AE-Air HydroTech HRC Series Instruction manual

Installation, Operation, & Maintenance Manual

IOM 787702

Rev. B 3/22

HRC(C,X) High Rise Series

Water Source Heat Pump

HRC(C,X) HIGH RISE SERIES - IOM

2

HRC(C,X) HIGH RISE SERIES –IOM (REV. B 3/22)

COPYRIGHT

AE-Air works to continuously improve its products and as a result, it reserves the right to change design and specifications

without notice.

The warranty may be void unless the Startup & Performance Checklist is completed and returned to the warrantor. If the HVAC

unit is not installed properly, the warranty will be void, as the manufacturer cannot be held accountable for problems that stem

from improper installation.

©2022 AE-Air, 8273 Moberly Lane, Dallas, TX 75227

***WARNING TO INSTALLER, SERVICE PERSONNEL AND OWNER***

Altering the product or replacing parts with non-authorized factory parts voids all warranty or implied warranty and may

result in adverse operational performance and/or a possible hazardous safety condition to service personnel and

occupants. Company employees and/or contractors are not authorized to waive this warning.

HRC(C,X) HIGH RISE SERIES –IOM

HRC(C,X) HIGH RISE SERIES –IOM (REV. B 3/22)

3

TABLE OF CONTENTS

SAFETY CONSIDERATIONS

4-5

MODEL NOMENCLATURE

6-7

GENERAL INFORMATION

8

INTRODUCTION

8

STORAGE

9

SHIPPING & PACKAGE LIST

9-10

UNIT INSPECTION CHECKLIST

11

UNIT DIMENSIONAL DATA

12-15

UNIT PHYSICAL DATA

16

ELECTRICAL DATA

17

INSTALLATION

18-28

CABINET CONFIGURATION

29-32

ELECTRICAL

33

APPLICATION

34-35

CONTROLS

36-41

PERFORMANCE DATA

42

WIRING DIAGRAMS

43-50

CIRCUIT SCHEMATIC

51

STARTUP INSTRUCTIONS

51-52

STARTUP & PERFORMANCE CHECKLIST INSTRUCTIONS

52

MAINTENANCE & SERVICE

53

TROUBLESHOOTING

54-55

SUPPORT/REFERENCE MATERIAL

56

STARTUP & PERFORMANCE CHECKLIST

57

NOTES

58

HRC(C,X) HIGH RISE SERIES - IOM

4

HRC(C,X) HIGH RISE SERIES –IOM (REV. B 3/22)

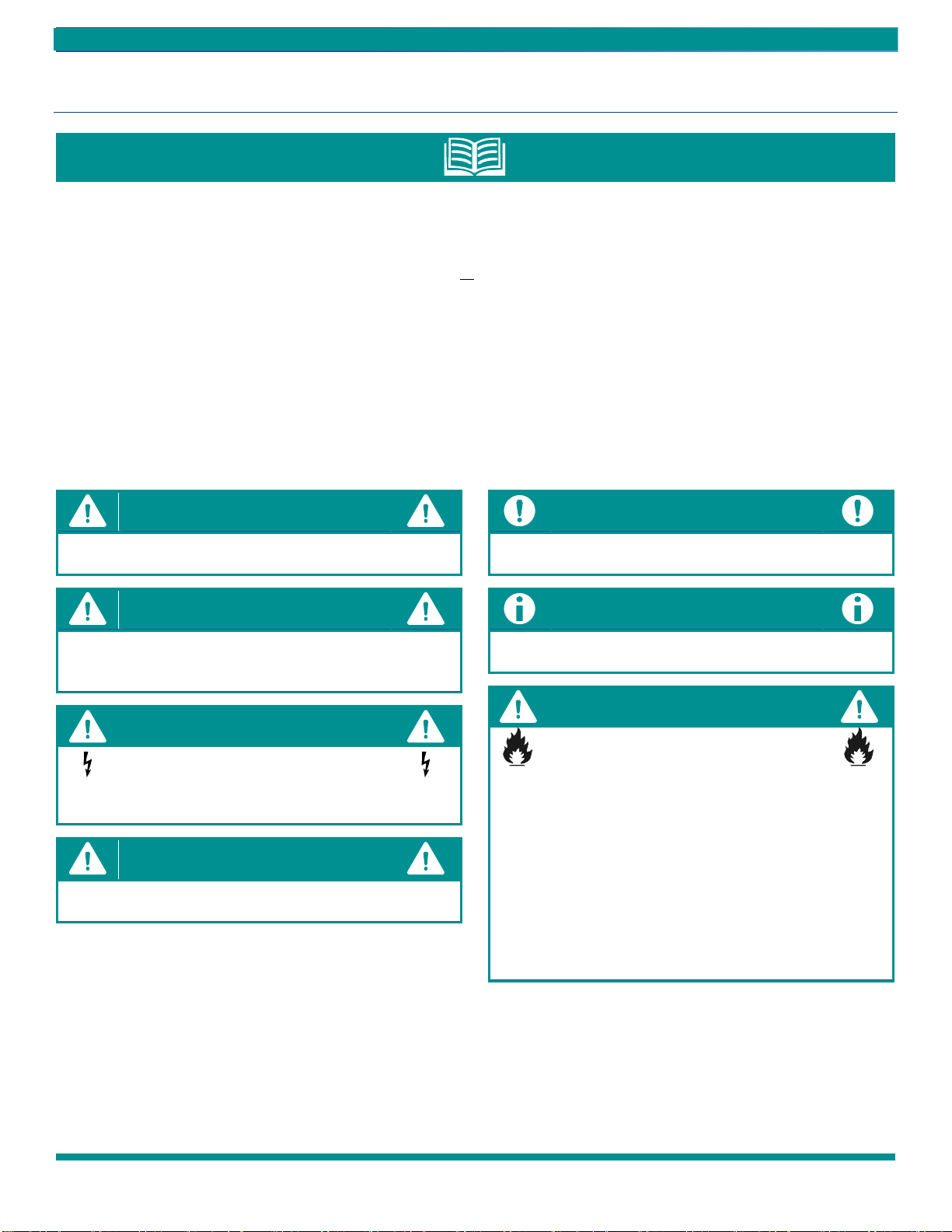

SAFETY CONSIDERATIONS

1. READ THE ENTIRE MANUAL BEFORE STARTING THE INSTALLATION.

2. These instructions are intended as a general guide and do not supersede national, state, or local codes in any way.

3. Altering the product, improper installation, or the use of unauthorized factory parts voids all warranty or implied warranty

and may result in adverse operation and/or performance or may result in hazardous conditions to service personnel and

occupants. Company employees or contractors are not authorized to waive this warning.

4. This product should only be installed and serviced by a qualified, licensed, and factory authorized installer or service agency.

5. All “kits” and “accessories” used must be factory authorized when modifying this product. Refer and follow instructions

packaged with the kits or accessories when installing.

