Adtech ADT-RC400 User manual

User Manual

(Servo Debugging for Pre-motion)

ADTECH Robotic Drive System

ADT-RC400

Information of manual

I

Information of Manual

This manual is edited By ADTECH (SHENZHEN) TECHNOLOGY CO., LTD.

The editors of this manual: Jipeng Yang and Yan Chen.

The version of this manual: V1.1.1

Copy Right

All parts of this manual, property right owned by ADTECH (Shenzhen) Technology

Co.,LTD (hereinafter referred to as) to all, without permission, no unit or individual is not any

imitation, copying, copying or translation. Position this guide without warranty of any kind,

expressed or implied. As mentioned by this manual or its product information, arising out of,

directly or indirectly, information flow, loss of interest or career ending, and its employees

will not take any responsibility. In addition, the products and information mentioned in this

manual are for reference only, subject to updates without notice.

All rights reserved, do not reproducing.

ADTECH (SHENZHEN) TECHNOLOGY CO., LTD.

II

Range of Manual

This is the first manual of QC400 drive robotic control system concluding full

description, drive control for the initial users, to help users select reasonable motor type;

followed this specification for drive control electrical wiring between the machine and the

robot in detail.

III

Precautions

※Transport and storage

Product package iteration of no more than six

It is not available in the product box on the climb, stand or place heavy objects

Cannot use drag the cables attached to the product or handling products

No collision, scratching the Panel and display screen

Product box should avoid wet, dry and the rain

※Opening inspection

After opening the packaging please confirm whether you purchased the product

Check whether the products in transit damage

Control list identifies whether the part is complete, there is no damage

Product model, lack accessory or transport damage, please contact with me

※Wiring

To participate in connections and inspection personnel must have the appropriate

skills for professionals

Products must be reliable earthling, grounding resistance should be less than 4

ohms; you cannot use the neutral (zero line) instead of ground

Wiring must be properly and firmly, so as not to lead to product failure or

unexpected consequences

And surge absorption diode must be connected in accordance with the regulations

are connected with, otherwise you will damage

Plug plugs or open the front of the chassis, you must cut off the power supply

※Maintenance

Must cut off the power before repair or replacement of components

Should check the fault when a short circuit or overload occurs, troubleshooting

before they can restart

Cannot pass off frequently, if required to re-apply after a power failure, separated by

at least 1 minute

※Others

Do not open the Cabinet without permission,

Long when not in use, please cut off the power.

To pay special attention not to let dust, iron powder into the controllers.

Output relay if the use of solid state relays shall be freewheeling diode in parallel in

the relay coil. Check if the power supply meets the requirements, put an end to the

controller is burnt out.

Life of the controller temperature has much to do with the environment, if the

processing temperature is too high, please install the cooling fan. Controller working

IV

ambient temperature range between 0 ℃-60 ℃.

To avoid high temperatures, humidity, dust or corrosive gas environments.

Shake strongly to add buffer rubber Rails.

※Maintenance

Under normal conditions of use (environment conditions: average 30 ℃, load 80%,

running 12 hours a day), please press the following items for routine checks and regular

checks.

Daily Check

Daily

Recognition of environmental temperature,

humidity, dust and foreign bodies

●There are no abnormal vibrations,

sound

●Ventilation holes without being

clogged with yarn and other

Period Check

1 year

●Substantial part is loose or not

●Terminal block damage

Since the robot system is more complex, dangerous. The manual records and

security-related precautions, please strictly observe transactions as recorded.

Safety Precautions and mark

Mark

Mark meaning

Danger

Use wrongly, it will lead to a dangerous situation,

causing serious injury or death

note

Use wrongly,It will lead to a dangerous situation that

may cause personal injury or damage to equipment

which caused material damage.

Ban

Absolutely unenforceable

!

Forcibly

Must be implemented

Danger

Please do not use this system in the flammable and explosive environment.

V

Likely to cause injuries or fire.

Please follow the instructions drawings or wiring.

Prone to electrical shock and damage the

motor.

In an energized state, do not arbitrarily pull the plug, in the operating state; do not touch

the robot operation site.

Easy electric shock, causing personal injury.

Energized state, not for wiring, maintenance and other operations, be sure to power at

least 5 minutes before proceeding.

Easy electric shock.

Please be sure to take a reliable grounding between the drive and the robot body.

