Advantech PCL-843 User manual

PCL-843

16-bit

Ethernet Card

Copyright Notice

This documentation and the software included with this product are

copyrighted 1995 by Advantech Co., Ltd. All rights are reserved.

Advantech Co., Ltd. reserves the right to make improvements to the

products described in this manual at any time without notice.

No part of this manual or software may be reproduced, copied,

translated or transmitted, in any form or by any means without the

prior written permission of Advantech Co., Ltd. Information provided

in this manual is intended to be accurate and reliable. However,

Advantech Co., Ltd. assumes no responsibility for its use, nor for any

infringements of rights of third parties which may result from its use.

Acknowledgments

All trademarks and registered trademarks mentioned herein are the

property of their respective owners.

FCC Warning

This equipment uses and generates radio frequency (RF) energy. If

not properly installed and used in accordance with this manual this

product may cause interference to Radio and TV reception. This

product has been tested and found to comply with the limits for a

Class A digital device as per FCC Rules, Subpart J of Part 15. These

guidelines have been designed to provide reasonable protection

against harmful interference in a commercial environment.

Part No. 2000843000 1st Edition

Printed in Taiwan Jan. 1995

Contents

CHAPTER 1 Introduction .................................................. 1

Description............................................................................. 2

Applications.................................................................................. 3

Features ......................................................................................... 3

Specifications................................................................................ 4

Emissions...................................................................................... 4

CHAPTER 2 Hardware Installation .................................. 5

Initial inspection.................................................................... 6

PCL-843 Jumper/connector locations................................ 7

Card configuration ............................................................... 8

Jumper settings ..................................................................... 8

Configuration software/jumper (JP4)........................................... 9

Interrupt (IRQ) level setting (JP2)................................................ 9

I/O address setup (JP1) ............................................................... 10

Boot ROM address (JP3)............................................................ 10

Mode selection (JP4) .................................................................. 11

Configuration using software ............................................ 12

Remote boot operation ....................................................... 13

Installing boot ROM chips ......................................................... 13

Card installation ................................................................. 15

CHAPTER 3 Wiring and Networks ................................. 1 7

Typical network connections.............................................. 18

Wiring .................................................................................. 19

BNC connection ......................................................................... 19

RJ-45 connections ...................................................................... 20

RJ-45 pin assignments................................................................ 20

Diagnostics........................................................................... 21

Card software diagnostics........................................................... 21

LED indicator diagnostics .......................................................... 22

Appendix A Quick Boot Installation Guide.................... 2 3

Installing quick boot ROM......................................................... 24

Creating multiple remote boot image files................................. 26

Using different frame types ........................................................ 28

Chapter 1 Introduction 1

1

Introduction

CHAPTER

2PCL-843 User's Manual

Description

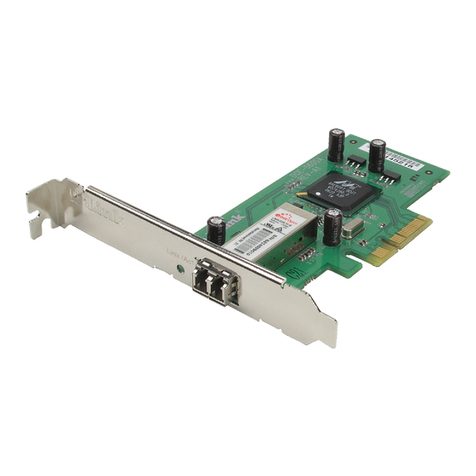

The PCL-843 is a high performance jumperless 16-bit Ethernet

adapter that connects to either thin Ethernet coax or twisted pair

cabling.

The card is fully compatible with the popular Novel NE2000 PC bus

adapter. As a result the card can be used with most network operating

systems, drivers and utilities.

The PCL-843 provides a thin coax (10BASE-2) interface and a

twisted pair (10BASE-T) interface. Both interfaces fully comply with

the IEEE 802.3 10BASE-2 and 10BASE-T standards for 10-Mbps

CSMA/CD local area networks.An auto-sensing circuit automatically

detects which of the two interfaces is being used. The PCL-843 not

only supports the two most popular cabling types, it also minimizes

the cost of media conversion and maintenance for future use.

