INTRODUCTION

2

Table of Contents

INTRODUCTION ........................................................................................................................................ 3

Using This Manual ................................................................................................................................ 3

Safety Information ............................................................................................................................... 3

Contact Adrona .................................................................................................................................... 3

PRODUCT OVERVIEW ............................................................................................................................... 4

Adrona Q-Front N Water System General Description ........................................................................ 4

System Overview ................................................................................................................................. 4

Water Specifications ............................................................................................................................ 5

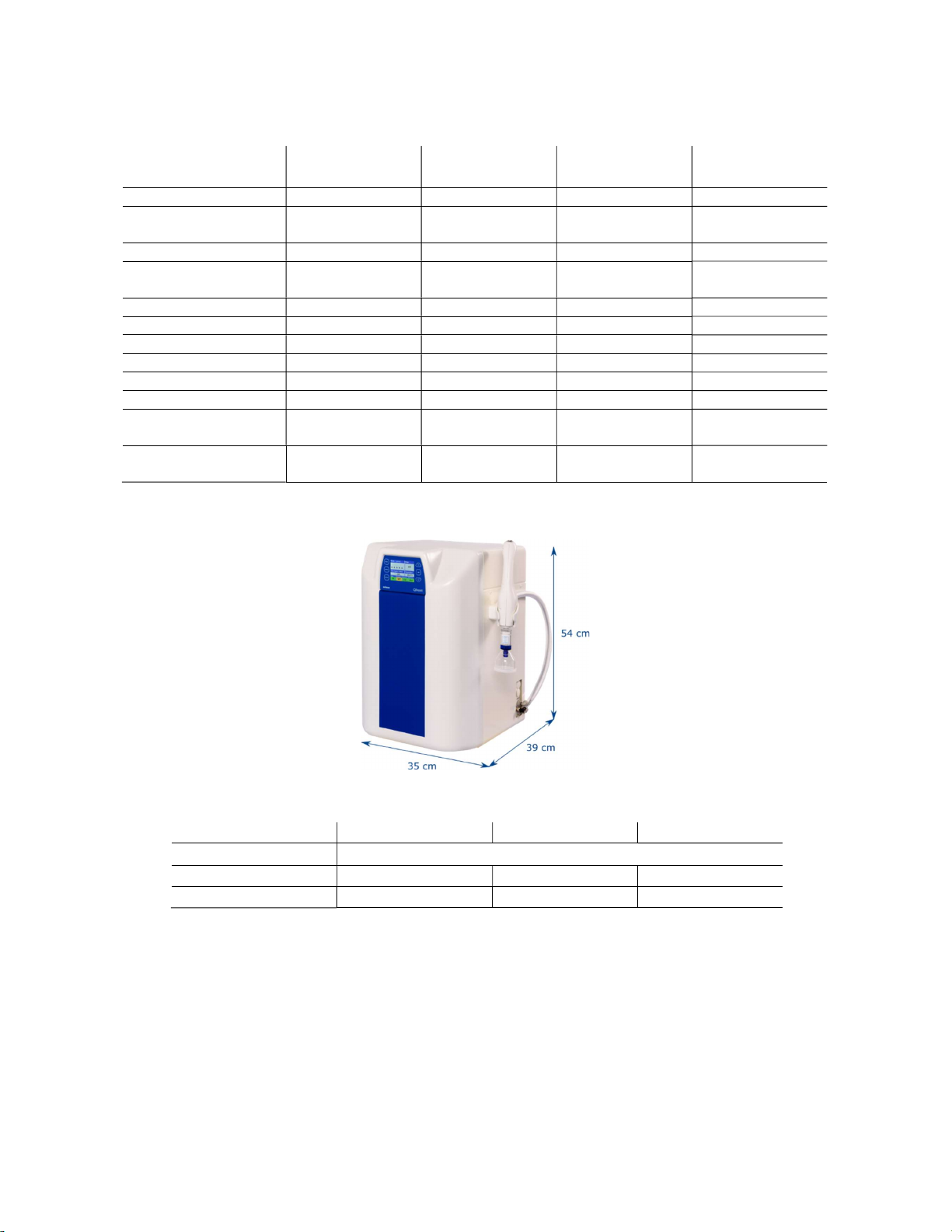

Technical Specifications ....................................................................................................................... 5

