6 / 72

BA 5080 en 06/2014

6. Fitting 32.............................................................

6.1 General information on fitting 32.........................................................

6.2 Unpacking 33.........................................................................

6.3 Fitting the gear unit 33..................................................................

6.3.1 Fitting the gearunit on a housing base 33.................................................

6.3.1.1 Foundation 33.........................................................................

6.3.1.2 Fitting the hydraulic cylinder 34..........................................................

6.3.2 Description of fitting work 35.............................................................

6.3.2.1 Alignment 37..........................................................................

6.3.2.2 Fitting on a foundation frame 38..........................................................

6.4 Shrink disk 39.........................................................................

6.4.1 Fitting the shrink disk 39................................................................

6.4.2 Demounting the shrink disk 42...........................................................

6.4.3 Cleaning and greasing the shrink disk 43..................................................

6.4.4 Refitting the shrink disk 44..............................................................

6.4.5 Inspection of the shrink disk 44..........................................................

6.5 Oillevel monitoring (optional) 44.........................................................

6.6 General notes on addon components 44.................................................

6.7 Fitting the limit switch (optional) 44.......................................................

6.7.1 Tangential alignment of the limit switch relative to the switch plate (optional) 45.................

6.7.2 Axial positioning of the limit switch relative to the switch plate (optional) 45.....................

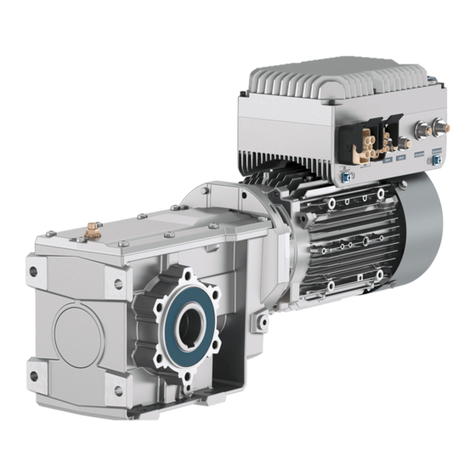

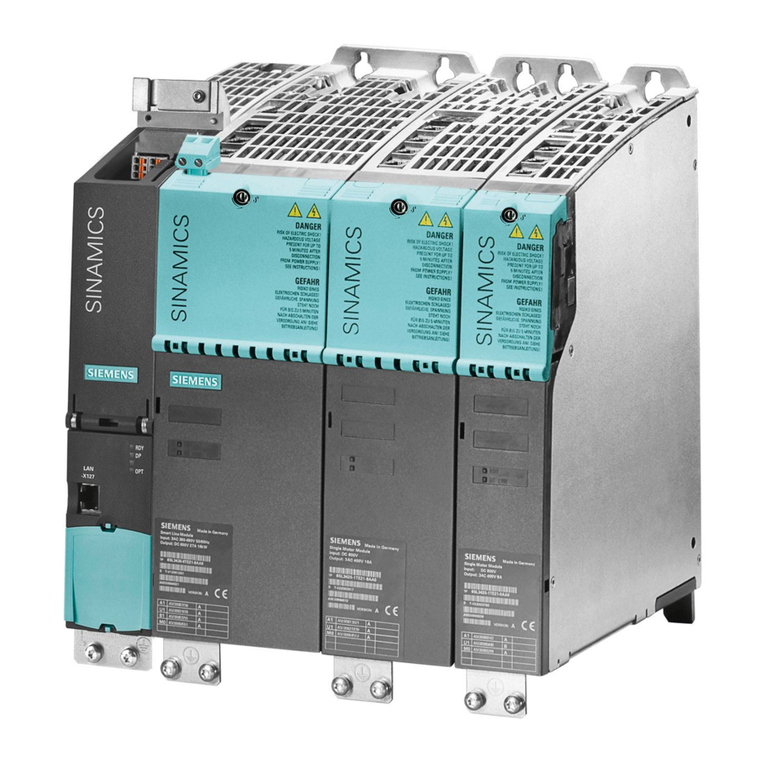

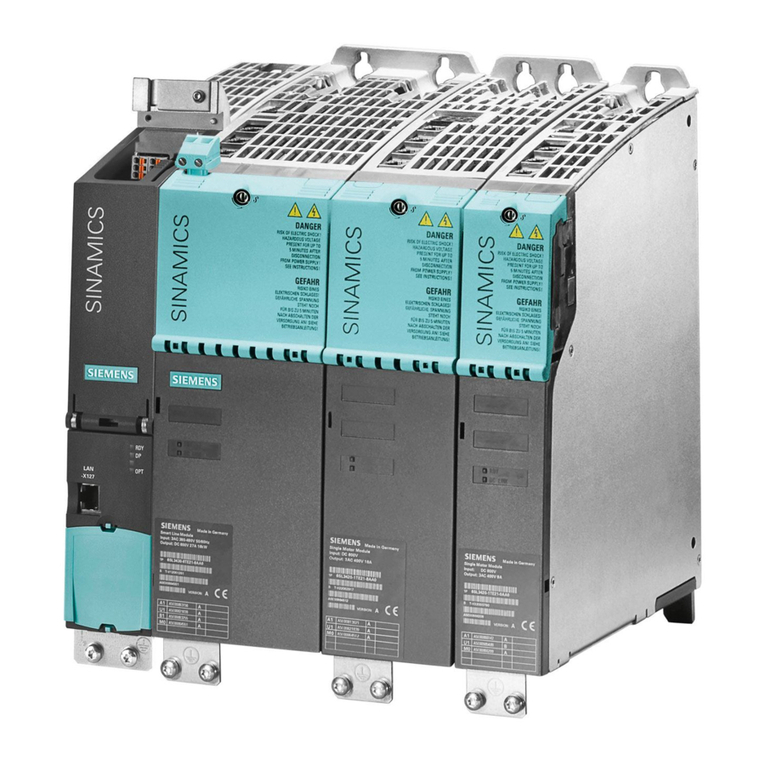

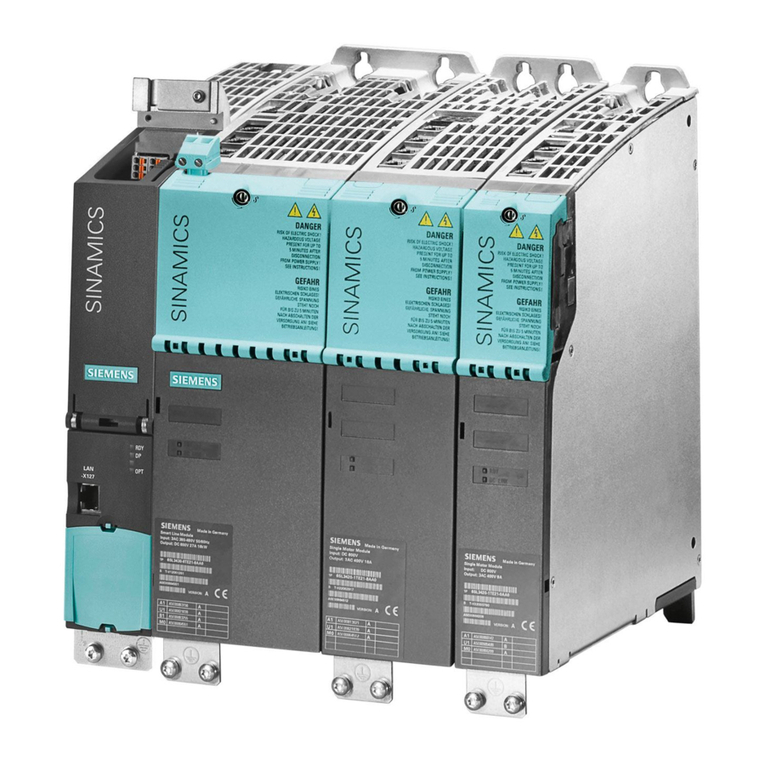

6.8 Fitting the frequency inverter (optional) 45.................................................

6.9 Final work 45..........................................................................

6.10 Screwconnection classes, tightening torques and initialtensioning forces 46..................

6.10.1 Screwconnection classes 46............................................................

6.10.2 Tightening torques and initialtensioning forces 46..........................................

