AEBI MEYER DIAMOND EDGE User manual

Form No. 1-1241

April 2022

Assembly Instructions

Standard Operating System with Hands Free Plowing

Includes: 41680

© 2022 Printed in the U.S.A.

18513 Euclid Ave. • Cleveland, Ohio 44112-1084

Phone 216-486-1313 www.meyerproducts.com

Table of Contents

General Information.........................................................................................................................................................................................................................1

Black Iron Parts Lists.....................................................................................................................................................................................................................2-3

Moldboard Parts List ........................................................................................................................................................................................................................4

E73 Hydraulics ....................................................................................................................................................................................................................................5

Standard Operating System Wiring............................................................................................................................................................................................6

Plow Assembly & Adjustments.................................................................................................................................................................................................7-8

Mounting Plow...................................................................................................................................................................................................................................9

Dismounting Plow ......................................................................................................................................................................................................................... 10

Pre-Delivery Inspection................................................................................................................................................................................................................ 11

Registration ...................................................................................................................................................................................................................................... 11

(1)

Please visit our website to nd our most updated technical information; including installation instructions, user manuals, parts

diagrams, EZ Troubleshooter, and more.

Please see your owner’s manual for Pre-Season, Post-Season, and General Maintenance.

www.meyerproducts.com

NOTICE:NOTICE: Meyer Products LLC reserves thje right, under its continuing product imporvement program, to change construction, design, details,

specications, and prices without notice or without incurring any obligation. Meyer Products LLC assumes no responsibility for installations not

made in accordance with these instructions.

GENERAL INFORMATION

Always disconnect battery prior to installation.

SAFETY PRECAUTIONS should be used when Quik Lift® is in a RAISED position.

LOWER plow to the ground when vehicle is PARKED.

OVERHAUL and SERVICE information is covered on separate instructions.

Note:

1. Connect ground cable to negative side of battery for a solid connection to ground.

2. Route all cables away from moving engine parts, Manifolds, and sharp sheet metal.

3. For weather protection, coat all connections with Meyer Dielectric Grease Part No. 15632

4. The vehicle must be equipped with a “Heavy Duty Battery” (70 Amp, Hr. Min.), 550 C.C.A. and“Alternator” (60 Amp. Min.) to obtain

maximum performance.

5. Follow these instructions explicitly. Warranty does not apply to a Meyer product which has been negligently or improperly

assembled or installed.

TORQUE CHART FOOT

Pliers

1/2" socket

1/2" box wrench

9/16" box wrench

9/16" socket

3/4" box wrench

15/16" box wrench

15/16" deep well socket

Bolt Nut Size Gr. 2 Gr. 5 Gr. 8

1/4-20 4-5

5/16-18 9-11

3/8-16 17-20 26-29

7/16-14 42-46 60-66

1/2-13 64-72 99-100

5/8-11 127-141 179-198

Tool List for Plow Assembly

(2)

