Advance Welding AW315 User manual

AW315 - Operator Manual

Operating Controls

AW315

© 2019. Advance Welding 1

Operating Controls ........................................................................................................................

Safety Notes .....................................................................................................................................

Product Specication ...................................................................................................................

Intended Use ....................................................................................................................................

Introduction ......................................................................................................................................

Delivered Items ................................................................................................................................

Electrical Safety ................................................................................................................................

Using the Equipment .....................................................................................................................

Data Log Memory ............................................................................................................................

Manual Welding .............................................................................................................................

Fusamatic Welding .......................................................................................................................

Bar Code Welding .........................................................................................................................

Fusion Operator Badge ..............................................................................................................

GPS Location .................................................................................................................................

Extreme Low Temperature Operation .................................................................................

Downloading the Weld Memory .............................................................................................

Upgrading the Operating Software .......................................................................................

Set Up Options ..............................................................................................................................

Information .....................................................................................................................................

Fault Finding ...................................................................................................................................

Maintenance ..................................................................................................................................

Disposal ............................................................................................................................................

Calibration and Warranty ...........................................................................................................

Declaration of Conformity ........................................................................................................

Service and Repair.........................................................................................................................

Quick Start Guide ..........................................................................................................................

AW315

Operating manual

AW315 - Operator Manual

AW315

© 2019. Advance Welding 2

Operating Controls .................................................................................................................................

Safety Notes ..............................................................................................................................................

Product Specication ...........................................................................................................................

Intended Use ............................................................................................................................................

Introduction .............................................................................................................................................

Delivered Items ......................................................................................................................................

Electrical Safety .....................................................................................................................................

Using the Equipment . ..........................................................................................................................

Fault Finding ............................................................................................................................................

Maintenance ............................................................................................................................................

Disposal ...................................................................................................................................................

Calibration and Warranty ...................................................................................................................

Declaration of Conformity .................................................................................................................

Service and Repair ...............................................................................................................................

Index

3

4

5

6

6

6

7

8

9

11

11

12

14

15

AW315 - Operator Manual

AW315

© 2019. Advance Welding 3

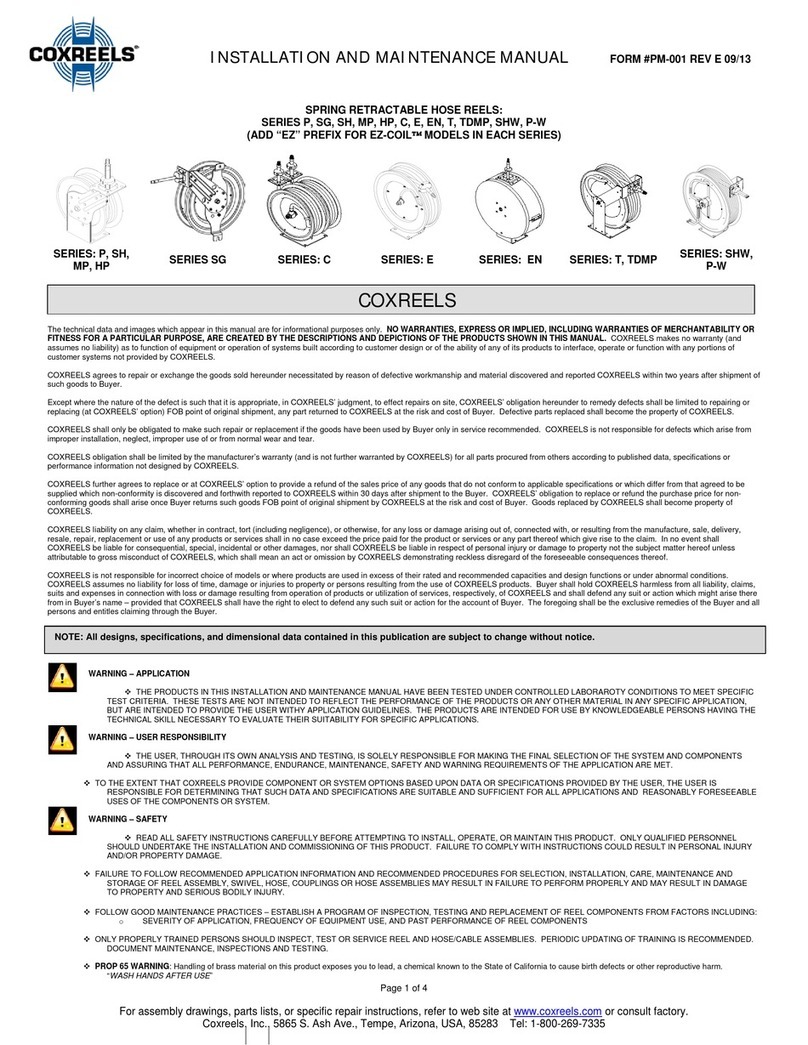

1. Lid Catch

2. On/O Switch

3. Supply Fuse

4. Supply Lead (tted with plug)

5. Carrying Handle

6. Output Leads

7. Start/Stop Button

8. Indicator Display

Operating Controls

5. Carrying Handle

4. Supply Lead

(tted with plug)