The PCL-843's advanced design eliminates the need to use it's

switches and jumpers, making it ideal for industrial applications

requiring low MTTR. An easy-to-use setup program lets you config-

ure the card completely in software. (Alternatively, you can use the

card's jumpers.)

The PCL-843 conforms to FCC Class A standards. Put a boot ROM in

its supported socket and you can boot the workstation automatically

from a file server without any local disk drives, excellent for operation

in stand-alone and harsh industrial environments.

Chapter 1 Introduction 3

Applications

• Factory automation systems

• Data acquisition systems

• Networking

• POS (point of sale) systems

• Instrument control

Features

• Novel NE2000 compatible

• Conforms to IEEE 802.3 10BASE-2 and 10BASE-T

• Software or jumper configurable (IRQ, I/O address and

remote ROM address)

• High-speed operation (10 Mbps)

• Provides BNC and RJ-45 connectors with auto-sensing

• 8-bit/16-bit auto-sensing

• On-board 16K high performance multi-packet buffer

• Includes easy-to-use setup/diagnostic utility to select IRQ, I/O

address and Boot ROM address

• NetWare 286/386, NDIS, ODI and Packet drivers included

• SMT technology for increased product reliability

• Complies with FCC ClassA

• Quick diagnostic LEDs indicate adapter status

• External LED indicates traffic status

4PCL-843 User's Manual

Specifications

•Standards: IEEE 802.3 10BASE-2 and 10BASE-T

•I/O Base address: 240, 280, 2C0, 300, 320, 340, 360H

•Boot ROM address: Disable, C0000H, C4000H, C8000H,

CC000H, D0000H, D4000H, D8000H and DC000H

•IRQ: 2, 3, 4, 5, 6, 10, 11 or 12

•Data bus width: 8-bit and 16-bit auto-sensing

•Connectors:

BNC port - IEEE 802.3 10BASE-2 thin Ethernet supported by

BNC T-connector to RG-58 AUI coaxial bus cable

RJ-45 port - Unshielded twisted pair wire (22AWG~26AWG)

for RJ-45 phone jack. Max. length is 100 meters (24AWG

recommended)

•Software support: Setup/diagnostic utility

•Driver support: NetWare 286/486, Microsoft LAN manager,

DECnet PathWork, 3COM 3+Room, BanyanVINES, IBM LAN

support Program, WIN/TCP PathWay Access for DOS,

FTP PC/TCP, Windows For Workgroups

•Power consumption: +5 V @ 1.0 A max.

•Operating temperature: 0 to 55oC

•Dimensions: 6.4" x 3" (162 x 75 mm)

•Shipping weight: 0.44 lb (0.2 Kg)

Emissions

Conforms to FCC part 15 Class A

Chapter 2 Hardware Installation 5

2

Hardware

Installation

CHAPTER

6PCL-843 User's Manual

Initial inspection

Depending on the option you ordered, you should find (in addition to

this manual) the following items inside the shipping container:

• PCL-843 Ethernet Card

• One T-connector for 10BASE-2

• One 3.5" diskette (software driver)

We carefully inspected the PCL-843 mechanically and electrically

before we shipped it. It should be free of marks and scratches and in

perfect working order on receipt.

As you unpack the PCL-843, check it for signs of shipping damage

(damaged box, scratches, dents, etc.). If it is damaged or it fails to

meet specifications, notify our service department or your local sales

representative immediately. Also notify the carrier. Retain the ship-

ping carton and packing material for inspection by the carrier. After

inspection we will make arrangements to repair or replace the unit.

When you handle the PCL-843, remove it from its protective packag-

ing by grasping the rear metal panel. Keep the anti-vibration packing.

Whenever you remove the card from the PC, store it in this package

for protection.

Warning! Discharge your body’s static electric charge by

touching the back of the grounded chassis of the

system unit (metal) before handling the board.You

should avoid contact with materials that hold a

static charge such as plastic, vinyl and styrofoam.

Handle the board only by its edges to avoid static

damage to its integrated circuits. Avoid touching the

exposed circuit connectors.