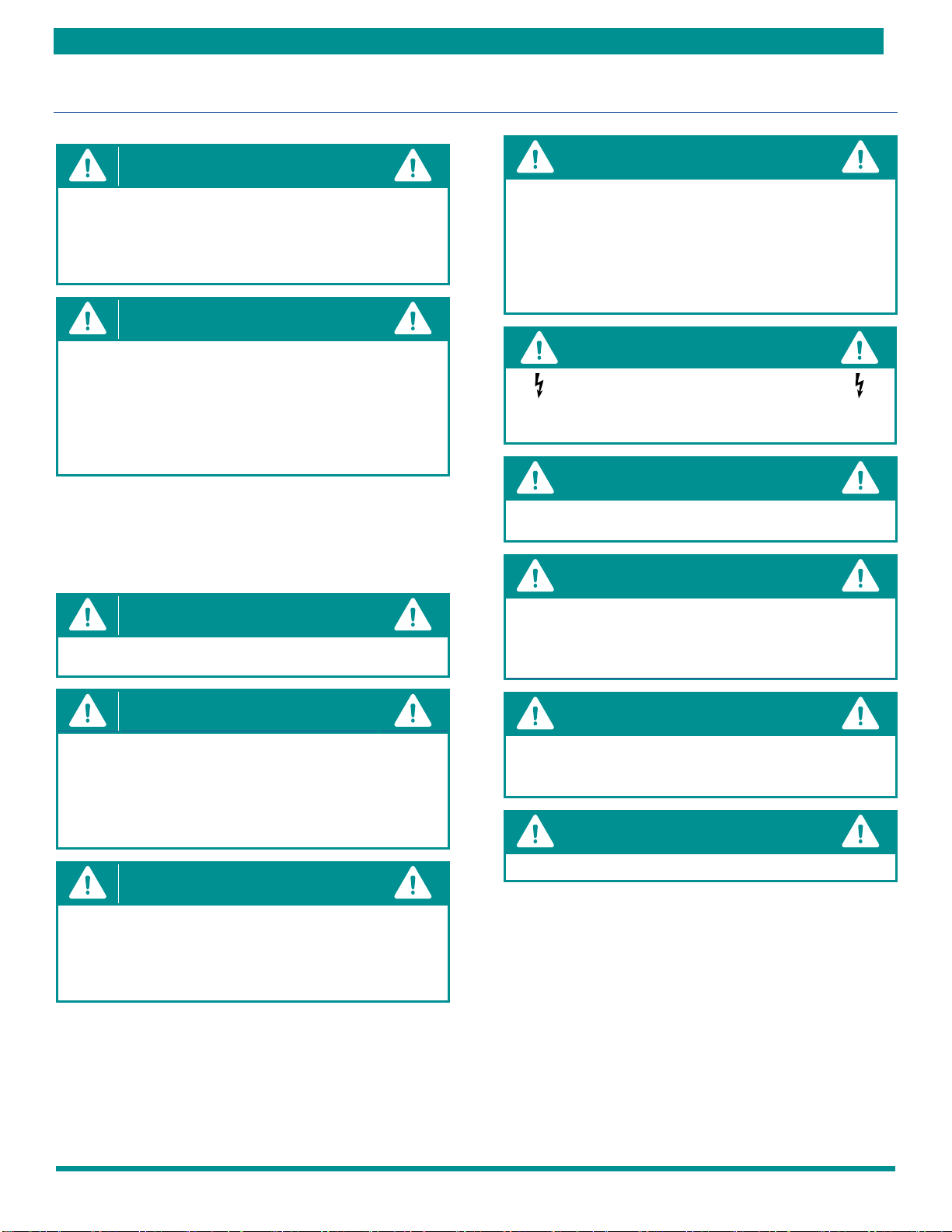

RECOGNIZE THE FOLLOWING SAFETY NOTATIONS THROUGHOUT THIS MANUAL

AND POSTED ON THE EQUIPMENT:

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation or unsafe

practices that could result in severe personal injury or death

and/or damage to property.

This warning signifies potential electrical shock hazards that

could result in personal injury or death.

The CAUTION symbol indicates a potentially hazardous

situation that may result in minor or moderate injury.

Suggests important procedure steps to insure proper

installation, reliability, or operation.

Used to highlight suggestions, which may result in enhanced

installation, reliability or operation.

Failure to follow safety warnings exactly could result in

dangerous operation, serious injury, death or property

damage.

Improper servicing could result in dangerous operation,

serious injury, death or property damage.

Before servicing, disconnect all electrical power to

the HRC(C,X) water source heat pump.

When servicing controls, label all wires prior to

disconnecting. Reconnect wires correctly.

Verify proper operation after servicing.

HRC(C,X) HIGH RISE SERIES –IOM

HRC(C,X) HIGH RISE SERIES –IOM (REV. B 3/22)

5

SAFETY CONSIDERATIONS CONTINUED

Mechanical components and filters can become clogged with

dirt and debris, which can cause damage to the system.

The manufacturer does not warrant equipment subjected to

abuse. Construction debris can void warranties and liability

for equipment failure, personal injury, and property damage.

Material in this shipment has been inspected at the factory

and released to the transportation agency in good condition.

When received, a visual inspection of all cartons should be

made immediately. Any evidence of rough handling or

apparent damage should be noted on the delivery receipt in

the presence of the carrier’s representative. If damage is

found, a claim should be immediately filed against the carrier.

These models are designed for indoor installation only.

Installation of this equipment, wiring, ducts, and any related

components must conform to current agency codes, state

laws, and local codes. Such regulations take precedence over

general instructions contained in this manual.

DO NOT USE FOR HEATING AND COOLING BUILDINGS OR

STRUCTURE UNDER CONSTRUCTION!

Improper installation, adjustment, alteration, service, or

maintenance can cause property damage, personal injury or

loss of life. Refer to the user’s information manual provided

with this water source heat pump. Installation and materials,

service must be performed by a qualified installer, or service

agency.

Installation and service must be performed by a licensed

professional installer (or equivalent), or service agency.

Attempting to install or repair this unit without such

background may result in product damage, personal injury or

death.

These instructions are intended as an aid to qualified,

licensed service personnel for proper installation, adjustment

and operation of this unit. Read these instructions thoroughly

before attempting installation or operation. Failure to follow

these instructions may result in improper installation,

adjustment, service or maintenance possibly resulting in fire,

electrical shock, property damage, personal injury or death.

Disconnect all power before servicing. Failure to do so may

result in property damage, personal injury, or death.

Use care when handling compressors. Some surfaces could

be hot!

Compressors should NOT be used to evacuate the air

conditioning system. Vacuums this low can cause internal

electrical arcing resulting in a damaged or failed

compressor.

The unit must be permanently grounded. Failure to do so

can cause electrical shock resulting in severe personal

injury or death.

“USE COPPER SUPPLY WIRES ONLY!”

HRC(C,X) HIGH RISE SERIES - IOM

6

HRC(C,X) HIGH RISE SERIES –IOM (REV. B 3/22)

SAFETY CONSIDERATIONS CONTINU ED

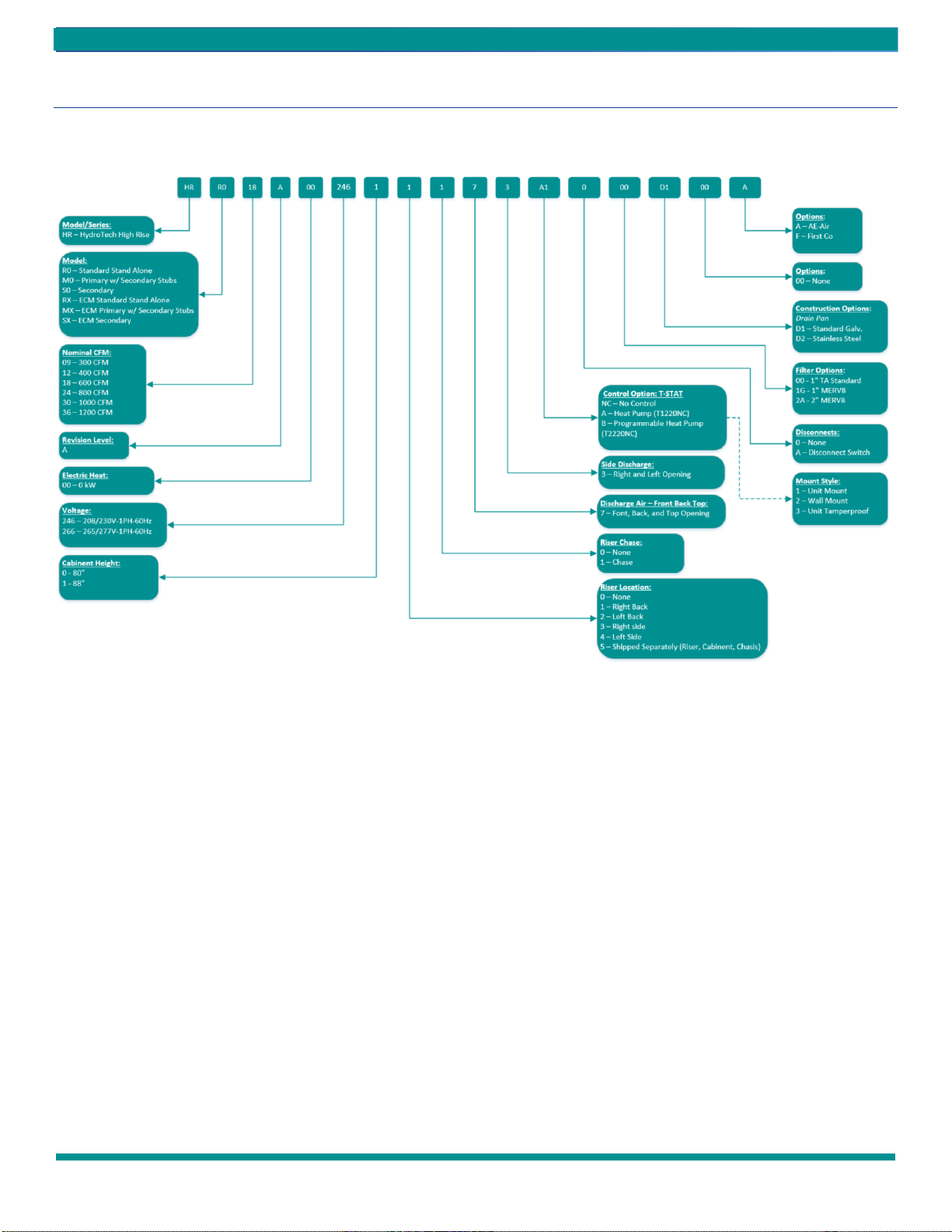

MODEL NOMENCLATURE

FIGURE 1 –Cabinet Model Nomenclature

HRC(C,X) HIGH RISE SERIES –IOM

HRC(C,X) HIGH RISE SERIES –IOM (REV. B 3/22)

