2. Device information

These instructions contain important information about safe

and professional assembly, commissioning and maintenance

of the boiler.

These instructions are for installers who have knowledge for

work with heating installations due to their professionalism and

experience.

2.1 Overview of types

This manual applies to the following types:

2.1.1 Declaration of conformity

We declare that the devices are tested in accordance with the

directives 2014/35/EU (Low Voltage Directive, LVD) and

2014/30/EU (Electromagnetic Compatibility Directive, EMC).

2.1.2 Proper use

The boiler can only be used for heating hot water and indirectly for

preparation of hot water. To ensure proper use, one must follow the

operating instructions, the data on the factory tile and the technical

data.

2.2 Instructions for installation

Use only original spare parts of the manufacturer or

spare parts approved by the manufacturer. There shall

not be any responsibility for damages caused by spare

parts which have not been delivered by the

manufacturer

When installing the heat system please abide to the following:

Valid regulations in construction industry

Regulations and norms on safety-technical equipment of

heating installations

Changes on the place of mounting according to valid

regulations

2.3 Operating instructions

When working with heating installation follow next instructions:

Boiler should work in working range up to max temperature

of 90°C and min pressure of 0.4 bars to max pressure of 3

bars, which should be controlled on regular basis

Boiler should be operated only by adults with technical

knowledge and qualifications to work with heating systems

and which are acquainted with the instructions and operation

of the boiler

Do not close safety valve

Inflammatory objects must not be put on the boiler surface

or close to it (within safety distance)

Boiler surface clean only with non-inflammatory products

Inflammatory substances do not keep in the room for boiler

installation (e.g. petroleum, oil, etc.)

No lids should be opened during the operation

Keep a safe distance according to the applicable local

regulations

2.4 Freezing protection agents and

inhibitors

It is not allowed to use protective products against frost neither

inhibitors. Id it is not possible to avoid anti-frost protection then

should use anti-frost products allowed for heating installations.

Anti-frost products:

Reduce lifetime of the boiler and its parts

Reduce heat transmission

2.5 Norms, regulations and standards

The product is in compliance with the following norms and

regulations:

BS EN 50110-1:2013; EN 50110-1:2013 –Operation of electrical

installations - Part 1: General requirements

BS EN 55014-1:2017; EN 55014-2:2015; EN 55014-1:2017; EN

55014-2:2015 –Electromagnetic compatibility - Requirements for

household appliances, electric tools and similar apparatus - Part 1:

Emission - Part 2: Immunity - Product family standard

BS EN 60335-1:2012; EN 60335-1:2016 Household and similar

electrical appliances - Safety - Part 1: General requirements

BS EN 61000-3-2:2019; EN 61000-3-2:2019 Electromagnetic

compatibility (EMC) - Part 3-2: Limits - Limits for harmonic current

emissions

BS EN 61000-3-3:2013/A1:2019; EN 61000-3-3:2014/A1:2020

Electromagnetic compatibility (EMC) - Part 3-3: Limits - Limitation

of voltage changes, voltage fluctuations and flicker in public low-

voltage supply systems

2.6 Tools, materials and auxiliary

components

Boiler installation and maintenance requires standard tools

used in the area of installation of heating systems, plumbing

and electrical installations.

2.7 Minimum spacing and flammability of

construction materials

Depending on valid regulations, other minimum distances

could be applied, different than mentioned below.