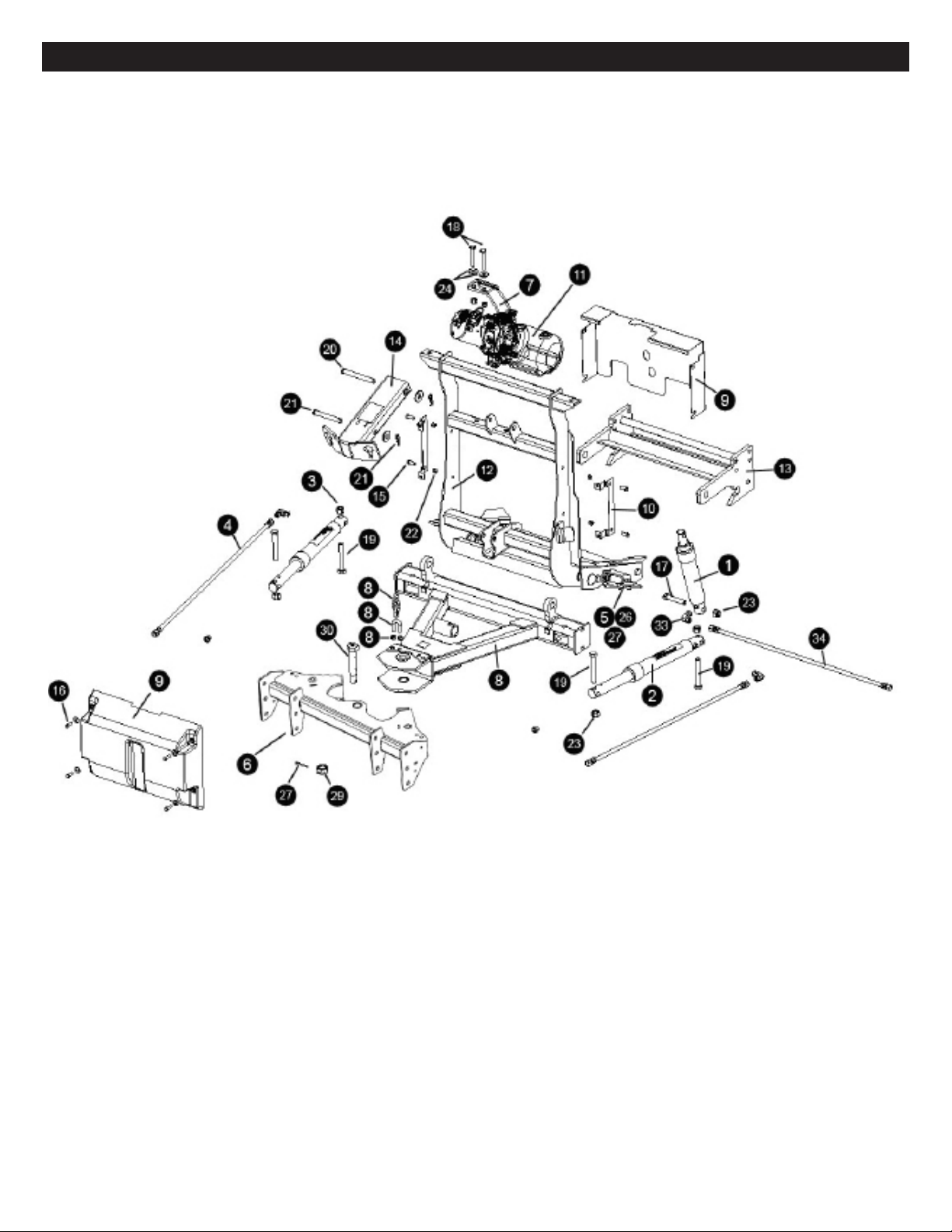

Black Iron Parts List

Black Iron Parts List

(3)

Item Part QTY Description

41620 1 DE SOS E73 7.5-9.0

1 05818 1 Lift Ram 1.75 x 8”

07772 1 • L.H. Ram with Hose & Fittings

2 05887 1 •• Ram (1-1/2” x 10”)

3 22866 1 •• SAE Mx3/8 90 Degree Elbow

4 22885 1 •• Hose 1/4 x 54”

07783 1 • R.H. Ram with Hose & Fittings

2 05887 1 •• Ram (1-1/2” x 10”)

3 22866 1 •• SAE Mx3/8 90 Degree Elbow

4 22921 1 •• Hose 1/4 x 38”

5 11859 2 • Blue Handle Pin

6 81041 1 • Pivot Bar

7 14185 1 • E-73 Mounting Bracket

814704 1• A-Frame

8a 21541 2 • Chain 5/16 x 38” Gr. 43

8b 8518001026 2 • U-Bolt 7/16-14

8c 20306 4 • Locknut 7/16-14

9a 14596 1 • Lift Unit Cover Front

9b 14288 1 • Lift Unit Cover Rear

10 14290 2 • Lift Unit Cover Bracket

11 16027 1 • Lift Assembly (Unit only)