System Components in Flow Chart ...................................................................................................... 6

Principle ............................................................................................................................................... 6

PRE-INSTALLATION ................................................................................................................................... 7

Feedwater requirements ..................................................................................................................... 7

Feedwater connection ......................................................................................................................... 7

Site requirements ................................................................................................................................ 8

Environmental requirements ............................................................................................................... 8

Water leakage safety ........................................................................................................................... 8

UNPACKING .............................................................................................................................................. 9

INSTALLATION .......................................................................................................................................... 9

Preparation of the System ................................................................................................................... 9

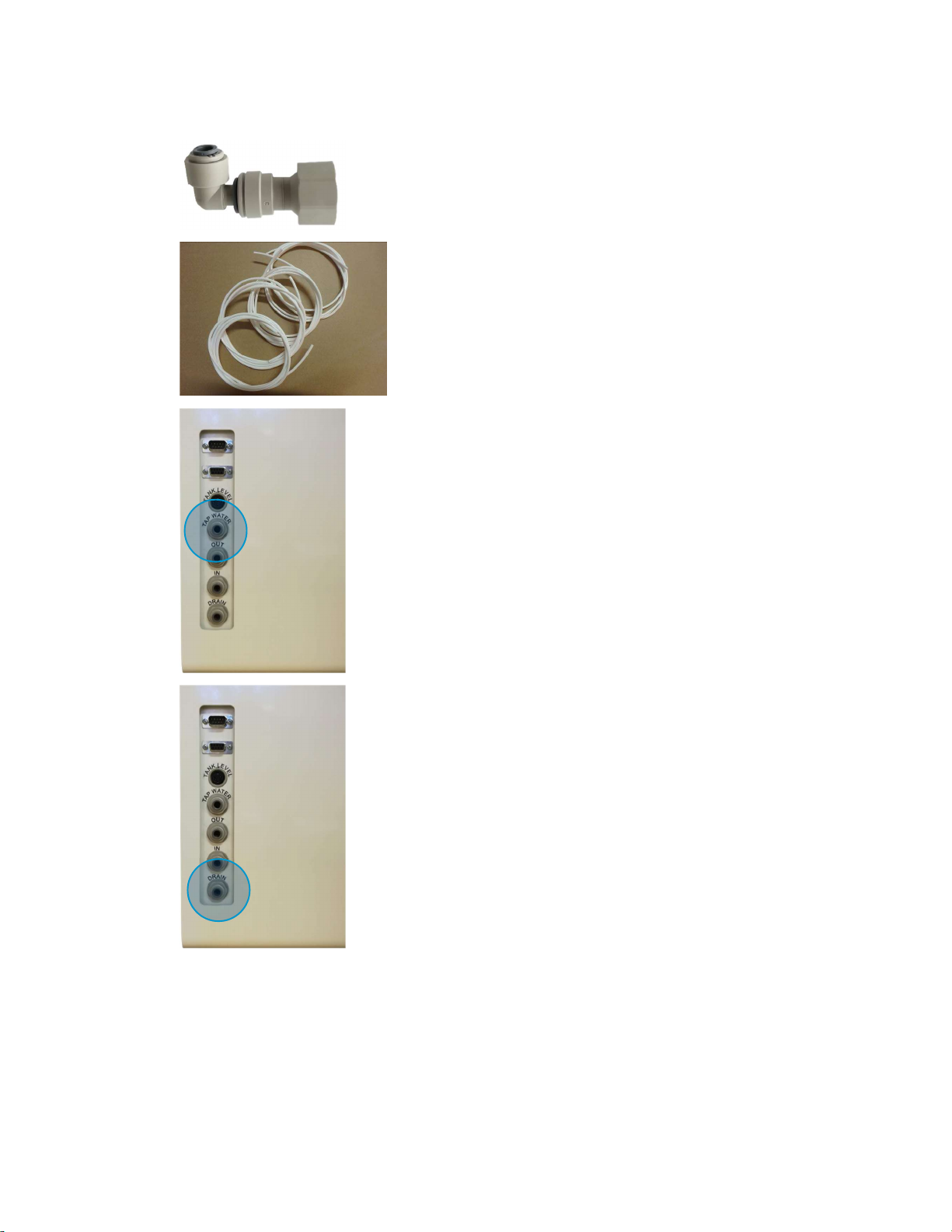

Introduction to John Guest tubing system .......................................................................................... 9

