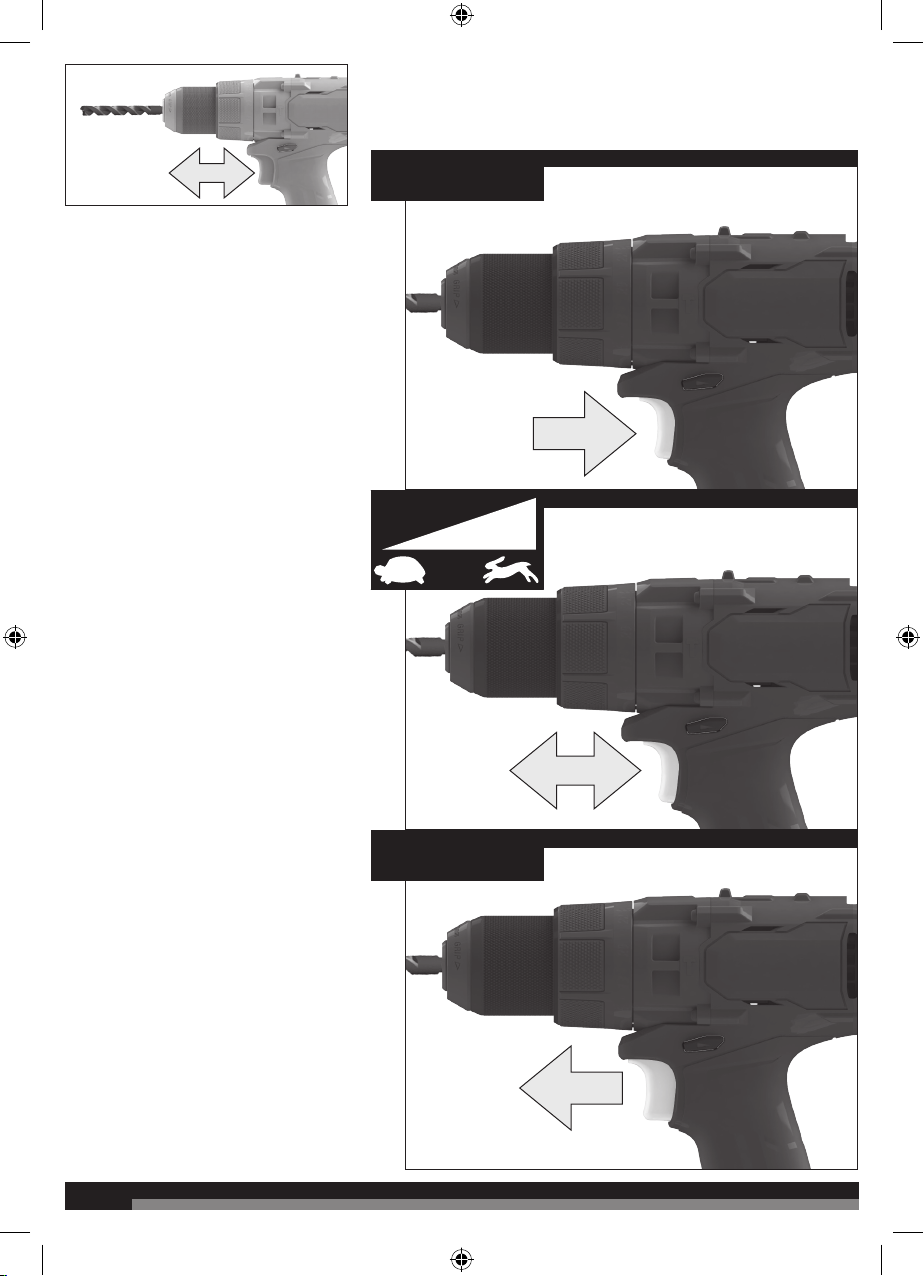

AEG A18PDB User manual

Other AEG Drill manuals

AEG

AEG BS 18SBL Operation instructions

AEG

AEG BSB18B2M User manual

AEG

AEG DB 1500-2 XE User manual

AEG

AEG SB2E 12 STX User manual

AEG

AEG BS18 G2A User manual

AEG

AEG POWERTOOLS PN 11 E 412440 User manual

AEG

AEG BE 705 R User manual

AEG

AEG PNEUMATIC 3500 X User manual

AEG

AEG BH26LXES User manual

AEG

AEG BE 750 R User manual