Innowater SMC10 User manual

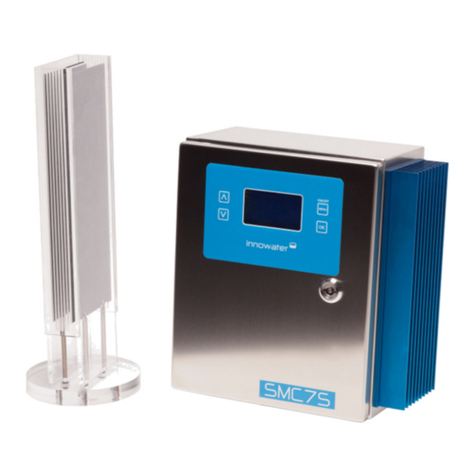

smc chlorinator

manual

03-21

Page

1 Introduction 1

2 Technical characteristics 2

3 Chlorinator 3

4 Installation 4

5 Water preparation 6

6 Adding salt 7

7 Operation 8

8 Menus 9

9 Fault messages 12

10 Recommendations and Warnings 13

11 Manual Cell Cleaning 14

12 Warranty, Technical Service and

Spare Parts 15

All Rights Reserved

1 SMC

1. INTRODUCTION

We thank you for your purchase of an Innowater chlorinator. Innowater chlorinators

are manufactured following the strictest quality controls using the most advanced

technology of electrolysis resulting from our many years of swimming pool industry

experience .

With minimum maintenance and following elementary rules for installation and use,

you will enjoy an extremely efficient device for many years.

Please read this manual carefully before installation or start-up, and keep it for

further reference.

The sections concerning the installation require certain technical knowledge and we

always recommend that installation is conducted by an industry professional.

Please pay special attention to the points marked with the following symbol:

Any damage caused to the chlorinator resulting from not complying with these

warnings may lead to a void of warranty.

We trust you will enjoy your Innowater chlorinator—thanks for choosing Innowater.

SMC 2

2. TECHNICAL CHARACTERISTICS

SMC10 SMC15 SMC20 SMC30

Maximum flow lt/min 450 450 450 450

Maximum pressure bar 4444

Pressure drop kpa 5555

Chlorine production gr/h 10 15 20 30

Max. output voltage VDC 24 24 24 24

Max. Output current ADC 2,0 2,5 3,5 5,0

Cell configuration Bipolar Bipolar Bipolar Bipolar

Recommended salt

concentration gr/l 5-35 5-35 5-35 5-35

Cell housing material PC PC PC PC

Cell life span h 14.000 14.000 14.000 14.000

Electrode substrate material Titanium

grade 1

Titanium

grade 1

Titanium

grade 1

Titanium

grade 1

Maximum swimming pool size m3

- Temperate climate 30 50 90 150

- Tropical climate 20 34 60 100

Power supply VAC 230 230 230 230

Power consumption W 58 75 100 144

Weight Kg 3,2 3,5 4,0 4,3

3 SMC

3. CHLORINATOR DESCRIPTION

You will find the following items in your Innowater SMC box:

1 Control unit

a LCD screen

b Keyboard

c DC cell cable and connector

2 Power supply cable

3 Electrolytic cell

4 Cell housing

5 Thread lock

6 Cell O Ring

7 Cell tap

3

42

5

b

a

c

1

6

SMC 4

Chlorinator Control Unit

Mount the control unit on a wall using the bracket on the back and the screws

provided. Choose a place for easy access and reading. The control unit can only be

placed at a maximum of 1.5 meters away from the electrolytic cell due to cable

length. Choose a place with good ventilation and protection from the rain and other

possible water leaks or splashing.

We recommend that you have an electrical safety circuit breaker

fitted to your swimming pool electrical circuit.

Connect the earth wire (yellow and green) of the 230 VAC power supply cable to

the earth of the swimming pool electric panel. Connect the phase (brown) and the

neutral (blue) to the output contacts of the pump contactor in such a way that the

chlorinator will be powered only when the pump is working. Connect the chlorinator

wires to non occupied contacts. Do not use the contacts in use by the pump.

This will prevent the chlorinator to be electrically connected to the pump when the

contactor is switched off what could cause serious damage. Verify that the

chlorinator switches off itself when the pump stops. This operation should be

performed by a professional.

