Adtech Q2BYG403MD User manual

Adtech (Shenzhen) Technology Co., Ltd.

Q

Q2

2B

BY

YG

G4

40

03

3M

MD

D

D

Dr

ri

iv

ve

er

r

U

Us

se

er

r’

’s

s

M

Ma

an

nu

ua

al

l

Add: F/5, Bldg/27-29, Tianxia IC Industrial Park, Yiyuan Rd, Nanshan District, Shenzhen

Tel: 0755-26099116 Fax: 0755-26722718-616 Postal code: 518052

E-mail:export@machine-controller.com

Website: http://www.machine-controller.com

Q2BYG403MD Driver User’s Manual

-1-

Copyright

Adtech (Shenzhen) Technology Co., Ltd. (Adtech hereafter) is in

possession of the copyright of this manual. Without the permission of

Adtech, the imitation, copy, transcription and translation by any

organization or individual are prohibited. This manual doesn’t contain

any assurance, stance or implication in any form. Adtech and the

employees are not responsible for any direct or indirect data disclosure,

profits loss or cause termination caused by this manual or any

information about mentioned products in this manual. In addition, the

products and data in this manual are subject to changes without prior

notice.

All rights reserved.

Adtech (Shenzhen) Technology Co., Ltd.

Q2BYG403MD Driver User’s Manual

-2-

Chapter I. Safety Notice

To avoid personal injury and property damage, please read the following

safety information carefully before testing and using the Driver. Please

strictly follow the safety measures below:

¾Please read the User’s Manual carefully, and follow the safety rules

strictly.

¾If the input voltage of Q2BYG403MD is higher than 36V, please

check whether voltage of the Driver terminal is in safe range with a

multimeter after the power is cut off, and then connect the wire or

check, or else it may cause electric shock.

¾Do not connect the wires or insert/remove the terminal when the

Driver and motor are working, or else it may cause electric shock.

¾Do not open the shell of the Driver after the power supply is

connected or when the Driver is running, or else it may cause

electric shock.

¾To avoid personal injury or property damage, please ask qualified

personnel to operate the Driver.

¾Please follow the technical specification and electrical installation

standard during the installation. The Driver must be grounded

properly, and the cross-sectional area of the grounding cable should

be at least 1.25mm2.

¾Do not put any object in the Driver, or else it may damage the

Driver.

¾If the Driver has any failure, please send it to the maintenance

center. Disassembling the Driver without authorization or improper

operation may damage the Driver. It will violate the warranty if the

user opens the Driver shell without authorization.

¾To dispose of the Driver, please follow local regulations on

industrial waste disposal to avoid environment pollution.

※Statement:

If this Driver is applied to the machinery and equipment

directly related to personal safety (nuclear power control,

medical equipment, truck, train, aircraft, entertainment and

security equipment), it is required to install protection

equipment to avoid personal injury.

Electronic equipment isn’t permanently reliable. The equipment

must have sufficient safety measure, in order to protect the

safety of personnel and equipment in case of Driver failure. The

customer shall assume the losses due to machine failure or

Q2BYG403MD Driver User’s Manual

-3-

misoperation if the Driver is installed or used by the customer.

Chapter II. Product Overview

2.1 Introduction

Q2BYG403MD is a two-phase digital hybrid step motor Driver basing

on AC servo control. It is a new generation digital step motor Driver that

integrates advanced DSP control chip and unique control circuit. This

design can increase the integrity significantly, and reduce the size and

weight. The advanced current control algorithm is used to make it have

excellent performance, low vibration, low noise, less heat radiation and

high speed large torque output. Integrate undervoltage, overvoltage and

overcurrent protection, and the reliability is further improved. In

addition, this product also integrates RS-232 serial port communication.

Through PC installed with Driver software, the user can set the

parameters and test, which simplifies the production and test process.

2.2 Features

¾Allow driving 4, 6, 8 wires two-phase step motor

¾Ultra low vibration noise

¾Internal software uses micro-segmentation technology, which can

obtain high segmentation effect in low speed low segmentation

¾Integrate EMF compensation function, and the torque is constant

when the speed is increased

¾Parameter self-tuning

¾Current setting is convenient, and allow selecting freely between

1.2A and 4.2A

¾High precision segmentation, 1~256 optional

¾Pulse response frequency is up to 200KHz

¾Serial port communication, parameter is real-time adjustable,

meeting high performance requirement

¾In still state, the current decreases by half automatically, and the

maximum driving current is 4.2A/phase

¾Integrate protection for undervoltage, overvoltage, short circuit,

etc.