Chapter 2 Hardware Installation 7

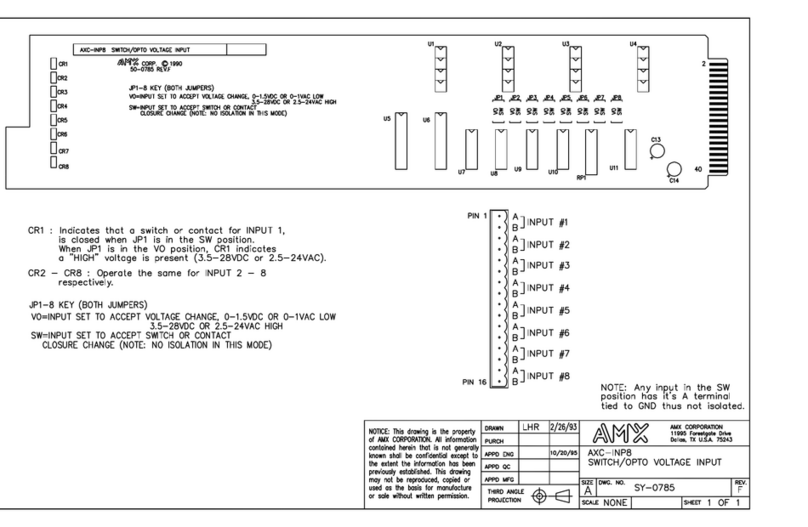

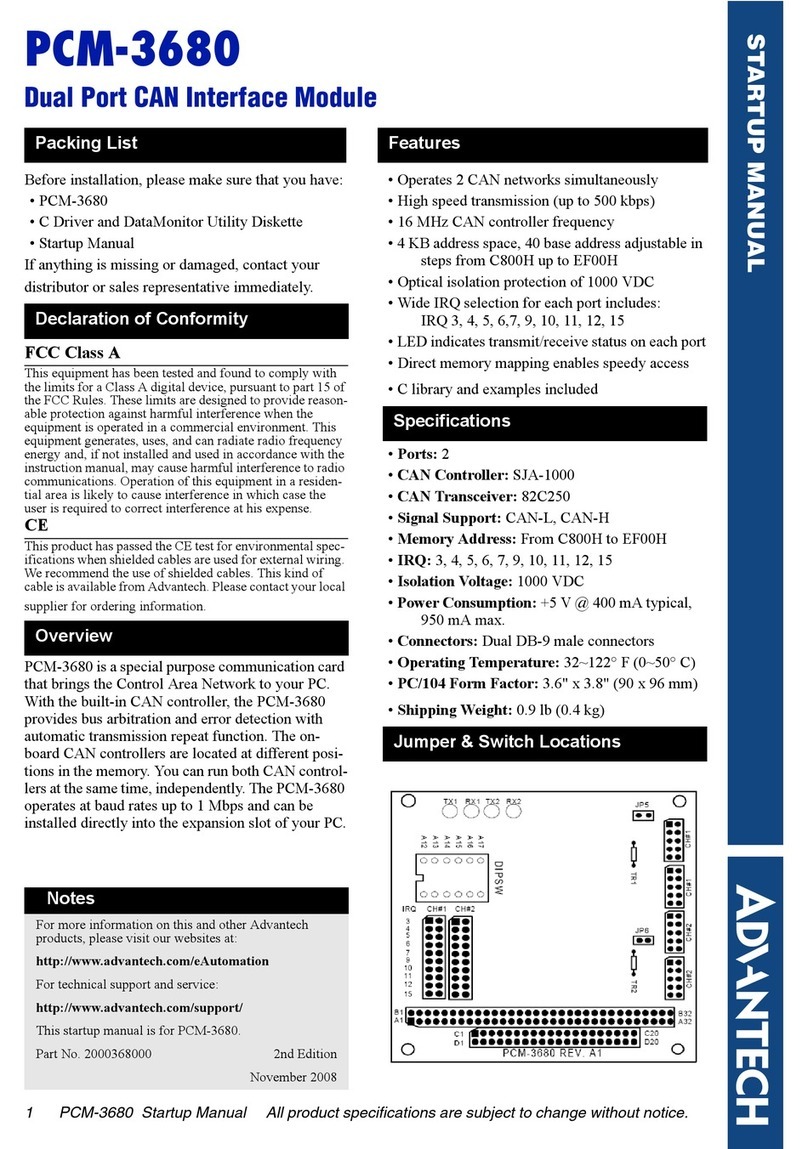

PCL-843 Jumper/connector locations

Trouble

shooting

LEDs

Twisted pair

connector

BNC

connector

IRQ

selection

Configure/mode

setting

Boot ROM

address

setting

I/O address

setting

Ext. LED

connector

Boot ROM

socket

JP4

JP3

JP2

JP1

8PCL-843 User's Manual

Card configuration

Configuration of the PCL-843 can be done with jumpers or via the

software utility. Only five parameters need to be set, these are:

PCL-843 Jumper Options

Selection Switches/jumpers Default

Software/Jumper Selection JP4 Jumper Setting

IRQ JP2 IRQ3

I/O Address JP1 300H

Boot ROM Address JP3 Disable

Mode Selection JP4 Mode 0

Please refer to the diagram on the previous page for jumper locations.

Using the software to configure the card is covered in the software

section of this chapter.

Jumper settings

This section tells how to set the jumpers to configure your card. It

gives the card default configuration and your options for each jumper.

How to set jumpers

You configure your card to match the needs of your application by

setting jumpers. A jumper is the simplest kind of electric switch. It

consists of two metal pins and a small metal clip (often protected by a

plastic cover) that slides over the pins to connect them. To “close” a

jumper you connect the pins with the clip. To “open” a jumper you

remove the clip. If you have any doubts about the best hardware

configuration for your application, contact your local distributor or

sales representative before you make any changes.

Chapter 2 Hardware Installation 9

Configuration software/jumper (JP4)

As already mentioned you can configure the PCL-843 with the above

jumpers or via the software utility. This option is selected via pins 3

and 4 on jumper JP4, as shown below:

Software Jumpers (default)

Interrupt level (IRQ) setting (JP2)

The PCL-843 card is designed to access interrupt levels 2 up to level

12 with the exception of 7, 8, and 9. Simply place the jumper link on

the required interrupt level as shown below:

IRQ 3 (default)

The table below shows the possible IRQ settings available for the

PCL-843. Ensure that the IRQ does not conflict with any other card's

IRQ you that you have installed in your system .

PCL-843 IRQ Settings (JP2)

IRQ Pin 1-2 Pin 3-4 Pin 5-6

2¡¡¡

3¡¡l

4¡l ¡

5¡l l

6l¡¡

10 l¡l

11 ll¡

12 lll

l:Close ¡:Open *:Default

1

2

3

4

1

2

3

4

135

246

*

10 PCL-843 User's Manual

135

246

*

135

246

7

8

I/O address setup (JP1)

The I/O base address the PCL-843 is selectable by a 3 position

jumper, JP1. Refer to page 7 for the location of the jumper. The base

address can be set anywhere in the I/O address area from hex 300H to

hex 360H. The factory default settings for the base address is hex

300H (no jumpers in place).

I/O Address 300H (default)

The required switch settings for various base addresses are as shown

below:

PCL-843 I/O Address (JP1)

I/O Address Pin 1-2 Pin 3-4 Pin 5-6

200H l¡¡

240H ¡l¡

280H ¡ll

300H ¡¡¡

320H l¡l

340H ll¡

360H lll

l:Close ¡:Open *:Default

Boot ROM address (JP3)

This enables the workstation to boot automatically from the file

server. The Boot ROM must be configured prior to use by jumper JP3

or via the software utility. The factory default settings for the Boot

ROM address is disabled (no jumpers in place).

Disabled (default)

Chapter 2 Hardware Installation 11

The Boot ROM can be disabled or set to eight different ROM address-

es as shown in the table below:

PCL-843 Boot ROM Address (JP3)

Boot ROM Pin 1+2 Pin 3+4 Pin 5+6 Pin 7+8

Disable ¡¡¡¡

C0000H ¡¡l ¡

C4000H ¡¡l l

C8000H ¡l ¡¡

CC000H ¡l ¡l

D0000H ¡l l ¡

D4000H ¡l l l

D8000H l¡¡¡

DC000H l¡¡l

l:Close ¡:Open *:Default

Mode selection (JP4)