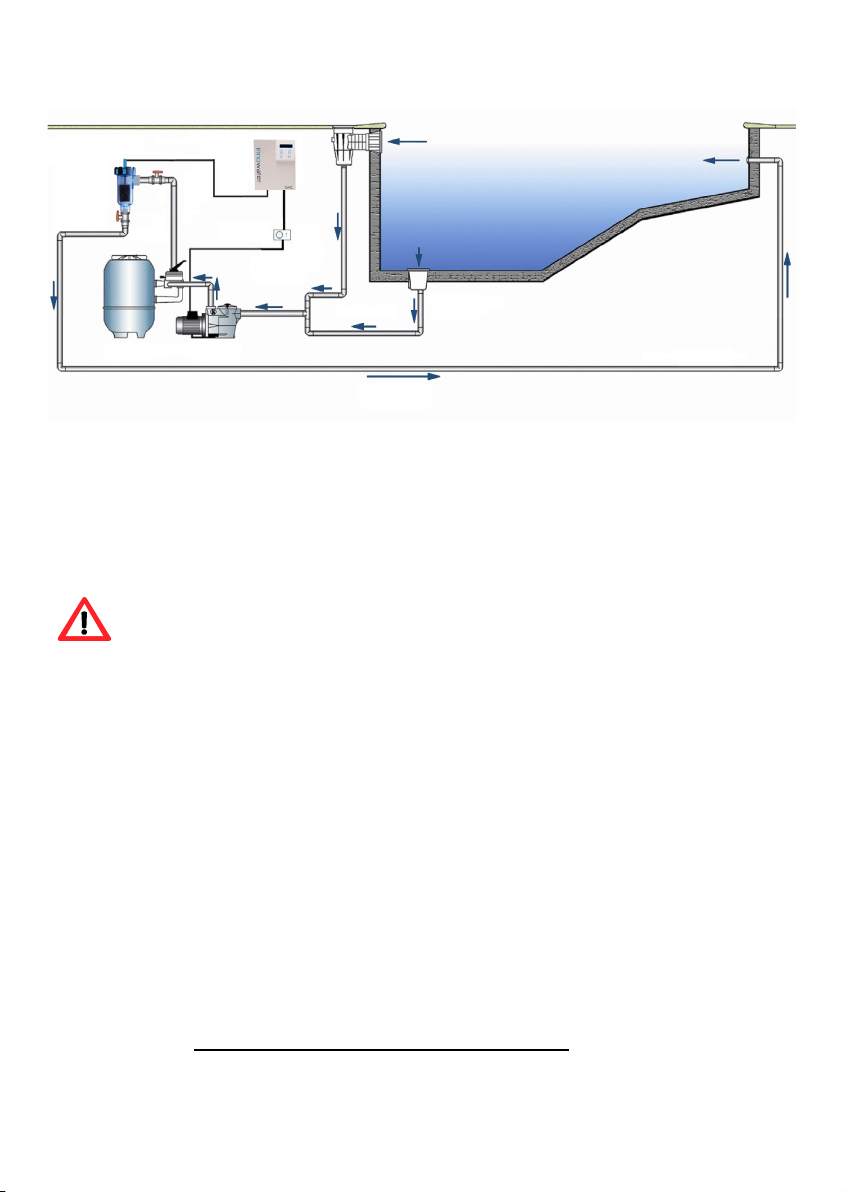

Cell housing

The cell housing must be installed in the return flow to the swimming pool and as

the last element the water goes through before returning to the pool: always after

the filter and any the heat pumps, solar panels, etc. Use special glue for rigid PVC

and wait until it completely dries before inserting the cell.

4 INSTALLATION

5 SMC

If an automatic pH regulation system has been installed, the

injection of the acid must take place unconditionally after the cell.

Otherwise, the electrodes will corrode due to the acid contact and

the warranty will be void. Do not place the acid tank near the

chlorinator with insufficient ventilation as the gases will corrode the

electronic components quickly. Any acid containers should be kept

outside of the plant room.

Whenever it is possible, a by-pass installation with three valves is recommended. This

allows the amount of water flowing through the cell to be adjusted and the swimming

pool to work with the cell housing disassembled. In any case, when there is a high

flowing single speed pump, the by-pass is necessary to reduce the speed of water

through the cell housing to lower the pressure and avoid vibrations.