3. Supply Fuse

2. On/O Switch

7. Start/Stop Button

8. Indicator Display

1. Lid Catch

6. Output Leads

AW315 - Operator Manual

AW315

© 2019. Advance Welding 4

• RISK OF EXPLOSION! This welding unit must not be used in a gaseous

atmosphere.

• RISK OF ELECTRIC SHOCK! Do not open. No user serviceable parts

inside.

• Before using, always visually inspect the unit to see that the cables and

connectors are not worn or damaged. Replace the damaged part before

welding.

• Switch o and remove the plug from the mains before adjusting, cleaning, or

if the cables are entangled and before leaving the equipment unattended for

any period.

• To avoid damaging the unit, do not interrupt the supply voltage or disconnect

the welding cable, while the unit is welding a tting.

• Do not lift or pull the equipment by its cables.

• Do not disconnect the welding cables by pulling on them, always pull o the

connectors from the tting.

• Do not start a weld without the pipe correctly inserted into the tting.

• Do not touch the tting while welding.

• Do not weld in the rain or leave the equipment outdoors whilst it is raining.

• Weld only in daylight or in good articial light.

• The operator is responsible for accidents or hazards occurring to other people

or their property while using this equipment. Keep the work area safe!

• Keep bystanders a safe distance away from the machine while welding.

• Never allow people unfamiliar with these instructions to use the welding unit.

Safety Notes

AW315 - Operator Manual

AW315

© 2019. Advance Welding 5

Product Specication

Advance Welding has a policy of continuously improving product design, and as such reserve the

right to change specication of its products without prior notice and with impunity.

Input Power Connections

for this model:

• 110V version

Input plug for your region or

country are available

Contact us for more information

Specication details - AW315

Operating Modes Automatic

Welding Voltage 30V to 220V

Welding Current 5A-13A

Welding Time 80-420 seconds

Supply Voltage 115V ± 15% 110V

(40-60Hz)

Supply Current 1-32A (115V)

Supply Power 3500 W

Weight 15 kg

Size 41 x 34 x 20cm

Operating Temp. -15ºC to +50ºC

AW315 - Operator Manual

AW315

© 2019. Advance Welding 6

This equipment is intended to weld Drainage Fittings

5 Amp Low Pressure Fittings from 32mm to 160mm

10 Amp Low Pressure Fittings from 200mm to 315mm

230 Volt Low Pressure Fittings from 200mm to 315mm

This manual gives instructions on the correct assembly and safe use of your welding unit. It

is important that you read these instructions carefully, and keep these instructions for the

life of the unit.

This manual does not detail the specic welding procedure for the ttings: scraping,

clamping and assembly of joints. For this information you must contact the manufacturer of

the ttings.

Carefully remove the welding unit from its packaging and check that you have the following

items:

• Welding unit.

• Yellow Output lead.

• Red Output lead

• (Optional) Blue Output lead.

• (Optional) Brown Output lead.

• Manual.

When parts are missing or damaged, please contact your dealer.

Intended Use

Introduction

Delivered Items

AW315 - Operator Manual

AW315

© 2019. Advance Welding 7

Electrical Safety

WARNING! Switch o and remove the plug from the mains before adjusting,

cleaning or if the cable is cut, damaged or entangled.

This welding unit is Class 1 and requires an earthed connection. (An earth spike must

be used with generators.) The operating voltage is 110 volts ac 50 Hz, and a power

source capable of 3500 Watts is required.

Extension cables should only be used if they comply with the H07RNF harmonized

standard. They must be tted with connectors to the BS EN 60309-2 standard. All

cables must be unwound from the reel to stop inductive heating eects. The cable

dimensions should be as follows:

• 1.5mm2 cable = 25m

• 2.5mm2 cable = 50m

• 4.0mm2 cable = 75m

It is recommended for increased electrical safety to use a Residual Current Device

(RCD) with a tripping current of not more than 30 mA. Always check your RCD every

time you use it.

The supply cable must be inspected for signs of damage before each use and the

equipment may only be used if in perfect condition. Damaged cables must be

replaced by an approved service agent.

