Adjustment

This manual suits for next models

16

Table of contents

Other Adp Heater manuals

Popular Heater manuals by other brands

Celcia

Celcia RH03A-P operating instructions

Comfort Glow

Comfort Glow QDE1340 owner's manual

LUCHT LHZ

LUCHT LHZ TECHNOTHERM TTB-E Duo+ Series Manual Installation

Black & Decker

Black & Decker BXRA1500E manual

FAFCO

FAFCO SUPER solar beat Installation and owner's manual

FELLER ENGINEERING

FELLER ENGINEERING OR 23110 manual