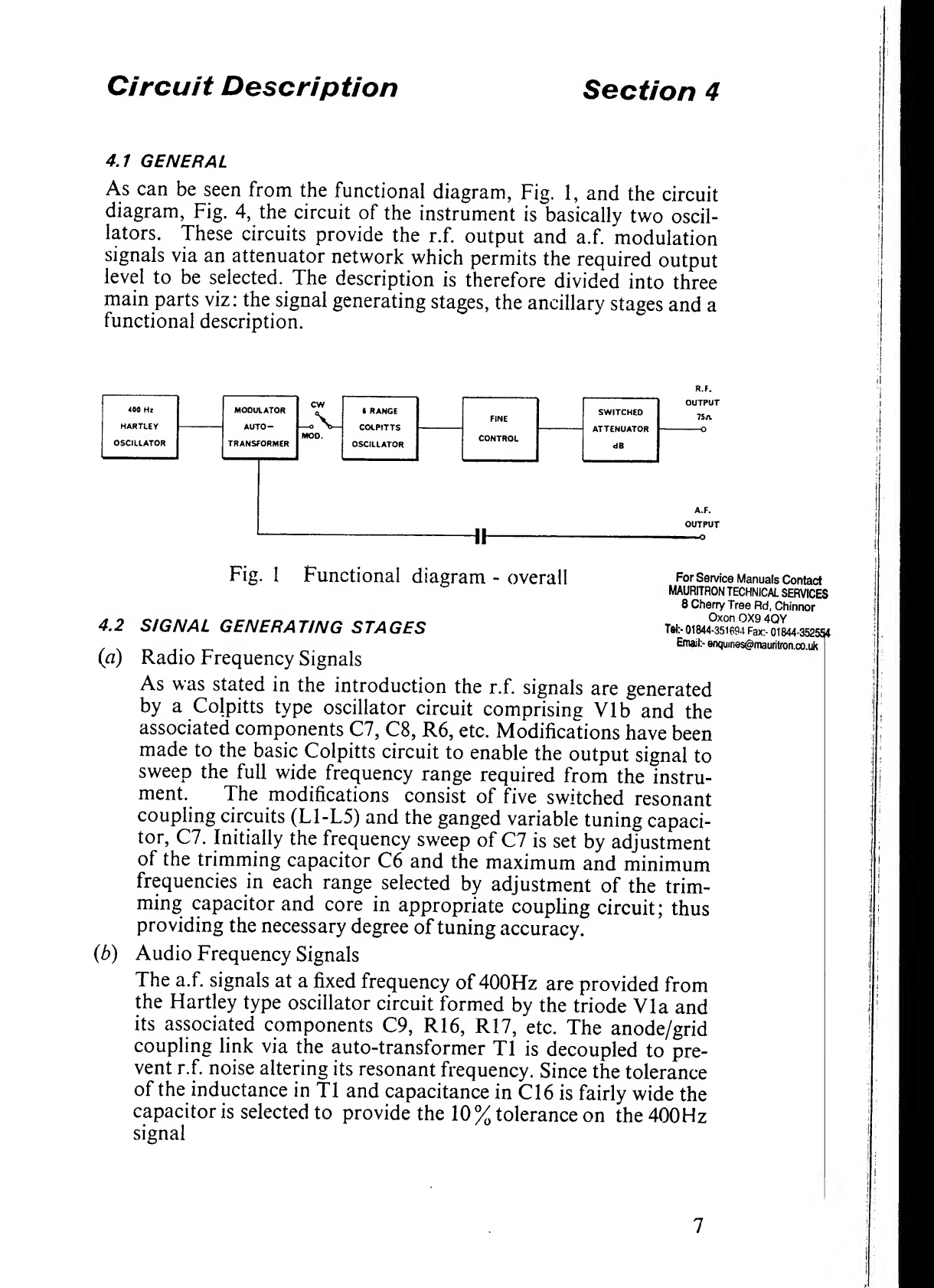

Circuit Description Section 4

4.3 ANCILLARY STAGES

(a) Power Supply Circuit

The incoming a.c. supply is fed to the power transformer, T2 via

apair of r.f. suppression filters (L14/C24 and L15/C25) and the

on/off section of the function switch, S2. Three outputs are

derived from the power transformer which are utilised as

tollows:

—

IfD r-m.s. output is half-wave rectified via the diode,

MRl, and fed through asmoothing circuit (C23A/B and

R20) to produce anegative earthed 140V d.c. supply with

low ripple content.

(2) The 6V r.m.s. supply is used as the heater voltage for the

double-triode valve, VI. This supply is heavily decoupled to

r.t. via L9, L13, and CI2, to prevent extraneous signals

from being fed back to the power transformer.

(3) The third supply is derived by auto-transformer action

from the 105/125V primary winding of T2 to provide the

energisation voltage for the neon supply indicator when

S2 IS set to any position other than off.

(b) Attenuation Stages

The attenuation stages are provided in the outout circuit of the

insyument to enable the operator to control the r.f. output level

and, if necessary reset the output level accurately. The at-

tenuation controls consist of acoarse, step-attenuator, output

voLTAGE/dB, and acontinuously variable fine attenuator

OUTPUT VOLTAGE. Switch S3 and its associated resistors R8 to

KI5 form the coarse attenuator circuit whilst the fine attenuator

is formed by the variable resistor RVl.

4.4 FUNCTIONAL DESCRIPTION

{a) C.W. Mode

This ^ode of operation is selected by setting the function

switch, S.2, to the c.w. position. In this condition the MOV ht

supply is fed directly to the anode circuit of the r.f. oscillator”

Vib, which functions in the manner indicated in sub-section 4.2’

Although the h.t. supply is also applied to the anode circuit of

Via this stage will not oscillate since only part of the auto,

transformer T1 is in circuit; thus, the output at the r.f. socket

will be unmodulated r.f and no output will be available at the

A.F. socket.

8