This equipment is classied as “Portable for use on industrial applications”, and must

undergo a formal electrical safety check (Portable Appliance Test) every six months.

AW315 - Operator Manual

AW315

© 2019. Advance Welding 8

This welding unit takes the ambient temperature into account when calculating the

energy required to weld the tting. It must therefore be allowed to reach ambient

temperature before use and must be at the same temperature as the tting to be

welded.

• Switch the welder on and it will self test.

• The green power light will be on. Make sure no errors are showing.

• Connect the required colour welding cable to the socket, the indicator light will

show.

• YELLOW: 32mm – 160mm

Geberit, Wavin Waviduo, Akatherm, Valsir

• RED: 200mm – 315mm

Geberit

• BROWN: 200mm – 315mm

Wavin Waviduo

• BLUE: 200mm – 315mm

Akatherm, Valsir

• Connect the welding cable to the tting.

• Press and hold-in the start button for two seconds to begin welding.

• The weld time will count up to 100% and the green light will come on.

• Any errors will be shown.

• Disconnect the welding cable from the tting.

• To reset the welder press and hold-in the Start/Stop button for ve seconds.

• To help avoid errors, use a good quality 2.5 kW / 3.0 kVA power generator to the

specications TIN12/ECE3.

Using the equipment

AW315 - Operator Manual

AW315

© 2019. Advance Welding 9

If a fault happens with the unit, the red fault light will illuminate along with one other

indicator light to show the error number. Information on the causes of these faults is shown

below. If this does not identify or remedy the problem, contact your service agent.

Error 1. Power failure during weld.

The power to the welding unit went o during the weld.

• Check that the unit is switched on.

• Make sure the supply plug has not come out of the supply socket.

• Check that the supply fuse or breaker has not tripped.

• If using a generator, check the generator is operating and there is enough fuel.

• Check the cables are not damaged or broken.

• Check the fuse is OK in the welding unit.

Error 2. Stop button pressed

The stop button was pressed while welding.

• Restart the weld after the tting has returned to ambient temperature.

Error 3. Power supply frequency fault. The supply frequency is out of limits.

• Check the generator is operating correctly.

Error 4. Ambient temperature fault.

The ambient temperature has been measured as lower than -20oC or higher than +50oC.

• If the temperature is very cold, wait until the ambient rises back into specication.

• If the unit is in direct sunlight, it may have heated up the sensor. Move the unit into the

shade and allow it to reach ambient again.

Error 5. No welding current.

The unit has detected that no welding current is passing into the tting.

• Make sure that the connectors have not come o the tting.

• Make sure that the welding cable is securely connected to the unit and that it isn’t

damaged.

• Try welding again, but hold the start button in for three seconds. A short press of the

start button can cause this fault.

Fault Finding

AW315 - Operator Manual

AW315

© 2019. Advance Welding 10

Error 6. Low welding current.

The unit has detected a low welding current as follows:

1.5% low, fail in 3 seconds.

90% low, fail in 1 second.

• Make sure that the correct ttings are being welded.

• If multiple welding ttings, make sure the combined diameters do not exceed

200mm.

• Make sure the supply is within limits: 110 volts with a capacity of 3500 watts.

• Make sure any extension leads being used are the correct length and rating.

Error 7. High welding current.

The unit has detected a high welding current as follows:

1.5% high, fail in 3 seconds.

6.25% high, fail in 2 seconds.

12.5% high, fail in 1.5 seconds.

25% high, fail in 1 second.

50% high, fail in 0.3 seconds.

• Restart the weld after the tting has returned to ambient temperature.

• If the fault persists, return the unit to an approved service agent.

To reset the unit after an error, press and hold-in the Start/Stop button for ve

seconds.

AW315 - Operator Manual

AW315

© 2019. Advance Welding 11

Regularly check for obvious defects such as loose or damaged cables and connectors.

Look for warn components and broken covers or housings.

There are no user serviceable parts inside the unit. It should be returned to an

approved service agent for repair and calibration.

This unit should be calibrated every twelve months.

After use, clean the outside of the unit with a soft brush or cloth. Carefully wind up

and store the cables in the compartments provided in the carry case.

Maintenance

Pb

The equipment and packaging should be sorted for environmentally friendly

recycling.

DO NOT DISPOSE OF THIS EQUIPMENT

INTO HOUSEHOLD WASTE !

According to the European Directive

2002/96/EC Waste Electrical and Electronic

Equipment (WEEE), when no longer suitable

for use, this equipment must be separately

collected and sent for recycling.