12 18965 1 • Lift Frame

13 14700 1 • Clevis

14 14439 1 • Lift Arm

15 20027 4 • Bolt H 5/16-18 x 1”Gr. 2

16 20049 4 • Bolt H 3/8-16 x 1”Gr. 2

17 20146 1 • Bolt H 5/8 - 11 x 3-1/4”Gr. 5

18 20102 2 • Bolt H 1/2 - 13 x 3-1/4”Gr. 5

19 20150 4 • Bolt H 5/8 - 11 x 4-1/2”Gr. 5

20 22989 1 • Pin 5/8 x 5-3/4”

21 23050 1 • Pin 5/8 x 4-7/8”

21a 20152 2• BOLT H 5/8 11 X 5 G5 ZN

22 20305 4 • Locknut 3/8-16

23 20309 12 • Locknut 5/8-11

23a 20140 12 • Bolt H 5/8-11 x 1-3/4” Gr. 5

24 20307 2 • Locknut 1/2-13

25 22153 1 • Lockbolt 5/16 x 5/8

26 20406 3 • Cotter Pin 3/16 x 1-1/2”

27 20420 2 • Cotter Pin 1/4 x 2”

28 22022 1 • Crank Stand

29 22274 1 • Slotted Nut 1-8

30 22398 1 • King Bolt 1-8 x 5-1/2”

31 22436 2 • Pin 1 x 3”

32 23039 1 • Plow Side Harness

33 22866 1 • SAE Mx3/8 90 Degree Elbow

34 22884 1 • Hose 1/4 x 33”

Item Part QTY Description

41622 1 • Accessory Box

35 23025 1 •• Power Cable

36 07178 2 •• Trip Spring

23067 1 •• Nite Saber LED Kit

09917 1 •• Plow Marker Kit

37 08214 2 ••• Plow Marker

38 20027 4 ••• Bolt H 5/16-18 x 1 Gr. 2

39 20304 4 ••• Locknut 5/16-18

40 20352 8 ••• Flatwasher 5/16”

41 11844 1 •• Receiver Tube Cap

42 15372 1 •• Starter Solenoid - 12 volt

43 21832 1 ••• Split Bushing

44 23047 1 •• Controller

45 23059 1 •• Truck Side Harness (4 Pin)

41202 1 •• Hardware Bag

46 09124 2 ••• Eye Bolt

47 20406 2 ••• Cotter Pin 3/16 x 1-1/2”

48 22333 2 ••• Pivot Pin

49 814000005 2 • Spring

50 15187 1 • Breather

Parts indented are included in the assembly under which they are indented.