7. Startup 48...........................................................

7.1 Procedure before startup 48............................................................

7.1.1 Removal of preservative agent from exterior 48............................................

7.1.2 Removal of preservative agent from interior 48.............................................

7.1.3 Filling with lubricant 51.................................................................

7.1.3.1 Helicalgear unit (main gear unit) 51......................................................

7.1.3.2 Bevel-gear unit 52.....................................................................

7.2 Setting of the cam-operated switches (in the gearunit cam operated switch) 53.................

7.3 Setting the rotary angle transducer (in the gearunit cam operated switch) 53...................

7.4 Setting of the EMERGENCYOFF limit switches 53.........................................

7.5 Startup 54...........................................................................

7.5.1 Oil level 54............................................................................

7.5.2 Temperature measurement 54...........................................................

7.5.3 Oillevel monitoring (optional) 55.........................................................

7.5.4 Checking procedure 55.................................................................

7.6 Shutting down 55......................................................................

7.6.1 Interior preservation for longer disuse 56..................................................

7.6.1.1 Interior preservation with gearunit oil 56..................................................

7.6.1.2 Interior preservation (main gear unit) with "Castrol Alpha SP 220 S" preservative agent 57........

7.6.2 Exterior preservation 58................................................................

7.6.2.1 Exteriorpreservation procedure 58.......................................................

8. Operation 59.........................................................

8.1 General 59............................................................................

8.2 Oil level 59............................................................................

8.3 Irregularities 59........................................................................

9. Faults, causes and remedy 60.........................................

9.1 General information on faults and malfunctions 60..........................................

9.2 Possible faults 61......................................................................

9.2.1 Leakage and leaktightness 63...........................................................