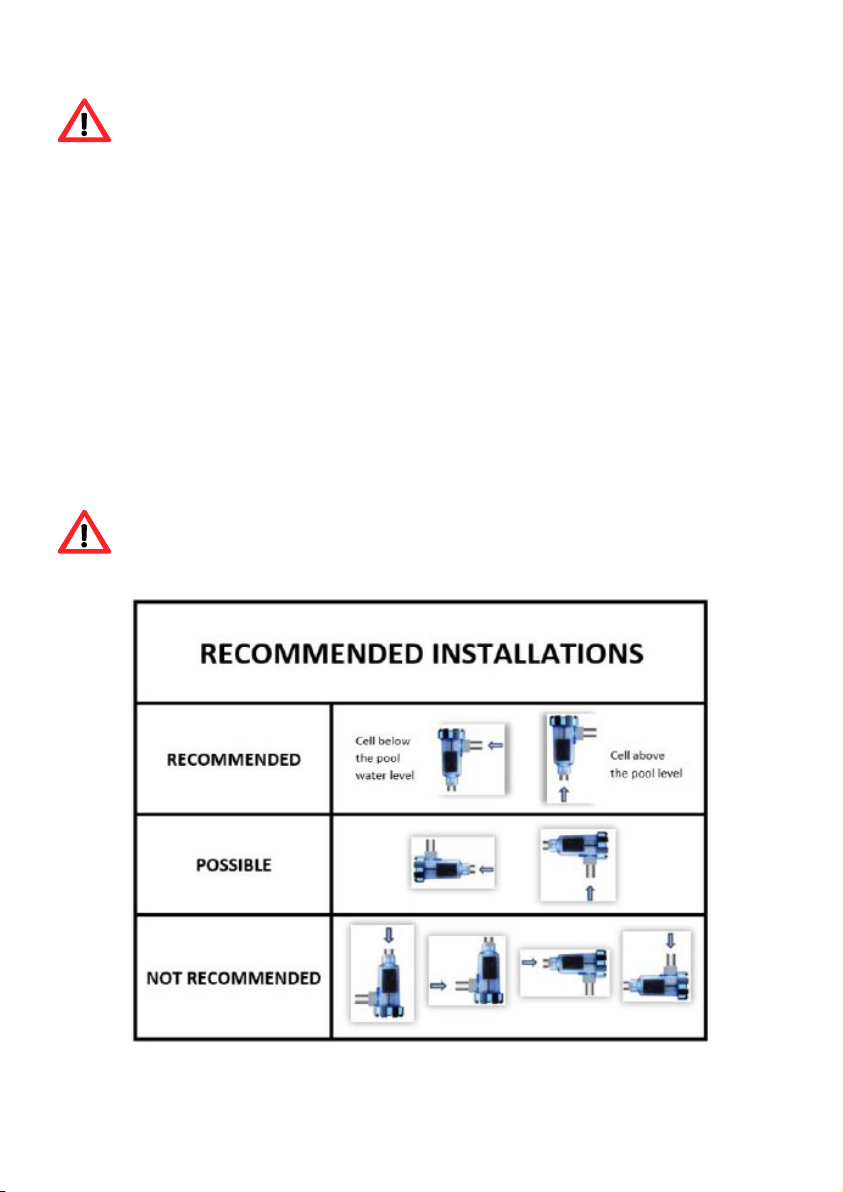

Although the vertical cell position is recommended, the cell housing may be installed

vertically or horizontally, according to the characteristics of your site. The vertical

position also allows for disassembling the cell without water spillage. Allow enough room

to unscrew the thread and extract the cell once the housing has been installed. WATER

MUST ENTER THE CELL THROUGH THE HIGHER SIDE OPENING.

A good filtration is essential in salt chlorination. Please, verify that your

filter and filtrating material are in optimal working conditions.

SMC 6

5. WATER PREPARATION

Use preferably water from the metropolitan network. If water from a different origin is

used, have it analyzed and verify so that there is no contraindication regarding salt

electrolysis (such as a high concentration of metals or calcium, for example). Make

also sure the water complies with health standards.

Balance the water before starting your chlorinator and add the amount of chlorine

stabilizer prescribed by the manufacturer (usually 1 kg per 25m3 of water). Do not

exceed the dose because this will block the disinfection action of the chlorine.

