SnowPro SP 1128 HD Owner's manual

SNOWPRO SNOW BLOWER

OWNER OPERATOR MANUAL

1-866-324-0688 FOR SERVICE AND INFORMATION

XX

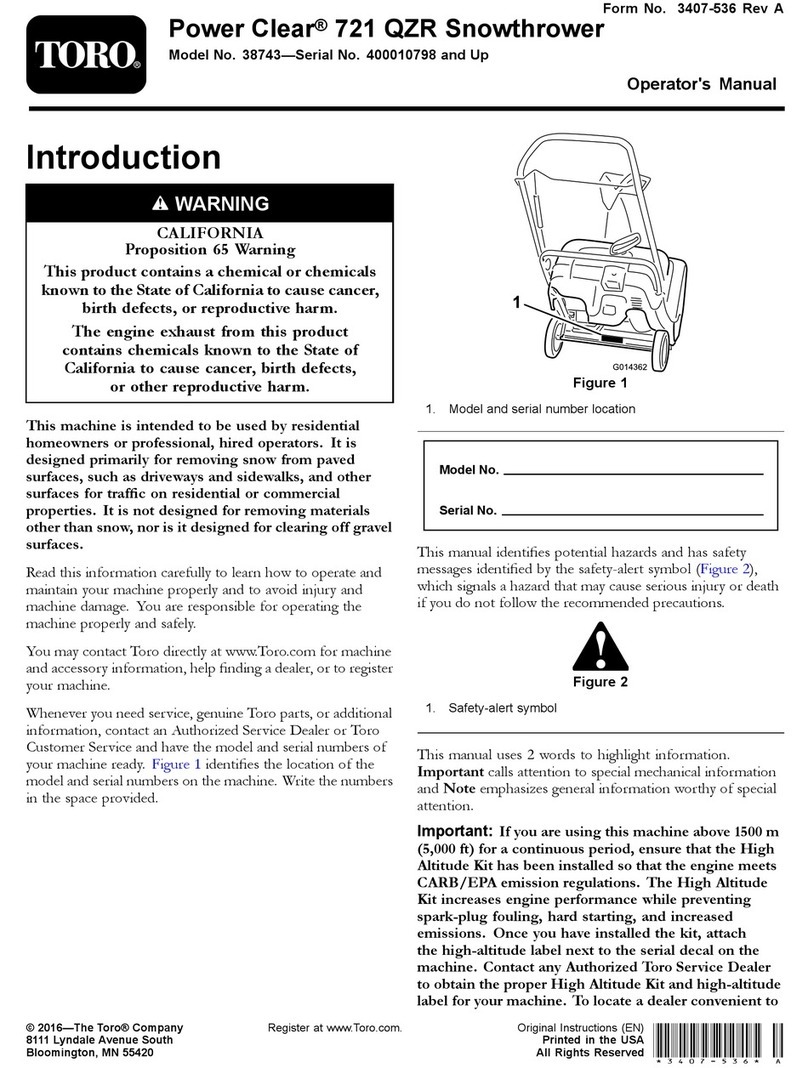

This information is very important for

late identication of the machine

when ordering spare parts and using

customer service.

You will nd the identication plate in

the vicinity of the engine.

Copy all the information plate into the

following space.

Various models are described in these

operating instructions. These models

are designated as 4.0HP, 5.5HP, 6.5HP,

9.0HP and 11HP

As user of this machine read these operating in-

structions through carefully before using this ma-

chine for the rst time. Follow these instructions

and keep them safe for later use or in case of

change of ownership. Only trained adults should

operate the machine. Do not allow any person

under the age of 18 to handle this machine (it is

possible that local regulation dene the minimum

age of the user).

KEEP AWAY people, expecially children, and do-

mestic animals from danger area. Pay attention

to national regulation in force if you are in charge

of the machine on public roads or paths. Never

use themachine to transport someone.

DO NOT operate unit without wearing gloves

protective goggles, closely tting winter clothing

and robust footwear with non-slip soles.

NEVER refuel the machine in an enclosed

space or when the engine is on.

NEVER direct discharge towards persons or

property that may be injured or damaged.

Avoid uneven and rough terrain. DO NOT opeate

near drop offs, ditches, or embankments.

NEVER operate unit after or during the use of

medication, drugs or alcohol. Safe operation

requires your complete and unimpaired attention.

ALWAYS turn off the engine, remove the ignition

key and the spark-plug connector

whenever

Adjust coupling cable (See

“Adjust coupling for the

worm drive”)

Adjust shift lever (see

“Adjusting the shift lever”)

Remove ice accumulation

(See “Tightening the

V-belt”)

Shift lever not correctly adjusted

See “Engine instructions”

Have this work carried out only by our service department.