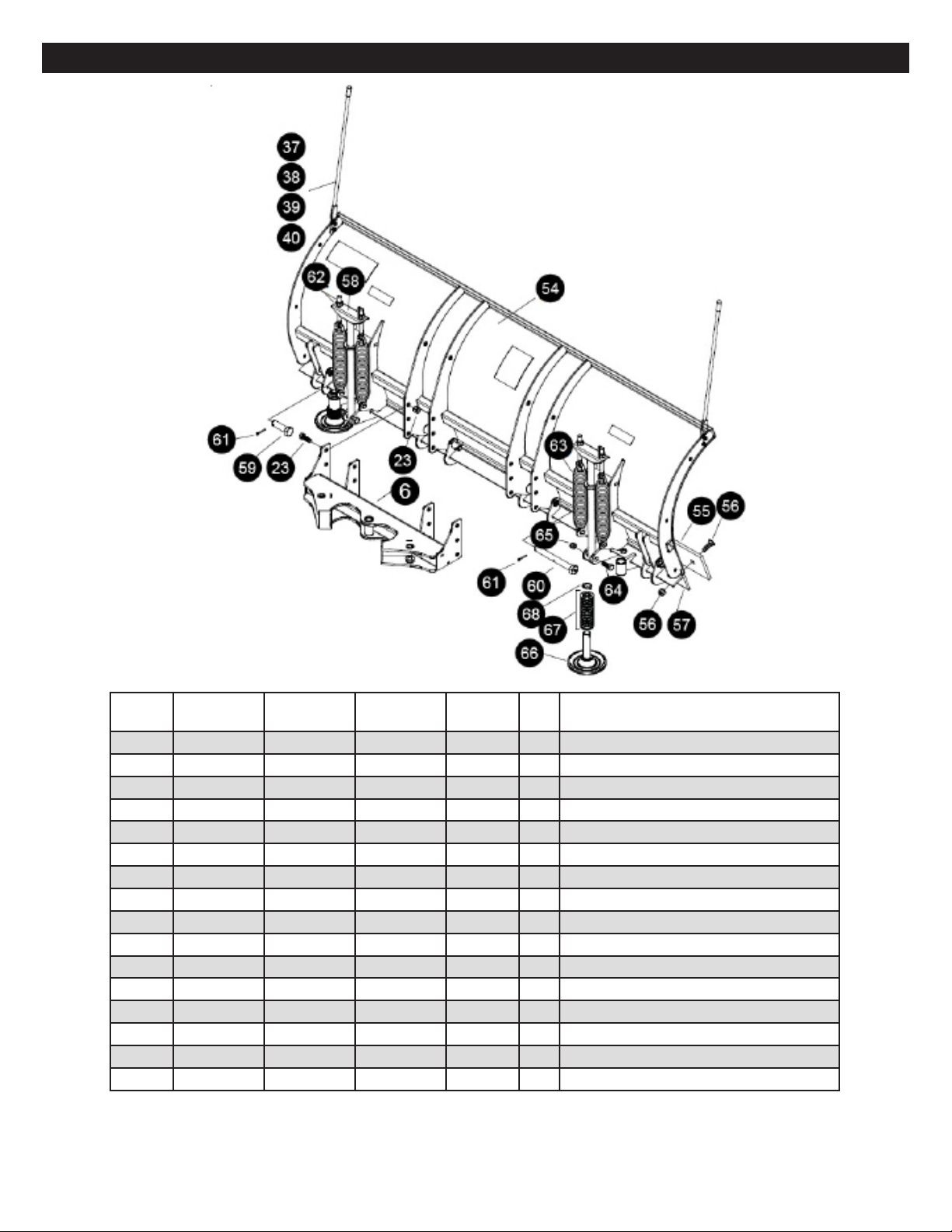

Item Part No.

7’ 6”

Part No.

8’

Part No.

8’ 6”

Part No.

9’ Qty Description

84350 84351 84352 84353 1 Moldboard Assembly

54 84360 84361 84362 84363 1 • Moldboard Weld

55 84127 84128 84129 84130 1 • Cutting Edge

56 08223 08223 08223 08223 1 • Bolt C 5/8-11 x 2” Gr.5 & Locknut (Kit of 10)

57 84370 84371 84372 84373 1 • Trip Edge Weldment

58 84285 84285 84285 84285 2 • T-Bar Weldment

59 22331 22331 22331 22331 2 • Pivot Pin 1 x 3-5/16”

60 22375 22375 22375 22375 2 • Pivot Pin 1 x 8-3/4”w/grease tting

61 20406 20406 20406 20406 4 • Cotter Pin 3/16 x 1-1/ 2”

62 09124 09124 09124 09124 4 • Eye Bolt w/Locknut & Cap

63 07017 07017 07017 07017 4 • Trip Spring

64 20144 20144 20144 20144 2 • Bolt H 5/8 - 11 x 2-3/4” Gr. 5

65 20318 20318 20318 20318 2 • Locknut Esna 5/8-11

66 13150 13150 13150 13150 2 • Wear Shoe Assy

67 20363 20363 20363 20363 24 • Runner Washer

68 22083 22083 22083 22083 2 • Lynch Pin

(4)

Moldboard Parts List

Parts indented are included in the assembly under which they are indented.