NOTE : Stabilizer prevents the disintegration of chlorine due to UV radiation. The lack

of stabilizer could make it difficult to reach a chlorine residual concentration during

high sunshine periods and will oblige you to produce more chlorine reducing the life

span of your cell. In general, and specially if you don't use stabilizer, we recommend

to chlorine during low sunshine hours.

The water must be clean and clear, presenting the following parameters:

Salt 5-6 kg/m3 (gr/l)

pH 7,2-7,6 (cement) 6,8-7,0 (polyester)

TAC 60-100 ppm

TH 15-20º French

Stabilizer 20-30 ppm (or according to the indications by the

manufacturer)

Temperature >10 º C

Cell

Insert the cell in the cell housing making sure that its open side window is pointing

to the side water inlet. Make sure the O-ring is fitted correctly and tighten the thread.

Then, connect the cell cable connector to the cell terminals. Verify that the connector is

orientated so that its small hole is aligned with the thin pin on the cell before trying to

plug the connector.

NOTA: The cell pins should only be tighten slightly and always by hand. Never use a

tool because the cell could be damaged. Water tightness is assured by the internal seal.

7 SMC

6. ADDING SALT

The chlorinator must remain OFF during this operation and until the

additive is completely dissolved. Operating the chlorinator with non

dissolved salt could irreversibly damage the cell and the power supply,

and lead to a void of the warranty.

Calculate the volume of the swimming pool and add 5 to 6 Kg of salt per cubic meter.

Make sure the chlorinator is disconnected and make the filtration system to work for at

least 24 hours.

For any new pool builds please wait for four weeks before adding salt

into any recently cement coated pool or discuss this with your pool

builder.

The salt dissolving process can be accelerated using the pool cleaner. Check the salt

concentration is between 5 and 6 kg/m3 using a kit from a specialized pool shop.

The salt chlorination process doesn’t consume salt. However, the salt concentration may

be reduced over time due to the rain or other periodic freshwater contributions (filling

up, filter cleaning, etc.). Whenever the salt concentration needs to be corrected, pour

salt as close as possible to the return lines. Never pour salt in the skimmers or in the

drain inlet.

SMC 8

7. OPERATION

The chlorinator and its different menus are controlled with a four key keypad. Three of

these keys, Λ , MENU and OK, also have a secondary function accessible by pressing

and holding down the corresponding key for 2 seconds

NOTE: At some points of activity or during a change of function the keyboard may

seem as it is not responding immediately. This is completely normal. Just wait a few

seconds for the task to be completed and the display will respond.

7.1 ON/OFF

The ON/OFF function (MENU key held for 2 seconds) turns the chlorinator

alternatively ON and OFF.

Once the chlorinator is switched on, the main production screen will appear:

This screen indicates the current production rate and the existing salt level in the

water. It may take a few seconds for the salt level to appear. If you are on a different

screen you can always come back to the production screen by pressing the MENU

button repeatedly.

To increase or decrease the chlorine production rate press the Λ or V arrows. The

chlorinator modules the production by varying the operating time in periods of 10

minutes. At 100% the chlorinator works constantly.

You will soon get to know the needs of your pool which will depend on the different

conditions (number of users, temperature, etc.) allowing you to anticipate in the

production setting. In general, to enjoy the benefits of salt water chlorination, we

recommend setting the minimum production rate that produces a crystal clear water

in your pool. Avoid chlorinating during high sunshine hours because chlorine will

quickly disappear due to the UV radiation and won’t have the time to disinfect your

pool thoroughly. We recommend to program the chlorinator during the night or at low

sunshine hours.

Production: 70%

Salt: OK

OFF

9 SMC

7.2 SHOCK FUNCTION

The shock function allows you to apply a shock treatment (chlorinator at 100%) for a

selectable period of time with automatic return to the previous production rate once the

shock period has ended. This feature is useful if the chlorine level has fallen suddenly

for some reason and you want to recover it quickly.

To activate the shock, go to the production screen and press Λ SHOCK for a few

seconds. The following screen will appear:

Select a number of hours, by using the Λ or V arrows

and press OK to accept or MENU to exit. If you click

OK, you will enter the Shock function and the

following screen will be displayed:

If you want to quit the Shock function press any key.

The following screen will be displayed:

Press OK to exit the shock function or MENU to

continue the shock treatment.