Front and side panel .......................................................................................................................... 10

Pro tank .............................................................................................................................................. 11

Installation procedure ....................................................................................................................... 12

Side mounted dispenser installation ................................................................................................. 14

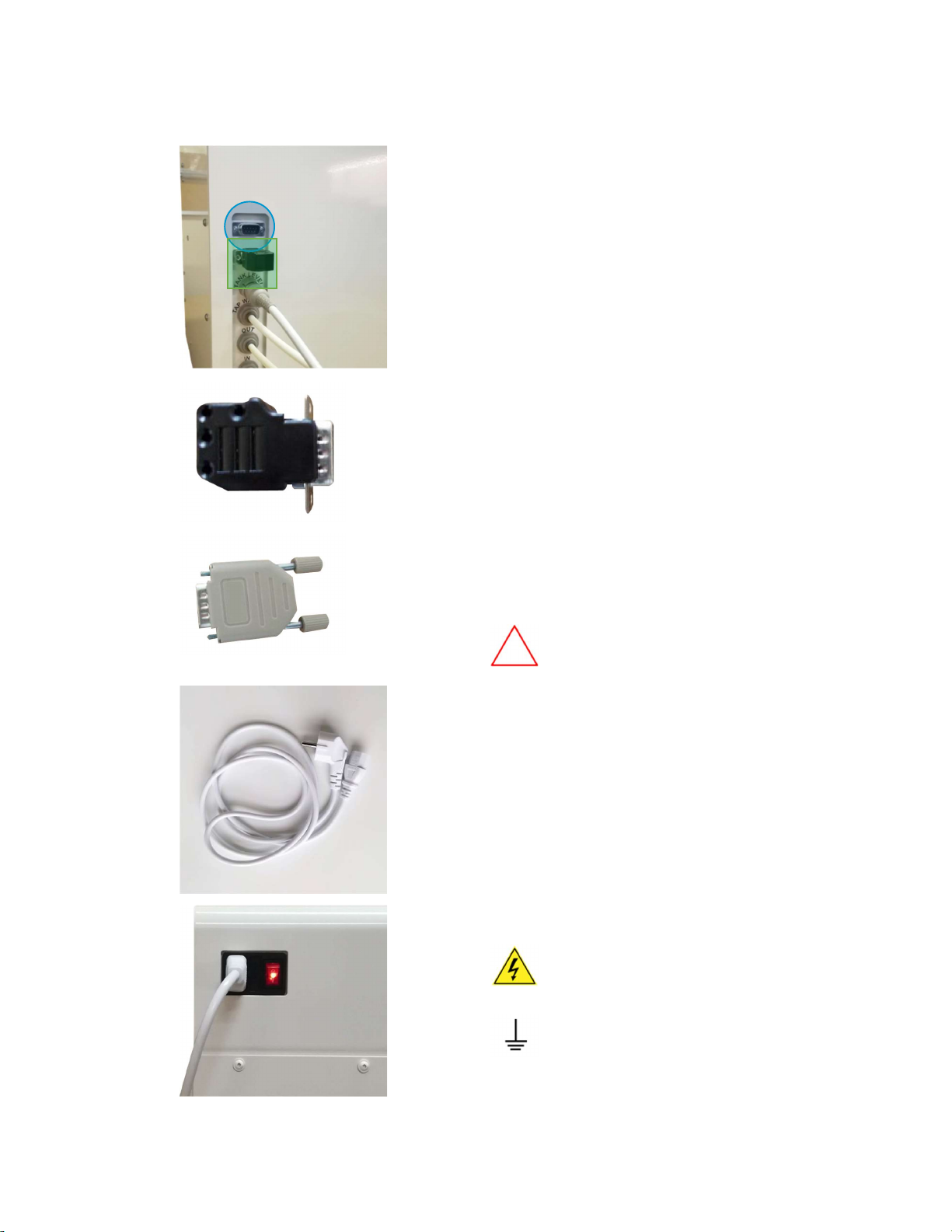

Connection to tank cable ................................................................................................................... 18