(5)

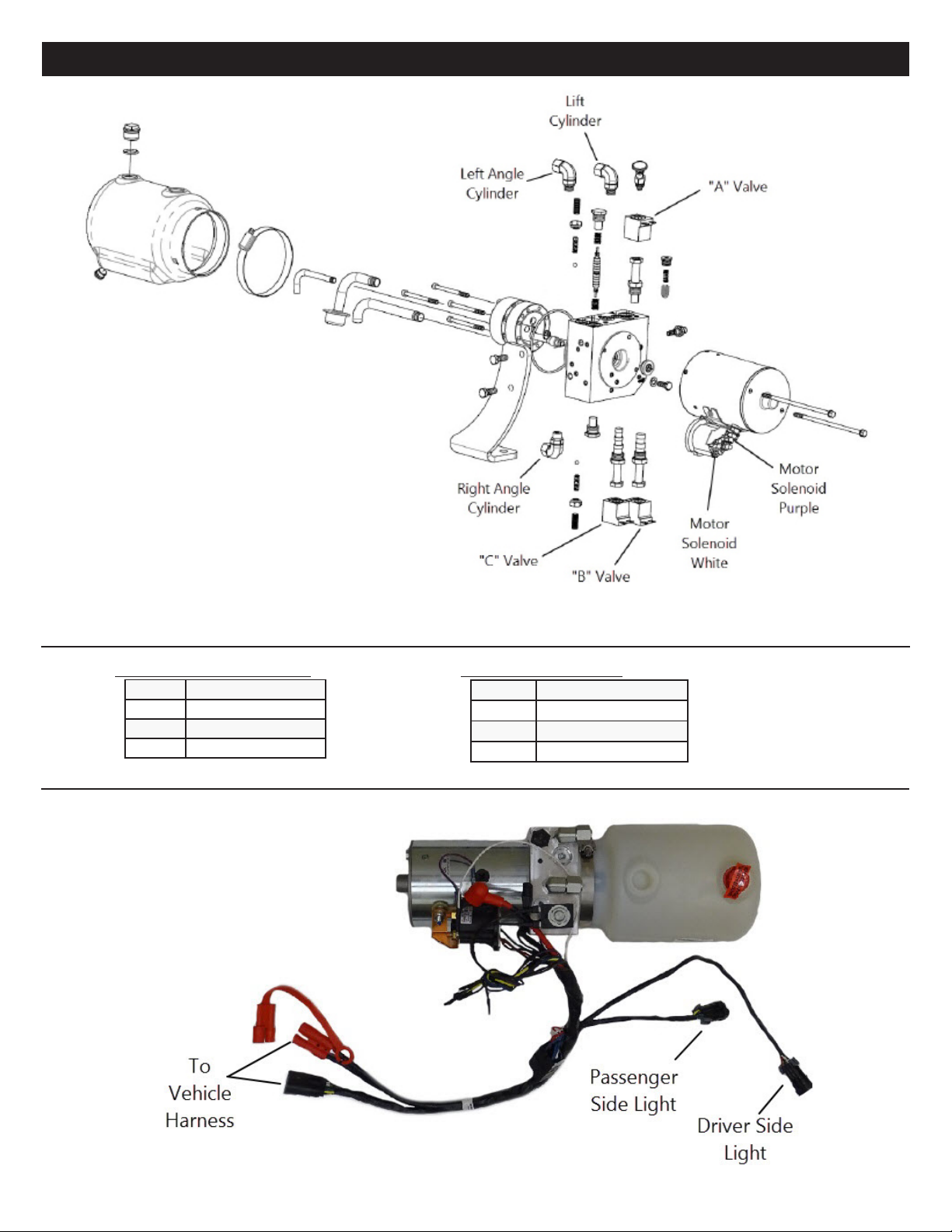

Hydraulic Solenoid Color

Raise Motor Solenoid +“B” Solenoid

Lower “A” Solenoid

Left Angle Motor Solenoid

Right Angle Motor Solenoid + “C” Solenoid

Motor White

A Black

B Red

C Green

Coil Wire Color Code:

Note:Note: Ground wire for each coil is

Black with a White Stripe

E73 Hydraulics

(6)