Drive system iced up

Gear can only be

changed with difculty.

(5.5/6.5/9.0 and 11HP)

You are not working with the machine.

You leave it for a time or

You make adjustments to it or

undertake maintenance or repair work.

as a snow-clearing machine to

remove show from hard-surface

paths and at ground

in accordance with the

specications and safety

instruction given in these

operating instructions

All other usage is considered to be

contrary to the intended purpose of

the machine.

Usage of the contrary to its intended

purpose or the making of

unauthorized changes to the machine

rule out any liability on the part of the

manufacture.

The user is liable for damages to third

persons and their property which

occurs as a result of improper use of

the machine.

This machine is intended only for use

Let the engine cool down before you park the

machine in an enclosed space. Store the ma-

chine and fuel in a safe place

Have the machine repaired only by a

professional workshop.

DO NOT wear loose clothing or jewelry and tie

back of hair that may get caught in rotating parts

Protect eyes, face and head from objects that

may be thrown from unit. Wear appropriate

hearing protection.

ALWAYS keep hands and feet away from all ro-

tating parts during operation. Rotating parts can

cutoff body parts.

122

away from sources of re (sparks, ames)

inaccessible to children

Information on the

identication plate

Use the machine properly

SAFETY RULES

2) General notes on safety

1) For your safety

Xxx X.XXX.XXX.

XXX 2

Safety feature

For 5.5/6.5/9.0HP

Coupling bar (For 4.0 HP)

Coupling lever for the worm

drive (1)

Coupling lever for the drive

system (2)

Symbols on the machine

At various places of the machine you will

nd a safety and warning notice

represented by symbols or pictograms.

These symbols have the following precise

meanings:

Figure 1

Fault

Lever is not set to “CLOSE”

Spark-plug connector loosely

connected

Stale fuel water or dirt in the fuel

system

Drain off stale fuel into a

suitable container in the

open air1).Fuel up tank

with clean, fresh fuel

Clean fuel lter cap and

vent hole

Clear air lter1)

Have carburetor rest2)

Put in a new shear bolt

(see “replacing a shear

bolt”)

Stop engine and eliminate

blockage.

Adjust coupling cable (see

“Adjust coupling for the

worm drive”2)

Tighten slack V-belt (See

“Tightening the V-belt”).

Have torn V-belt replaced

Adjust coupling cable (see

“Adjust coupling for the

drive system”)

Tighten slack V-belt (See

“Tightening the V-belt”)2).

Have torn V-belt replaced2)

Remove ice accumulation

(See “Tightening the

V-belt”)

Stop the engine. Tighten

loose bolts and nuts. Have

damaged worm repaired2).

Have friction-wheel rubber

replaced2)

Set choke lever to “CLOSE”

Vent hole in fuel ller cap blocked

Air lter dirt

Carburetor altered

Shear bolts broken off.

Worn or throw-out chute blocked

Coupling cable for worm drive not

correctly adjusted

V-belt slack or torn (4.0 HP)

Machine does not work

Excessive vibration

Machine does not drive

forward

V-belt slack or torn (4.0 HP)

Drive system iced up (4.0 HP)

Friction-wheel runner torn

Loose parts or damaged worm

Coupling cable for drive system

not adjusted correctly

Connect spark-plug

rmly

Engine rubs unevenly

Possible cause Action to take

Risk of injury or damage

to property

Read these operating

instructions through

carefully before

operating the machine

in particular the chapter

entitled “For your safety”

Risk of being burnt.

Keep at a safe distance

from hot parts of the

machine.

Only touch parts of the

machine when they have

come to a complete halt.

The worm driver switches off if the

user releases their hold on this

coupling lever.

The drive system switches off if the

user releaes their hold on this

coupling lever.

Safety devices are provided for your

protection and must always function

properly. You may not remove,

change or circumvent them.

Risk of injury from

rotating parts. Keep hands

and feet away from

rotating parts.

Check the contents as you unpack the

machine.

When user releases hold of this bar, the

worm driver switches off and the

machine comes to a halt.

For 4.0 HP

Risk of injury from

throw-out snow or solid

objects.

Unpacking and assembly

21

Xxx xxxxxxxxx xx xxxxxxx xxxxxxx

Xxxx xxxxxxxxxxx xxxxx xxxxxxx

X.X

Xxxxx xxx xxxx xxxx xxxx xxxxx xxxxx xxx

xxxx xxx xxx xxx xxxxxxx xxxx xxxx.