7

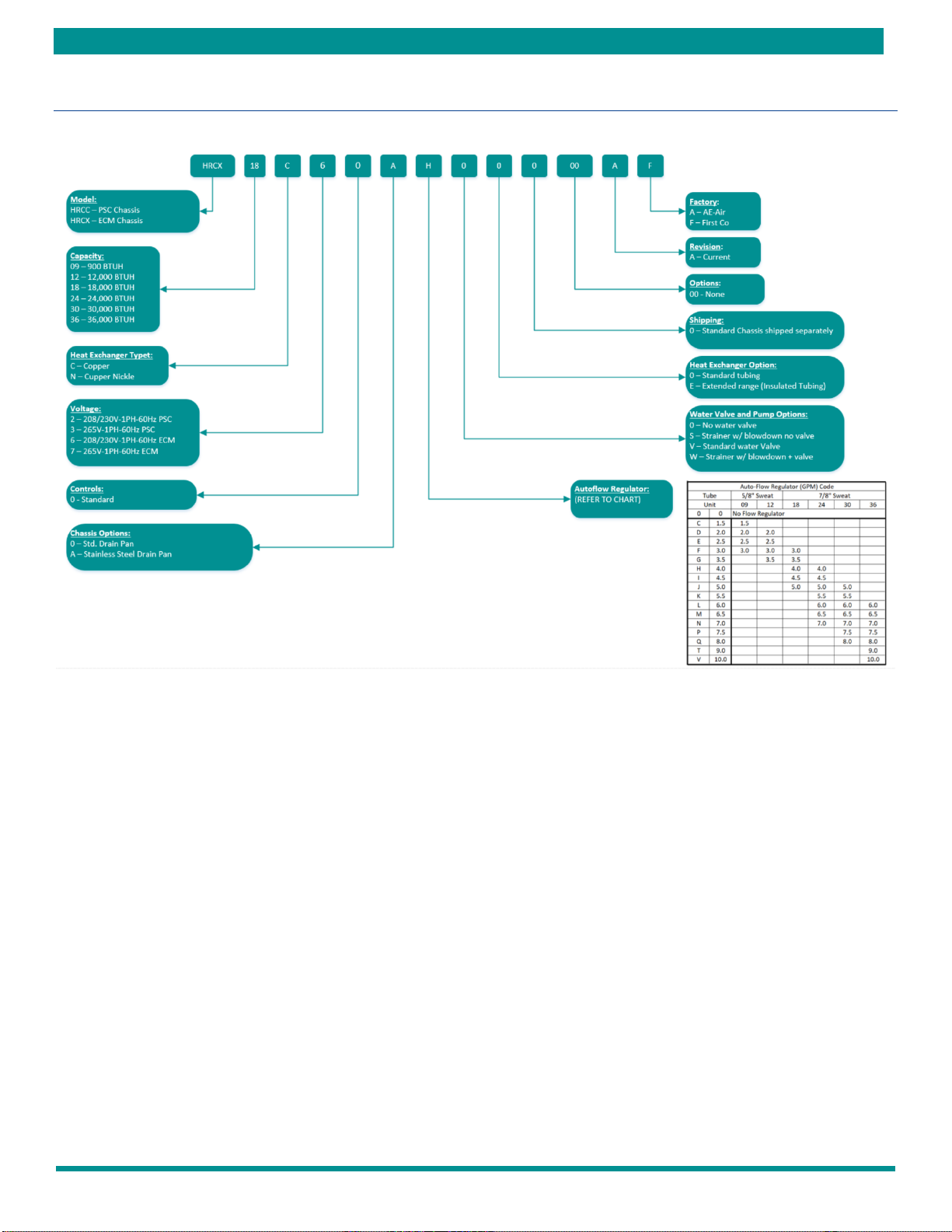

MODEL NOMENCLATURE CONTINUED

FIGURE 2 –Chassis Model Nomenclature

HRC(C,X) HIGH RISE SERIES - IOM

8

HRC(C,X) HIGH RISE SERIES –IOM (REV. B 3/22)

GENERAL INFORMATION

DO NOT use these units as a source of heating or cooling

during the construction process. Mechanical components

and filters can become clogged with dirt and debris, which

can cause damage to the system.

The manufacture does not warrant equipment subjected

to abuse.

Before servicing equipment, ALWAYS turn off all power to

the unit. There may be more than one disconnect switch.

Electrical shock can cause injury or death.

Clear surrounding area of all tools, equipment, and debris

before operating this unit.

These instructions are provided for the installation of the

HRC(C,X) high rise water source heat pump specifically. For

any other related equipment, refer to the appropriate

manufacturer’s instructions.

This water source heat pump must never be operated

under any circumstances without an air filter in place.

Material in this shipment has been inspected at the

factory and released to the transportation agency in

good condition. When received, a visual inspection of all

cartons should be made immediately. Any evidence of

rough handling or apparent damage should be noted on

the delivery receipt in the presence of the carrier’s

representative. If damage is found, a claim should be

immediately filed against the carrier.

The HRC(C,X) high rise water source heat pump is designed

for indoor installation only. Installation of this equipment,

wiring, ducts, and any related components must conform

to current agency codes, state laws, and local codes. Such

regulations take precedence over general instructions

contained in this manual

Extreme caution must be taken that no internal damage

will result from screws that are drilled into the cabinet.

INTRODUCTION

The HydroTech HRC(C,X) series water to air heat pump

provide the best combination of performance, efficiency

and reliability in a compact form factor. The HRC(C,X)

series comes standard with PSC blower motors. It is also

available with ECM blower motors for high efficiency and

comfort. The heat pump features double compressor

vibration isolation for quiet operation, easy to remove

blower housing for quick service

All HRC(C,X) models are certified to AHRI ISO Standard

13256-1. The HRC(C,X) models are designed to operate

with fluid temperatures between 50°F to 110°F in

cooling mode and 50°F to 90°F in heating mode for

continuous operation. For operation below 50°F or

above 90°F entering water temperature, extended range

(insulated tubing) option is needed, and sufficient water

flow is required to prevent freezing. Antifreeze solution

is required for any application with entering water below

50 degree F.

Cooling Tower/Boiler and Geo Thermal applications

should have sufficient antifreeze solution when required

to protect against extreme conditions and equipment

failure. Frozen water coils are not covered under

warranty.

These installation instructions are intended as a general

guide only, for use by an experienced, qualified contractor.

Do not use this water source heat pump during any phase

of construction.

DO NOT use these units as a source of heating or cooling

during the construction process. Mechanical components

and filters can become clogged with dirt and debris, which

can cause damage to the system.

The manufacture does not warrant equipment subjected

to abuse.

HRC(C,X) HIGH RISE SERIES –IOM

HRC(C,X) HIGH RISE SERIES –IOM (REV. B 3/22)

9

STORAGE

Equipment should be stored in a clean dry, conditioned

area with maximum temperatures up to 120°F [48.89°C]

and minimum temperatures to 32°F [0°C]. Units should be

stored upright and in an indoor environment. It is

recommended to leave packaging on the unit until the

installation is to begin. Store or move chassis in an upright

position at all times. If stacking of chassis is required, do not

stack more than two units high.

Store cabinets how they are shipped (horizontal or

vertical), keeping them crated and on their pallets for

protection. Cabinets with risers should not be stacked

more than three units high. Failure to follow these

instructions may result in improper installation,

adjustment, service or maintenance, property damage,

personal injury or death.

DO NOT operate these units during the construction

process. Mechanical components and filters could become

clogged with dirt and debris, which can cause damage to the

system.

The manufacturer does not warrant equipment subjected

to abuse.

SHIPPING & PACKAGE LIST

Material in this shipment has been inspected at the factory

and released to the transportation agency in good

condition. When received, a visual inspection of all cartons

should be made immediately. Any evidence of rough

handling or apparent damage should be noted on the

delivery receipt in the presence of the carrier’s

representative. If damage is found, a claim should be

immediately filed against the carrier.