2.3 Application

The Driver is suitable for a variety of small and medium sized

automation equipment and instruments, such as: dispenser, marking

machine, cutting machine, engraving machine, labeling machine, plotter,

automatic assembly equipment, numerical control machine tool, etc. The

application is especially good in the equipment that users expect low

Q2BYG403MD Driver User’s Manual

-4-

vibration, low noise and high-speed.

Chapter III. Product Parameters and Installation

3.1 Parameters

Table 1: Electrical Parameters Table

Parameter Description

Input voltage Single power supply 24V~40VDC

Overvoltage

protection point

45VDC

Undervoltage

protection point

18VDC

Phase current

(A)

1.2, 1.6, 2.0, 2.4, 2.8, 3.0, 3.6, 4.2

Subdivisions 1, 2, 4, 8, 16, 32, 64, 128, 256, 5, 10, 25, 50, 100,

200

Control mode Pulse + direction

Type of

protection

circuit

Undervoltage, overvoltage and overcurrent

protection

Table 2: Operation Environment and Parameters Table

Cooling mode Natural air cooling

Occasion Avoid oil mist, metal powder

and corrosive gas

Environment humidity 30%~90%

Environment

temperature

0℃~50℃

Operation

environment

Vibration 5.9m/s2 max

Weight 250g

Size 118×5×34mm

Q2BYG403MD Driver User’s Manual

-5-

3.2 Port description

(1) Description of control signal interfaces

Signal Function Description

DR+

DR-

Direction

control signal

High/low voltage level state; requirement:

low voltage level 0~0.5V, high voltage level

4~5V, corresponding to two directions of

the motor The initial running direction of

the motor depends on the wiring of the

motor, and it can be changed by

interchanging any phase.

PU+

PU-

Pulse control

signal

Rising edge is valid; every time the pulse

signal rises from low to high, the motor

runs one step; requirement: low voltage

level 0~0.5V, high voltage level 4~5V, pulse

width ≥1.5us

EN+

EN-

Enable control

signal

Used to enable/release motor; EN+ is

connected to +5V, EN- is grounded, the

Driver will cut off the current of the motor

and enter the free state; at this moment, the

temperature rise and heating of the Driver

and the motor will reduce. If this function

isn’t used, make the signal terminal float.

(2) Motor and power interfaces

Signal Name Description

DC- DC power

grounding

Power supply grounding terminal

DC+ DC power

positive

terminal

Positive terminal of the power supply, single

phase DC power supply might be any value

between 24V and 45VDC, and the

recommended value is 36VDC.

B-

B+

B phase

winding Motor B phase winding coil

A-

A+

A phase

winding Motor A phase winding coil

Q2BYG403MD Driver User’s Manual

-6-

(3) RS-232 communication interface

Allow connecting to PC serial port through dedicated cable, modify and

save parameters, and monitor the running status through dedicated upper

computer commissioning software.

PIN No. Name Symbol Application

1 5V power

supply

positive

terminal

+5V The internal power supply of the

Driver is +5V, and is reserved for

external debugger

2 SCI

transmitter

terminal

TXD Serial data transmitter terminal

3 SCI receiver

terminal

RXD Serial data receiver terminal

4 NC Reserved

5 5V power

supply

grounding

GND Power point

(4) Driver status indicator

The green LED is power indicator. When the power supply of the Driver

is connected, this indicator is constantly on; when the power supply is

cut off, the indicator is off. The red LED is failure indicator. If there is

any failure, this indicator flashes repeatedly in a period of two seconds.

Please see the table below for the details of failure.

Alarm

No.

