3

1. General Information

This is a combined appliance f or the production of centr al heat-

ing (C.H.) and domestic hot water (D.H.W.). This appliance must

be used only for the purpose for which it is designed. The man-

ufacturer declines all liability f or damage caused b y improper or

negligent use.

Do not allow children or inexperienced persons to use the appli-

ance without supervision.

If you smell gas in the room, do not turn on light switches, use

the telephone or any other object which might cause spar ks.

Open doors and windows immediately to ventilate the room.

Shut the gas mains tap (on the gas meter) or the valve of the gas

cylinder and call your Gas Supplier immediately.

If you are going away for a long period of time, remember to shut

the mains gas tap or the gas cylinder v alve.

Before any intervention within the boiler it is first necessary

to cut off the electrical power supply by turning the external

switch to “OFF”.

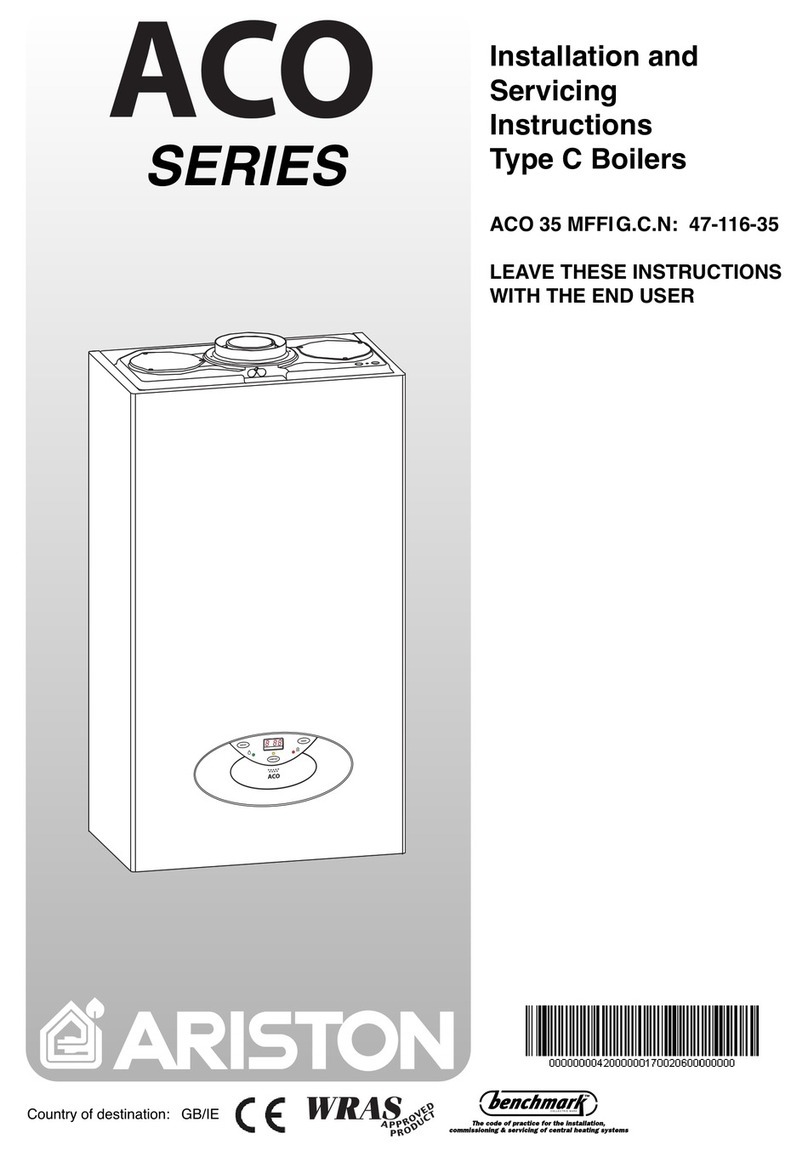

Control Panel

LEGEND:

A- On/Off button

B- Central heating temperature adjustment

C-Domestic hot water temperature adjustment

D- Heating system pressure gauge

E- Time clock

F- Central heating selector

G- Central heating L.E.D. (green)

H- Flue sensor L.E.D.(yellow)

I- Ignition failure (lockout) and/or overheat reset button

J- Overheat and/or ignition failure (lockout) L.E.D. (red)

K- ON/OFF L.E.D. (green)

To get the most out of y our boiler, we have provided you with

some useful advice on proper use and maintenance:

- Periodically check the system pressure

using the pressure gauge “D”, make sure

that the pressure is at 1.5 bar when the sys-

tem is off and cool. If the pressure is belo w

the minimum recommended value.

Consult your installer for checking and refill-

ing the system.

- The outer panels of the units case must only be cleaned with a

damp cloth. Do not use abr asive cleaners. The control panel

can be wiped with either a damp or dr y cloth. Spray polishes

must not be used on the control panel surf ace or knobs.Care

must be taken in preventing any liquid entering the appliance.

- If the water is very hard, it is recommended that a water soften-

er be added to the system so as to reduce the f ormation of

limescale in the heat e xchanger.This will ensure that the effi -

ciency of the unit remains the same o ver time, reducing gas

consumption and maintenance costs.

-If the boiler should be out of use f or a prolonged per iod, it is

recommended that the electr ical power supply be disconnect -

ed and that the e xternal gas coc k be closed. If low tempera-

tures are expected, the boiler and system pipe work should be

drained in order to prevent frost damage.

- To improve comfort and tak e full adv antage of the heat pro-

duced by the boiler, it is recommended that an external (room)

thermostat be installed.

- It is good practice to clean and service the appliance and cen-

tral heating system every year.

Call an Authorised Service Centre.

2. Operating Instructions

Installation, start-up, adjustments and maintenance must be

performed by a competent per son only, in accordance with

the current Gas Safety (Installation & Use) Regulations and

the instructions pr ovided. Improper installation may cause

damage or injury to individuals, animals and personal prop-

erty, for which the manufacturer will not be held liable.

To ensure efficient and saf e operation it is recommended

that the boiler is serviced annually by a competent person.

If it is kno wn or suspected that a fault e xists on the appli-

ance, it must not be used until the fault has been corrected

by a competent person.

D

Ignition Procedure

Press button “A”. The green L.E.D. “K” will

illuminate indicating that the boiler is ready to

operate. The centralised electronic control unit

will ignite the b urner, upon demand f or either

C.H. or D.H.W. If, after approximately 10 sec-

onds, the b urner has not ignited, the boiler

safety devices will shut off the gas and the red

L.E.D. “I” illuminates. To reset the ignition sys-

tem, the reset “J” must be pressed and

released. Should the boiler f ail to ignite a sec-

ond time, check that the e xternal gas coc k is

open (see diagrams on the left). If the problem

persists, contact a local Service Agent.

IMPORTANT!! Always wait 2 min utes before

resetting each time.

K

A

I

J

USERS GUIDE