8 MENUS

8.1 Language menu

From the main screen press MENU. Press V until the following screen will appear:

Press OK to enter the Language menu.

Choose a language using the arrows Λ V and confirm

by pressing OK. Press MENU to return back to the

production screen. You can also exit without saving the

setting by pressing MENU.

8.2 Polarity Menu

The polarity applied to the cell is periodically reversed to remove calcium build-up. The

factory pre-programmed period is 8 hours and this is recommended. Depending on the

conditions of your pool it may be necessary to reduce this period in order to increase

the frequency of cleaning. Note that the longer this period is, the longer the cell

duration will be. A period of less than 4 hours will drastically reduce the life of the cell.

Inversely, you can increase this period if your cell doesn’t need to be cleaned that

Shock 7 h

Select duration

SHOCK 7 h

Remaining: 07:00

Exit Shock?

YES:OK NO:MENU

MAIN MENU

1 Language

SMC 10

frequently. We recommend, in general, to set this period to the larger number of hours

as long as there is not calcium build-up on the electrodes.

To change the polarity period, go to the production screen and press MENU. Press the

Λ or V keys once or more until the screen on the left will appear.

Then press OK.

Use the Λ or V buttons to select the period and then press OK to confirm and save the

setting. Then press MENU once or more to return to the production screen. You can

also exit without saving the setting by pressing MENU.

NOTE: When a polarity change is taking place, the unit

will enter a pause mode lasting 10 minutes. This will be

indicated by the screen on the left.

8.3 T V I Readings

TVI readings are used to assist us in diagnosing if any issues arise.

This menu allows you to read find the temperature inside

the control unit, the voltage applied to the cell and the

current passing through it. These parameters can be

very useful when servicing or diagnosing.

8.4 LCD contrast

Adjust the LCD contrast using the Λ or V keys.

Press OK to save and exit.

Chang. polarity

remaining: 8 min

MAIN MENU

2 Polarity per.

Polarity 7h

Select period

T= 29.8ºC

V= 23.40V I=3.4A

MAIN MENU

3 T V I readings

LCD contrast

- ■ ■ ■ ■ ■ ■ +

MAIN MENU

4 LCD Contrast

11 SMC

8.5 External control

TVI readings are used to assist us in diagnosing if any issues arise.

This function allows you to use the external control input to change automatically the

percentage of production. External control input works by connecting the two wires of

the control cable (optional) to a dry contact. If you have a cover, for example, you can

use it to reduce or stop production when the cover is extended. You can also use it to

control the chlorinator with a chlorine or redox regulator.

When the external control signal is detected the display

on the left and the production is locked to the control

percentage programmed.

NEVER connect the external control cable to a contact with voltage.

Connect it only to a dry contacts (voltage-free).

8.5.1 Contact type

Select the behaviour of the relay to be connected to the external control input:

Open = active Ext. Control will activate when the contact open

Closed = active Ext. Control will activate when the contact close

8.5.2 Production

Choose the production percentage when the external control signal is detected.

If you are using an Innowater chlorine or redox regulator, program the relay

output of the regulator in ON / OFF mode and the chlorinator input as Open = active

and Production if active 0%

CONTROL EXT: 70%

SALT: OK

MAIN MENU

5 Ext. control

OK EXT CONTROL MENU

1 on/off

EXT CONTROL MENU

2 Contact type

OK Contact type

open = active

EXT CONTROL MENU

3 Production

OK Production if

active 50%

SMC 12

8.6 pH config

This menu is used with the pH Wireless option. See the

Wireless Pump manual for configure the function.

8.7 Factory configuration

This menu is used for factory settings and its parameters

must not be modified by the user.

9 Fault messages

This screen is displayed when the water does not contact the probe in the cell and the

control system stops the production. Firstly verify that there is water in the cell and that

its level reaches the top where the probe is located.

A low water level in the cell may be due to a dirty filter, obstructed skimmer basket,

obstructed pump basket or to a pump not powerful enough. As soon as the water level

is restored the fault disappears.

This screen appears when the salt concentration in the water is too low. At this stage it

would be best to take a water sample up to your local pool professional for testing and

then add the required amount to maintain a level between 3000-4000 ppm. As previ-

ously advised, wait until the additive is completely dissolved before running the chlorin-

ator. Then press any key to restart the chlorinator.