Flashing

times

LED status Description

1 1 Open circuit

failure

2 2 Undervoltage

3 3 Overvoltage

4 4 Overcurrent and

short circuit

failure

Q2BYG403MD Driver User’s Manual

-7-

3.3 Installation and wiring diagram

3.3.1 Machine installation size (mm)

3.3.2 Connecting control wires

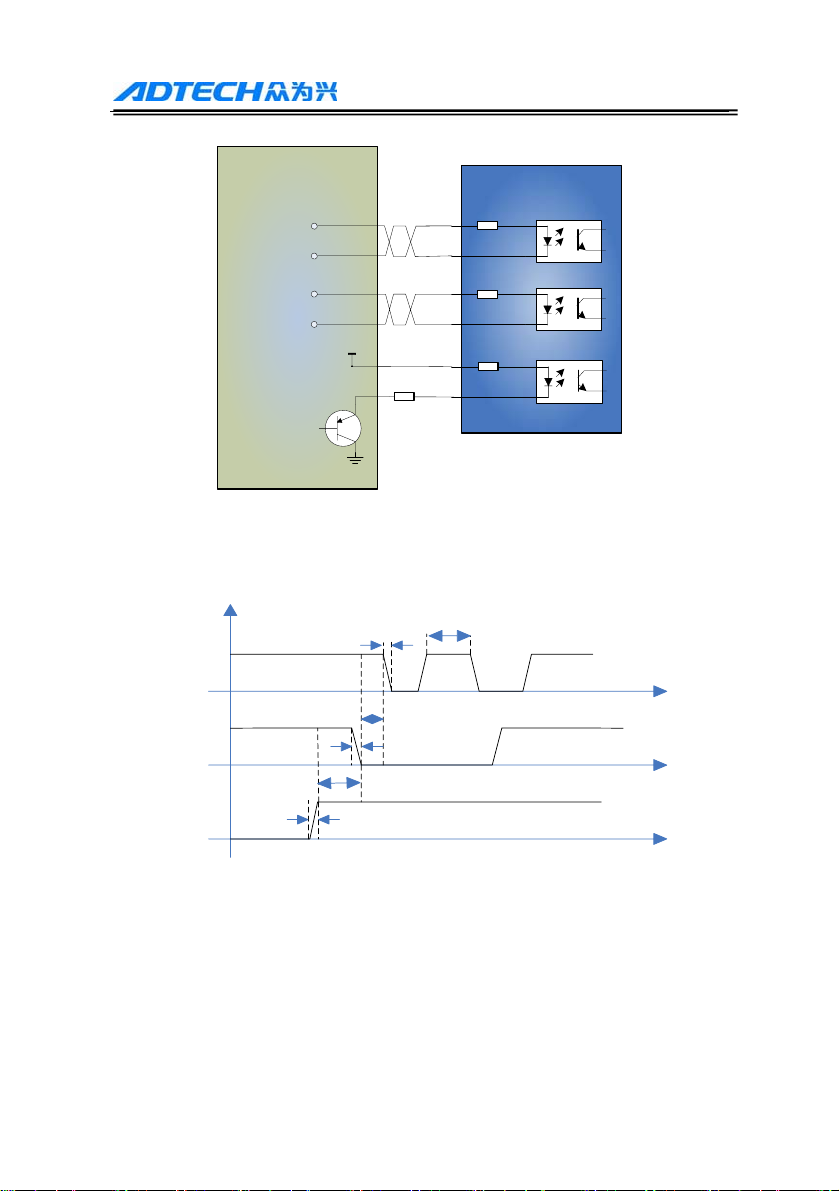

This Driver adopts differential interface circuit, builds in high-speed

optocoupler, the receiving frequency is higher than similar products,

interface is highly compatible, and anti-jamming capacity is strong

(especially differential output mode), and is applicable to NPN

open-collector output, PNP type output and differential mode output.

The connector circuit is shown below:

Q2BYG403MD Driver User’s Manual

-8-

(1) Common anode wiring: when VCC is connected to +5V, R is short

connected; when VCC is connected to +12V, R is 1KΩ; when VCC

is connected to +24V, R is 2KΩ;

(2) Common cathode wiring: when VCC is connected to +5V, R is

short connected; when VCC is connected to +12V, R is 1KΩ; when

VCC is connected to +24V, R is 2KΩ;

(3) Differential wiring: when VCC is connected to +5V, R is short

connected; when VCC is connected to +12V, R is 1KΩ; when VCC is

Q2BYG403MD Driver User’s Manual

-9-

connected to +24V, R is 2KΩ;

VCC

Controller Driver

GND

200欧

200欧

200欧

PU+

PU-

DR+

DR-

EN+

EN-

R

PUL+

PUL-

DIR+

DIR-

3.3.3 Control signal timing diagram

To avoid malfunction and deviation, PU, DR and EN signals should

meet certain timing requirement, as shown below:

3.3.4 Motor connection

If the Driver and motor are connected in different modes, the motor

running will have significantly different effect. Generally, the supply

voltage of the Driver determines the high speed performance of motor

running. The higher the voltage is, the larger the high speed torque is.