The PCL-843 can be set to Mode 0 or Mode 1. This option is de-

signed to compensate for motherboard ISA bus timing controls. For

the majority of systems, select Mode 0 (default). Mode 1 is for older

systems utilizing C&T chipsets, IBM 286 (or compatible) systems or

Compaq 286 portable systems. This is done via pins 1 and 2 on a four

position jumper, JP4, as shown below:

Mode 1 Mode 0 (default)

This concludes the hardware setup section

*

1

2

3

4

1

2

3

4

12 PCL-843 User's Manual

Configuration using software

To set up the PCL-843's configuration using the software utility,

follow the procedures below:

Step 1. Ensure that jumper JP4 (pins 3 and 4) is open

Step 2. Run the SETUP.EXE file located in the root directory of the

software utility diskette. The software will thenbring you to

the software setup screen as shown below.

Setup/diagnostic main screen

Step 3. For initial setting up of you card select "S" for setup. The

other option "D" is for later diagnostic testing.

Step 4. When you select setup the screen shown on the next page will

appear. Move the highlight bar to the setting required and

press "ENTER" to select the options.

Current Configuration

Node Address : 00 C0 6C 51 14 26

I/O Address : 300H

Interrupt Request : IRQ 3

Remote Boot ROM : DISABLE

Mode : MODE 0

16-bit Etherboard Setup/Diagnostic Utility V2.12

Press S to run SETUP

Press D to run DIAGNOSTIC

Press Esc to exit

ESC Setup Diagnostic

Chapter 2 Hardware Installation 13

Setup function screen

Step 5. When you have made your selections, save them by

pressing "S". This will preserve the cards configuration in

the EEPROM until future changes are made.

This concludes setting up via the software utility.

Remote boot operation

In some systems where a diskless workstation is used, a remote boot

ROM can be utilized. This automatically boots the workstation from

the file server. As briefly mentioned in the previous sections, the

ROM's address can be set up using an on-board jumper (JP3) or the

utility software. The procedure for remote booting using ROM is

similar to that of most other ROMs but can be fairly detailed. If you

are not familiar with the setting up you can print a detailed boot

information text file "BOOT.TXT" which is located on the utility

diskette or refer to Appendix A. This file gives detailed information

on how to remote boot from a file server.

Installing boot ROM chips

After you’ve configured the PCL-843, you should install your ROM

chip. These following procedures are only intended as a supplement

16-bit Etherboard Setup/Diagnostic Utility V2.12

Enter-select Esc-Previous Save Diagnostic

Current Configuration

I/O Address : 300H

Interrupt Request : IRQ 3

Remote Boot ROM :

Mode :

240H

280H

2C0H

300H

320H

340H

360H

I/O address has 7 available values - 240H, 280H, 2C0H, 300H, 320,

340H 360H.

14 PCL-843 User's Manual

to the information your chip manufacturer has given you. If you are

inexperienced in installing chips, you may want to read a good

hardware reference book before you begin. One recommendation is

by Winn L. Rosch, The Winn Rosch Hardware Bible (NewYork;

Brady), 1989.

Warning! Ground yourself when handling memory devices

and insert them with as little force as possible!

Make sure that you are properly grounded before handling memory

devices or the board. You can discharge any static electricity you may

have built up by touching the case (metal) of your computer before

you begin installation.You should also avoid contact with materials

that hold a static charge such as plastic, vinyl, and styrofoam. Avoid

touching the exposed circuit connectors.

•Treat connectors gently

The legs of integrated circuits are delicate, and may bend before

reaching the bases of sockets. Inspect each leg before you begin, test-

fit it gently into the socket, and straighten any bent legs before you

insert.

