LBI-33057

10

• Break the connection at TX MOD, J102/P2 pin

1.

• Bias TX MOD into the RF Board to 2.7 Vdc by

connecting the junction of the 10K resistors to

J102 pin 1.

2. Using a 100 µF (or greater) capacitor, couple a 1

kHz, 600 mV rms audio signal into TX MOD,

J102 pin 1.

Modulation adjustments should only be neces-

sary if changes in the Tracking Data values will

not compensate deviation levels to within speci-

fications. Adjustment of R18 and R19 will obso-

lete all Tracking and Channel Data modulation

values. See the TRACKING AND CHANNEL

DATA section in this manual for further details.

The following procedure balances and "course

aligns" the VCO and the Reference Oscillator

deviation levels. The Audio Processor IC will

perform "fine level adjustment" of TX deviation

adjustment via the Tracking and Channel Data.

3. Connect the radio to the modulation analyzer and

key the transmitter at the MIDDLE test channel

listed in Table 2.

4. Adjust R19 (VCO modulation pot) for a deviation

of ±2.5.0 kHz ±50 Hz. Unkey the radio.

5. Remove the 1 kHz signal and apply a 20 Hz, 1

Vpp square wave. NOTE: The modulation ana-

lyzer should have a low-frequency response of

less than 1 Hz for this test.

6. Key the transmitter and monitor the demodulated

output from the modulation analyzer. Adjust R18

(modulation balance pot) for a good square wave

response.

Transmitter Distortion Test

Measure transmitter audio distortion on the LOW,

MIDDLE and HIGH-side test channels. Distortion read-

ings should be less than 3% at ±1.5 kHz deviation with a

1000 Hz tone.

RECEIVER ALIGNMENT

The following information can be used to check and

align the receiver circuits. Successful completion of these

alignment procedures will verify a near 100% operating

synthesizer and receiver stages.

2nd Local Oscillator

1. Check Reference Oscillator alignment as outlined

in the TRANSMITTER ALIGNMENT section.

2. Channel the radio to MIDDLE test channel listed

in Table 2.

3. Set the RF signal generator to corresponding

channel at a -20 dBm RF level and no modula-

tion. Apply this signal to the radio.

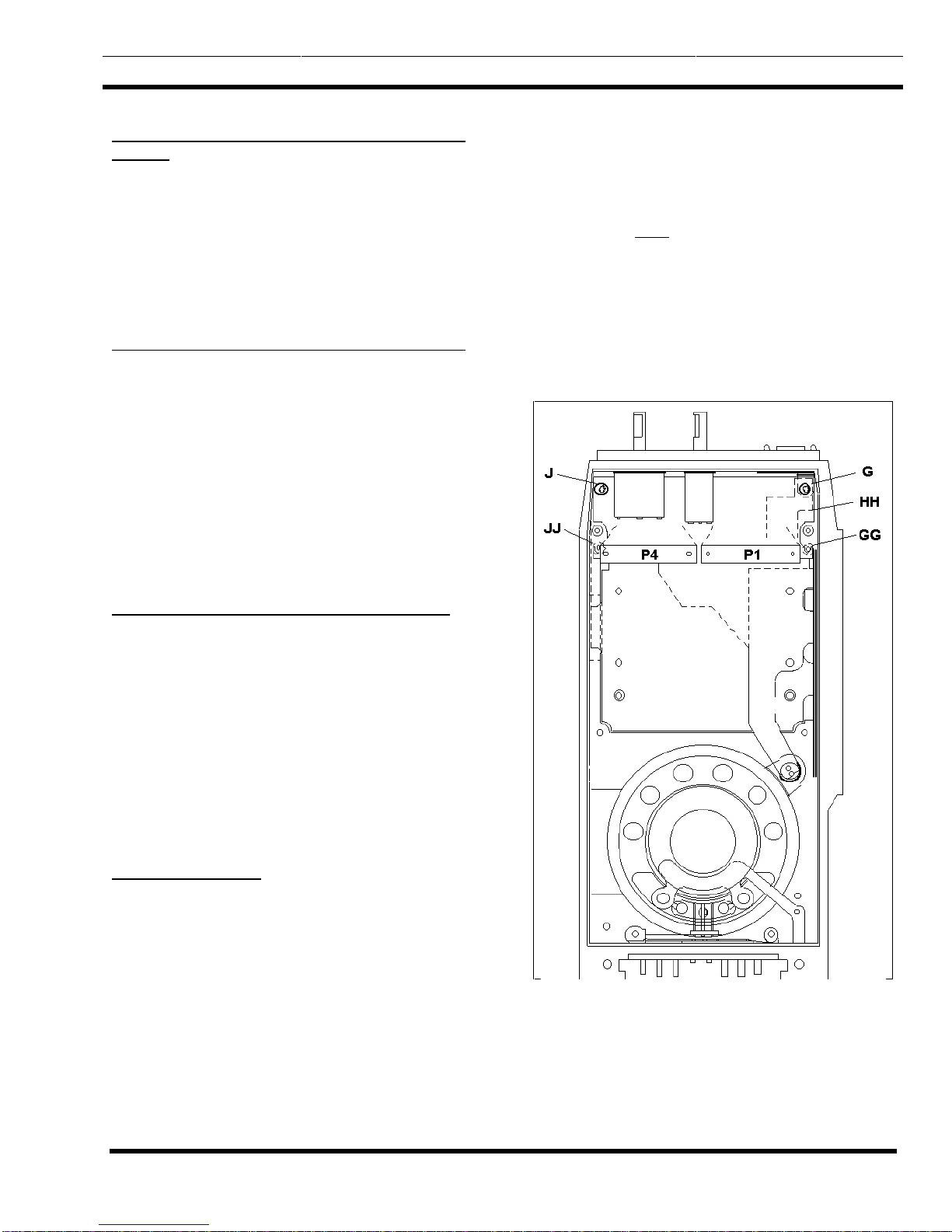

4. To measure the IF signal, connect a frequency

counter to U6 pin 5. Use an appropriate high im-

pedance probe (op-amp).

5. Adjust the signal generator level to achieve accu-

rate counting of the IF signal. The RF signal gen-

erator should be set 10 dBm above the lowest

level which gives accurate counting.

6. Adjust the 2nd local oscillator via T1 for 455.000

kHz ±90 Hz.

Quadrature Detector

1. Modulate the signal generator with a 1 kHz tone,

±1.5 kHz deviation at the MIDDLE test channel

listed in Table 2. Set the RF level to -50 dBm.

2. Adjust T2 for maximum audio level at J101/P1

pin 4.

12 dB SINAD and Distortion Tests

1. Connect the distortion analyzer or SINAD meter

to the speaker load (in Dummy Battery).

2. With the RF signal generator and radio set to the

MIDDLE test channel listed in Table 2, modulate

the generator with a 1 kHz tone at ±1.5 kHz de-

viation. Measure the 12 dB SINAD sensitivity.

This reading should be equal to or better than -

116 dBm (0.35 µV).

3. Return the signal level to -50 dBm.

4. Check audio distortion. Readings should be less

than 5% at rated audio output. Audio amplitude

should be 50-100 mVrms (≅200 mVp-p) at

J101/P1 pin 4.

NOTE