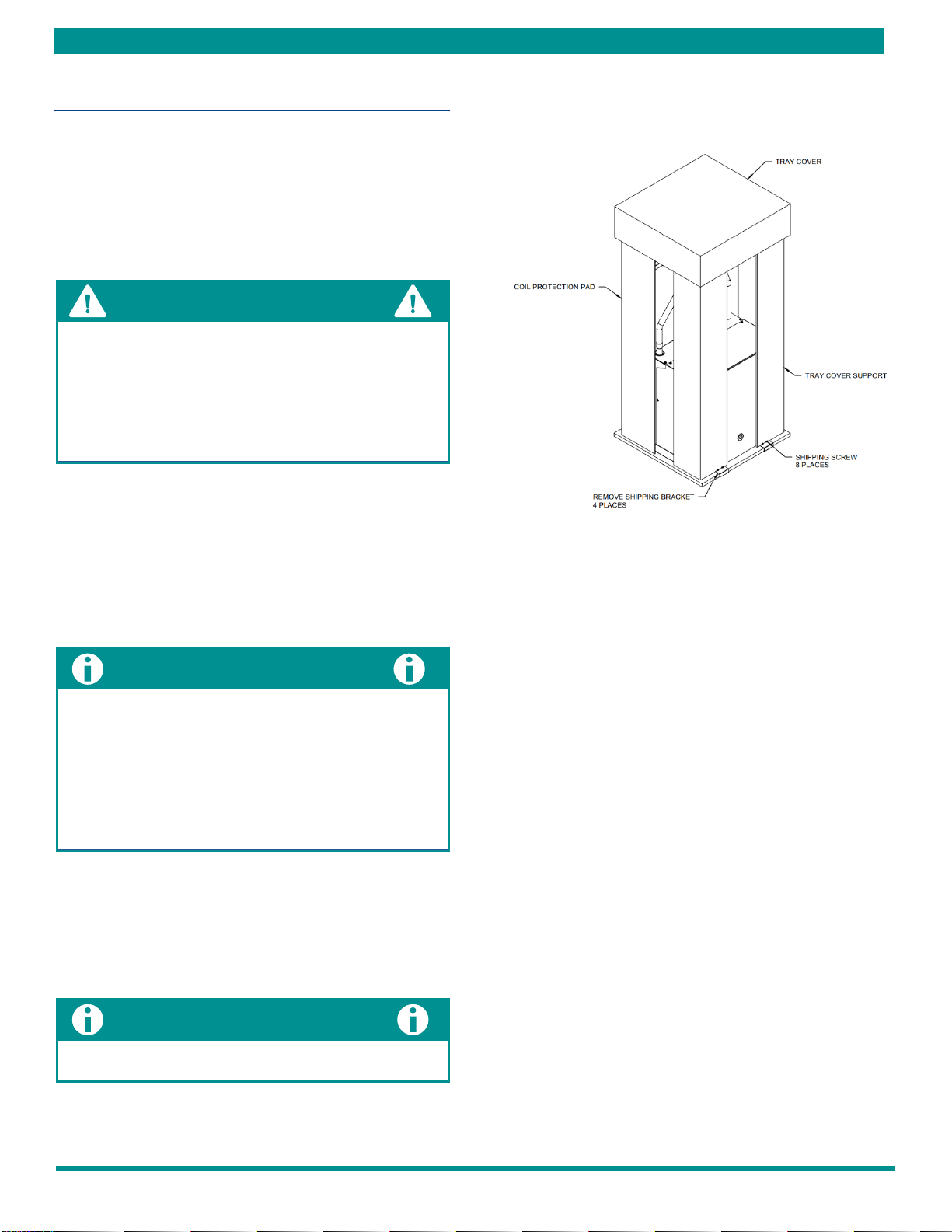

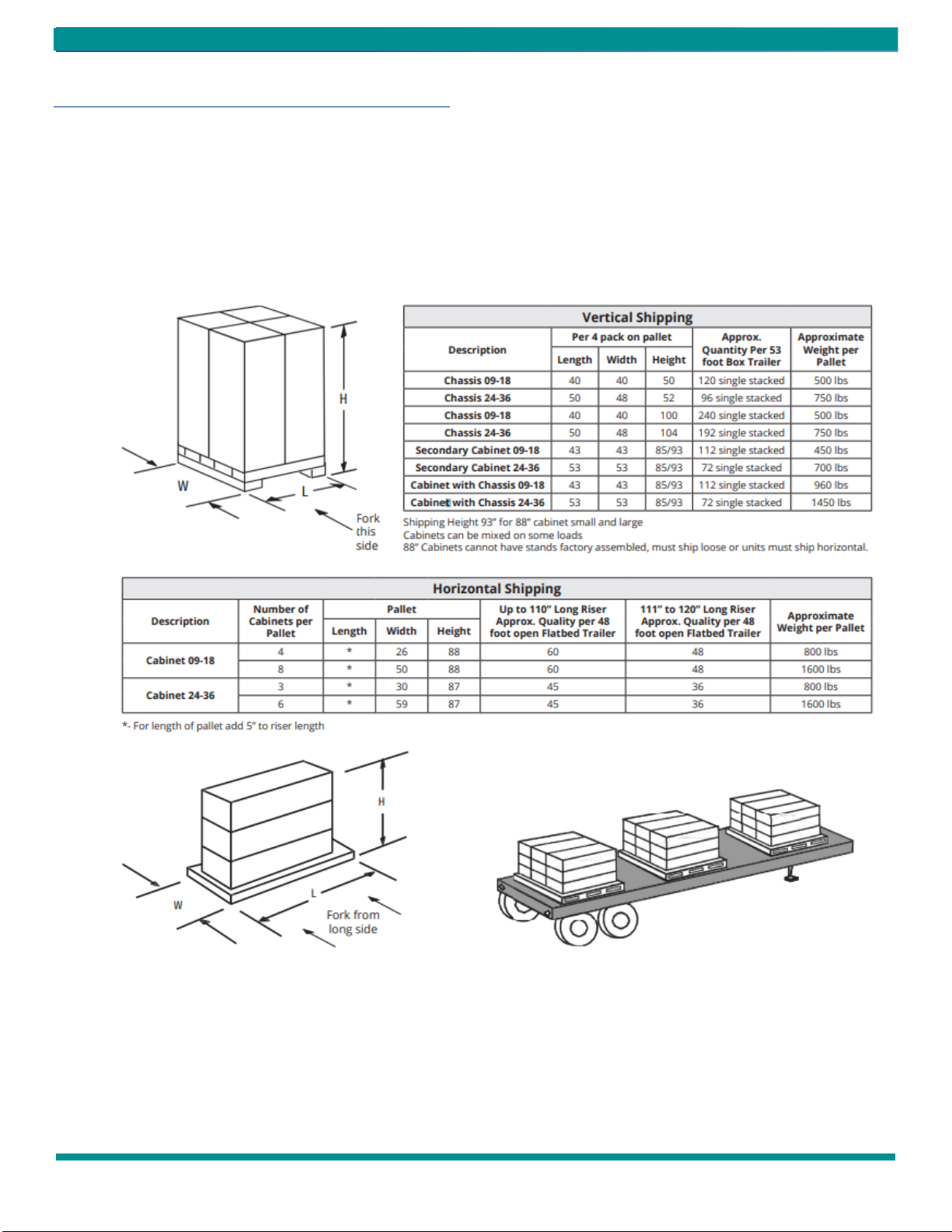

SHIPPING INSTRUCTIONS

HRC(C,X) chassis must remain in the upright position as

seen in FIGURE 3 –Standard Packaging throughout the

shipping and handling process to maintain a proper level of

oil in the compressor. HRC(C,X) cabinets are shipped in the

horizontal or vertical position.

Shrink-wrap is located around the unit for protection.

Remove before installation.

FIGURE 3 –Standard Packaging

PACKAGE LIST

The units will be shipped with the following items:

1- HRC(C,X) high rise unit:

A- Shipping brackets

a. Screws

2- Literature package

A- IOM - Installation & Operations Manual

Check the unit for shipping damage; if found, immediately

contact the last carrier.

HRC(C,X) HIGH RISE SERIES - IOM

10

HRC(C,X) HIGH RISE SERIES –IOM (REV. B 3/22)

SHIPPING & PACKAGE LIST

Units Are Shipped FOB Factory

Chassis can be shipped 2 ways.

1. Upright in carton 4 per pallet, see FIGURE 4 –Shipping

Options.

2. Upright inside cabinet (risers shipped separate or

customer supplied) 4 per pallet, see FIGURE 4 –Shipping

Options

FIGURE 4 –Shipping Options

HRC(C,X) HIGH RISE SERIES –IOM

HRC(C,X) HIGH RISE SERIES –IOM (REV. B 3/22)

11

UNIT INSPECTION CHECKLIST

Complete the inspection procedures below before

preparing unit for installation:

1) Visually inspect unit for any shipping damage. Damage

must be reported immediately to the shipping

company to make a claim.

2) Ensure that the carrier makes proper notation of any

shortages or damage on all copies of the freight bill

and completes a common carrier inspection report.