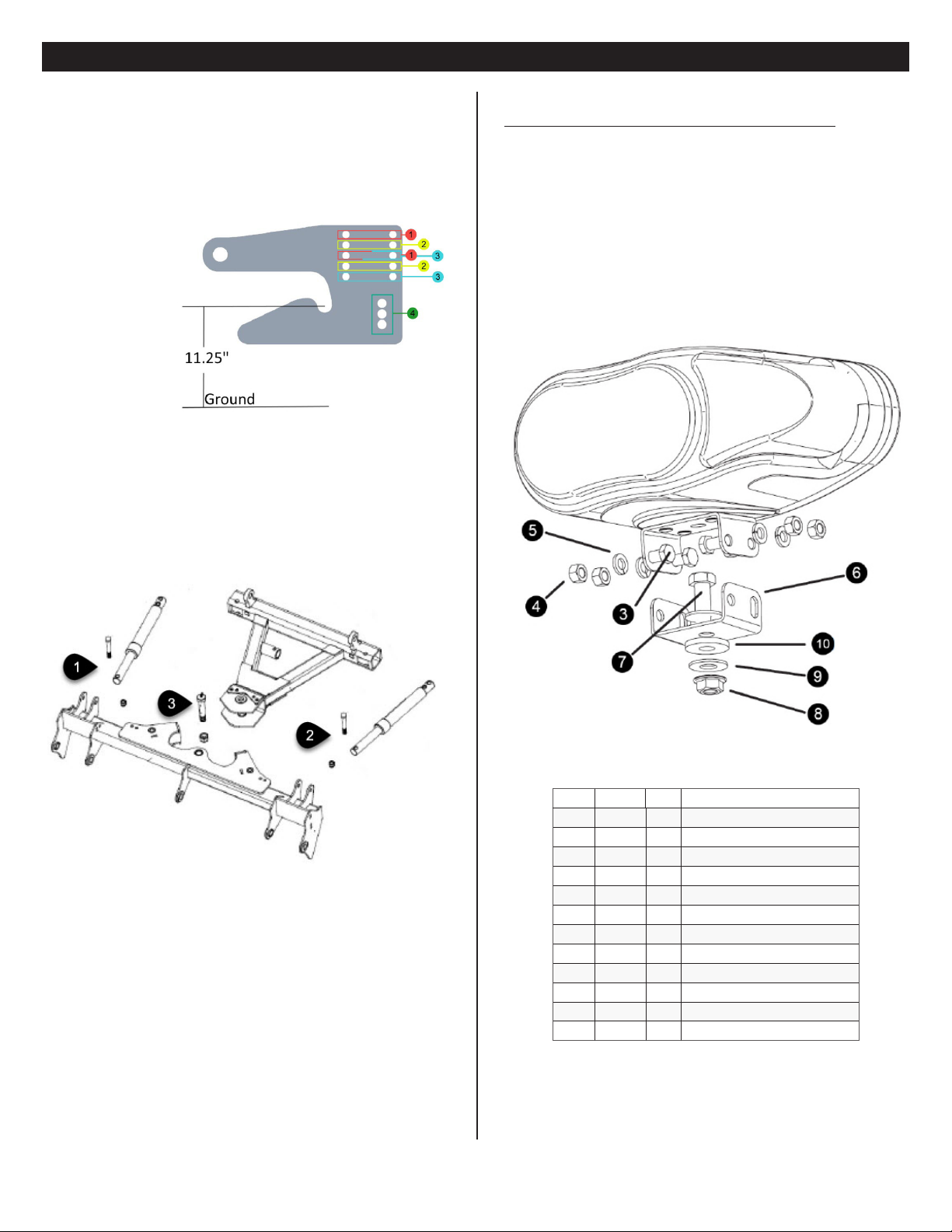

Wiring Harnesses & Controller

Vehicle Side HarnessVehicle Side Harness

1) Route the 12 pin connector into vehicle’s cab and plug into controller.

2) Route the 16 pin connector to the front of the vehicle and plug into the plow side harness.