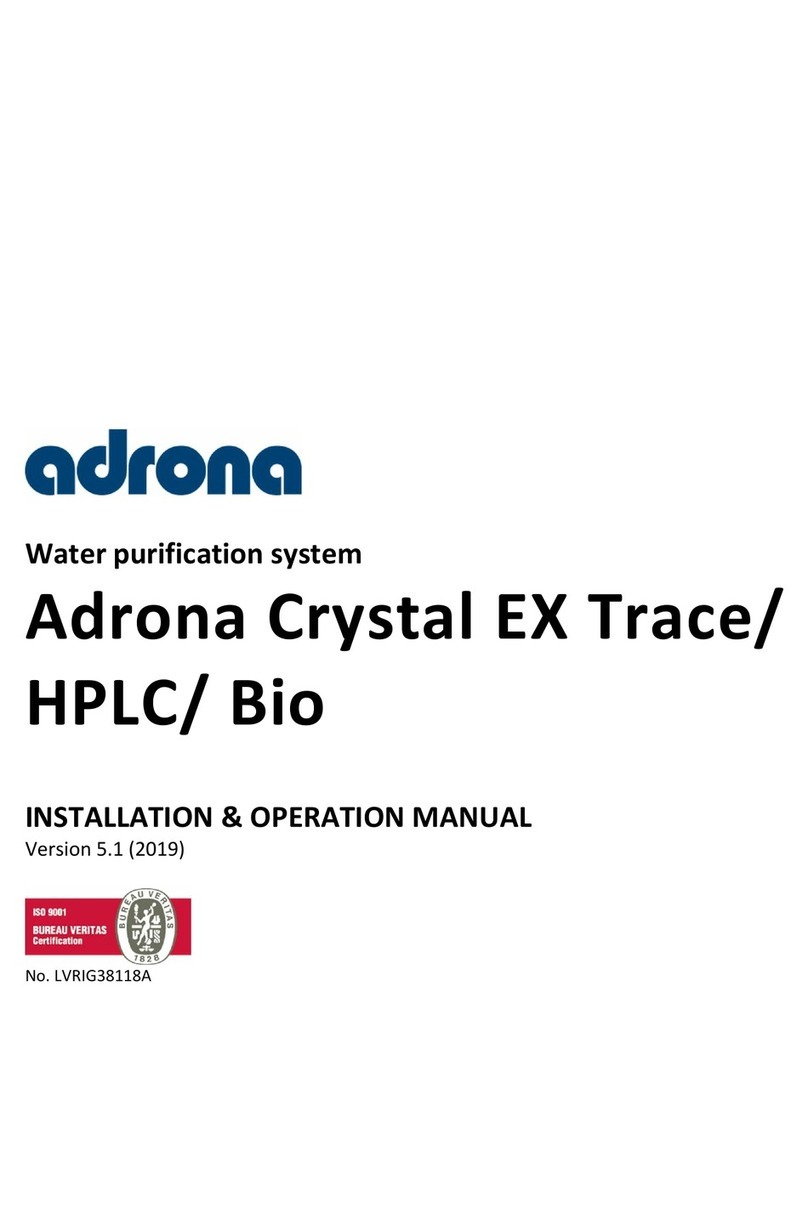

Connection to PC, validation port and power plug ............................................................................ 19

Calibration ......................................................................................................................................... 20

USING THE SYSTEM ................................................................................................................................ 20

Display ............................................................................................................................................... 20

Sensor validation ............................................................................................................................... 21

TOC reduction and monitoring .......................................................................................................... 22

TOC monitoring module (optional) operation principle .................................................................... 22

Diagnostic screen ............................................................................................................................... 22

Connection to PC ............................................................................................................................... 23

Rinsing the system ............................................................................................................................. 23

Introduction to Q-Front N operating modes ..................................................................................... 24

Operating Q-Front N tap water systems ............................................................................................ 32

MAINTENANCE ....................................................................................................................................... 35

Maintenance schedule....................................................................................................................... 35