Xxxxx xxx xxxxx xxxx xxxx xxxxx xxxxx xxx

xxxxx xxxx xxx xxx xxx xxxxxxx xxxxx xxxxx.

X XX

objects.

Before making any adjustments

The operation of turning control

(for caterpillar drive machine 9.0

and 11.0HP)

4): Oil change every 25 hours of heavy work

Assemble the machine as illustrated

at the end of these operating

instructions.

It is essential to check the oil level

Rell or top up with engine oil (see

“engine instructions”) as required.

For transportation reasons, the

tires may show a higher tire

pressure. Check the tire pressure

and ajust accordingly (approx. 1

bar).

Adjust coupling for the worm drive

and drive system (see

“maintenance”).

(5.5HP, 6.5HP, 9.0HP and 11HP)

Adjust drive lever (see

“maintenance”).

Turn off the engine

Remove the ignition key and the

spark-plug connector.

Wait until the engine has cooled

down.

Press the left turn grip which is under the left

hand bar and the machine turns left.

Press the right turn grip which is under the

right hand bar and the machine turns right.

Before using the machine

for the rst time (5.5HP,

6.5HP, 9.0HP and 11HP)

Adjust the machine to conform

to the snow conditions:

Setting a drive wheel to

freewheel (Machines with

wheel drive without

free-wheeling lever)

Risk of injury

Figure 4

Adjust working position (machines

with caterpillar drive)

For 9.0/11HP caterpillar drive

Position I: For heavy snow which has

iced over, worm is pressed into the

ground

Position II: For normal snow

conditions

Position III: For clearing uneven

paths or transporting the machine.

Worm is at a greater distance to the

ground.

Engine does not work

Fuel tank empty

Fuel has gone stale

Fill fuel tank

Drain out fuel into a

suitable container in the

open air. Fill up tank with

clean fresh fuel

Set the choke lever to

“CLOSE”

Set throttle lever to

“SLOW”

Put spark-plug connector

on the spark plug

Clean air lter1)

Clean spark plug1) . Have

defective one replaced2)

Set choke lever to “OFF”

and start engine

Engine is cold. Choke Lever is not

set to “CLOSE”

Throttle lever is not set to “SLOW”

Spark-plug connector not

connected

Air lter dirty

Spark-plug dirty or defective

Carburetor ooded

Figure 8

Do not operate the

machine without wearing

adequate winter garments. Wear

footwear which will improve footing on

slippery surface.

The operation of any powered

machine can result in foreign objects

thrown into eyes, always wear safety

glasses or eye shields during

operating or while performing an

adjustement or repair.

Before using the snow blower

equipment, please thoroughly inspect

the area and remove all doormats,

sleds, boards, wires and other foreign

Troubleshooting

Risk of injury from starting the machine by accident

turn off the engine

Remove the ignition key and the spark-plug connector.

Wait until the engine has cooled down.

Caution

Faults encountered when operating the machine sometimes have simple causes which you

can remedy yourself. If you are in any doubt, or if you expressly instructed to do so, seek

the help of our service department.

Have repair work carried out only our service department which will use original

replacement parts.

Before doing any work on this machine

Action to take

Fault Possible cause

20

3

XXX

Maintenance

Maintenance schedule

Once a year:

Each time before the start of the season or after season ends:

Adjust the skids (for 5.5HP,

6.5HP, 9.0HP and 11HP)

Adjust clearing Plate

(For 4HP)

Have the machine checked over and maintained by our service department.

•

•

Check the oil level and top up as necessary.

Check all screw ttings for rm seating, tighten them if necessary.

Check the safety features.

(2) and wheels (3) must be touching the

ground at the same time. If the clearing

plate is set too high, snow will be hurled

backwards. If it is too low it will be worn

down faster.

To set the clearing plate:

Figure 7

Figure A

After

use

Maintenance tasks

Clean throw-out chute, warm and

warm casing

Check tire pressure, increase as

required

Check coupling adjustment,

re-adjust as required

Have the carburetor setting

checked

Inspect the clearing plate, replace

worn-out clearing plate

Check skids replace worn-out skids

in pairs

Check caterpillar track, readjust as

required. Replace defective

caterpillar track

Clean sir cooling system and

exhaust2)

Replace air lter1)

Clean spark plug1)

Change oil3)

Clean air lter

Lubricate mobile and rotating parts

Replace fuel ller cap

Have exhaust silencer replaced2)

See “Engine instructions”

Have this work carried out only by our service department

First oil change after 5 hours

10

hours

100

hours

End of

season

As

required

25

hours

50

hours

For small to moderate amounts of

snow and terrain that includes many

curves, the connection between right

wheel and driver can be disconnected.

The machine is easier to steer.