3) Verify that unit nameplates on the data label match

the sales order or bill of lading (including, unit

configuration, size and voltage).

4) Immediately before installation, remove unit front

panel and verify that all electrical connections are

tight and that there are no loose wires.

5) Check to make sure that the refrigerant piping is free

from any kinks and there is no interference between

unit piping and sheet metal or electrical wires.

6) Check that the blower spins freely within the housing

and that there are no obstructions between the wheel

and housing. The wheel can sometimes come loose in

shipping.

7) Ensure that the evaporator distributor tubes are not

touching one in another and that they are over the

drain pan.

8) Check the air-coil fins for any damage during shipping.

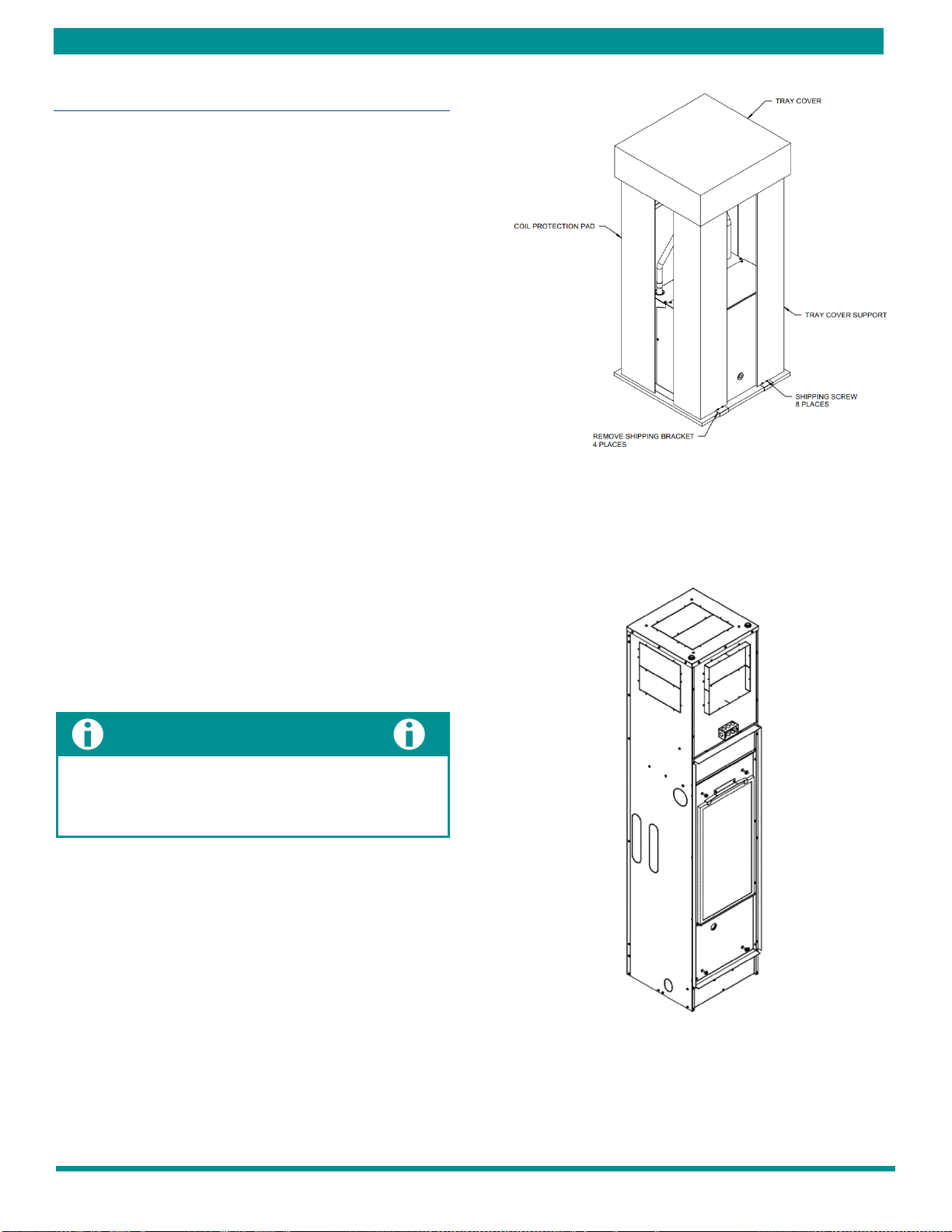

9) Ensure that the shipping screws are removed from

the unit. Refer to FIGURE 5 –Standard Packaging with

Brackets - Chassis for more information.

Check the unit nameplate for correct voltage with the

plans before installing the equipment. Also, make sure all

electrical ground connections are made in accordance

with local code.

FIGURE 5–Standard Packaging with Brackets –Chassis

FIGURE 6 –Standard Cabinet

HRC(C,X) HIGH RISE SERIES - IOM

12

HRC(C,X) HIGH RISE SERIES –IOM (REV. B 3/22)

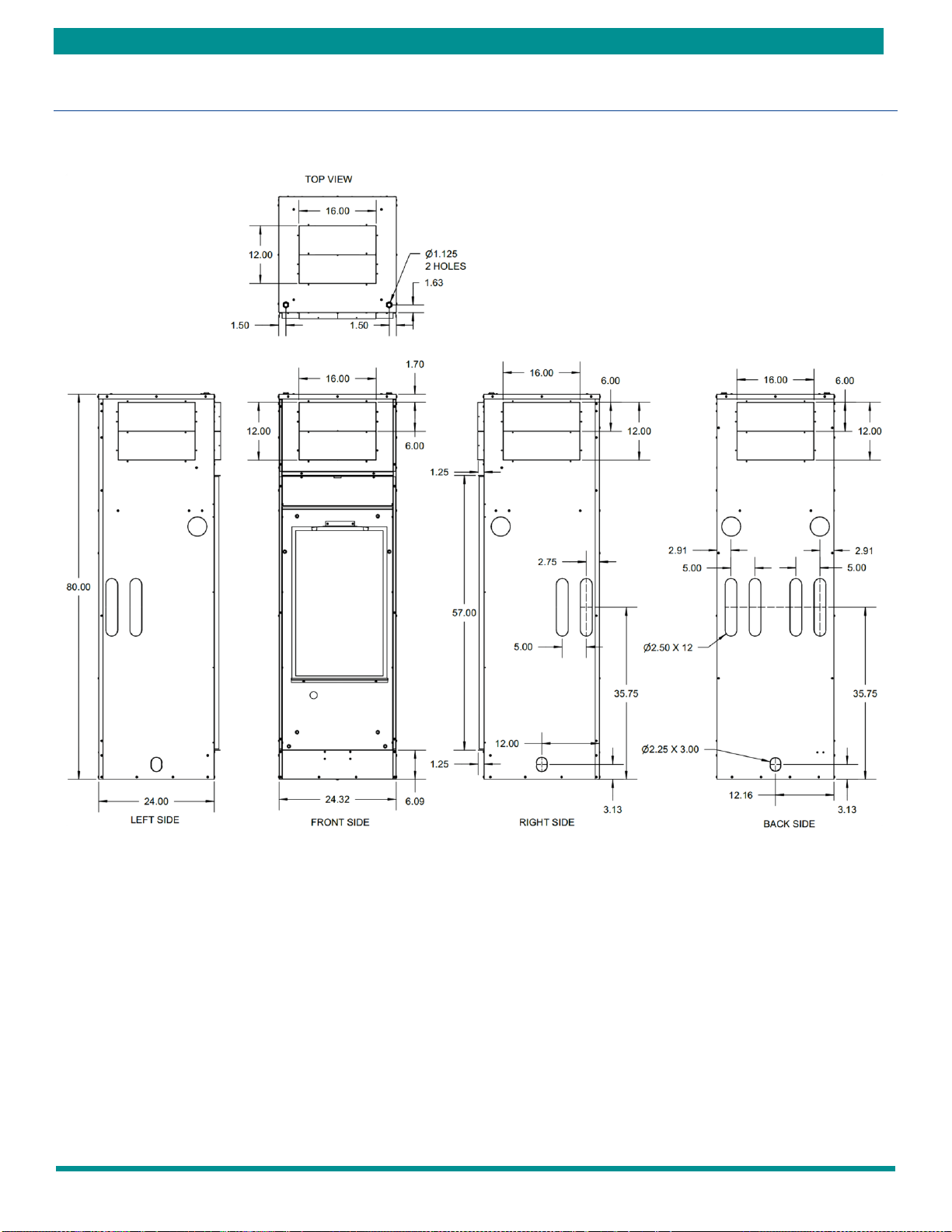

UNIT DIMENSIONAL DATA

FIGURE 7 –Unit Dimensions

HRC(C,X) HIGH RISE SERIES –IOM

HRC(C,X) HIGH RISE SERIES –IOM (REV. B 3/22)