Current value determines the output torque of the motor. The higher the

current is, the larger the output torque is. However, if the supply voltage

is high, the vibration during low speed running is also large; if the

Q2BYG403MD Driver User’s Manual

-10-

current value is high, the heating of the Driver and motor will be serious.

Therefore, the user needs to select appropriate connection accordingly to

get desired effect. The following wiring modes are available.

8-wire

motor

A+

A-

B+ B-

4.8-wire serial connection

4-wire

motor

A+

A-

B+ B-

1.4-wire motor connection

6-wire

motor

A+

A-

B+ B-

2.6-wire serial connection

BC

AC 6-wire

motor

A+

A-

B+ B-

3.6-wire center point connection

BC

AC

8-wire

motor

A+

A-

B+ B-

5.8-wire parallel connection

4-wire motor: only one connection is available, and the current should

be no higher than the rated current.

6-wire motor: serial and center tap connection are available. Serial

mode has large torque at low speed, but it can’t rotate fast as connected

to center tap and the current should be set to 70% of the rated current;

center tap mode has high speed performance and the current should be

no higher than the rated current.

8-wire motor: serial and parallel mode are available. Serial mode has

large torque at low speed and small torque at high speed, and the current

should be set to 70% of the rated current; parallel mode has excellent

performance at high speed, and the current should be set to 1.4 times of

the rated current.

: When the motor is connected to the Driver, please make sure that

the power supply has been turned off. Make sure that the motor leads

not used can’t contact other objects. When the Driver is electrified, do

not disconnect the motor directly. Do not connect the motor lead to

ground or power supply.

Q2BYG403MD Driver User’s Manual

-11-

3.3.6 Wiring requirements:

(1) To prevent the Driver from interference, it is recommended to use

shielded cable for signal control, and short connect the shielding layer

and ground wire; unless otherwise specified, ground one end of the

shielding cable that controls signal cable: ground the upper computer

end of the shielded cable, and leave the Driver end of the shielded cable

floating. In the same machine, only one point can be grounded; if the

ground wire isn’t true, it may cause serious interference, and the

shielded layer isn’t connected at this moment.

(2) Pulse and direction signal wires can’t be bundled together, and keep

at least 10cm clearance, or else the motor noise will interfere with the

pulse and direction signal, cause inaccurate motor positioning, instable

system and other faults.

(3) If one power supply is provided to several Drivers, it is required to

connect them in parallel, rather than in chain.

(4) Do not insert or remove the strong current CN1 terminal of the

Driver when the power is still on. The motor still has large current

through the coil even when it is stopped, and inserting/removing CN1

terminal will cause instantaneous induced EMF and burn out the Driver.

(5) It is strictly prohibited to add tin to the lead head and connect to the

terminal, or else the terminal may be damaged due to large contact

resistance and overheating.

(6) The wire connector can’t expose out of the terminal, to avoid

damaging the Driver due to short circuit.

3.5 DIP switch setting

Q2BYG403MD step Driver uses 8-bit DIP switch to set the output

current, subdivision precision, quiescent current and self-tuning of

parameters. The front view of DIP switch is shown below:

Fig. (2) Front View of DIP Switch

Q2BYG403MD Driver User’s Manual

-12-

(1) Current setting (Ipeak= Irms×1.4):

Irms(A) SW1 SW2 SW3

1.2 OFF OFF OFF

1.6 ON OFF OFF

2.0 OFF ON OFF

2.4 ON ON OFF

2.8 OFF OFF ON

3.0 ON OFF ON

3.6 OFF ON ON

4.2 ON ON ON

(2) Subdivision setting:

Subdivisions SW5 SW6 SW7 SW8

1 OFF OFF OFF OFF

2 ON OFF OFF OFF

4 OFF ON OFF OFF

8 ON ON OFF OFF

16 OFF OFF ON OFF

32 ON OFF ON OFF

64 OFF ON ON OFF

128 ON ON ON OFF

256 OFF OFF OFF ON

5 ON OFF OFF ON

10 OFF ON OFF ON

25 ON ON OFF ON

50 OFF OFF ON ON

100 ON OFF ON ON

150 OFF ON ON ON

200 ON ON ON ON

(3) Quiescent half current setting

Set half/full current (SW4=OFF: half current; SW4=ON: full current).

