CHAPTER 2

USES, LIMITATIONS AND ADVANTAGES

Harold Heywood wrote "I often refer to

sieving as the 'Cinderella' of particle size

analysis methods; it does most of the hard

work and gets little consideration."(3)

There are numerous reasons for the

selection of high quality testing sieves as a

first choice in particle size analysis work.

Leschonski said "... because of its

simplicity - everyone immediately

understands the purpose of a stack of

sieves and its operation -and its

inexpensive- ness." (4) Standard sieve

analysis is probably the fastest and most

widely used quality control procedure in

any powder process control industry. Used

frequently as a mediating device between

the production and sales divisions of a

process corporation or between the sales

force and the customer, test sieve analysis

work enjoys the universal recognition of

being the best 'quick and dirty' test

procedure for rapid particle size distribution

data. The outcome of the analysis is easily

calculated and interpreted for comparison

between laboratories. Start-up cost to

institute a basic sieving quality control

program is minimal, and operators at most

levels of training are capable of performing

a successful sieve analysis. With these

factors in mind, it is easy to see why

testing sieves are as ubiquitous as they are

in industry. Materials from crushed ore

chunks of over 114.3 mm (4 ½”) in

diameter to slurred alumina and porcelain

powders of less than 20 micrometers are

all analyzed with test sieves on a regular

basis.

Whether hand or machine sieving, wet or

dry preparations, analysis or production

work, testing sieves have found a niche in

the quality control laboratory. Given this

overall acceptance of test sieves as a viable

analytical device and the widespread

presence of the sieve in laboratories of all

industries, any shortcomings of such an

analytical device would be magnified. For

all of the advantages available to the test

sieve user, limitations must be recognized

and accounted for in the presentation and

analysis data.

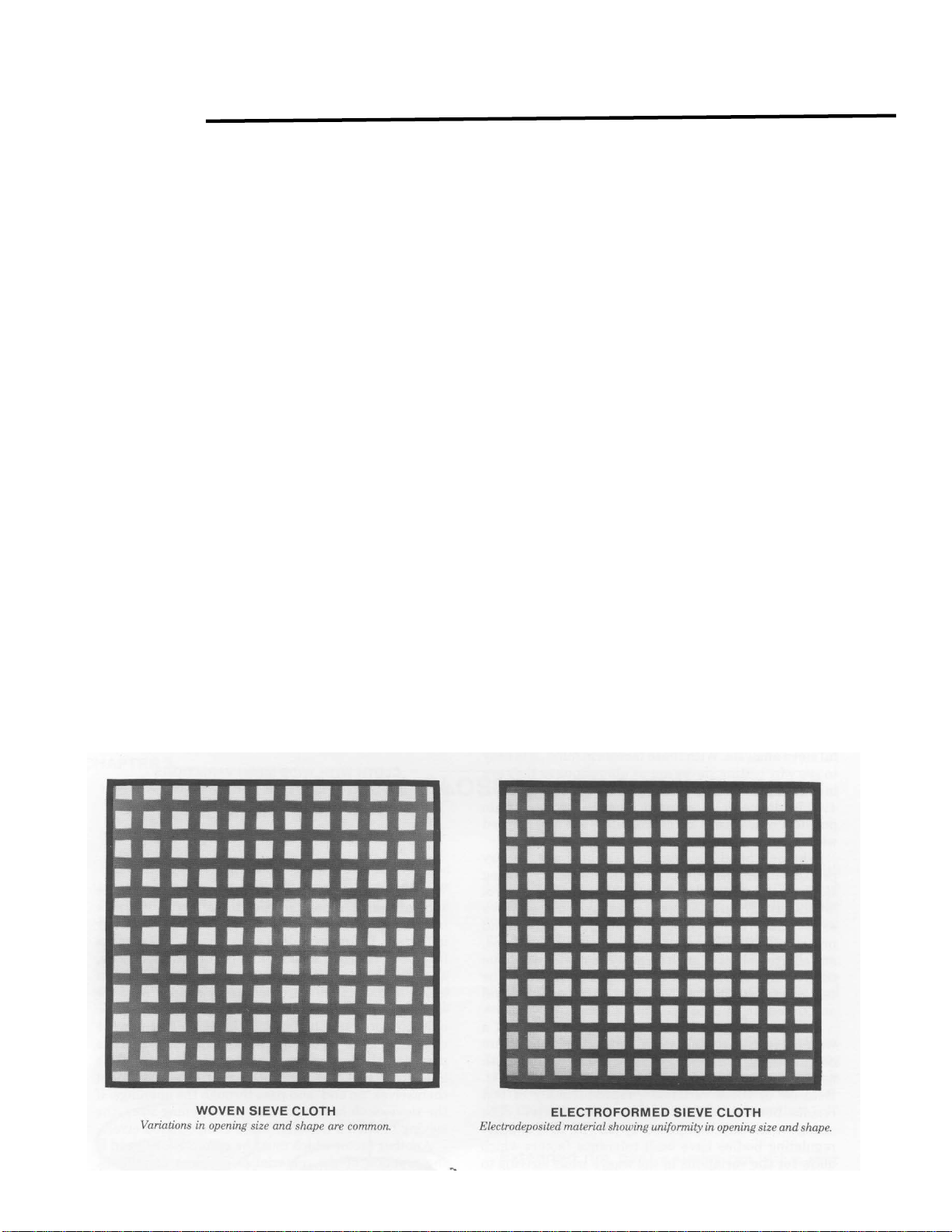

Test sieves are individuals. Being

fabricated of a woven mesh material,

variations in the weave are common. The

chances of locating two sieves with an

identical distribution of opening sizes are

extremely remote. Due to these variations,

the reproducibility of test results between

sieves can be adversely affected. The

stringent standards imposed by ASTM, ISO

or other regulating bodies have established

tolerance factors which allow for the

permissible variations in the weave while

striving to maintain a level of uniformity in

the performance of the 'test grade' sieve

cloth. (See Table 1)

With this variation of opening sizes

present, some smaller than the nominal

and some larger, the time interval of the

sieve analysis becomes extremely

important. If, for example, a sieve has

several openings far above the nominal

opening size for the particular mesh size,