WSS6 Series - IOM

WSS6 SERIES – IOM (REV. A 4/21) 20

CONTROLS CONTINUED

BOILERLESS CONTROL

The system can operate in boilerless mode by switching

Dip 1.5. If CO1 goes below the setting of Dip 1.6 the

compressor will be de-energized and control goes into

emergency heat mode staging on “W1”. The compressor

will be locked out for 60 minutes to prevent nuisance

cycling.

The set point for boiler less changeover temperature can

be adjusted by switching Dip 1.6.

WATER-COIL LOW TEMPERATURE CUT-OUT LIMIT

Jumpers JW1-CO1 provide field selection of the

temperature limit settings for CO1.

Not Clipped = 30°F Clipped = 10°F

CAUTION

For all applications below 50°F entering water

temperature, anti-freeze solution is required. Failure

to follow this warning could result in heat exchanger,

equipment or property damage.

ALARM RELAY SETTING

Jumper 3 (JW3 Alarm) provides field selection of alarm

relay terminal AL2 to be jumpered to 24VAC or to be

dry. The alarm relay is activated during lockout mode.

Not Clipped = AL2 Connected to “R”

Clipped = AL2 dry contacts (No connection)

DEHUMIDIFICATION MODE

The system can operate in Dehumidification mode by

switching Dip 1.4 on the WSCM module. In this mode,

the unit will run continuously in fan speed G2 when Y,O,

G calls are given to the board. Dehumidification mode

will not run in heating mode.

WSCM SAFETY FEATURES

ANTI-SHORT CYCLE PROTECTION

The WSCM module incorporates a 5 minute anti-short

cycle protection for the compressor.

RANDOM START

The WSCM module features a 5-80s random start upon

receiving a call to operate.

FAULT RETRY

While in Fault Retry Mode the LED will display a code

representing retry and the fault code. The unit will

initiate the Anti-short cycle timer and try to restart after

the delay. If 3 consecutive faults occur without satisfying

the thermostat the unit will go into hard lockout. The

last fault causing the lockout will be stored in memory

and displayed on the two digit LED display.

WATER-COIL LOW TEMPERATURE CUT-OUT (CO1)

The control module will recognize a CO1 fault during a

compressor run cycle if:

a) Thermistor temperature is below the selected set

point limit.

b) The thermistor temperature is rising at a rate less

than 2°F per 30s time period. The CO1 input is

bypassed for the first 120s of a compressor run

cycle. On the second and third retry CO1 is

bypassed for the initial 90s and 60s of run-time

respectively.

AIR COIL LOW TEMPERATURE CUT-OUT (CO2)

The control module will recognize a CO2 fault during a

compressor run cycle if:

a) Thermistor temperature is below the selected set

point limit.

b) The thermistor temperature is rising at a rate less

than 2°F per 30s time period. The CO2 input is

bypassed for the first 120s of a compressor run

cycle.

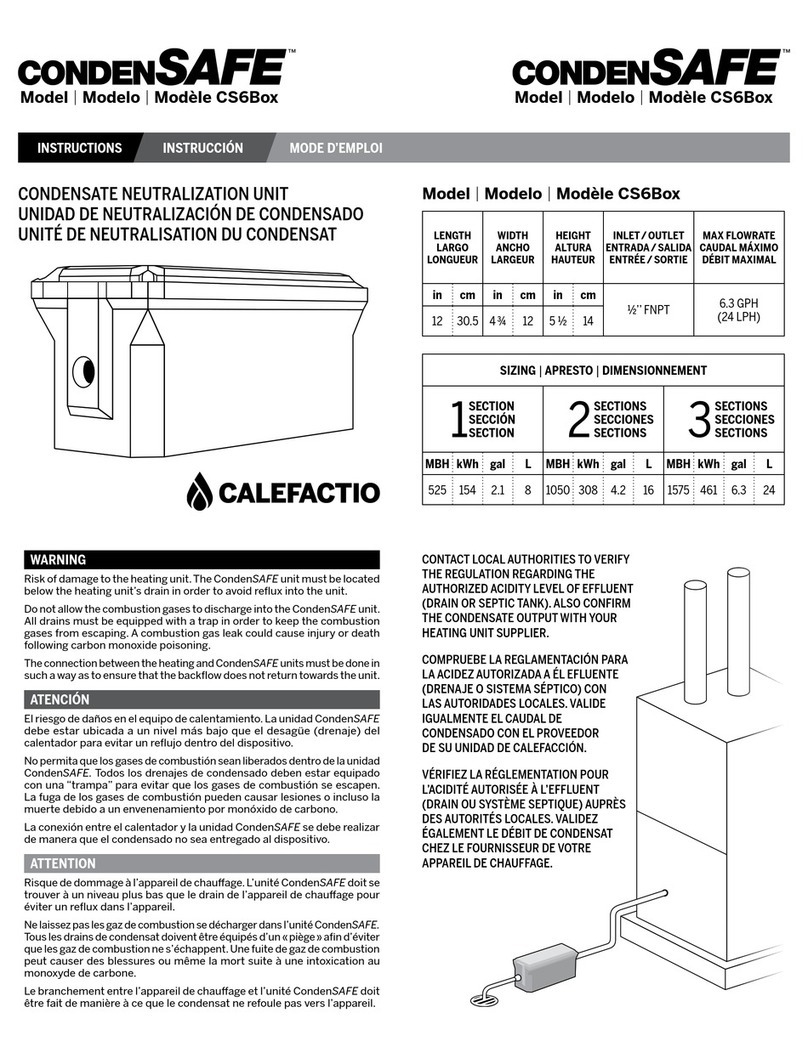

CONDENSATE OVERFLOW SENSOR

The condensate overflow sensor must sense overflow

levels for 30 continuous second to initiate a COF fault.

The condensate overflow sensor will be monitored

during the compressor run cycle.

LOW PRESSURE

The low pressure switch must be open and remain open

for 30 continuous seconds during the “on” cycle to be

recognized as a low pressure fault. The low pressure

switch input is bypassed for the initial 120s of

compressor run-time.

HIGH PRESSURE

If the high-pressure switch opens at any time, the

compressor relay is de-energized immediately.