For larger amounts of snow and

iced-over paths, both wheels must

be driven.

Line up hole (2) of the wheel hub

and the hole of the wheel axle.

Insert ring spring (1) both holes

(2). The wheel may not be xed

through the hole (3).

When the machine is starting on even

ground, the worm (1), clearing plate

--Fasten the skids with nuts (2) in such a

way that they uniformly touch the

With the skids (1), the distance between

the ground and the clearing plate (5) can

be set in such a way that no parts of the

ground (e.g. earth or stones) can be

taken up.

(machine with caterpillar dirve) set

setting lever ( Figure 4, item 1) to

position II

Loosen nuts (2) on both sides of

the machine.

Adjust skids to conform to the ground

distance:

-- Lower for uneven or non-hard

surfaced paths.

Higher for even paths.

Move the ring spring (1) to outer

hole (3)

Tip the machine backwards.

Loosen the nuts (5).

Set the clearing plate lower or higher

as appropriate and tighten nuts

again.

Tip the machine forward again, check

the setting and repeat as necessary.

19 4

xxxxX

xxxxX

X XX

ground. The details assemble step, please

reference to 6.5HP type.

Step 8: 8-1) Assemble knighthead to

the clean staff

8-2) Fix the knighthead to

right handle bar.

Figure 1

Fill up with fuel only in the

open air and when the engine has

been switched off and is cold. Do not

smoke whilst lling up.

Never ll up with fuel to top. If fuel

overows, let the overowed fuel

evaporate completely before you start

engine.

Store fuel only in suitable containers

designed to take fuel

Check oil level, top up as required

(see “engine instructions”).

Fill up with fuel (for types of fuel

see specications in the engine

instruction), close the fuel tank

cap and wipe away remains of fuel

Risk of injury

Keep other people, in

particular children and

domestic animals away from the

danger area.

Operating the machine only when it is

in the faultless and safe-to operate

condition.

Inspect the ground over which the ma-

chine is to operate and remove all

objects which could be picked up by

the machine and hurled out.

Working only when there is sufcient

illumination. Always be sure of your

footing, and keep a rm hold on the

handle, walk, never run.

If the machine should start to vibrate

abnormally, stop the engine and check

Danger of explosion

and risk of being burnt.

immediately for the cause. Vibration is

generally a warning of trouble.

Work slowly and carefully, especially on

uneven or non-hard-surfaced paths, or

when you are moving backwards.

Never operate the machine without

proper safety guards.

Do not overload the machine capacity by

attempting to clear snow at too fast a

rate.

Set the distance between worm housing

and ground in such a way that no

extraneous material (e.g. stones) is

taken up by the machine.

If the machine strikes extraneous

material (e.g. stones) or exhibits

unusual vibrations, switch off the

machine and inspect it for damage. Get

any damage you discover repaired

before you work the machine again.

Befor you put the machine to work, let

the engine run to warm up.

When you have nished work, leave the

engine running for a few mintues to

eliminate the moisture.

Adjust throw-out chute (see “Set the

direction and distance of throw”)

Starting the engine (see “starting the

engine”)

With the coupling lever (1 and 2)

released, choose a forward gear with

shift level (6)

Press the coupling lever for worm

drive (1) and hold it down; worm and

throw turbine are driven.

Press the coupling lever for drive

system (2) and hold it down; the

machine moves forward and clears the

snow.

Caution

Risk of damage to the

machine

Fill up with fuel and check the

oil level

Working with the snow

clearing machine

(For 5.5HP, 6.5HP, 9.0HP and 11HP)

3) For 9.0/11.0 HP

caterpillar track

18

5

XXX 6

Step 7: 7-1) Take off the sleeves of the

coupling cables.

(For 4.0HP)

Figure 2

Risk of injury from machine

tipping over

Work slowly and carefully,

especially if you change direction.

Guide the machine up or down the slope

not crosswise to it.

Watch out for obstacles, do not work

near inclines.

Do not use the machine on slopes with a

radient greater than 20%

Let engine and machine adjust to

outdoor temperatures before starting

to clear snow.

Clear snow immediately after it has

stopped snowing, later on the

underneath layer will ice up and will

make clearing the snow more

difcult.

If at all possible, clear snow in the

direction of wind.

Clear the snow in such a way that

tracks you have cleared, overlap

slightly.

Starting the engine (see “Starting

the engine”)

Starting the engine (see “Starting

the engine”)

Press the coupling lever (1) and

hold it down; the worm in use.

As a result of the worm

establishing contact with ground,

the machine moves forward.

If you want to increase the travel

speed, raise the side handle (8)

slightly; the worm has greater

contact with the ground and then

drives the machine forward faster.