When the fault occurs easily lead to electric

shock, fire incident, easy to trigger errors.

Non professional personnel, please do not open the drive and control one machine shell,

please do not use hand to touch the drive and control of internal components

Easy electric shock

In the case of power, do not touch the power plug of the integrated machine.

Easy electric shock.

Please do not damage, the weight of cable or cable suspended load

Easy electric shock

VI

The energized state, do not plug the drive terminal machine control on

Easy electric shock and short circuit

Running state, do not pull out the terminal on the one machine

Easy electric shock and short circuit

VII

Attention

Please pay attention to the drive and control of the motor and the heat of the peripheral

equipment.

Easy to burn.

When a fault occurs, the power supply is cut off, the cause is identified and removed, and

the low speed running equipment should be removed.

If there are adverse factors, easy to cause

false action.

When using the controller and the robot body, it cannot exceed the scope of its

specification.

Easily cause damage to the product.

When the robot is moved, it needs to be fixed with the attached fixed tool.

To prevent the lifting arm, due to accidents.

The installation, operation, maintenance and inspection before, be sure to read the

instructions carefully, according to the operating instructions in step.

Easy electric shock, fire

Power supply voltage, power capacity must be specified by the company's specifications.

Improper use of equipment failure, easy to

cause a fire.

Please correct use of the correct control of each other to drive one machine and robot.

Prone to failure

VIII

Should be regularly on the implementation of the robotics drive system maintenance and

inspection operations.

Neglect of maintenance and inspection is an

important cause of equipment failure and

accidents.

Please do not put heavy objects on the product.

Easily cause damage

Please correct the wiring in the instruction manual.

The wrong wiring way is easy to cause the

robot or the drive control one machine

damage or cause a fire.

When an exception occurs, please stop.

Easy electric shock, personal injury, fire

Need to repair, please contact our company, please do not disassemble.

Easy cause trouble.

Do not impact

Easy cause trouble

IX

Ban

In the course of the robot's movement, no person is allowed to stand in the robot action

area.

There will be a major injury accident.

Equipment to prevent the movement of the robot in the workplace.

When the device is abnormal, it is easy to

cause damage.

The emergency stop switch on the handheld display device is prohibited.

Robots in an accident or is not running

properly, you need an emergency stop

switch, stop operation of the equipment.

There is no correct operation of the prohibition on the instruction manual.

Incorrect operation will bring about the

incorrect operation of the equipment.

Other personnel outside the operating personnel to close to the equipment

Touching the dangerous area can cause the

injury or the major accident.

When an accident, to cut off the power supply, clear reasons.

When there are bad reasons, the robot may

have a wrong action, causing adverse

consequences.

Users are prohibited to carry out parts of the exchange and transformation.

Will reduce the system performance and

may malfunction

X

Please do not remove the cleaning.

Easy to cause fire, easy to get electric shock.

Please don't make the product stored in the leaks, water, and other harmful gases in the

environment.

Prone to failure

Forced

!

Please keep the sun out of the sun.

!

Easy cause trouble

Please use the specified range.

!

Easily cause burn, failure

Equipment protection cover must be shut off during operation.

!

Open the protective cover will have electric

shock, the disabled.

Operator to go through the full training.

!

Incorrect operation will cause the device to

malfunction, resulting in disability or major

disaster.

If the robot is not in accordance with the specified direction of action, press the emergency

stop, stop the equipment operation.

!

Accidents and failures.

Power cord must be used with the specified wire.

!

Prone to fire and failure.

Notification

XI

Safety regulations

●Before starting the run, we need to know all the tasks of robot in accordance with the

program to be executed;

●Robots run in automatic mode, personnel are not allowed to enter any of its

movement reach areas;

●When the need for programming, testing and maintenance work, the robot shall be

placed under manual mode;

●When debugging personnel enter the robot work area, he shall carry a teach pendant,

to prevent others from malfunction;

●When the robot does not work for a long time, the fixture should not place items; it

shall be empty machine;

●After a power outage, the main power on the robot should shut down timely, and

remove the clamp on the work piece.