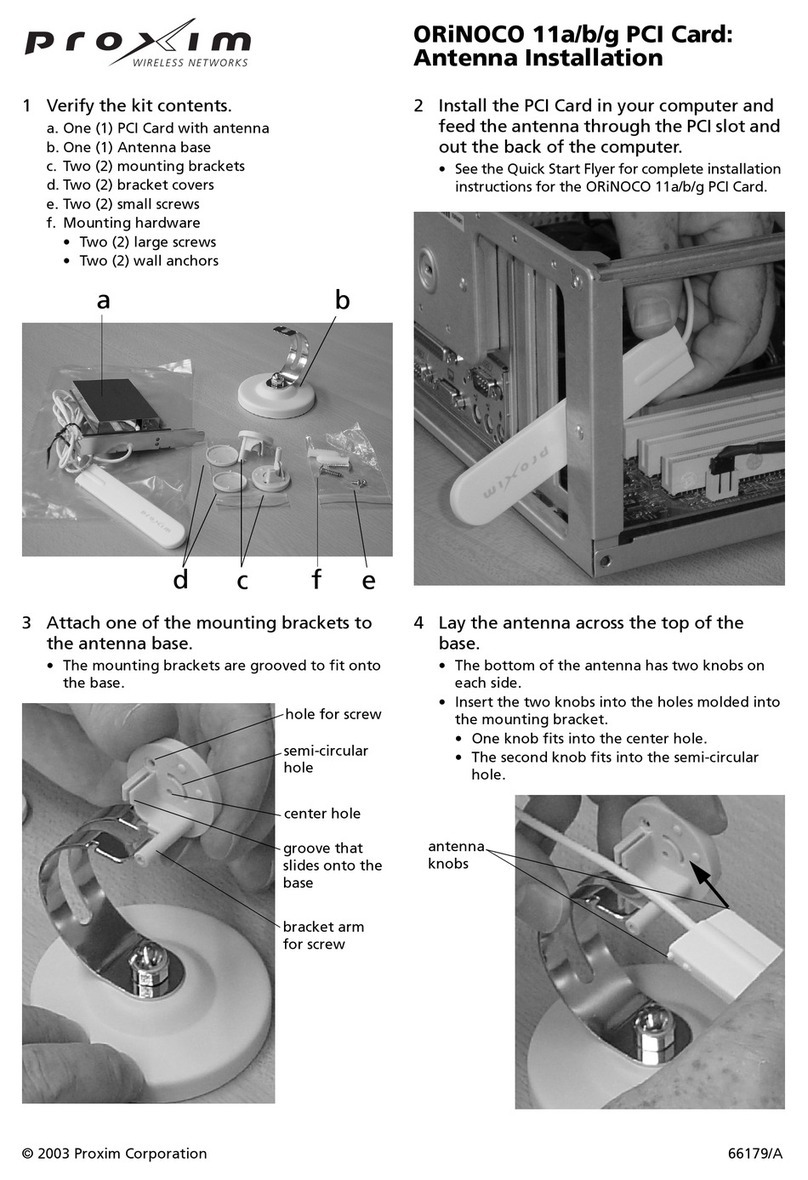

• Install memory chips with the correct orientation

Memory chips must be installed the correct way around. If this is not

done the chip will be damaged. Each chip and it's corresponding

socket will have a small ident (or spot) at it's top end. These must be

aligned when the chip is inserted into the socket.

ROM chip insertion

Notches

Table of contents

Other Advantech Network Card manuals

Advantech

Advantech Network Device USB-4761 User manual

Advantech

Advantech PCM-3680 Installation and operation manual

Advantech

Advantech ECU-P1524SPE Installation and operation manual

Advantech

Advantech PC-LabCard PCI-1784 User manual

Advantech

Advantech MIC-3660 User manual

Advantech

Advantech Data Acquisition Modules ADAM 4000 User manual

Popular Network Card manuals by other brands

Denkovi

Denkovi DAEnetIP2 user manual

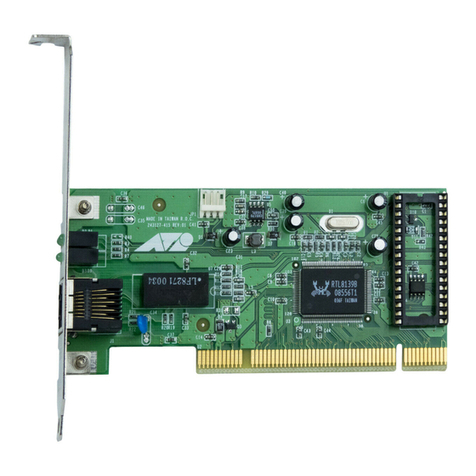

Allied Telesis

Allied Telesis AT-2500TX user guide

Gemtek

Gemtek WL-350F user manual

Compaq

Compaq iPAQ Networking Installation and setup guide

Emerson

Emerson Liebert OpenComms-485 reference guide

Net to Net Technologies

Net to Net Technologies UIM-E1 installation instructions