This leads (if repeated frequently)

to the rubber lip on the worm

wearing down faster.

To reduce the travel speed, press

down on the side handle.

For 4.0HP

If you want to change gear, rst

release the coupling lever for the

drive system (2) and then change

gear with the shift lever (6).

(In some machines)

The machine is tted with

freewheeling levers (3 and 4).

Using these, enable the machine to

be steered more easily:

-- To the right: Pull on the right

freewheel lever (4)/

--To the left: Pull on the left

freewheel lever (3).

Step 6: Assemble the gear shift lever.

5-2) Fix the knighthead to

7-2) Connect the sleeves to

Figure 10

coupling levers.

7-3) Connect the sleeves to the

coupling cables.

5-3) Adjust the knighthead

and make sure the whorl and the

throw-out chute gear completely

match and tighten the knighthead

screw, lock the rocker to the

knighthead.

left handle bar.

Working on slopes

Tip on clearing snow

Set the direction and distance

of throw

17

X XX

Step 5: 5-1) Assemble knighthead to the

rocker:

Step 2: Connect handle bar and shift

board by screws.

1) Push the fuel lock (under air clear)

to “ON”

2) Push the choke lever to “CLOSE”

(cold engine).

3) Move the throttle lever away from

SLOW position, about 1/3 of the way

toward the FAST position.

4) Turn the engine switch to “ON”

Check contents of fuel and oil level,

as required ll up with fuel and oil

(see “Engine instruction”)

Danger

If you start the engine in

an enclosed space, move

Start the engine

Figure 2

For machine with lever (Figure 1,

Item 5): press lever forward to set

the ap (2) higher and back for

lower.

For machine with lever: loosen

knob (1) and set ap (2) higher or

lower as required.

The steeper the angle of the ap (2) is

set, the higher and the further the

snow will be ejected.

Set the throw distance

Set the direction of throw

Risk of injury

Do not set the ap (2) of

the throw-out chute (3) in

the direction of people, animals,

windows, cars and doors.

Put the throw-out chute (3) in the

desired direction by rotating the

rocker (gure 1, item 7)

the machine immediately afterwards

into the open air. Never leave the

engine running in an enclosed space.

Before starting the engine, release

coupling levers (Figure 1, item 1 and

2)/coupling bar (Figure 1 item 1)

Start with pull starter

assembled as the picture shows. The other

two sets of arc-shaped clip plate sets

assemble same as previous.

4-3) Tighten the screw as the

picture shown.