For self tuning setting of parameters, move the SW4 switch once in two

seconds to realize the self tuning of motor parameter and Driver

parameter.

Q2BYG403MD Driver User’s Manual

-13-

Chapter IV. FAQ

4.1 Motor selection

Q2BYG403MD is suitable for 4, 6, 8-wire two phase hybrid step motor.

However, to make the motor have optimized running effect, it is usually

required to select appropriate motor to match the Driver.

(1) It is known from the torque-frequency characteristics of the step

motor that the output torque decreases along with the increase of

motor speed. Generally, at light load, the maximum working speed is

below 15 rev/sec, and at heavy load, the maximum working speed is

about 10 rev/sec. If the system has a higher requirement on speed,

please select servo motor.

(2) If step motor is selected, please select the model of appropriate torque

according to the load.

(3) During working, it is allowed to change the system transmission ratio

through gear box and synchronous belt, and thus adjust the

relationship between output torque and load speed.

(4) Increase the supply voltage of the step motor to improve the working

speed of the motor; increase the working current of the step motor to

improve the torque of the motor; increase the subdivisions of the step

motor to improve the precision of motor, and also improve the

stability of the motor, and reduce vibration and noise.

4.2 Typical wiring

The control signal wiring of the controller and Driver can be one of the

three wiring modes shown in 3.3.2. The power supply and motor wiring

is shown below:

Q2BYG403MD

Driver

DR+

DR-

PU-

PU+

EN+

EN-

DC-

DC+

B-

B+

A-

A+

Cotroller

DC power

supply

24-40VDC

Q2BYG403MD Driver User’s Manual

-14-

4.3 Troubleshooting

Failure Possible reason Solution

Power supply system

has error

Check the power supply circuit

Power indicator is

off Supply voltage is low Increase the supply voltage

Motor wire isn’t

connected properly

Check the wiring

Voltage is too high or

too low

Check the power supply

Alarm indicator is

on

Current is too large Check the power supply

The power supply isn’t

connected

Check and connect the power

supply

Motor wiring error Check the wiring

Protection circuit works Reconnect the power supply

Enable signal is low Disconnect EN signal

Current setting is too

low

Reset the current

Subdivision is too small Reset the subdivisions

Motor doesn’t run

No pulse signal input Adjust the pulse signal

Subdivision has error Reset the subdivisions

Motor load is too high Change the motor or increase the

current

Position is

inaccurate Motor wire bad contact Check and connect the wires

properly

Direction signal isn’t

connected properly

Interchange two wires in the

winding of same phase

Motor rotation is

wrong Motor wire is

disconnected

Check and connect properly

Acceleration is too high Reduce the acceleration

Motor torque is too

small

Select appropriate motor

Motor

acceleration

stalled Maximum speed is too

high

Reduce the maximum speed

☻Prompt

Dear customers:

Thanks for purchasing the step motor Driver of our company. We hope

that the excellent performance, superior quality and high

performance-price ratio of our products can accomplish your value. If

there is any problem, please don’t hesitate to contact us. Please call our

hotline 0755-26099116 or E-mail us: export@machine-controller.com

Table of contents

Other Adtech DC Drive manuals

Popular DC Drive manuals by other brands

KSB

KSB PumpDrive 2 Eco Installation & operating manual

ABB

ABB Baldor BC200 Installation & operating manual

TMB

TMB ProPlex IMS Universe Drive IP65 quick start guide

Siemens

Siemens FLENDER H3LV Assembly and operating instructions

Invertek Drives

Invertek Drives Optidrive ODE-2-11005-1H01 Series user guide

YASKAWA

YASKAWA VS MINI J7 Replacement instructions

Allen-Bradley

Allen-Bradley powerflex 700 quick start guide

phytron

phytron phyMOTIONT I1AM02.1 TRANSLATION OF THE GERMAN ORIGINAL MANUAL

Parker

Parker 890CS product manual

Masterflex

Masterflex L/S MFLX07528-40 operating manual

YASKAWA

YASKAWA E-V-SD Series user manual

Danfoss

Danfoss VLT HVAC Drive FC 102 installation guide