Comply with regulations of electrical installations and

minimum distances which are in force in the subject

country

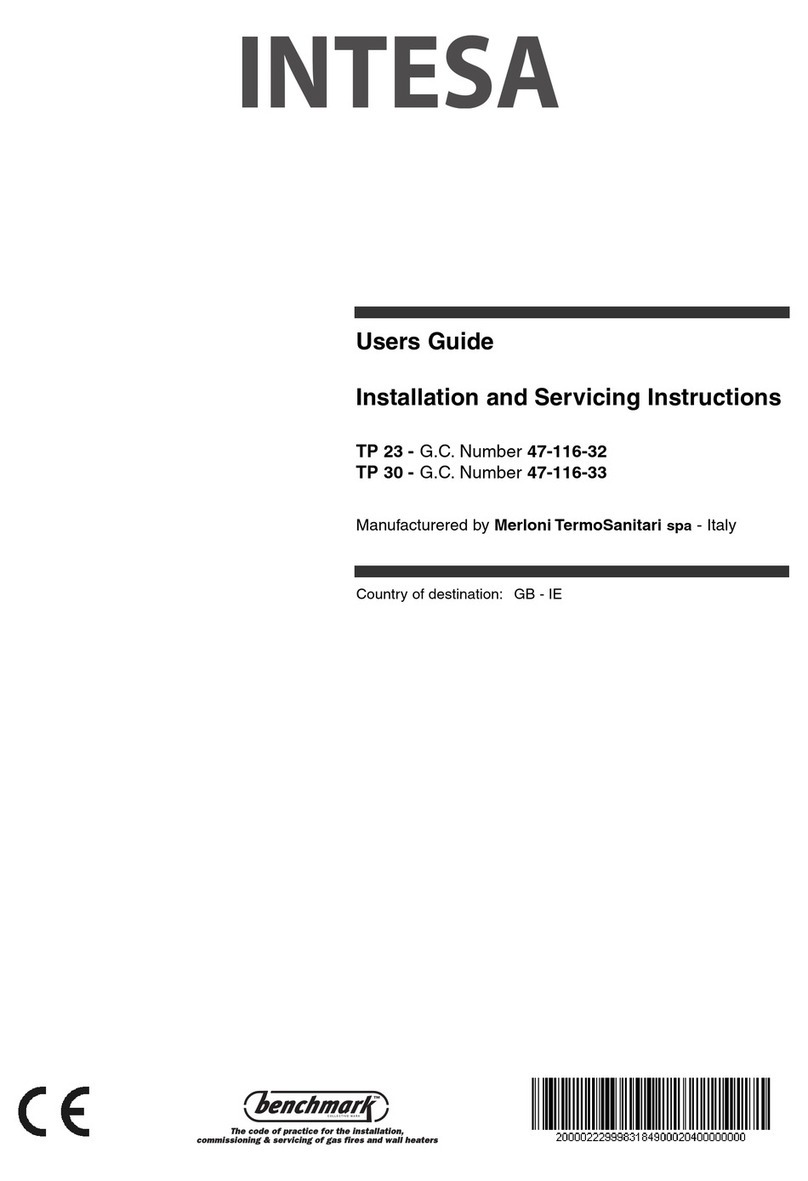

Minimum distance for heavy inflammable and self-

extinguishing materials is 200 mm

Inflammability of components

Asbestos, stone, wall tiles, baked

clay, plaster (with no organic

additives)

With smaller

quantity of

added

elements

(organic

components)

Plaster cardboards plates, base

felt, glass fibres, plates of

ACUMIN, ISOMIN, RAIOT,

LOGNOS, VELOX, AND

HERACLITUS

Beech, oak, veneered wood, felt,

HOBREX, VERSALIT and

UMAKARTplates

Pine, larch and spruce, veneered

wood

Asphalt, cardboard, cellulose

materials, tar-paper, plywood

plates, cork plates, polyurethane,

polystyrene, polyethylene, floor

fibre materials

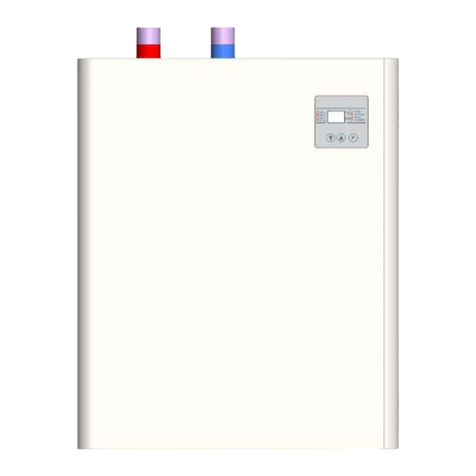

Adveco Standard

Electric Boilers

Table 1: Ignitable materials and composition of

elements according to DIN 410