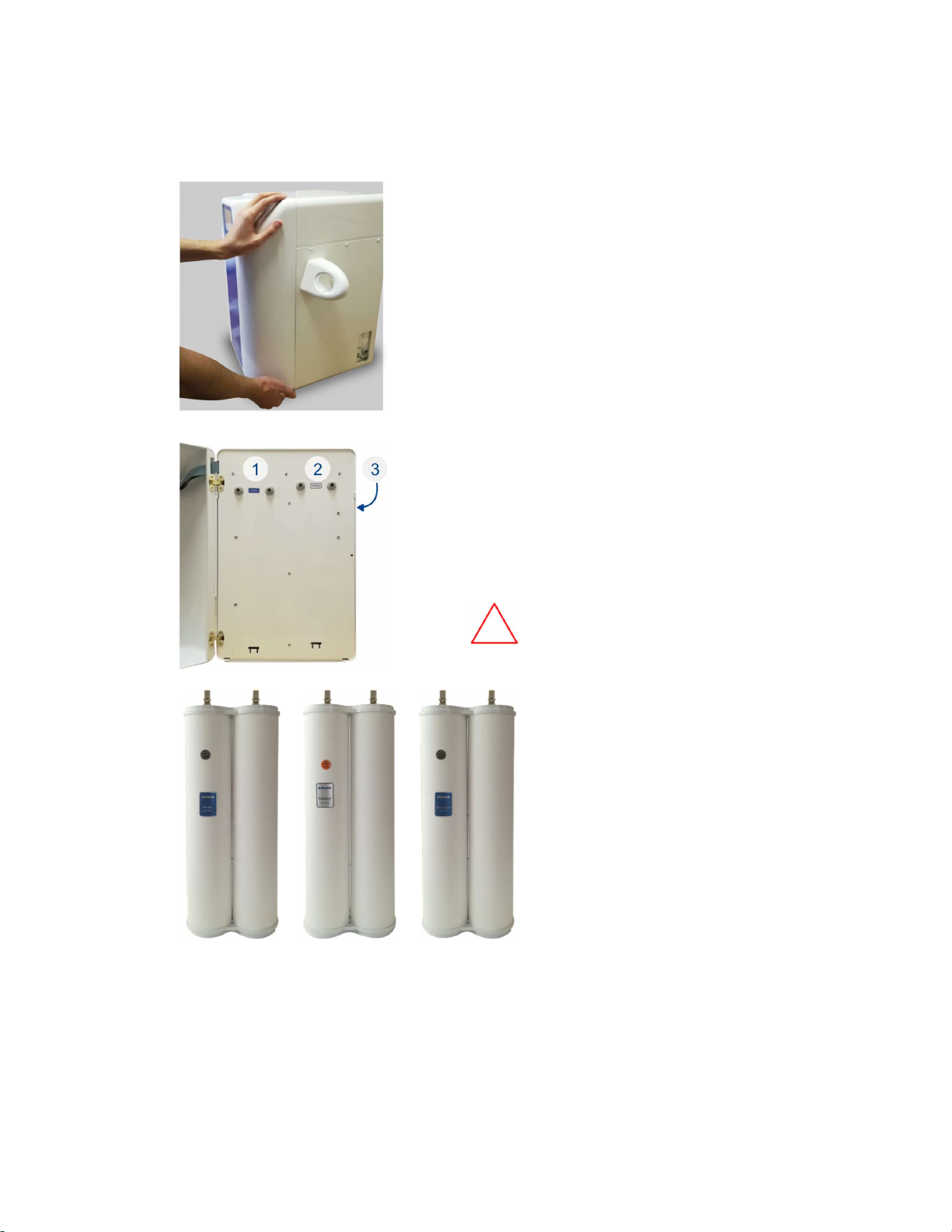

Replacement of pre-filter module ..................................................................................................... 36

Replacement of polishing module ..................................................................................................... 38

Calibration ......................................................................................................................................... 39

Empty the tank .................................................................................................................................. 40

Adrona Recirculation Sanitization...................................................................................................... 40

TROUBLESHOOTING ............................................................................................................................... 41

SPARE PARTS AND CONSUMABLES ........................................................................................................ 42

WARRANTY AND CLAIMS ........................................................................................................................ 42