According to the European Directive

2005/95/EC Restriction of Hazardous

Substances (RoHS), this equipment does

not contain more than the agreed levels

of lead, cadmium, mercury, hexavalent

chromium, polybrominated biphenyl (PBB)

and polybrominated diphenyl ether (PBDE)

ame retardants.

Disposal

RoHS Compliant

Directive 2005/ 95/ EC

AW315 - Operator Manual

AW315

© 2019. Advance Welding 12

Conditions of Warranty:

This warranty covers only those defects to the product which arise from normal use of

the product, and will become invalid if any of the following apply:

• Failure to follow the operating instructions.

• Improper or inadequate maintenance.

• Unauthorised modication.

• Misuse or any use not in accordance with the operating manual or good

industry practice.

• Physical abuse of the product.

• Operation outside the products specications.

• Improper site preparation or site maintenance.

• Faulty pipe or tting.

Extent of Warranty:

Subject to the conditions and limitations of warranty; Advance Welding warrants that

its electrical products will be free from defects in materials and workmanship for a

period of twelve months, and its mechanical products for six months, from the date of

purchase by the end-user customer.

If during this period, notice of a defect which is covered by this warranty is received,

then Advance Welding will either repair or replace the product at its option. Any

replacement product will have functionality at least equal to that of the product being

replaced, and will in our opinion, perform consistently with its age and usage.

Unless otherwise agreed, all warranty work will be carried out by Advance Welding or

an authorised and approved service facility.

This welding unit has been manufactured, inspected and tested in accordance with

the quality control systems in place at Advance Welding.

This welding unit has been calibrated using equipment that is traceable to national

and international standards, through a NAMAS accredited laboratory. NAMAS

(National Accreditation of Measurement and Sampling) is a service of UKAS (United

Kingdom Accreditation Service).

This welding unit has a TWELVE month calibration and warranty period, active from

the rst use of the unit by the end user customer.

Calibration and Warranty

AW315 - Operator Manual

AW315

© 2019. Advance Welding 13

If during this period, notice of a defect which is covered by this warranty is received,

then Advance Welding will either repair or replace the product at its option. Any

replacement product will have functionality at least equal to that of the product being

replaced, and will in our opinion, perform consistently with its age and usage.

Unless otherwise agreed, all warranty work will be carried out by Advance Welding or

an authorised and approved service facility.

Customers will prepay all shipping charges for products returned under warranty, and

Advance Welding will charge for return of the products back to the customer.

This warranty statement gives the customer specic legal rights. The customer may

also have other rights which vary from country to country in the world.

Limitations of Warranty:

Advance Welding does not warrant the operation of any product to be uninterrupted

or error free.

Advance Welding specically disclaims the implied warranties of satisfactory quality

and tness for a particular purpose.

Advance Welding makes no other warranty of any kind, whether express or implied,

with respect to its products.

To the extent that this warranty statement is inconsistent with the law of the locality

where the customer uses the product, this warranty statement shall be deemed

modied by the minimum necessary to be consistent with such local law.

To the extent allowed by local law, the remedies provided in this warranty statement

are the customer’s sole and exclusive remedies.

This equipment has been designed for use with the range of ttings and pipe available

at the time of its design and development. Advance Welding can accept NO liability for

the equipments ability or otherwise to be used with new or dierent ttings or pipe

that subsequently appear in the market place.

This equipment is not intrinsically safe and must not be used in a gaseous or explosive

atmosphere. Advance Welding can accept NO liability if the equipment is used in

these circumstances.

Customers will prepay all shipping charges for products returned under warranty, and

Advance Welding will charge for return of the products back to the customer.

This warranty statement gives the customer specic legal rights. The customer may

also have other rights which vary from country to country in the world.

AW315 - Operator Manual

AW315

© 2019. Advance Welding 14

The applicable standards are:

89/336/EEC Electromagnetic compatibility

73/23/EEC Low voltage equipment

98/37/EC Machinery safety

More detailed information is available on our web site at

www.advancewelding.co.uk

On behalf of

Advance Welding: K.M.Wilkinson

Declaration of Conformity

This welding unit has been designed to comply

with the harmonised standards under the “New

Approach” directives, and has been CE marked

accordingly.

AW315 - Operator Manual

AW315

© 2019. Advance Welding 15

Manufactured in the UK by:

ADVANCE WELDING

Units 1 & 2

Taylor Street

Cleckheaton

West Yorkshire

BD19 5DZ

United Kingdom

Tel: UK 0844 880 7748

+44 1274 870112

Fax :UK 0870 752 6139

+44 870 752 6139

Email: [email protected]o.uk

Web: advancewelding.co.uk

Service and Repair

Table of contents