Be Sure to Read Instruction Manuals Before Use

Thank you for selecting DAIHEN arc welding robot Almega series.

Almega series are the robots with high performance and various functions developed by making full use of the

latest technology. Since the knowledge of welding peculiar to a welding machine maker is applied to both

hardware and software, we are sure that each user can be fully satisfied

In order to use the superior performance and the abundant functions safely and fully, be sure to read the

following instruction manuals including this manual and other attached documents, and understand the

knowledge of the machines, safety information, and notes thoroughly.

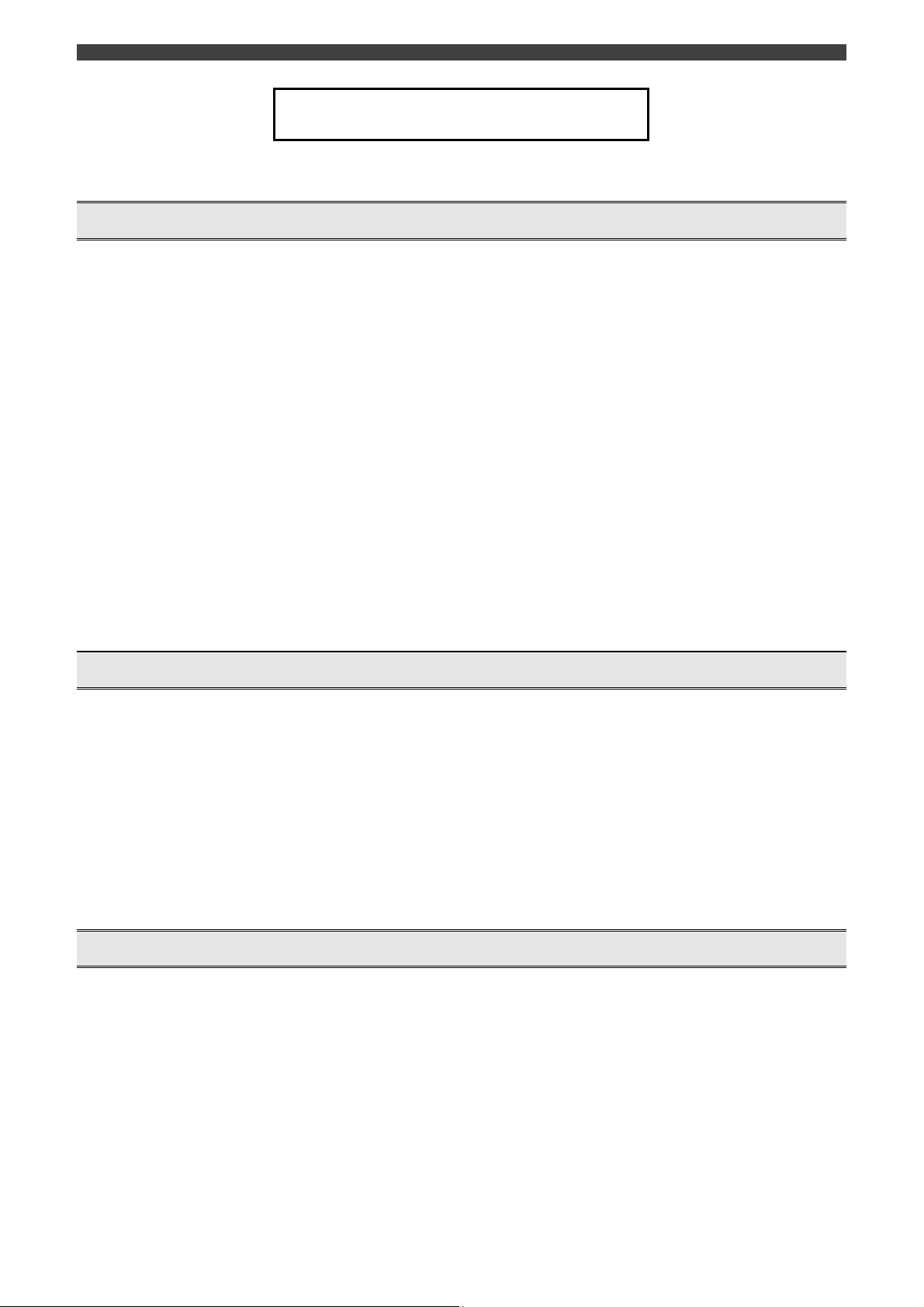

Instruction manuals related to the manipulator “AX-M series”, and the robot control unit “AX-C” are as follows.

■Standard Manuals

Instruction Manual Type Instruction

Manual No. Main Contents

INSTALLATION

1L8800A Safety precautions, installing & connecting method,

starting up, periodical inspection, solution at the time

of failure

CONTROLLER MAINTENANCE/

STANDARD CONFIGURATIONS

1L8800B Specifications of controller, explanation of each parts

and maintenance, parts list, etc.

MANIPULATOR

(

AX-MV4AP/ MV6/ MV6L/ MV16/ MG3/ MH3/ MS3

)

1L7700A

MANIPULATOR (AX-MV50) 1L7721A

MANIPULATOR (AX-MV133, MV166) 1L7722A

MANIPULATOR (AX-MV160) 1L7723A

Specifications or maintenance of manipulator, parts

list, etc.

BASIC OPERATIONS

1L8800C Explanation of manual operation, teaching, automatic

operation, file utilities, backing-up data, basic

operations of Arc/Spot welding application, etc.

REFERENCE (Built-in Tutorial)

1L8800D

Basic operations, terms, explanations of

Constants/Service menus, Details of function

command, list of short-cut code, parts replacing

procedure, trouble shooting, etc.

※This manual is not provided as the paper manual,

but is built in the robot as Help tutorial function.

EXTERNAL INPUT/OUTPUT

1L8800H Interfacing method with external control device, list of

I/O signals, start/halt the automatic operation, and

usage of software PLC, etc.

CONTROLLER MAINTENANCE

ADDENDUM

(for AXCLN1/ AXCLL1)

1L9440B

Measures for safety, transportation, installation, and

connection

Controller's specification, maintenance for each parts,

part list and others

■Application Manuals

Instruction Manual Type Instruction

Manual No. Main Contents

APPLICATION MANUAL

(ARC WELDING) 1L8800F Basic settings, functions for arc welding, teaching

technic, etc.

APPLICATION MANUAL

(HANDLING) 1L8800G Basic settings, functions for handling, teaching

technic, etc.

APPLICATION MANUAL

(SPOT WELDING) 1L8800E Basic settings, functions for spot welding, teaching

technic, etc.

Instruction manuals are available other than the above for each optional function that you have purchased.

[Notes] 1. Specifications and information contained in these manuals are subject to change at any time without notice.

2. Optional hardware or software is necessary in order to use the function described as “Optional” in the manual.

3. The screen display of a teach pendant shown in the manual are described as examples, which may be different from the actual

ones.

4. Although we cautiously compiled this standard specifications to eliminate as much error as possible, we do not take any

responsibility for damages resulting from neither direct nor indirect errors.

5. The manual is a part of robot products. When transferring or selling off a robot, be sure to append the manual.

6. No part of this manual may be reproduced without permission.

- 1 -