4-2) Please make sure the pieces are

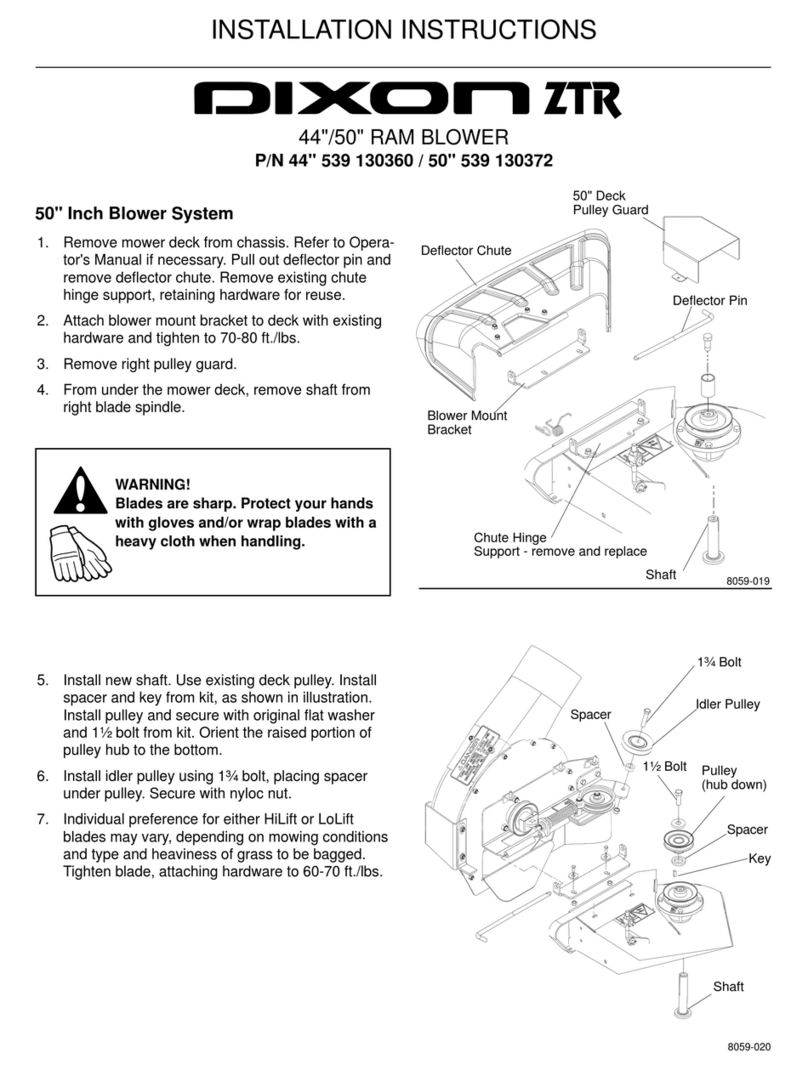

Step 4: 4-1) Put the throw-out chute to

the set and assemble arc-shaped clip

plate.

Step 3: Take off the wheels. Install

handle bar to the frame, x it by screws

and put on the wheels.

716

XXX

sure every part is complete, if there

are some parts missing, please contact

local dealer for a complement.

Step 5: Install the rocker with two

connect sticks and one screw. (See

gure 5)

Step 5: Install the cable. (See gure 6)

5) Pull slightly the starting rope

handle up until feeling anti-action,

and then make a rapid pull

6) Preheat the engine and push

back the choke lever to “OPEN”, if

the engine starting fails. Please

repeat No.2-No.5

Risk of electric shock

Make sure that the main

supply network is protected

To start the engine, the electric starter

must be connected to the main

power supply.

Use a 12-volt battery with an

ampere-hour rating at least 6.5 Ah.

Be careful not to connect battery in

reverse polarity, as this will short

circuit the battery charging system.

Always connect the positive (+)

battery cable to the terminal before

connecting the negative (-) battery

cable, so your tools can not cause a

short circuit if they touch a grounded

part while tightening positive (+)

battery cable end.

with fault current circuit-breaker. If

required, have an appropriate

circuit-breaker tted, but only by a trained

electrician.

For connecting the electric starter to the

mains, use only extension cables (not

supplied with the machine) which are

approved for use in the open air and

which are protected by an earth wire, e.g.

Connect the battery positive (+)

cable to the starter solenoid terminal

as shown.

Connect the battery negative (-)

cable to the engine mounting bolt,

frame bolt, or other good engine

ground connection.

Connect the battery positive (+)

cable to the battery positive (+)

terminal as shown.

Connect the battery negative (-)

cable to the battery negative (-)

terminal as shown.

Connect the light and light switch with

the cable and connect the cable to the

battery positive (+), and the battery

negative (-).

Coat the terminal and cable ends with

grease.

Caution

A battery can explode if you

do not follow the correct

procedure, seriously injuring anyone

nearby.

Keep all sparks, open ames, and

smoking materials away from the

battery.

Step 3: Take out two M8 screws to

fasten handle 1 and handle 2. (see

gure 3)

Step 4: Fasten the discharge chute

with three plastic plates, six M8

screws and six M8 nuts on the

bottom of the discharge chute. (See

gure 4)

Step 1: Please check the full components

against the picture 1 shown, and make sure

every part is complete, if there are some

parts missing, please contact local dealer

for a complement.

Step 2: Install the handle 2, take out

four M8 screws and x them tight on

both sides of the motherboard. (See

gure 2)

2) For 5.5/6.5/9.0 HP

Start with electrical starter

(Optional for 5.5HP, 6.5HP,

9.0HP and 11HP electrical

start model)

Type One: For 12V DC

Voltage start.

Type Two: For 220-230V and

50Hz (110V and 60Hz) AC

Voltage start.

8

15

Xxx X.XXX.XXX.

X XX

Warranty

For 4.0 HP

Assemble instruction.

non-use

Preparing the machine for

Replacing the clearing plate

(For 5.5HP, 6.5HP, 9.0HP and

11HP)

Stop the engine

The warranty term issued by SNOWPRO

valid in the USA and Canada.

We remedy faults to your machine free of

charge within the scope of the warranty

provided that the cause proves to be a

material or manufacturing defect. Should

you need to call upon the warranty,

please apply to the vendor of your

machine or the the nearest agency.

Please see warranty included.

open air (see “engine instructions”).

When the machine is not to be used for

more than a month, e.g. after the winter:

Prepare the engine (see “adjusting

the skids”).

Clean machine.

To protect from rust, wipe over all

mantel parts with an oily cloth or

spray with spray lubricant.

Park the machine in a clean, dry

enclosed space.