PLEASE NOTE: This screen can also be displayed if the water temperature is too low, if

there is a bad electrical connection between the control unit and the cell or if there is

calcium built up on the electrodes. If the water test shows your salt levels to be correct

please assess the cleanliness of your cell, the cell connection or it may be a fact of cold

water temperature only.

MAIN MENU

6 pH config

MAIN MENU

7 Factory conf.

LOW WATER

LEVEL IN CELL

SALT TOO

LOW

13 SMC

10. RECOMMENDATIONS AND WARNINGS

The bipolar cells of your Innowater chlorinator have been manufactured using an

exclusive technique and rigorous quality controls conferring extraordinary duration and

resistance. However, there are several factors that may irreversibly reduce the

properties of any electrode that you should avoid in order to obtain the best

performance and longest lifespan of your chlorinator. These are:

- Operating with calcium build up on the electrodes

- Excessive chlorine concentration (chlorine is corrosive above 3.0 ppm)

- pH too low or too high

- Insufficient salt concentration

- Adding salt to the pool with the chlorinator working

- pH corrector acid injection before the cell housing, in the

skimmers or in the bottom drain inlet

We recommend you to periodically check the cell for calcium build up, corrosion or

leakage. The rods insulation and top sealing must be in perfect condition. If there is any

damage please send the cell to the technical service for replacement.

NEVER operate the chlorinator if:

- Your installation is not provided with a residual current circuit breaker

- Water is not flowing through the cell

- Valves are closed

- The filter is being cleaned

- The swimming pool is being emptied

- The water is frozen

- Electrodes are blocked by calcium build-up

SMC 14

11. MANUAL CELL CLEANING

Your Innowater chlorinator is provided with a self-cleaning polarity change system

that in normal conditions eliminates maintenance work. However, in exceptional

cases, when the calcium concentration is very high (very hard water, old concrete

pools), polarity change may not be enough to completely eliminate the calcium build

up. Visually inspect the cell regularly to detect the presence of calcium and, if

necessary, clean the cell manually. Let the cell dry completely during one or more

days for the calcium build up to detach by itself. You can help this by slightly knocking

the cell but do not introduce any element that could scratch the electrodes. Their

coating is fragile. You can also use a high pressure water jet. DO NOT USE ANY

METALLIC OR STABBING ELEMENT TO SCRATCH THE ELECTRODES.

If you are not able to remove the calcium build up in the way described, proceed as

follows:

1 Turn off the pump and the chlorinator.

2 Disconnect the power cable for the cell, unscrew the thread lock and extract the

cell.

3 Immerse the electrodes in a hydrochloric acid solution made from 1 part of acid

and 9 parts of water. Do not immerse the rods or the cap of the cell. The hydrochloric

acid will react with the calcium and will dissolve it producing a fizzing sensation.

4 Once the calcium build up has dissolved, rinse the cell immediately with

freshwater, dry the terminal area properly and reinstall the cell in its housing.

Never leave the cell in the acid solution for more than 5 minutes.

Do not scratch the electrodes with metal objects. For safety

reasons, always add the acid into the water and never inversely.

15 SMC

12. WARANTY, TECHNICAL SERVICE AND SPARE PARTS

Warranty

1. The electrolytic cell and the control unit will be guaranteed for 3 years against any

manufacturing defect.

2.The manufacturer declines any responsibility in the following cases:

a. If the instructions in this manual are not followed

b. Faulty electrical connections

c. Accidental damage

d. Damage due to water in the control board

e. Pump of more than 1.5 V power without installation of a “By-

Pass” (according to assembly diagram on page 4)

f. If acids are poured into the skimmers or cell without having disconnected

the rectifier.

g. Presence of an acid tank near the chlorinator with insufficient ventilation.

h. Operation with calcium built up on the electrodes.

3. The chlorinator shipping cost will be paid by the client/distributor.

4. It should be clarified that the Innowater chlorinator installation is completely

independent from the filtration equipment, pump or multi-port valve. All they have in

common is their connection.

Spare parts

Innowater have spare parts available at your disposal via a network of pool shops

around the world. The use of non-original parts or the manipulation of the equipment by

personnel not authorised by Innowater may cause serious problems to your chlorinator

and will void the warranty.

If you do require any servicing or spare parts please contact us directly at

www.innowater.es.

This manual suits for next models

3

Table of contents

Other Innowater Water Filtration System manuals