3) Route the 4 pin connector to rear of vehicle and plug into vehicle’s trailer harness using the trailer adapter harness.

Use cable ties to ensure the harness is secured to the vehicle’s frame.

4) The BLUE wire will connect to the vehicle’s keyed accessory circuit. This is to ensure the plow turns on and o with the vehicle’s igni-

tion.

The following step is for 2015 & later GM vehicles with an alternator relay...The following step is for 2015 & later GM vehicles with an alternator relay...

5) The WHITE wire will connect to 2015 & Later GM vehicles with alternator relay. See Meyer Products Service Bulletin SB252.

6) The PURPLE wire will connect to the black /violet wire of 2015 and later models of RAM 2500, 3500, 4500, and 5500 models. See

mount instructions for further detail.

The following two steps are optional and may be enforced by local law which requires your vehicle lights to be o while your plowThe following two steps are optional and may be enforced by local law which requires your vehicle lights to be o while your plow

lights are on and vice versa...lights are on and vice versa...

6) Connect the RED to the HIGH beam function.

7) Connect the WHITE to the LOW beam function.

Power HarnessPower Harness

1) Route through the vehicle’s grille.

2) Connect the terminals to the vehicle’s battery. Red to Positive and Black to Negative.

Trailer Adapter Harness

(7)

Plow Assembly & Adjustments

Nite Saber LED LightsNite Saber LED Lights

See seperate Nite Saber LED instructions for further information.

Mount the lights as shown below.

Connect both male ends from the snow plow light to the female ends on the

Plow Side Harness. Ensure all wiring harnesses are secured against the lift

frame.

Check snow plow lights and blinkers to ensure proper operation. If operating

in reverse (i.e. driver side blinking instead of passenger side), reverse the har-

ness connections.

Note: All electrical connections should have both ends coated with a dielectric

grease (Meyer Part # 15632) prior to nal installation. This will ensure a good

connection and help in preventing corrosion.

Nite Saber LED Parts List

Item Part QTY Description

- 23067 1 Nite Saber LED Kit

- 23066 1 Passenger Side LED

- 23065 1 Driver Side LED

- 08126 1 Hardware Bag

3 ----- 8 • Hex Bolt 3/8” x 3/4”, SS

4 ----- 8 • Hex Nut 3/8”, SS

5 ----- 8 • Lock Washer 3/8”, SS

6 ----- 2 • Metal Bracket, Bottom

7 ----- 2 • Bolt 1/2”- 13 x 1 1/12”, SS

8 ----- 2 • Hex Lock Nut 1/2”- 13, SS

9 ----- 4 • Flat Washer 1/2”, SS

10 ----- 2 • Neoprene Grommet 1/2”

Adjustable ClevisAdjustable Clevis

The 14700 adjustable clevisThe 14700 adjustable clevis is now standard with all Standard Operating Sys-

tem black iron packages. The 14700 Adjustable Clevis cannot be used with any

EZ+ Operating System plow model.

The 14700 Clevis oers 3 levels of adjustability for a height dierence of +/- 1.5

inches. To use the adjustability feature, mounting the clevis using two sets of

applicable holes. Use one of the bottom 3 holes to secure to the clevis to the

mount.

Level 1 = Rows 1 and 3

Level 2 = Rows 2 and 4

Level 3 = Rows 3 and 5

The clevis requires a height of 11.25”o the ground in order for the plow to sit

level.

Pivot BarPivot Bar

The Pivot Bar will need to be bolted to the A-Frame and Angling Cylinders. Cut

any ties that are securing the cylinders to the crate prior to removing black

iron from the crate. The Angling Cylinders will already be connected to the Lift

Frame. Hardware to attach the Pivot Bar to the Angling Cylinders and A-Frame

can be found in the Accessory Box.

(8)

Plow Assembly & Adjustments

Lift ChainsLift Chains

Attach the Lift Chain to the Lift Arm through the two hooks on the lift

arm. Adjust the lift chain at the lift arm so that there are 2-3 links of slack.

This ensures that the plow blade will lift fully and be able to follow the ground

contour while plowing.