Contents

XII

Contents

INFORMATION OF MANUAL...........................................................................................................................I

1SOFTWARE INSTALLATION.................................................................................................................1

1.1 INSPECTION BEFORE DEBUGGING .........................................................................................................1

1.2 QUICK START........................................................................................................................................1

1.3 INTRODUCTION OF THE PC SUITE..........................................................................................................3

2 COMMUNICATION CONNECTION ....................................................................................................8

3 PARAMETER MANAGEMENT...........................................................................................................11

3.1 UPLOAD PARAMETERS ........................................................................................................................11

3.2 DOWNLOAD PARAMETERS ..................................................................................................................12

4 CONFIGURATION OF BASIC PARAMETER...................................................................................16

4.1 CONFIGURATION OF MOTION MODE ...................................................................................................16

4.2 CONFIGURATION OF MOTOR’S PARAMETERS.......................................................................................17

4.3 CONFIGURATION OF PROTECTION PARAMETERS .................................................................................20

5 GAIN TUNING........................................................................................................................................24

5.1 TEST OF ENCODER BEFORE TUNING....................................................................................................24

5.2 COMMUTATION TUNING......................................................................................................................25

5.3 GAIN TUNING......................................................................................................................................28

5.3.1 Tuning of Current Loop..............................................................................................................29

5.3.2 Tuning of Velocity Loop..............................................................................................................38

5.3.3 Tuning of Position Loop.............................................................................................................45

6 PRE-MOTION.........................................................................................................................................50

7 ERROR ALARM OF SERVO AND HANDLING................................................................................53

Debugging Process

XIII

You must tune some servo parameters for pre-motion before using QC400 robotic drive

system. If servo parameters have tuned before, you can download these parameters to drive

system directly, and then have a pre-motion. If not, you have to tune servo parameters with

following steps strictly.

Downloading

Parameters

Communication

Software Installation

Run

Commutation

Curr\Vel\Pos

Tuning

Parameters

Setting

Communication

Software Installation

Run

With Servo Parameters

Without Servo Parameters

【Notice】

In the following figures, marks such as

4321

represent execution order.

Servo Debugging for Pre-motion

1

1.Software Installation

1.1 Inspection before Debugging

For security and efficiency, some aspects should be checked before debugging.

(1) State of servo motor

Check fixed parts of motor to make sure that all the wires are connected well.

Check the encoder wire and power wire of motor whether they are connected

correctly.

(2) State of robotic drive system

Check the internal power of QC400 to make sure that it has the normal power

supply.

Make sure that the encoder and power wire are connected well with QC400.

1.2 Quick Start

This part is a quick tour of the PC suite to explain some of the basic concept and get

used to navigating the software. This part can be done without a controller or a running

system.

Operating System

Windows 7 32 位

Windows 7 64 位;

Windows XP

Screen Resolution

The PC Suite requires display with a resolution of at least

1280 768

. Even with

1280 768

resolution, you will need to “Auto-hide”the windows task bar to conveniently

access the main menu. Resolutions of

1280 900

or higher are recommended.

Installation

The steps of Installation are shown in the following diagram.

Servo Debugging for Pre-motion

2

Tes t whet her th e

drive is installed

s uc ce s sf u ll y b y

【Help *1】

Close the Antivirus Software

of the Computer

Unzip Debugging

Package

Install Microsoft .NET

Framework4.0

Install Drive

Program(Serial

Drive、USB Drive)

Double Click

”AgitoPCSuite.exe”

【Help*1】

Normally, we can test whether the drive is installed successfully by checking the

existence of terminal. You need to re-install the serial and USB drives if the terminal can not

be detected. The specific approaches of examining are listed based on your operating system:

(1) Window XP system: Right click “My Computer”icon

Left select “Device

Administration”

Left select “Terminal”(To check COM port);

(2) Window 7 System: Right click “Computer”icon

Left select “Device

Administration”

Left select “Terminal”(To check COM port).

Depending on your PC’s security settings, you may receive a request for permission (for

first time execution of the installed software). Please allow PC Suite access to the requested

resources.

Two applications will open:

QX Communicator

Servo Debugging for Pre-motion

3

QX PC Suite

Leave both of them open. The OX PC Suite firstly opens with a warning message.

Please read it carefully and click OK.

Notice

The software interface may appear incomplete phenomenon if screen resolution is too

low. Do not close the communication interface when using debugging software.

1.3 Introduction of the PC Suite

The QX PC Suite window of QC400 Robotic Drive system as follows:

Servo Debugging for Pre-motion

4

Main Menu Information

Current Tool

Favorite

Tool

Recent Tool

Operating Button Language

The window is made of a frame and the contents. The frame always has the same parts

and the contents changes according to the tool selected by the user. Then several specific

parts will be introduced.