13

UNIT DIMENSIONAL DATA CONTINUED

FIGURE 8 –Unit Dimensions

HRC(C,X) HIGH RISE SERIES - IOM

14

HRC(C,X) HIGH RISE SERIES –IOM (REV. B 3/22)

UNIT DIMENSIONAL DATA CONTINUED

FIGURE 9 –Unit Dimensions

HRC(C,X) HIGH RISE SERIES –IOM

HRC(C,X) HIGH RISE SERIES –IOM (REV. B 3/22)

15

UNIT DIMENSIONAL DATA CONTINUED

FIGURE 10 –Unit Dimensions

HRC(C,X) HIGH RISE SERIES - IOM

16

HRC(C,X) HIGH RISE SERIES –IOM (REV. B 3/22)

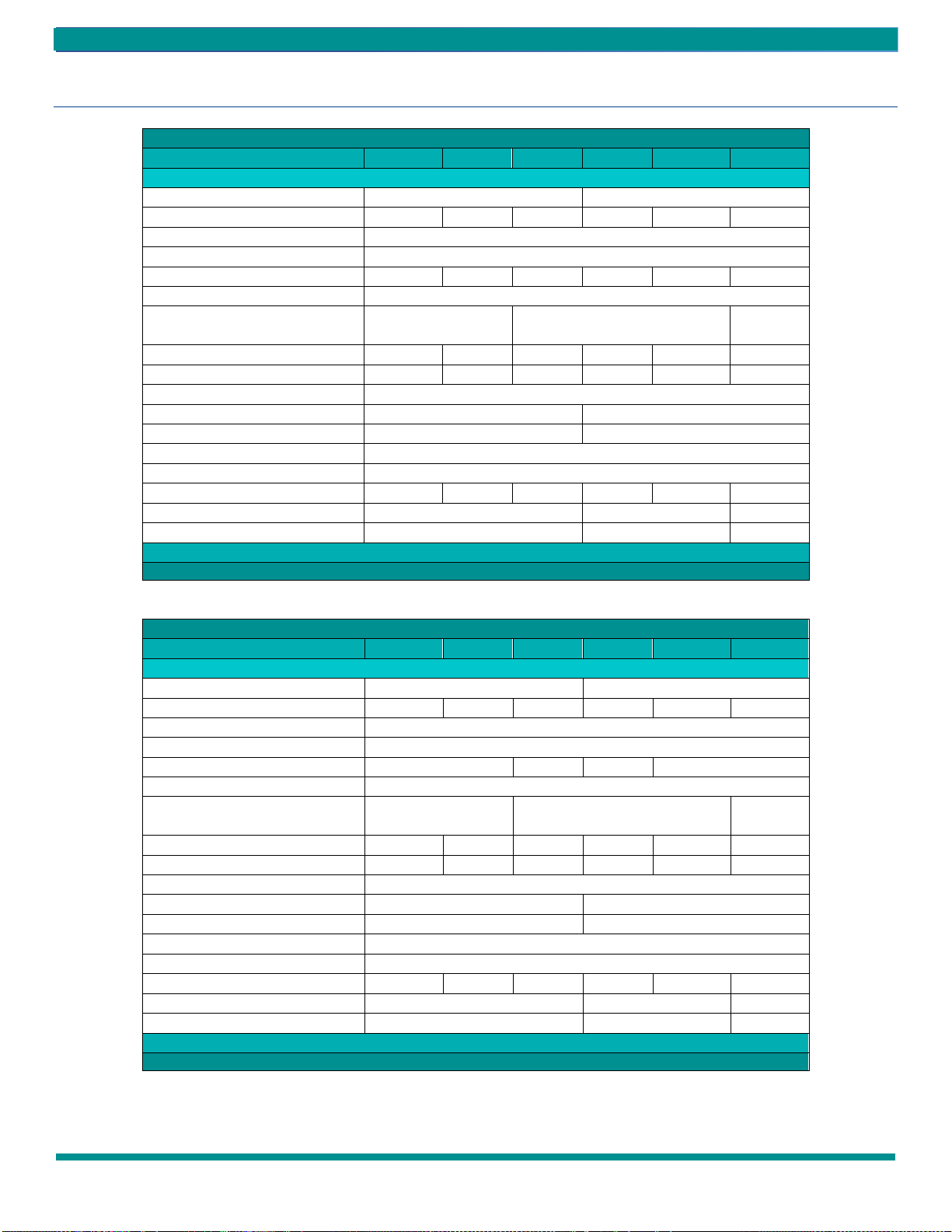

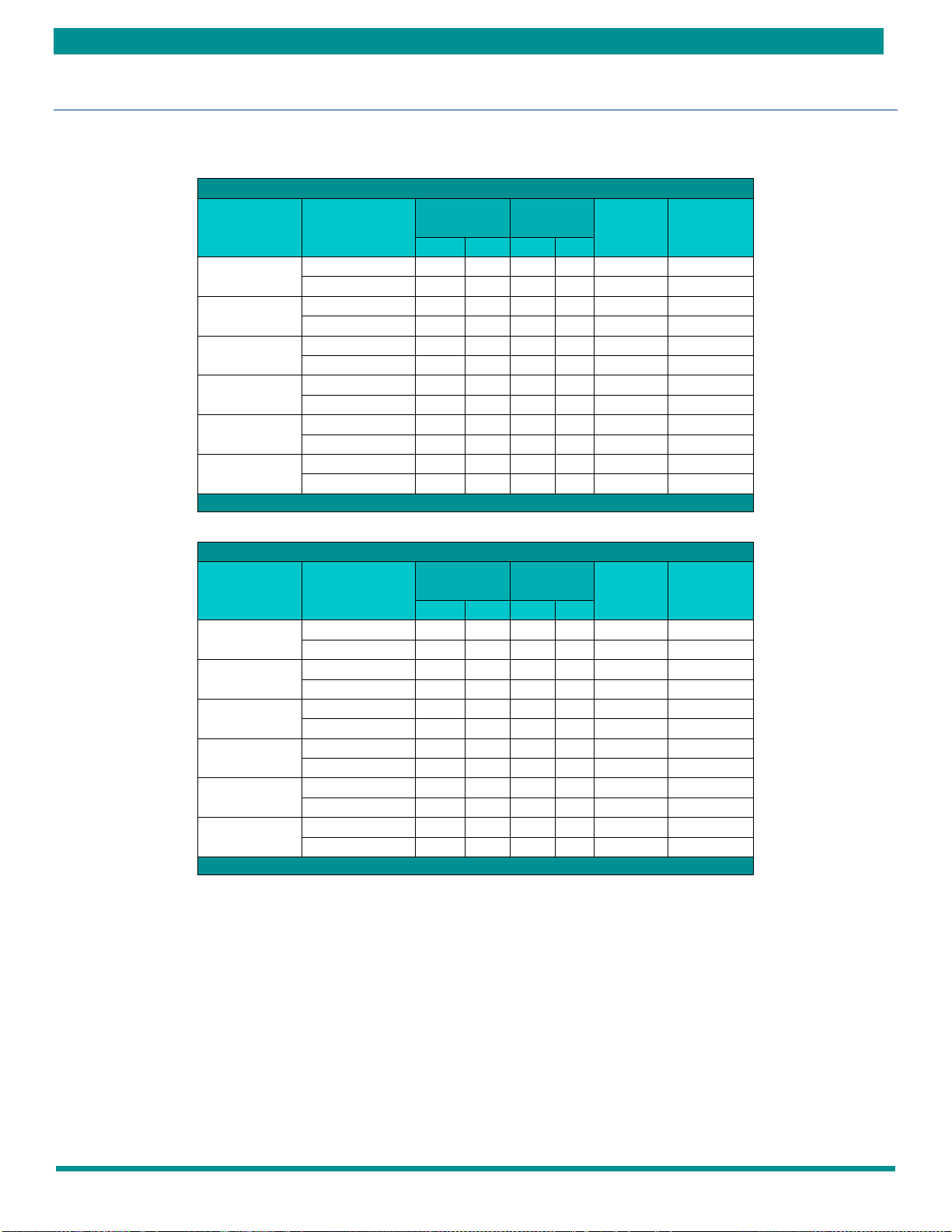

UNIT PHYSICAL DATA

PHYSICAL DATA

HRCC MODELS

HRCC09

HRCC12

HRCC18

HRCC24

HRCC30

HRCC36

UNIT INFORMATION

Compressor Type (Qty)

Rotary (1)

Scroll (1)

Factory Charge (R410A) lbs. [oz]

1.7 [27]

2.7 [43]

2.7 [43]

3.7 [59]