Remove screw (6), washers (7) and

nuts (8)

Replace clearing plate (5)

Screw new clearing plate to housing

with screw, washer and nuts.

Tip machine backwards.

Remove screw (4) and nuts (5).

Replace clearing plate (2).

Screw new clearing plate to housing

with screw and nuts.

Tip machinery back again; check

setting (see “adjusting the skids”).

Replacing the clearing plate (For 4.0HP)

Figure A

Step 1: Please check the full components

against above picture shown, and make

Danger of causing an

explosion by fume igniting.

Before you prepare the

machine for non-use, empty the fuel

tank into a suitable container in the

To avoid damage to the machine or

starting problems arising from

moisture, let the engine run for a

few minutes before switch off (to

dry out).

Set the throttle lever to “OFF”

up to a maximum lenth of 50cm:

- H07RN-F3X1.5mm2 up to -260C

- H07BQ-F3X1.5mm2 up to -400C

Caution

If the electric starter is not

connected properly,

damage could occur to the machine or

in its vicinity.

Make sure that the main supply

network

-- is operating in conformity with the

specications on the starter

identication plate at 220-230V

and 50 Hz (110/60Hz).

-- is protected by an appropriate fuse

system.

1) Push the fuel lock (under air

clear) to “ON”

2) Push the choke lever to

“CLOSE” (cold engine).

3) Connect extension cable rst

with the plug and then with a

mains socket.

4) Press start button long enough

(Max. 5 sec.) for the engine to

start. For a cold start, wait at least

10sec. before attemepting to start

the engine again.

5) Preheat the engine and push

back the choke lever to “OPEN”.

6) Separate the extenstion cable

rst from the mains and then from

the electric starter.

Push the engine switch to “OFF”

Push the fuel lock (under air clear) to

“OFF”

Put in gear (For 5.5HP, 6.5HP, 9.0HP and

11HP)

Figure 1

Figure 7

914

For 5.5/6.5/9.0HP

X XX

10

Remove spring clip (4) and washer

(5), extract spindle nut (6) from

the hole (7).

Press gearshift arm (2) downwards,

set shift lever (3) to gear “6”

Rotate spindle nut (6) in such a

way that the pin can be out into

the same hole (7)

Secure spindle nut with washer

and spring clip

Set machine on a secure and

horizontal support so that the

caterpillar tracks no longer touch the

ground.

Rotate nut (2) until the caterpillar track

has the correct tension:

-- to tighten, rotate in clockwise

direction.

-- to slacken, rotate in counter-

clockwise direction.

Replace caterpillar track and adjust the

tension of the new caterpillar track

with nut (2) (see “adjust the caterpillar

track”)

The worm (3) is fastened to the drive shaft

(4) with shear bolt (1) and lock-nuts (2).

The bolts are constructed in such a way

that they break (shear off) if the worm

strikes solid extraneous object. In this way

damage to the machine is prevented. This

bolt (1) and the nuts (2) may only be

replaced with original spare parts (two

replacement bolts and lock-nuts are

suppled with the machine)

Set machine on a secure and

horizontal support so that the

caterpillar tracks no longer touch

the ground

Rotate nut (2) until the caterpillar

track has the correct tension:

-- to tightern, rotate clockwise

direction.

-- to slacken, ratate in counter-

clockwise direction.

Caution

Release coupling lever (1

and 2) before you select a

Risk of injury

Before transportation

-- Turn off the engine.

Risk of injury

Before doing any work on this

machine

Caution

Risk of damage to the

machine

Driving

To maneuver or get across

short distance.

Start the machine.

Select forward or reverse gear.

Press coupling lever for driving

system/coupling bar and hold it

down.

Move the machine carefully.

When replacing parts of the machine use

only original spare parts.

Please lubricate all the rotating and

mobile parts with light oil.

Recommended tire pressure approx. 1

bar.

See “engine instructions”

Park the machine on a rm, even and

horizontal piece of ground.

Remove any dirt sticking to it.

Clean the machine by pouring water

through the throw-out chute. Leave it

to dry.

Clean engine with a cloth and brush.

In extreme weather conditions, snow

chain can be obtained from our

service department.

-- Turn off the engine.

-- Remove the ignition key and the

spark-plug connector.

-- Wait until the engine has cooled down.

-- Turn off the engine.

-- Wait until all the moving parts have

come to a halt.

-- Remove the ignition key and the

spark-plug connector.

-- Use a wooden rod or a shovel to

eliminate the blockage.

Risk of injury

Before doing any work on this

machine

Select a gear with shift lever (6)

-- Forward: “1” (slow) up to “5”

-- Reverse: “R” (slow) and “R”

(fast)

-- Remove the ignition key and the

spark-plug connector.