The operating button performs the following functions:

Save all parameters to the controller Flash memory.

Load all parameters from the controller Flash memory.

Kill all the axes and servo off.

Select axis drop down menu.

Main menu

In the main menu you can see all available tool sets, and each is represented by an icon

at a given color. The tool sets are arranged from left to right by the most probable order

which they should be used when setting up a new system. Clicking the below an icon of a

tool set at the main menu, the sub-menu will display. The detail function of each tool will be

introduced in the later chapter.

Servo Debugging for Pre-motion

5

Left menu bar

The left menu bar is used to personalize the display to the convenience of the user and to

enable easy and fast access to frequency used tools. The lasted tools and favorite tools are

displayed in the left menu bar. The latest tools are automatically displayed in the “recent”

menu and the favorite tools are displayed by right clicking button on any tool to pin them.

At the same time, the icon of current tool is also appeared on the upper left corner of the

PC Suite frame. Right click on this icon to invoke a context sensitive menu, which includes

“Pin to Favorite”, “More Info”, “View: Terminal Only”, “View: Terminal with Status and

“View: Terminal with Statuses and Data Recording”. Different views may be required

depends on the user and the specific task.

Current tool

Servo Debugging for Pre-motion

6

Pin to Favorite: Set the current tools to the favorite ones.

More Info: It contains more information;

View: Terminal Only —— Only terminal is displayed;

View: Terminal with Statuses —— Only statuses are displayed on the terminal;

View: Terminal with Statuses and Data Recording —— Upper-left of the frame

displays statuses, below-left displays terminal and right displays data recording.

Favorite tools

Right-click them, four operations can be performed as follows:

Recent tools

They have the similar operations as the favorite tools’.

Info

You can click “Info”(at the button-right corner of the PC Suite frame) to receive

information about QX PC Suit. The information of PC Suite, communication channel and

connected controller will be displayed in this frame.

Other manuals for ADT-RC400

1

Table of contents

Popular Robotics manuals by other brands

OTTO MOTORS

OTTO MOTORS 1500 Fast Charger V1.2 Operation and maintenance manual

bionicbird

bionicbird Metabird instruction manual

Prince

Prince Play The Best T8561 owner's manual

Universal Robots

Universal Robots OEM UR5 installation guide

OSOYOO

OSOYOO Omni-wheel manual

SMC Networks

SMC Networks JMHZ2-16D-X7400B-TM Operation manual

Omron

Omron Cobra 350 ePLC Quick setup guide

Universal Robots

Universal Robots 3PE Teach Pendant installation guide

TEACH TECH

TEACH TECH TTR-892 Assembly & instruction manual

Sony

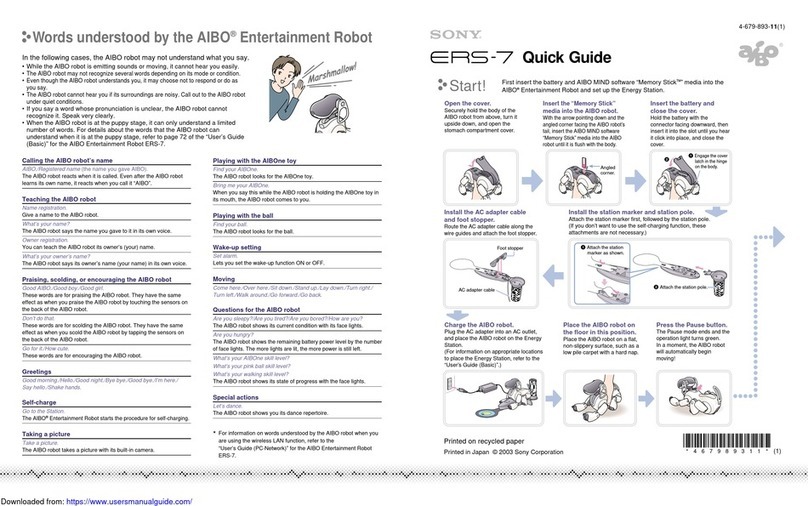

Sony Aibo ERS-7 quick guide

WEISS ROBOTICS

WEISS ROBOTICS IEG Series Mounting and operating manual

adept technology

adept technology Viper s650 user guide