3.7 [59]

3.6 [57]

Motor (Qty)

1

Fan Motor Type

PSC

Fan Motor HP [kW]

1/12 [.06]

1/10 [.07]

1/4 [.18]

1/6 [.12]

1/2 [.37]

1/2 [.37]

Blower (Qty)

1

Blower Wheel Size (D x W) in. [cm]

6.75 x 7 [17.15 x

17.78]

9 x 7 [22.86 x 17.78]

10 x 8 [25.4

x 20.32]

Hose Size (in)

1/2

1/2

3/4

1

1

1

COAX Volume (US Gallons)

0.116

0.116

0.144

.544

.544

.544

Condensate Connection O.D. (in)

1-1/8

Air Coil Dimension (H x W) in. [cm]

28 x 14 [11.0 x 5.5]

30 x 18 [11.8 x 7.1]

Filter Size (H x W) in. [cm]

30 x 16 [11.8 x 6.3]

32 x 20 [12.6 x 7.9]

Filter (Qty)

1

Operating Weight

Weight

Chassis lb. [kg]

125[57]

128[58]

131[59]

182[83]

185[84]

188[85]

80” Cabinet lb. [kg]

128[58]

173[78]

175[79]

88” Cabinet lb. [kg]

143[65]

188[85]

190[86]

Table 1 –Physical Data PSC

PHYSICAL DATA

HRCX MODELS

HRCX09

HRCX12

HRCX18

HRCX24

HRCX30

HRCX36

UNIT INFORMATION

Compressor Type (Qty)

Rotary (1)

Scroll (1)

Factory Charge (R410A) lbs. [oz]

1.7 [27]

2.7 [43]

2.7 [43]

3.7 [59]

3.7 [59]

3.6 [57]

Motor (Qty)

1

Fan Motor Type

ECM

Fan Motor HP [kW]

1/4 [.18]

1/3 [.25]

1/3 [.25]

1/2 [.37]

Blower (Qty)

1

Blower Wheel Size (D x W) in. [cm]

6.75 x 7 [17.15 x

17.78]

9 x 7 [22.86 x 17.78]

10 x 8 [25.4

x 20.32]

Hose Size (in)

1/2

1/2

3/4

1

1

1

COAX Volume (US Gallons)

0.116

0.116

0.144

.544

.544

.544

Condensate Connection O.D. (in)

1-1/8

Air Coil Dimension (H x W) in. [cm]

28 x 14 [11.0 x 5.5]

30 x 18 [11.8 x 7.1]

Filter Size (H x W) in. [cm]

30 x 16 [11.8 x 6.3]

32 x 20 [12.6 x 7.9]

Filter (Qty)

1

Operating Weight

Weight

Chassis lb. [kg]

125[57]

128[58]

131[59]

182[83]

185[84]

188[85]

80” Cabinet lb. [kg]

128[58]

173[78]

175[79]

88” Cabinet lb. [kg]

143[65]

188[85]

190[86]

Table 2 –Physical Data ECM

HRC(C,X) HIGH RISE SERIES –IOM

HRC(C,X) HIGH RISE SERIES –IOM (REV. B 3/22)

17

ELECTRICAL DATA

ELECTRICAL DATA PSC

MODEL

NUMBER

VOLTAGE-PH-HZ

COMPRESSOR

BLOWER

MOTOR

MIN.

CIRCUIT

AMPACITY

MAX.

CIRCUIT

PROTECTION

RLA

LRA

FLA

HP

HRCC09

208/230-1-60

3.7

22

0.6

1/12

6

15

265-1-60

3.5

22

0.7

1/15

6

15

HRCC12

208/230-1-60

4.7

25

0.65

1/10

7

15

265-1-60

4.2

22

0.65

1/10

6

15

HRCC18

208/230-1-60

7

38

1.4

1/4

11

15

265-1-60

6

30

1.4

1/4

9

15

HRCC24

208/230-1-60

10.9

62.9

1.6

1/6

16

25

265-1-60

9

54

1.4

1/6

13

20

HRCC30

208/230-1-60

12.8

67.8

3.1

1/2

20

30

265-1-60

11.2

60

2.7

1/2

17

25

HRCC36

208/230-1-60

15.4

82.6

3.1

1/2

23

35

265-1-60

12.2

72

2.7

1/2

18

30

Table 3 –Electrical Data PSC

ELECTRICAL DATA ECM

MODEL

NUMBER

VOLTAGE-PH-HZ

COMPRESSOR

BLOWER

MOTOR

MIN.

CIRCUIT

AMPACITY

MAX.

CIRCUIT

PROTECTION

RLA

LRA

FLA

HP

HRCX09

208/230-1-60

3.7

22

2.3

1/4

7

15

265-1-60

3.5

22

2.3

1/4

7

15

HRCX12

208/230-1-60

4.7

25

2.3

1/4

9

15

265-1-60

4.2

22

2.3

1/4

8

15

HRCX18

208/230-1-60

7

38

2.8

1/3

12

15

265-1-60

6

30

2.6

1/3

11

15

HRCX24

208/230-1-60

10.9

62.9

2.8

1/3

17

25

265-1-60

9

54

2.6

1/3

14

20

HRCX30

208/230-1-60

12.8

67.8

4.1

1/2

21

30

265-1-60

11.2

60

3.6

1/2

18

25

HRCX36

208/230-1-60

15.4

82.6

4.1

1/2

24

35

265-1-60

12.2

72

3.6

1/2

19

30

Table 4 –Electrical Data ECM

HRC(C,X) HIGH RISE SERIES - IOM

18

HRC(C,X) HIGH RISE SERIES –IOM (REV. B 3/22)

INSTALLATION

REQUIREMENTS

Follow manufacturer’s installation instructions, as well as

local and municipal building codes.

INSTALLATION PRECAUTIONS

Always wear all appropriate personal protection

Equipment when installing and servicing these units.

Use multiple people when moving and installing these

units. Failure to do so could result in injury or death.

Contact with metal edges and corners can result injury.

Protective gloves should be worn when handling.

Exercise caution when installing and servicing unit.

Observe the following precautions for typical installation:

Always use proper tools and equipment.

No wiring or any work should be attempted without

first ensuring the unit is completely disconnected from

the power source and locked out. Also, verify that a

proper permanent and uninterrupted, ground

connection exists prior to energizing power to the

unit.

Review unit nameplate and wiring diagram for proper

voltage and control configurations. This information

may vary from unit to unit.

When the unit is in operation components are rotating at

high speeds and caution should be taken.

When soldering and brazing, it is recommended to have a

fire extinguisher readily available. When soldering and

brazing close to valves or sensitive components, heat

shields or wet rags are required to prevent damage to the

valves or components.

Insulation is installed in the unit to provide a barrier

between varying atmospheres outside and within the unit.

If insulation is damaged condensation can occur and can

lead to corrosion, component failure, and possible

property damage. Damaged insulation must be repaired

prior to the operation of the unit. Insulation will lose its

effectiveness and value when wet, torn, separated, and/or

damaged.

When servicing this equipment, because of high pressures,

make sure the reversing valve, expansion device, filter

drier and other components are specifically designed for

R-410A refrigerant.

ONLY USE service equipment specifically designated for

use with R-410A.

R-410A can become combustible if mixed with air at

elevated temperature and/or pressure. Failure to follow

this warning could result in property damage and personal

injury or death.

Do not operate this equipment without an air filter.

HRC(C,X) HIGH RISE SERIES –IOM

HRC(C,X) HIGH RISE SERIES –IOM (REV. B 3/22)