-- Wait until the engine has cooled down.

Transporting the machine on or in a

vehicle in a horizontal position.

Secure the machine against rolling or

slipping.

gear or change gear.

The caterpillar track (1) is correctly

adjusted if it can be forced down by

hand by 10-12 mm. If it can be forced

down by a greater or lesser amount, it

must be adjusted.

Remove the shear-off bolt and nut,

clean place of attachment and

lubricate it.

Use a new shear bolt and lock-nut to

replace the broken one.

Figure 9

Figure 6

Adjusting the caterpillar track

(chain with caterpillar drive)

Eliminate any blockages in

the worm or the throw-out

chute

Transporting the machine

without it operating from its

own power

Maintenance work on the

engine.

Adjust tire pressure

Lubrication

Clear the machine

Snow chains (optional)

Replace the caterpillar track

(chain with caterpillar drive)

Replace a shear bolt

Transportation

13

X XX

11 12

Adjust coupling for the worm

drive

(For 5.5HP, 6.5HP, 9.0HP and

11HP)

Checking the drive system

(For 5.5HP, 6.5HP, 9.0HP and

11HP)

Adjusting the shift lever (For

9.0HP and 11HP)

Tightening the V-belt

Making adjustments to the

coupling cable (For 5.5HP,

6.5HP, 9.0HP and 11HP)

Adjust coupling for the drive

system

(For 5.5HP, 6.5p, 9.0HP and

11HP)

(For 4.0HP)

forward gear (higest gure).

Having release the coupling lever(2),

push the machine forwards.

While you are pushing the machine,

set shift lever (6) to the fastest

reverse gear and then set it to the

fastest forward gear.

If some resistance is felt while you

are pushing the machine or change

gear, you need to slacken the

coupling cable (see “making

adjustements to the coupling cable”)

While you push the machine,

press the coupling lever (2). The

wheel/caterpillar tracks must become

blocked. If not, tighten the coupling

cable a little (see “making

adjustments to the coupling cable”).

If you have not been able to perfect

adjustment or if in doubt about the

result, see “Checking the drive

system”.

Press the left coupling lever (1)

forwards (direction), at the same

time press down rubber (3).

Coupling cable (5) must be a little

slacker. Slacken it if necessary

(see “making adjustments to the

coupling cable”).

Release coupling lever (1). There

must be no slackness on the

coupling cable (5) but it must not

be tight either. Adjust if necessary

(See “making adjustments to the

coupling cable”).

The coupling lever (1) must allow

itself to be pressed down

completely. If it does not, the

coupling cable is tightened too

rmly and must be slackened (see

“making adjustments to the

coupling cable”).

(machine with caterpillar drive)

Set setting lever (gure 4, item 1)

to position III (transport).

Set shift lever (6) to the fastest

For coupling cables with adjusting

sleeves (6)

-- Tighten: loosen nut (7) and screw

adjusting sleeves (6) against it.

-- Slacking: loosen nut (7) and screw

adjusting sleeves (6) against it.

For coupling cables with adjusting

sleeves (6)

For coupling cables with load-removal

spring (8): before making an

adjustment, the spring must be

unhooked and afterwards hooked on

again. The coupling cable is

correctly adjusted when the spring

expends 2 to 3 cm when coupling

takes place.

-- Tighten: Screw Lock-nut (9) upwards

-- Slacken: Screw Lock-nut (9)

downwards

Loosen screw to frame cover; if

necessary tip the machine forward.

With the coupling lever for the

drive system released (gure 1,

item 2) change into all gears; in

doing so the friction wheel (2)

should not come into contact with

the drive wheel (3). If it does,

slacken the coupling cable (see

“making adjustments to the

coupling cable”).

As required clean the drive wheel

and the rubber on the friction

wheel; they must be free of

grease.

If necessary, remove ice on parts

which is iced over.

Take care when tipping the machine

to see that

-- The machine stays balanced and

-- No fuel or oil runs into the air

lter or out of the machine.

If the worm is running irregularly at the

constant engine speed, the tension of the

V-belt (5) must be adjusted.

If there is an additional hole (3b) on

the coupling lever (1), hook the

coupling cable (2) into the higher

hole (3b).

If there is no additional (higher) hole

or it is already in use, then

-- remove the V-belt cover (4).

-- Hook spring (6) at the end of the

coupling cable into the next highest

hole (from 7a to 7b, from 7b to 7c).

-- Replace V-belt cover.

Caution

Risk of damage to the

machine

Figure 5

Figure C

Figure B

Figure 3

Check the state of the coupling:

Figure 3

Figure 1

Table of contents