Trip Spring AdjustmentTrip Spring Adjustment

Attach Eye Bolts to Moldboard and Trip Springs to Pivot Bar, making certain

locknuts are positioned as shown below.

Make certain each Eye Bolt is in a vertical position as shown below so that the

Eye Bolt and Trip Spring hinge properly when the Moldboard trips.

Note: Proper tension is attained when the Trip Spring coils just begin to

seperate and then tightening top locknut four additional turns. Tighten

bottom locknut to secure Eye Boilt in positiion.

Install Eye Bolt Caps over exposed threads.

Plow MarkersPlow Markers

Attach Plow Markers to moldboard using 5/16-18 x 1”Bolt, 5/16” Flatwasher,

and 5/16-18 Locknut.

Drop Speed AdjustmentDrop Speed Adjustment

E73 Drop Speed Adjustment: Loosen jam nut and turn knob clockwise to slow

the drop of the plow and counter clockwise to speed the drop of the plow.

Tighten jam nut.

Drop Speed Adjustment

Hydraulic Fluid LevelHydraulic Fluid Level

Top o the unit to the ll line on the reservoir with Meyer M-1 Hydraulic Fluid.

NOTE: Proper uid level is to the ll line on the reservoir for the E73. It must be

checked with the lift cylinder fully retracted.

A.A. Pull vehicle into plow

assembly and push plow

assembly forward an

inch or two.

F.F. Attach crankstand to

lift frame.

E.E. Remove crankstand

from a-frame.

D.D. Adjust crankstand

until it is no longer in

contact with the ground.

C.C. Push back on lift

frame until both pins

spring through mount on

vehicle.

B.B. Twist handles on both

sides to engage spring

loaded pins.

G.G. Remove weather

cover on both ends and

connect both electrical

plugs.

(9)

Mounting Plow

NOTE:NOTE: Pictures may vary based on model

B.B. Push lift arm down until there is slack in the chain.

C.C. Remove crankstand

from lift frame.

D.D. Attach crankstand to

a-frame

F.F. While slightly pushing the lift frame towards vehicle pull

handles on either side to disengage pins then twist until the

leg locks the pin in the open position.

G.G. Disconnect both

electrical plugs and in-

stall weather cover on

both ends.

H.H. Back vehicle away

from plow assembly.

(10)

Dismounting Plow

A.A. Press down button

until oat light turns blue.

E.E. Adjust crankstand until

the crankstand comes in

contact with the ground

and then turn 1 to 2

revolutions.

Vehicle Make: Vehicle Model:

Vehicle Year: Vehicle VIN#:

Vehicle FGAWR: Installing Company:

Hydraulic Serial Number: Moldboard Serial Number:

PRE-DELIVERY INSPECTION

All bolts torqued to specication

Suspension interference

Clevis height in inches

Trip springs adjusted

Lift Chain Adjusted

Check for hydraulic uid leaks

Hydraulic uid Level

Dielectric grease applied to ALL electrical connection

All wires secured

Plow Stops Adjusted (plow cannot bump hyd. unit)

Controller Operation

Plow Operation Up

Plow Operation Left

Plow Operation Right

Plow Operation Down

Plow Light Blinker Left & Right Operation

Plow Light Low & High Beam Operation

Plow Lights Adjusted

Plow Mount/Dismount reviewed with Customer

Plow Operation reviewed with Customer

Warranty/Registration/Owners Manual

Reviewed with Customer

(11)

11-1/4"

Clevis height

Serial Number Decal Locations

Moldboard serial tags are attached to the back of the moldboard, the outter rib of the moldboard, and on the black iron near the

hydraulic unit.

Note: SV3 Plows use the same serial number for both hydraulic and moldboard.

Registration ID ________________

You must register your plow online to be eligible for the 5 year warranty. Please visit...

www.meyerproducts.com/product-registration

Please note your registration ID for future reference.

Registration

Notes:

Inspected By:

Customer Signature:

W.O.#: Date:

Table of contents