19

INSTALLATION CONTINUED

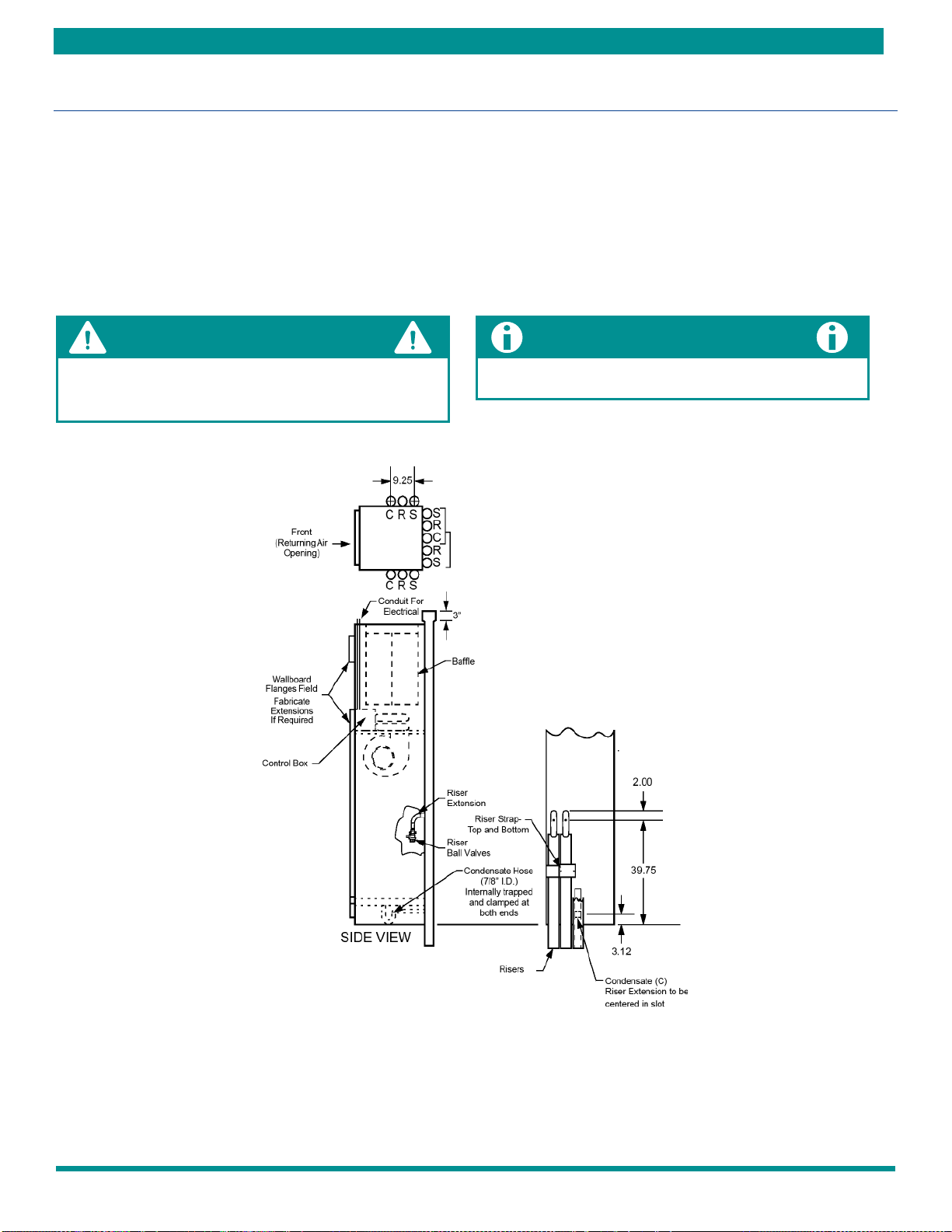

RISER & CABINET INSTALLATION

Risers can be ordered loose, not attached to the cabinet, and shipped in bulk. Entire riser stacks can be assembled, pressure

tested, flushed, and filled before setting cabinets. Insulate all drain risers and insulate all tubing for extended range applications

(operation below 60 degrees F) or if condensation will occur on riser tubes. Do not construct walls until cabinets are installed

and set.

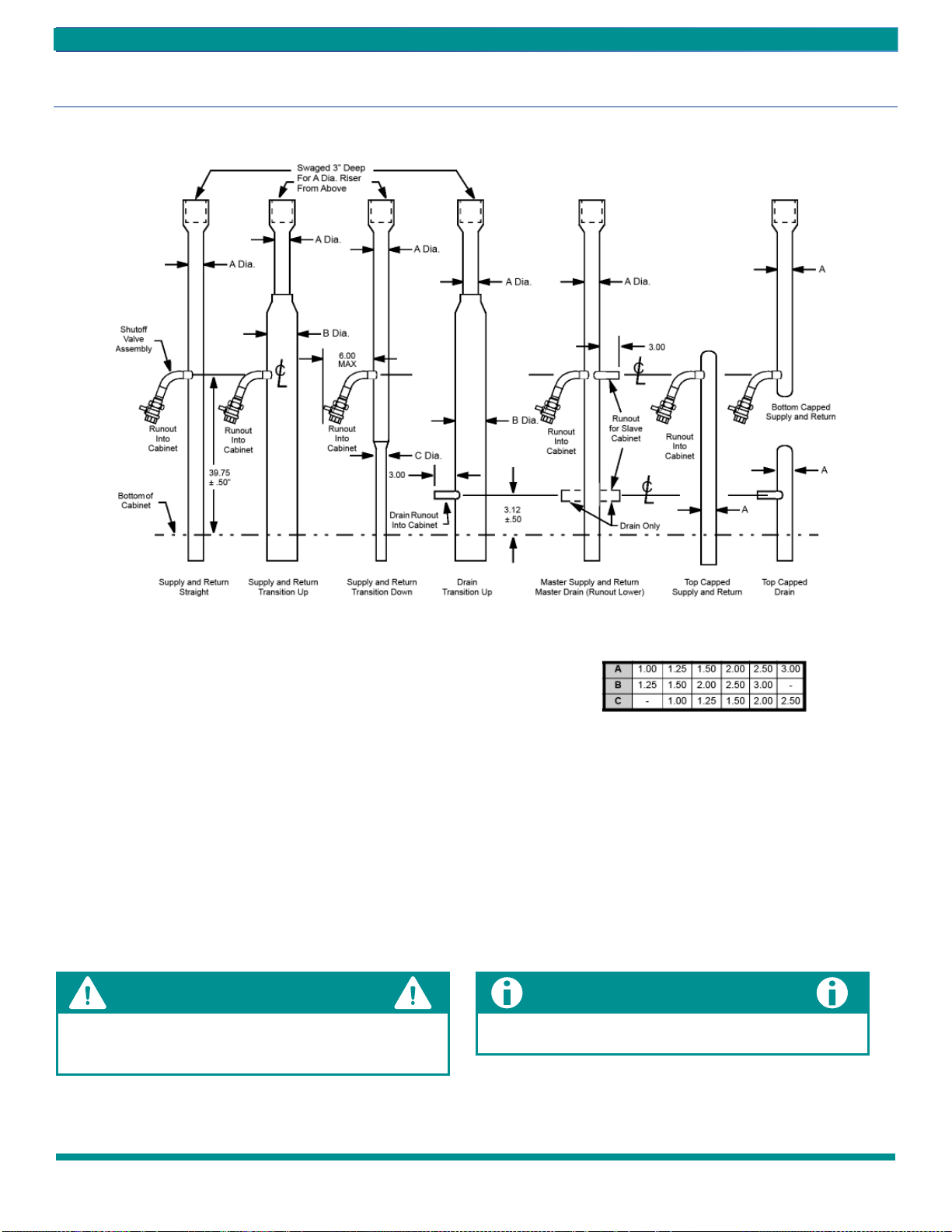

Supply and return risers can be straight, transition up, transition down, bottom capped, or top capped. Drain risers can be

straight, transition up, or top capped. All drain risers and extended range (operation below 50 ºF entering water temperature)

supply and return risers need insulation. See FIGURE 12 –Riser Identification

If filled risers are in unconditioned space, care must be

taken to prevent freezing or condensation to avoid

damage to risers and building.

Risers can be in 4 positions. Supply (S) riser will always be

closest to a corner. FIGURE 11 –Cabinet

FIGURE 11 –Cabinet

HRC(C,X) HIGH RISE SERIES - IOM

20

HRC(C,X) HIGH RISE SERIES –IOM (REV. B 3/22)

INSTALLATION CONTINUED

RISER & CABINET INSTALLATION

FIGURE 12 –Riser Identification

These units are for indoor installation ONLY!

Do not locate unit in areas subject to freezing temperatures or where high humidity levels could cause cabinet condensation.

Locate the unit in an area that provides minimum clearance accesses.

Refer to Table 1 –Unit Dimensional Data and Table 2 –Unit Dimensional Data Continued for detailed information on unit

dimensional sizes. Consider all additional clearances needed for water connections, electrical connections, duct connections

and sufficient return airflow.

Do not use soft, low temperature solders like 50-50, 60-40

or 85-15. With copper expansion and contraction, this type

of bond will fail.

Expansion loop design and placement is a function of and

best prescribed by consulting and design engineers.

DRAIN CONNECTION

1/4" (6.4mm) PITCH TOWARD

DRAIN FROM DRAINAGE

Riser Transition Diameters

This manual suits for next models

13

Table of contents

Other AE-Air Heat Pump manuals

Popular Heat Pump manuals by other brands

Dimplex

Dimplex LA 6MR Installation and operating instrictions

ACD

ACD FXD-ACD36 owner's manual

Daikin

Daikin ALTHERMA User reference guide

Bulldog Security

Bulldog Security SKV008 Installation operation & maintenance

Panasonic

Panasonic WH-ADC0916G9E8 Service manual

American Standard

American Standard 4A6H4018N installation guide